Tobacco dryer

A dryer and tobacco technology, which is applied in the fields of tobacco, tobacco preparation and application, can solve the problems of high heat consumption, environmental pollution, and easy generation of dust when burning coal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

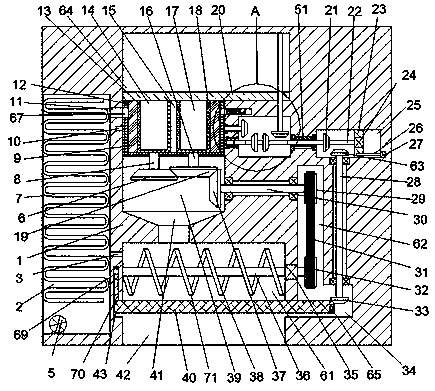

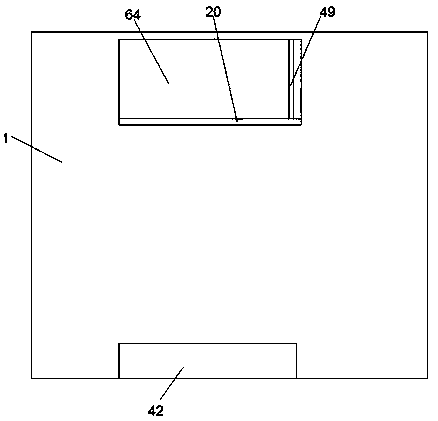

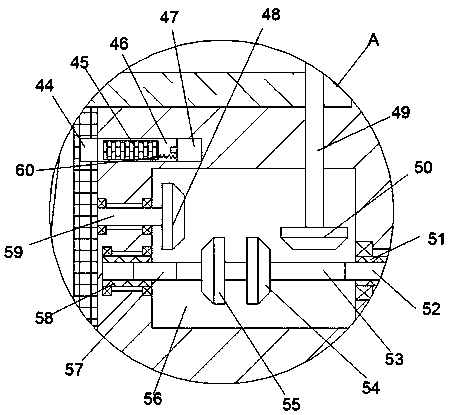

[0014] Combine below Figure 1-4 The present invention will be described in detail.

[0015] refer to Figure 1-4, a tobacco dryer according to an embodiment of the present invention, comprising a main box body 1, an electric heating cavity 2 extending up and down is provided inside the main box body 2, and a heating mechanism is arranged inside the electric heating cavity 2, which is located in the On the front end surface of the main box 1 on the right side of the electric heating chamber 2, there is a platen groove 64 extending backward, the opening of the platen groove 64 is set forward, and a platen mechanism is arranged inside the platen groove 64 The bottom end wall of the pressure plate groove 64 on the left side is provided with a first working chamber 39 extending downwards, and the main box 1 at the bottom of the first working chamber 39 is provided with a second chamber extending left and right. Working cavity 61, a funnel cavity 41 is arranged in the main box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com