A kind of mud solid-liquid separator and process

A solid-liquid separator and mud technology, applied in separation methods, filtration separation, sludge treatment, etc., can solve the problems of mud easily adhering to clogging filter cloth, etc., to improve production continuity, reduce frequent cleaning, and improve water filtration rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

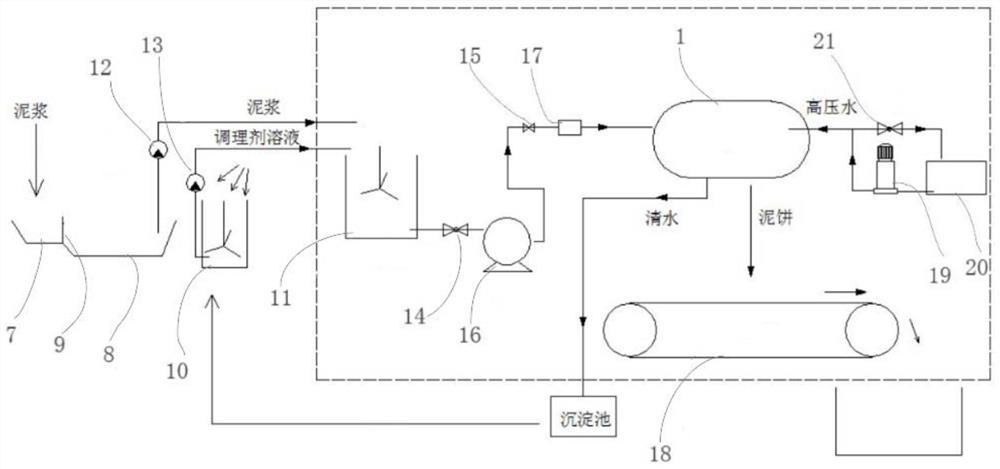

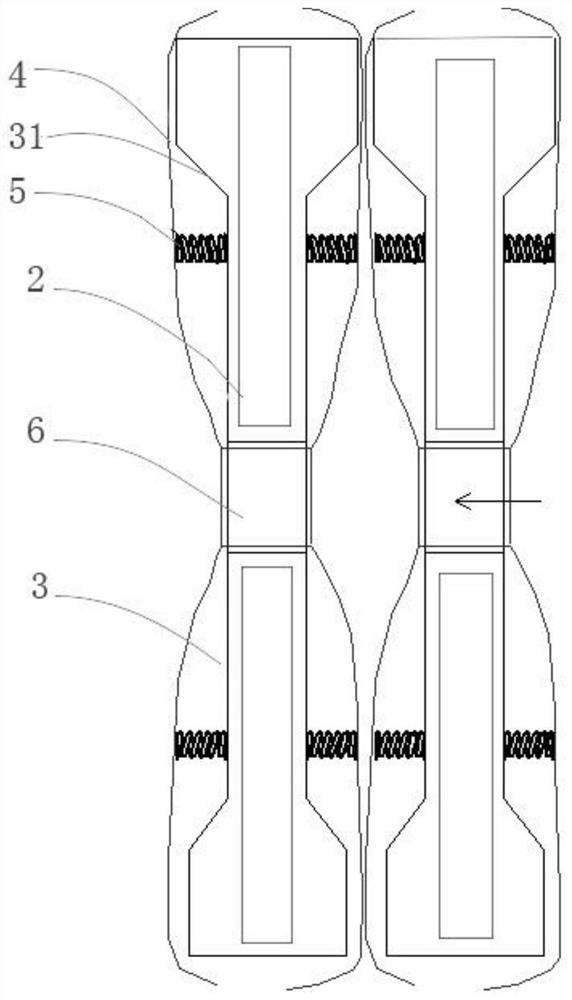

[0036] Such as Figure 1 to Figure 2 As shown, a mud solid-liquid separator includes a filter press 1, the filter press 1 is provided with filter plates 2 parallel to each other and arranged in a linear array, and the outer surface of the filter plate 2 is provided with Groove 3, two adjacent filter plates 2 are periodically bonded using the relevant action principle of the existing box-type filter press, that is, the common driving components in the prior art are used to periodically push the corresponding filter plates 2 for mutual The action of bonding, the groove 3 between two adjacent filter plates 2 is periodically closed to form a filter chamber, and the outside of the groove 3 is covered with a filter cloth 4 for separating the solids in the mud from the water in the mud, The middle part of the filter plate 2 is provided with a mud channel 6 through which the normal direction penetrates. By means of this channel, the pipeline for pumping the mud pumps the mud between t...

Embodiment 2

[0046] Such as Figure 1 to Figure 2 As shown, on the basis that the basic technical solution of Example 1 remains unchanged, the filter plate 2 is set as a cavity structure, and the side wall 31 of the groove 3 is set as an elastic rubber material. Fill the cavity of the filter plate 2 with water, and use the elastic deformation ability of the side wall of the filter plate 2. The high-pressure water in the cavity pushes the side wall of the filter plate 2 outward, and further squeezes out the water in the mud cake. .

[0047] In order to realize the above-mentioned technical operation, the required equipment and its connection relationship are: the No. 4 pump 19 and the water tank 20 , and the No. 4 pump 19 pumps the liquid in the water tank 20 to the cavity in the filter plate 2 . In order to adjust the pumping flow, a No. 3 valve 21 connected in parallel with the No. 4 pump 19 is also provided between the filter press 1 and the water tank 20 .

[0048] The above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com