Method for repairing dam crack defect by using magnetic mortar

A magnetic and mortar technology, used in water conservancy projects, coastline protection, marine engineering and other directions, can solve the problem of not being able to increase the filling rate of cracked mortar, and achieve simple and convenient construction procedures, easy access to materials, and improved filling accuracy. degree of effect

Pending Publication Date: 2022-04-26

CHINA THREE GORGES UNIV

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem to be approached by the present invention is to provide a method for repairing dam crack defects with magnetic mortar, which is used to solve the problem that the mortar in the existing crack repair method may not be able to increase the size of the crack well due to reasons such as water flow or gravity. The problem of mortar filling rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

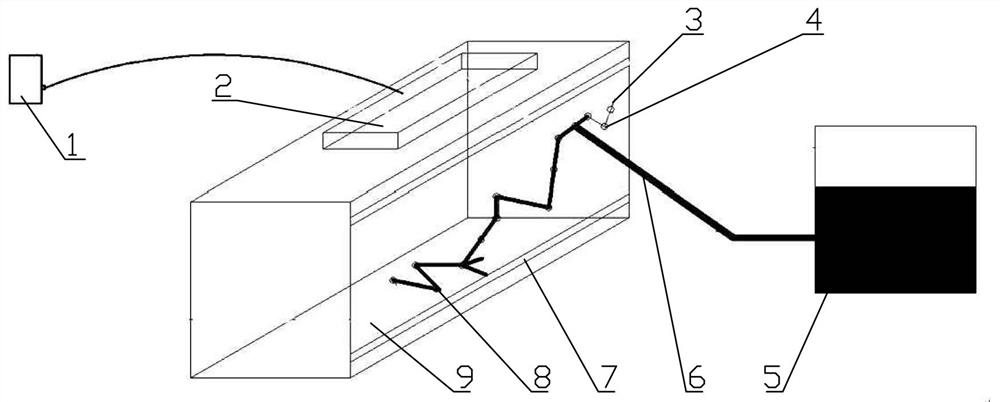

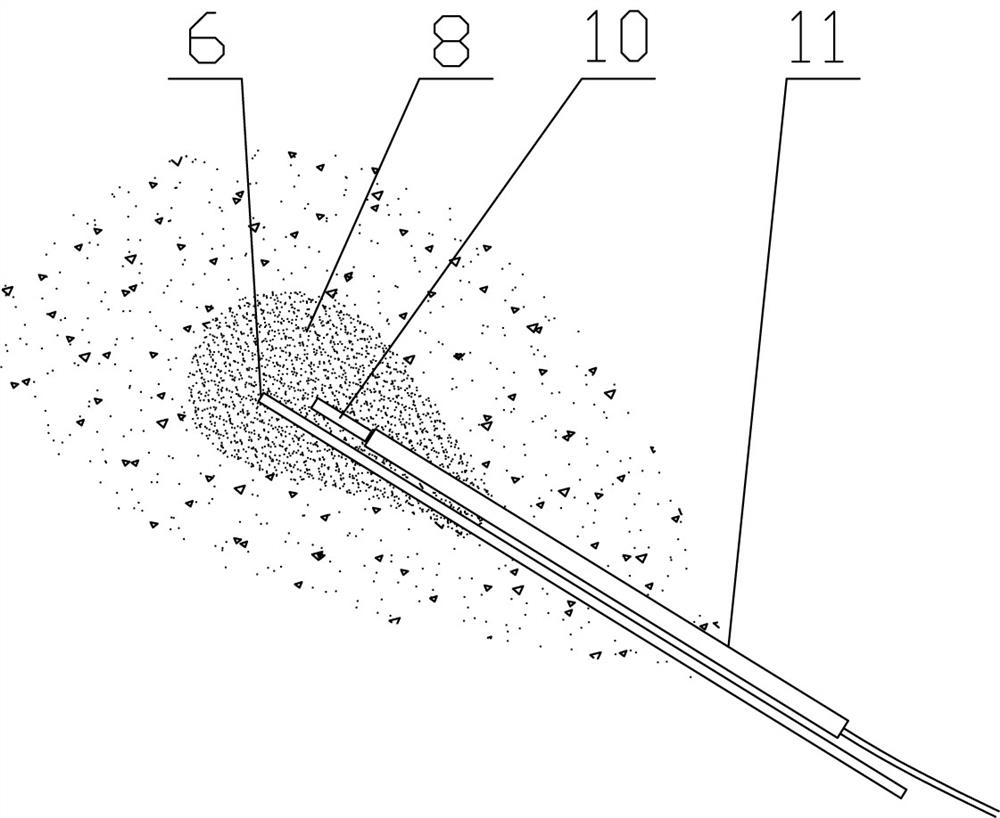

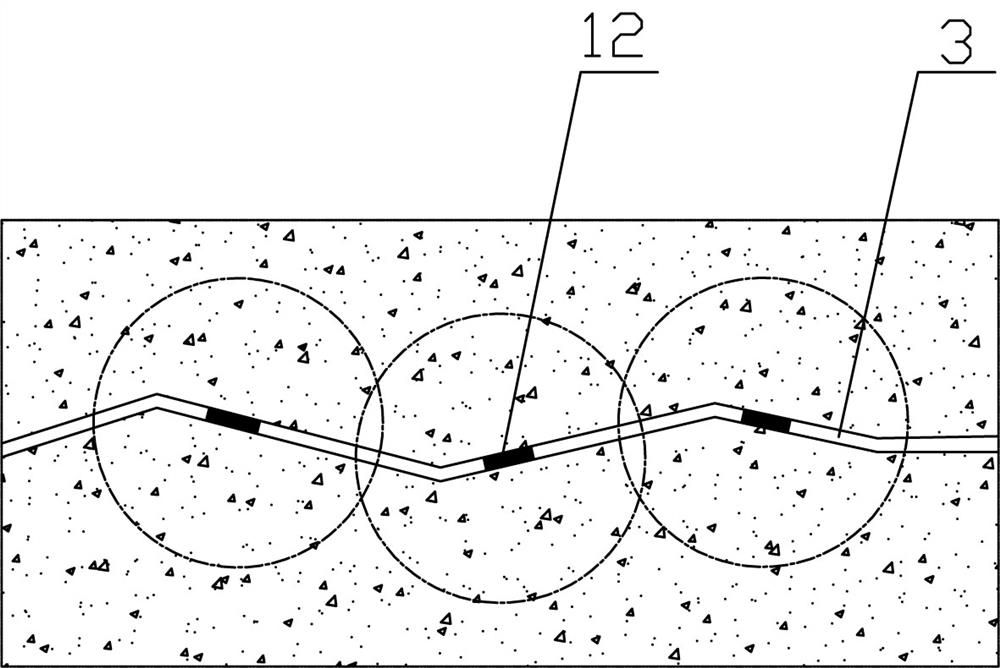

[0026] Such as Figures 1 to 3 Shown, a kind of method utilizing magnetic mortar to repair dam crack defect, comprises the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Login to View More

Abstract

A method for repairing dam crack defects by using magnetic mortar comprises the following steps: Step 1, detecting concrete dam cracks by using ultrasonic waves, and determining the specific position, size and trend of the cracks needing to be repaired; 2, a construction working face is cleaned and repaired, and precipitates on the concrete surface of the dam are chiseled away; 3, the number, the position, the depth, the diameter and the distance of grouting holes are determined according to the specific position, the size and the trend of the crack, and the grouting holes are drilled through a drilling machine; 4, a grouting nozzle is embedded in the drilled grouting hole, a grouting pipe is inserted, a power source is arranged outside the working face, and a movable electromagnet with the magnetic force capable of being adjusted and controlled is placed; 5, the magnetic mortar is placed in a grouting machine, and the grouting machine is used for sequentially injecting the magnetic mortar into grouting nozzles through grouting pipes; the crack repairing method is used for solving the problem that in an existing crack repairing method, the mortar filling rate in a crack can not be well increased possibly due to water flow or gravity and the like.

Description

technical field [0001] The invention relates to the technical field of dam defect elimination and reinforcement, in particular to a method for repairing dam crack defects by using magnetic mortar. Background technique [0002] The total amount of dams and reservoirs in China ranks first in the world. As of the end of 2017, data provided by the China Society of Dam Engineering shows that there are more than 98,000 dams in China. However, according to statistics from the Chinese Society of Dam Engineering, due to the fact that most of China's dams are designed for a long time and have serious aging problems, nearly half of the dams have hidden safety hazards, and the total number of large and medium-sized dangerous reservoirs has reached more than 1,200. Once the dam breaks, houses, fields, industrial facilities, railways, etc. will be washed away, causing a huge impact on the national economy. [0003] Dam cracks, as the most common defect of dams, are the biggest safety haz...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02B7/02E02B3/16C04B28/00C04B14/34

CPCE02B7/02E02B3/16C04B28/00C04B14/34C04B24/281C04B14/24C04B2103/408C04B2103/0068

Inventor 刘杰李政王天龙程其芬黎照孙涛郭建祥陈子悦宋瑞孙荣琪蔡显灿莫承林

Owner CHINA THREE GORGES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com