Reinforcing bar engineering waste recycling device

A technology of waste recycling and steel bar engineering, applied in the direction of grain processing, etc., can solve the problems of insufficient separation of cement blocks, waste of manpower, low efficiency, etc., and achieve the effect of convenient unified collection, secondary recycling, and thorough separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

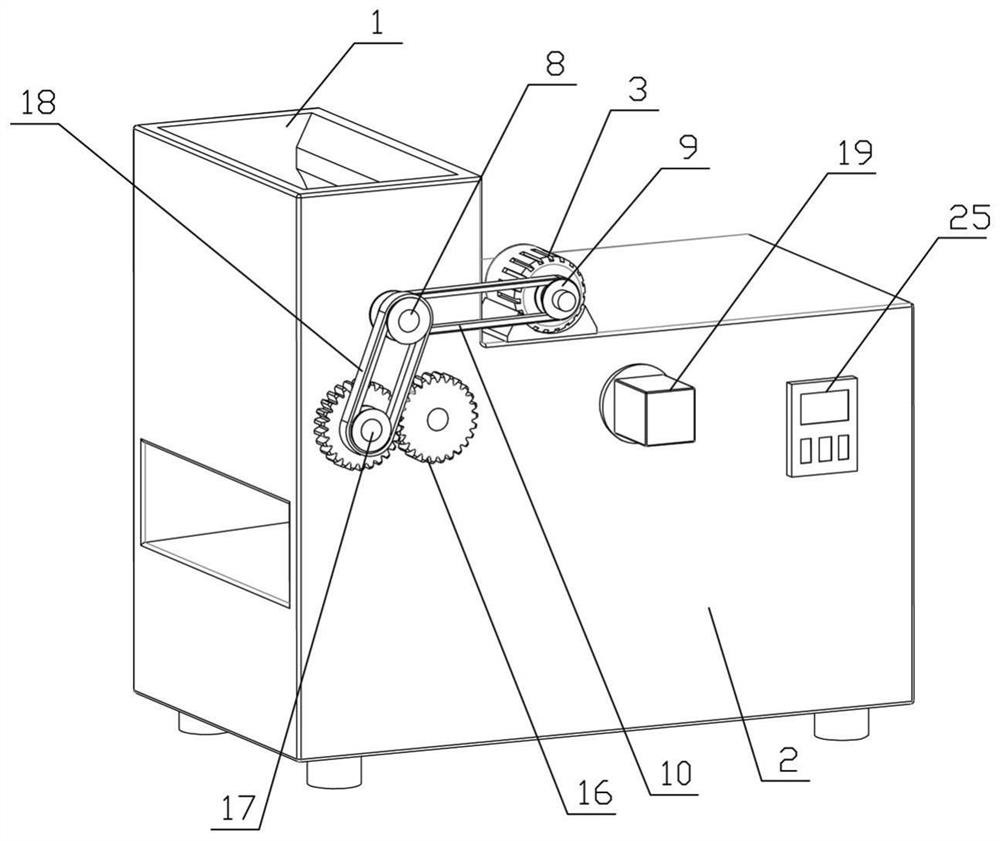

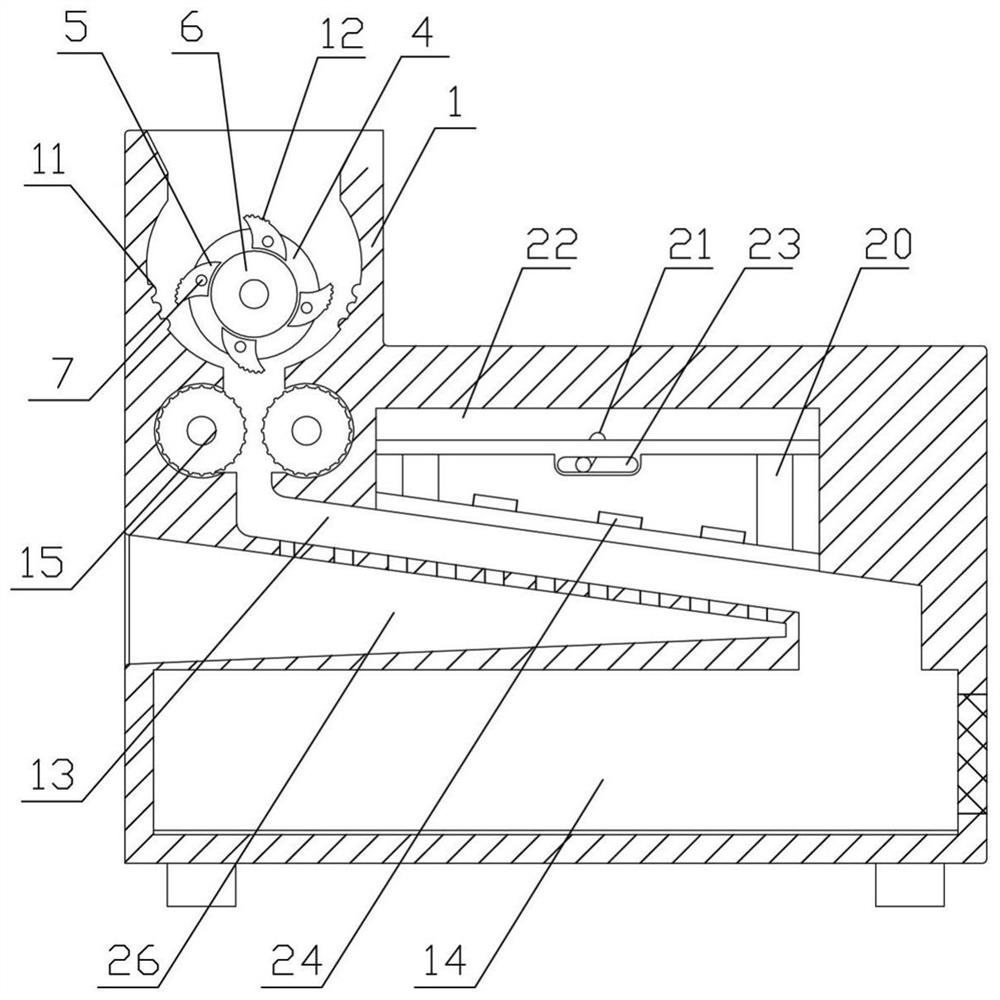

[0024] see Figure 1-2 , the present embodiment provides a technical solution: a steel engineering waste recycling device, including a hopper 1, a housing 2 and a first drive motor 3;

[0025] The inside of the hopper 1 is provided with a first crushing mechanism, the first crushing mechanism includes a knife seat 4 and a plurality of crushing knives 5 evenly distributed on the sides of the knife seat 4, the knife seat 4 is assembled and connected with the hopper 1 through the installation shaft 6, and the knife seat 4 The outer side is provided with an annular groove, and the crushing knife 5 is installed in the annular groove by a fixed shaft 7. The end of the installation shaft 6 is provided with a double-groove pulley 8, and the output shaft of the first drive motor 3 is provided with a second pulley 9, and the second pulley 9 It is connected with the double-groove pulley 8 through the transmission of the second belt 10. The inner wall of the hopper 1 is symmetrically pro...

Embodiment 2

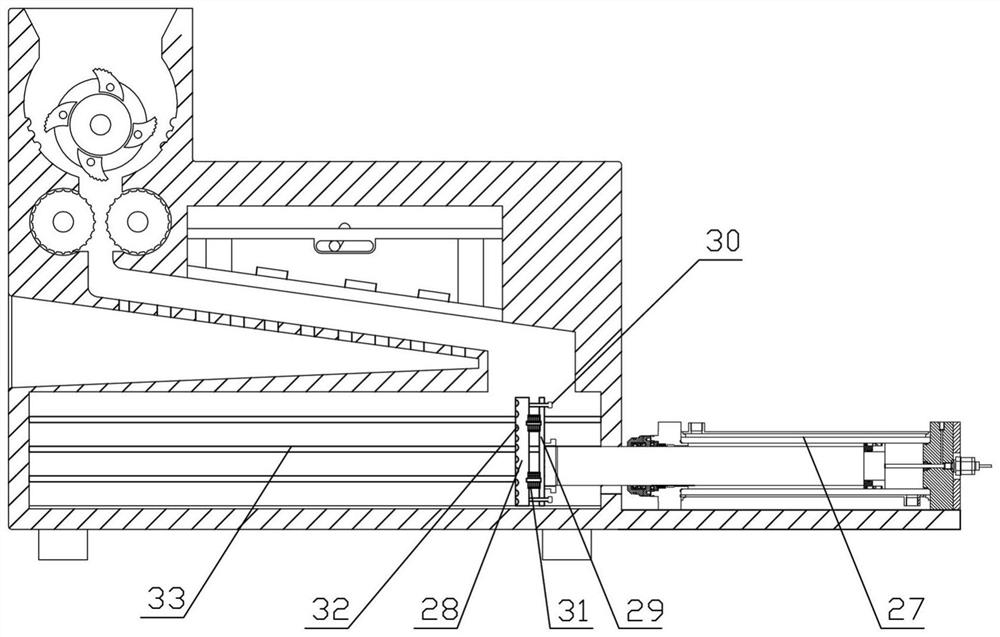

[0035] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as image 3 As shown, a steel bar extruding mechanism is set on the housing 2, and the steel bar extruding tool includes a hydraulic cylinder 27 and a pressing plate 28, the cylinder body of the hydraulic cylinder 27 is fixedly connected with the housing 2, and the piston rod of the hydraulic cylinder 27 extends into the collection chamber The inner rear is fixedly connected with an end plate 29, and the pressing plate 28 is assembled on the end plate 29 through four positioning columns 30, one end of the positioning column 30 is fixedly connected with the pressing plate, and the other end of the positioning column 30 penetrates the end plate 29 to set a limit block, Limiting block adopts the metal block that is welded on the positioning post 30 or the nut that is threadedly connected on the positioning post 30 all can, disc spring group 31 is set between pressing plate 28 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com