Dyeing nozzle and dyeing machine

A technology of nozzle and dye liquor, applied in the direction of spraying device, spraying device, spraying/jetting textile material processing, etc., can solve the problems of uneven impact force on the surface of the cloth, influence of the texture of the cloth, limited effect, etc., to improve the dyeing efficiency. and finished product quality, avoid tangling and knotting, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

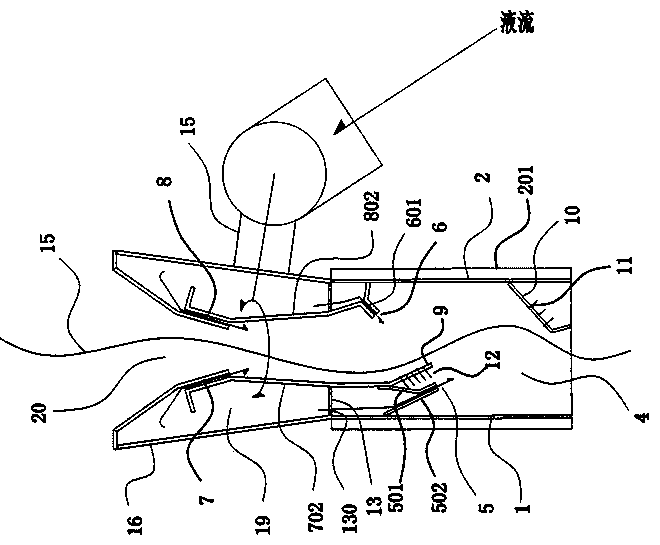

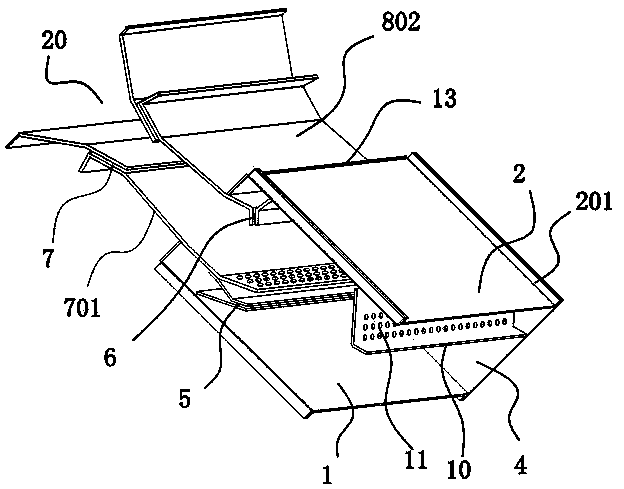

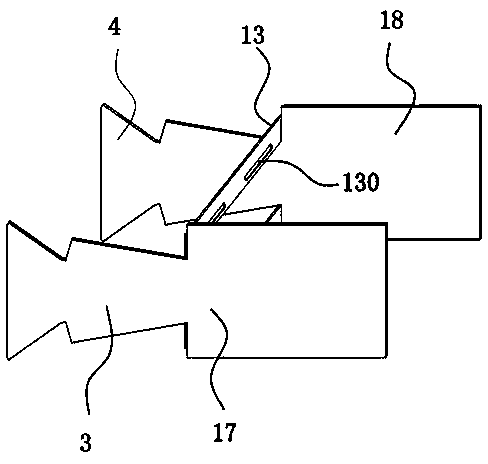

[0027] Such as figure 1 , 2 , 3, 4, and 5, the dyeing nozzle includes an inner wall and an outer wall 16, the inner wall forms a distribution channel 20, and the cross section of the distribution channel is a rectangular channel adapted to the width of the cloth. The passage has four inner wall surfaces, front, rear, upper, lower, and front. The front and rear sides are front wall panels 17 and rear wall panels 18 with the same structure. The lower dye solution outlet 7 and the upper dye solution outlet 8 facing the upper and lower sides of the cloth are respectively arranged on the upper and lower inner wall surfaces. The dyeing port is arranged obliquely in the advancing direction of the channel relative to the cloth, that is, it is inclined towards the advancing direction of the cloth, so that the liquid flow impacts the cloth and drives the cloth to advance. The lower inner wall surface includes the upper plate body 701 of the lower dye solution outlet and the lower plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com