Fabric printing and dyeing production line and method

A production line and fabric technology, applied in the direction of fabric surface trimming, textile and papermaking, textile material processing, etc., can solve the problems of changing the composition of dyeing liquid, prolonging drying time, worsening dyeing effect, etc., to achieve uniform dyeing and improve processing efficiency. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

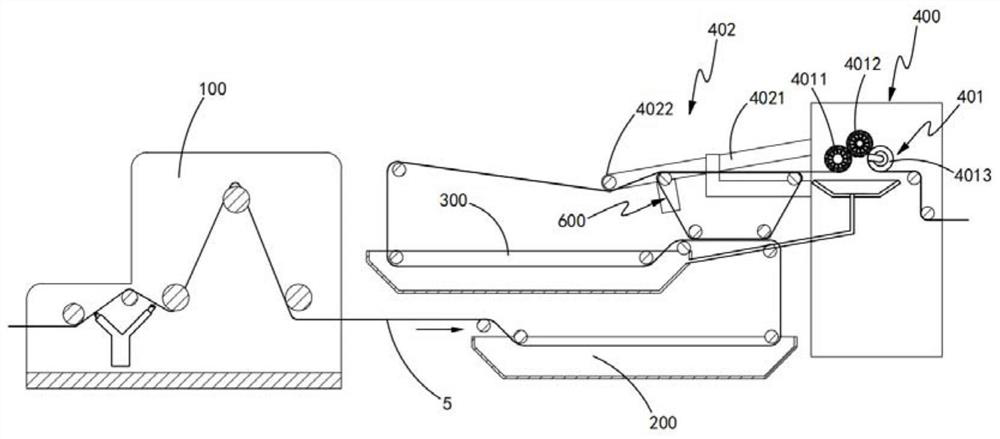

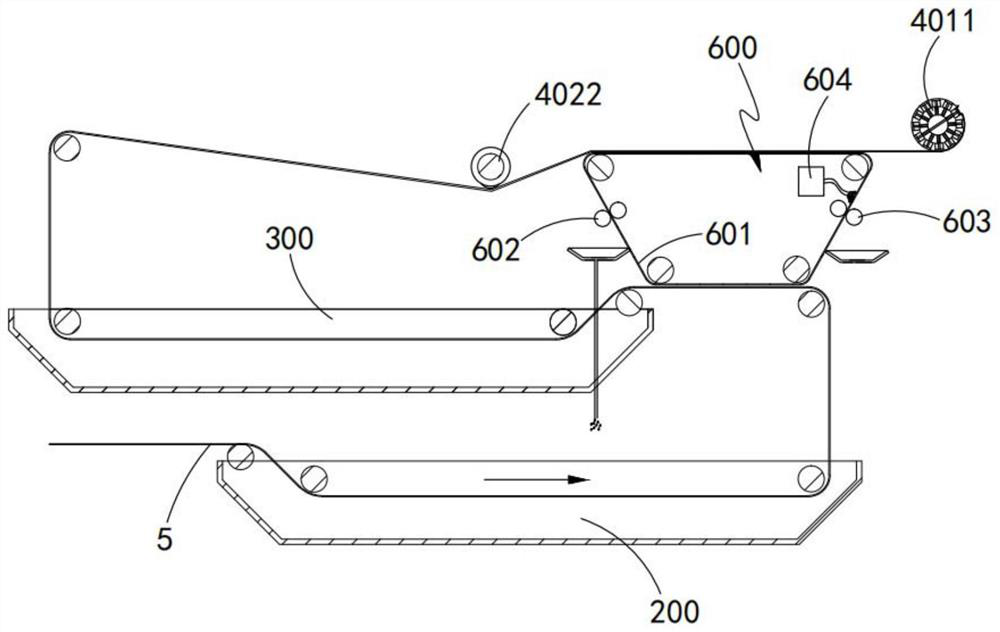

[0045] Such as figure 1 , 5 As shown, a fabric printing and dyeing production line includes a singeing device 100, a soaking and cleaning device 200, and a dyeing device 300. The singeing device 100 is used to singe the fabric 5, and the soaking and cleaning device 200 is arranged on the The outlet end of the singeing device 100, the dyeing device 300 is arranged above the soaking and cleaning device 200, and is characterized in that it also includes a wringing device 400, and the wringing device 400 is arranged at the outlet of the dyeing device 300 end, the fabric 5 is sequentially arranged in series with the singeing device 100, soaking and cleaning device 200, dyeing device 300 and wringing device 400, and the wringing device 400 includes a wringing assembly 401 and a tensioning assembly 402. The water assembly 401 squeezes the passing fabric 5 dry, and the water extrusion assembly 401 links the tension assembly 402 to tension the fabric 5; and

[0046] Adsorption device...

Embodiment 2

[0062] Such as figure 1 , 11 Shown, a kind of fabric printing and dyeing production method is characterized in that, comprises the following steps:

[0063] Step 1, the singeing process, sending the fabric to be dyed into the singeing device 100 to remove the burrs and hair balls on the gray cloth;

[0064] Step 2, the cleaning process. After step 1, the fabric 5 is sent to the soaking and cleaning device 200, where the NaCl solution is contained in the soaking and cleaning device 200, and the cleaning of the fabric 5 is completed;

[0065] Step 3, dyeing process, the fabric 5 passes through the dyeing device 300 storing the dyeing solution, before dyeing the fabric 5, a bleaching pool can be set in the dyeing device 300 for pre-bleaching operation, which is beneficial to the dyeing of the fabric;

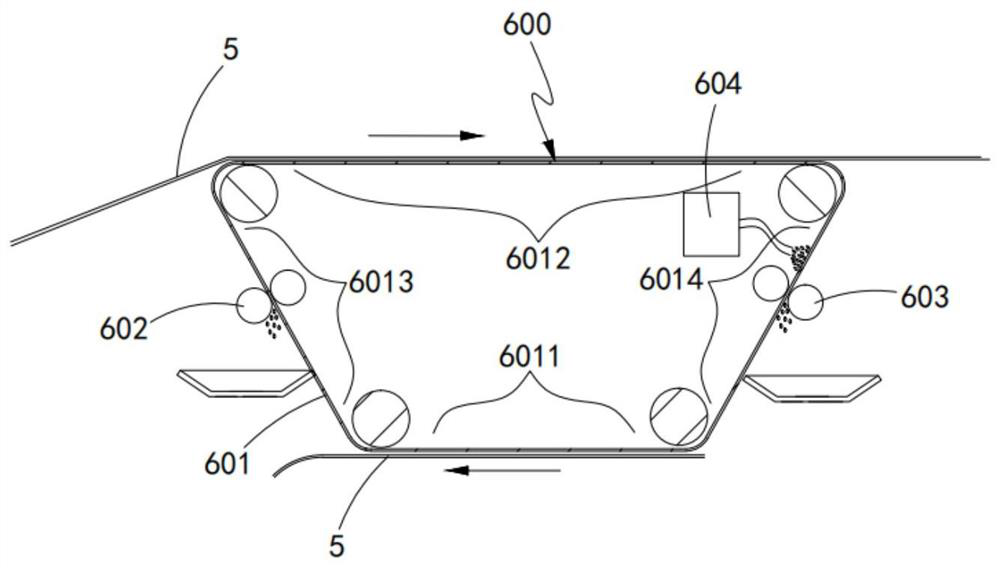

[0066] Step 4, liquid adsorption process. After steps 2 and 3, the adsorption part a6011 of the adsorption belt 601 absorbs liquid on the cleaned fabric 5, and then the adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com