Scutching equipment for water-soluble chitosan textile processing

A technology for water-soluble chitosan and equipment, which is applied in the field of open-width equipment for water-soluble chitosan textile processing, can solve the problems of clamping and fixing unwrinkled fabrics, affecting the effect of open-width, and taking a long time, and achieving Reduce the probability of wrinkling, improve the effect of opening, improve the effect of quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

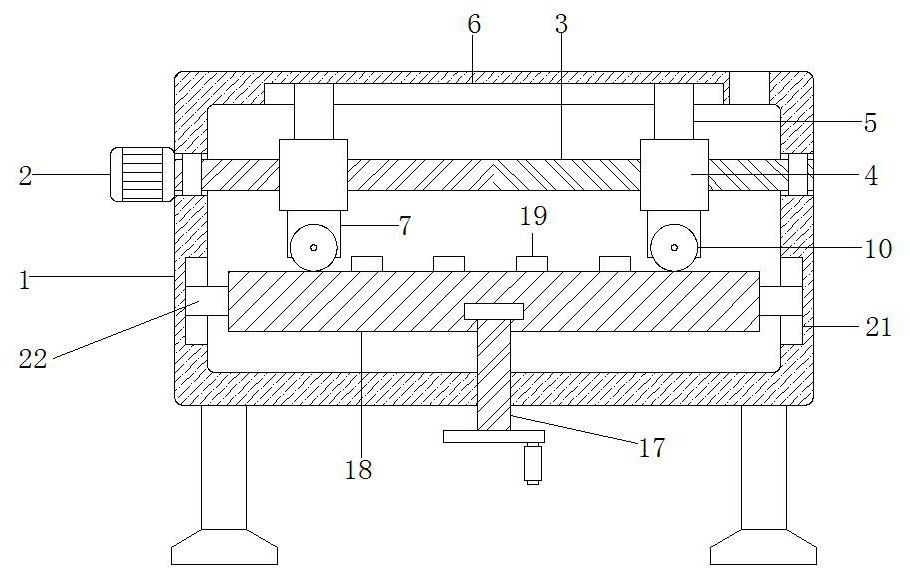

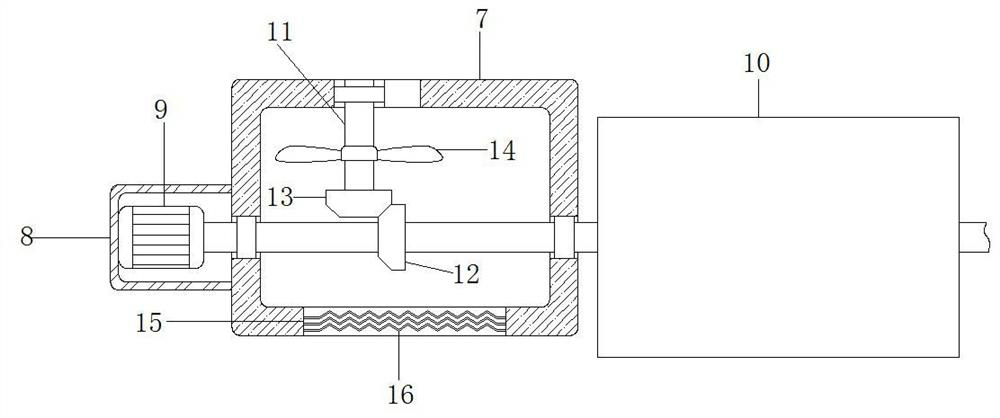

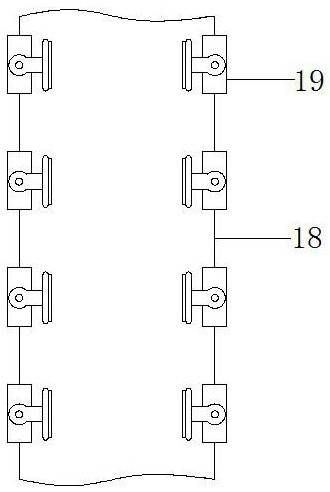

[0023] Embodiment 1, with reference to Figure 1-4 , a kind of open-width equipment for water-soluble chitosan textile processing, comprising an open-width box 1 with supporting legs welded at the four corners of the bottom, a servo motor 2 is installed on the upper part of the outer wall of one side of the open-width box 1 through bolts, and the servo motor The output shaft of 2 is connected with a two-way screw rod 3 through a coupling, and two threaded sleeves 4 are set on the two-way screw rod 3, and the top outer walls of the two threaded sleeves 4 are welded with a limit rod 5, and the top inner wall of the opening box 1 A limit groove 6 is provided, and the top outer wall of the limit rod 5 is slidably connected with the top inner wall of the limit groove 6, and the outer walls of the bottom of the two threaded sleeves 4 are welded with a hot air box 7, and two hot air boxes 7 are provided with Hot-blast mechanism, two hot-blast mechanisms all comprise the moisture-proo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com