Patents

Literature

66results about "Textile treatment guiding means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

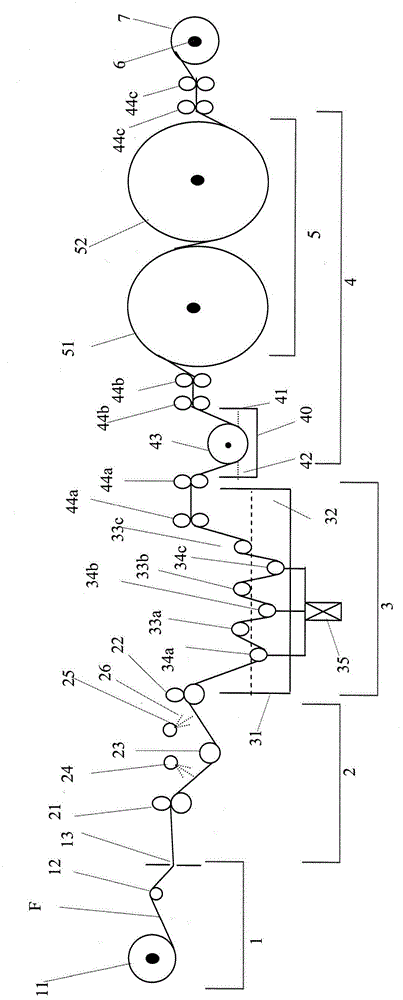

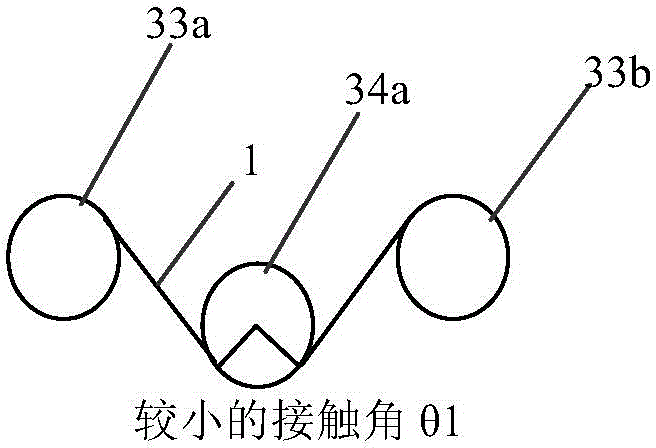

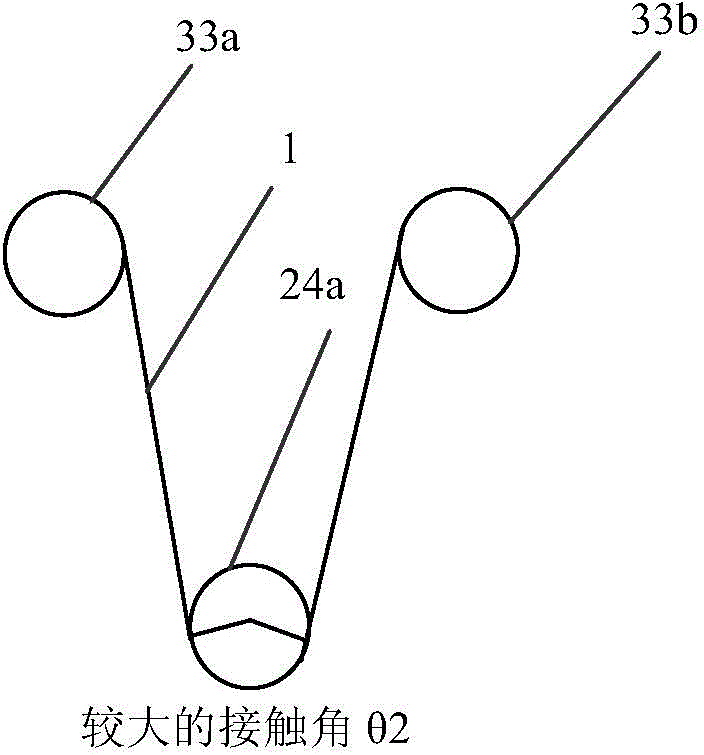

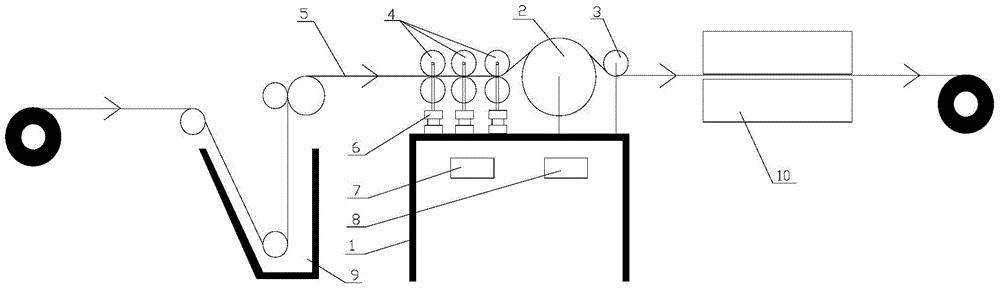

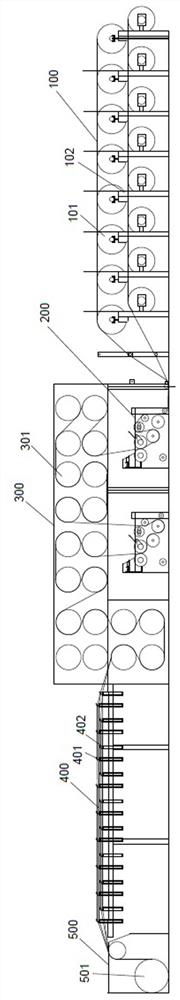

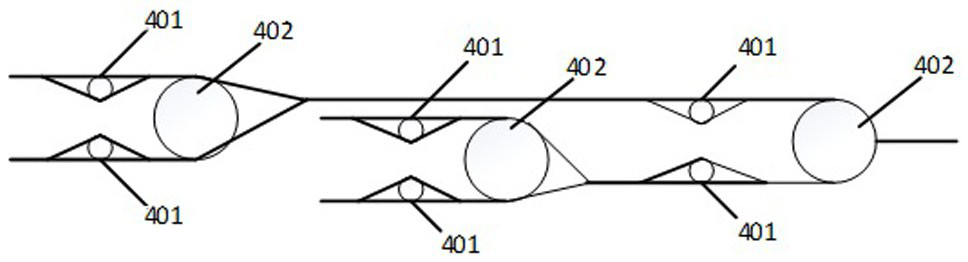

Processing equipment and method for continuous fiber tows

The invention relates to processing equipment and method for continuous fiber tows. The processing equipment comprises a desizing unit, an unfolding and dispersing unit and a sizing unit, wherein the desizing unit uses a fluid washing mode to enable fiber tows to desize, the unfolding and dispersing unit comprises round bars, tension braking rollers and a tension brake which are alternatively arranged, the round bars and the tension braking rollers are used for controlling the contact angles between the fiber tows and the adjacent round bars, the tension brake is connected to each tension braking roller and then used for regulating the tension generated when the tension braking rollers rotate, and the sizing unit is used for conducting re-sizing and drying on the fiber tows. The method for the continuous fiber tows is achieved through the above equipment, the fiber tows after being processed have lowered and uniform fiber distribution density and stable and consistent fiber tow widths, and therefore the fiber tows together with heat plastic plastics can directly be made into heat plastic composite materials or various types of composite material products.

Owner:FORMOSA TAFFETA CO LTD

Method Of Sizing Of Fibers And Articles Manufactured From The Same

The method includes the steps of functionalizing a polyaryletherketone (PAEK) polymer, and blending the PAEK polymer with water to form a sizing composition. The method may further include the step of applying the sizing composition to a fiber. The method may further include the step of heating the fibers, coated with sizing composition, for example to between 300C-400C. In some methods, the functionalized PAEK polymer comprises functionalized polyetherketoneketone (PEKK). In yet other methods, the functionalized PAEK polymer comprises sulfonated PEKK (sPEKK).

Owner:OXFORD PERFORMANCE MATERIALS

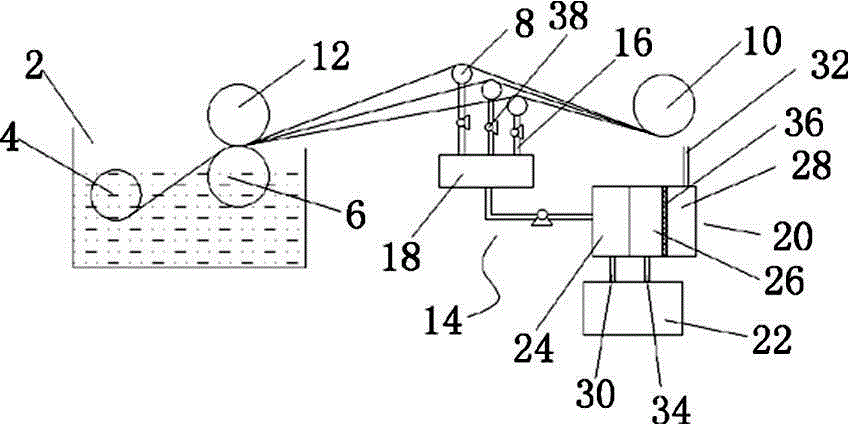

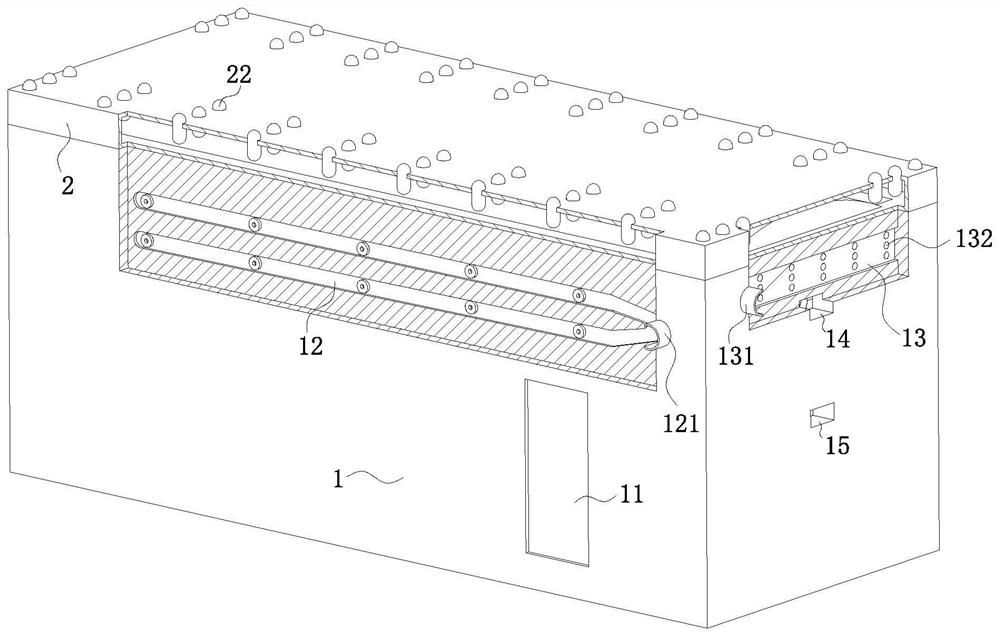

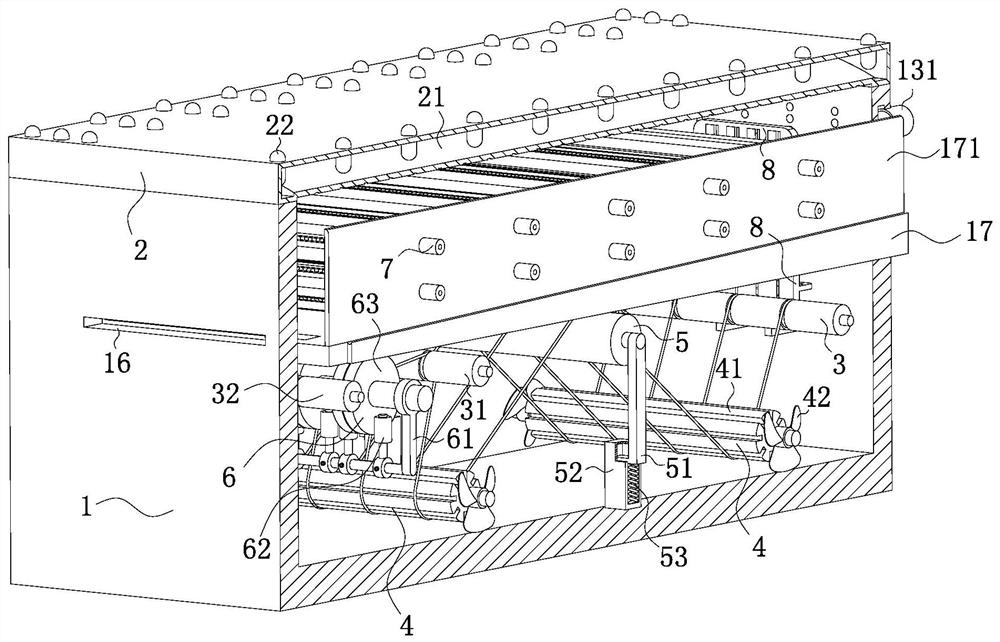

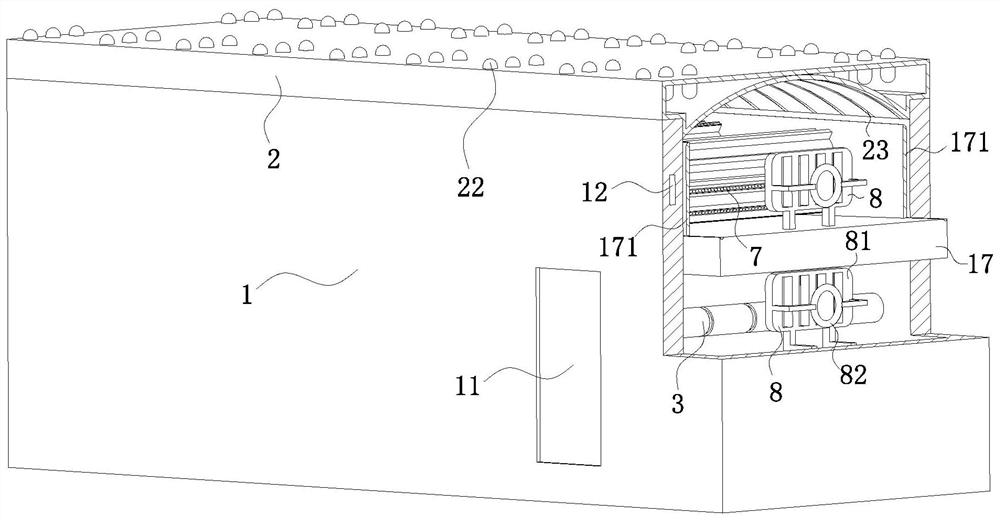

Yarn printing and dyeing automatic cleaning mechanism

InactiveCN106801304AHigh degree of automationImprove work efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment carriersYarnAgricultural engineering

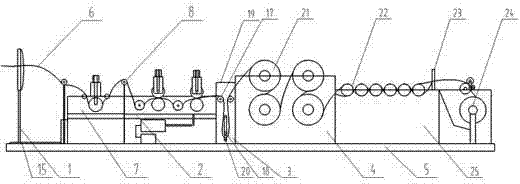

The invention discloses a yarn printing and dyeing automatic cleaning mechanism. The yarn printing and dyeing automatic cleaning mechanism comprises a frame, a yarn unreeling device, a first yarn separating rack, a yarn rinsing device, a water squeezing mechanism, a water blowing mechanism, a thermal drying mechanism, a yarn storage mechanism, a second yarn separating rack, a reeling device and a plurality of groups of transmission rollers, wherein the yarn unreeling device, the first yarn separating rack, the yarn rinsing device, the water squeezing mechanism, the water blowing mechanism, the thermal drying mechanism, the yarn storage mechanism, the second yarn separating rack and the reeling device are arranged on the frame; the transmission rollers are arranged between the unreeling device and the reeling device. The yarn printing and dyeing automatic cleaning mechanism can automatically achieve the steps of automatic yarn unreeling, cleaning, drying, reeling and the like, thereby being high in automation degree and working efficiency, and by means of the yarn storage mechanism, can temporarily store cleaned yarn reels to achieve continuous production, to avoid downtime and further to improve the production efficiency.

Owner:张丹丹

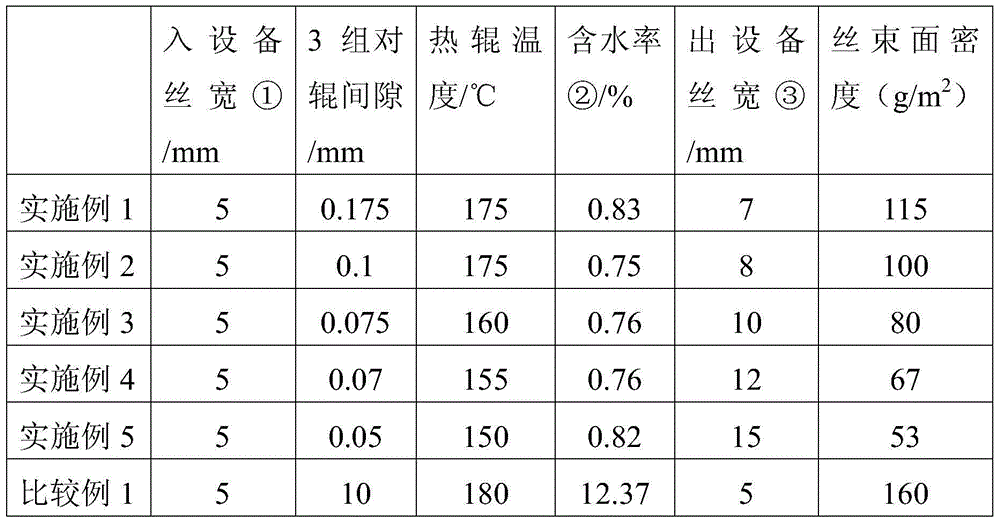

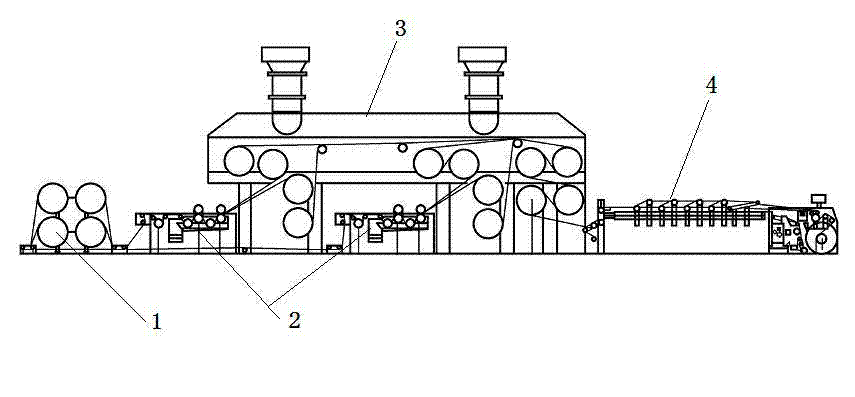

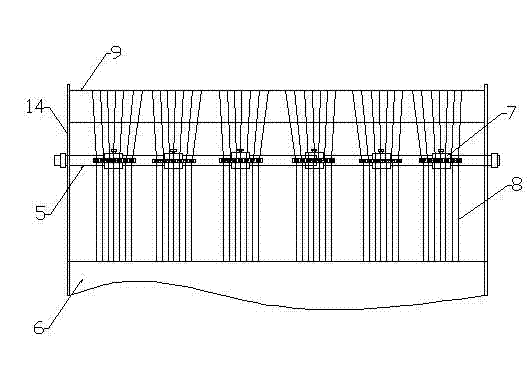

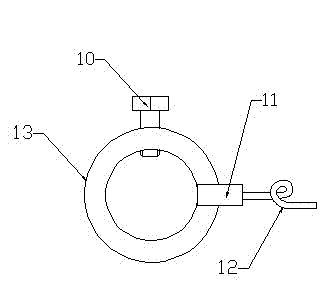

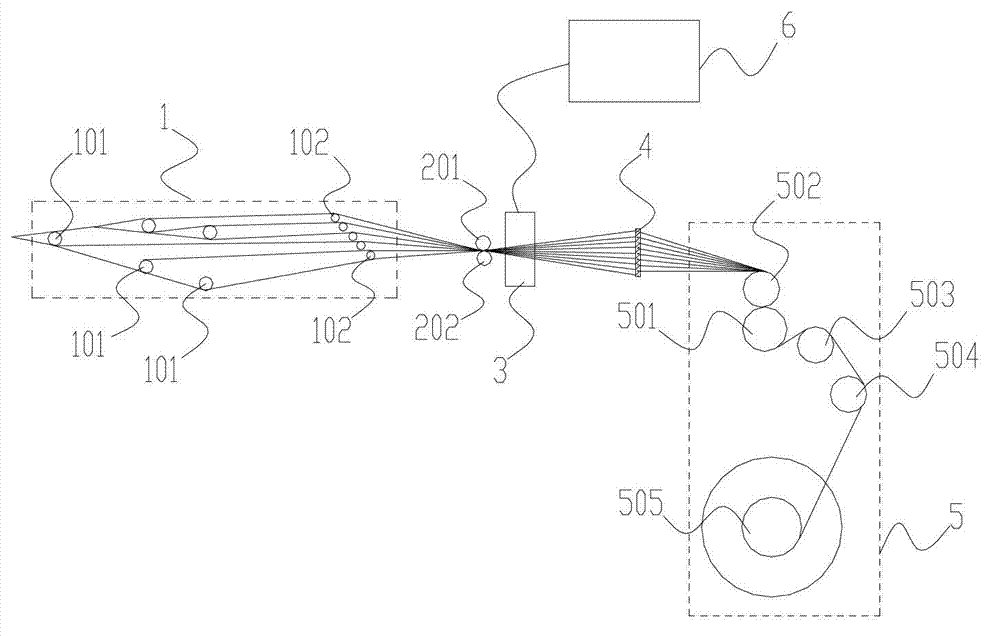

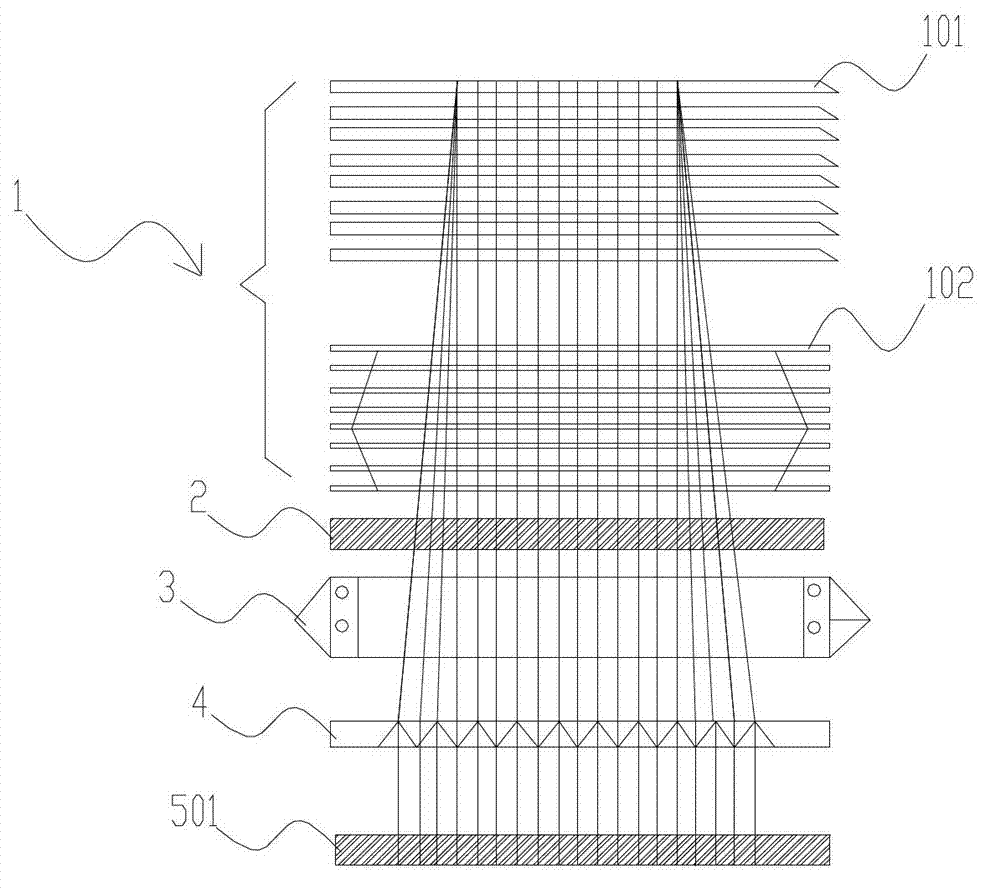

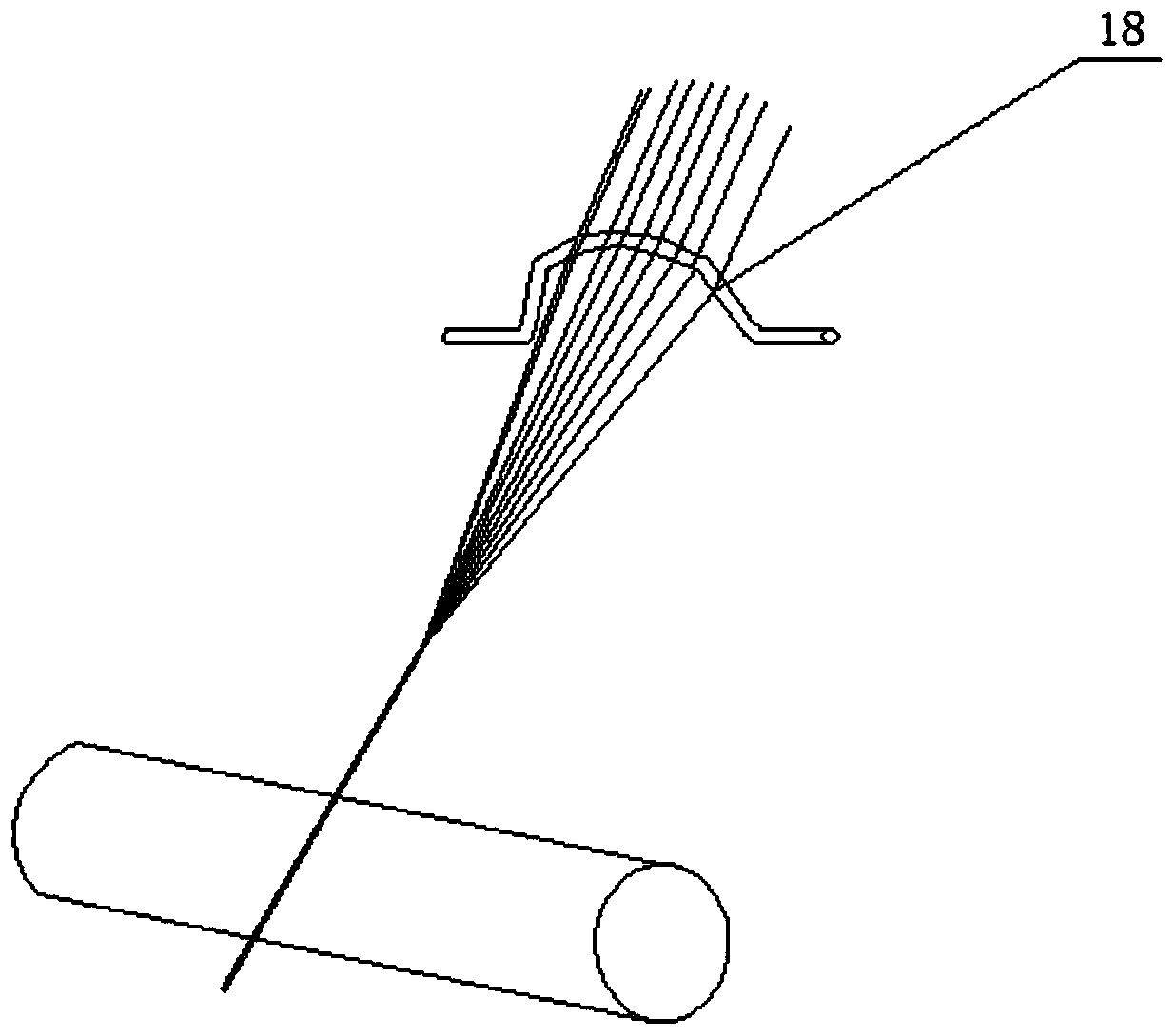

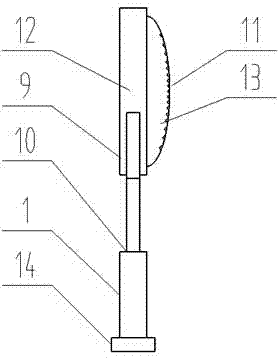

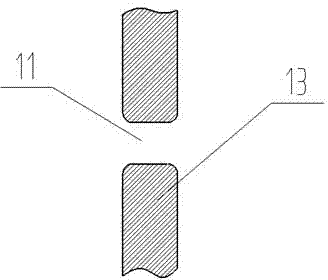

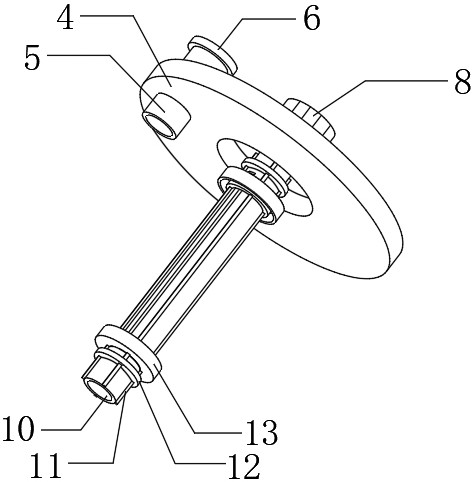

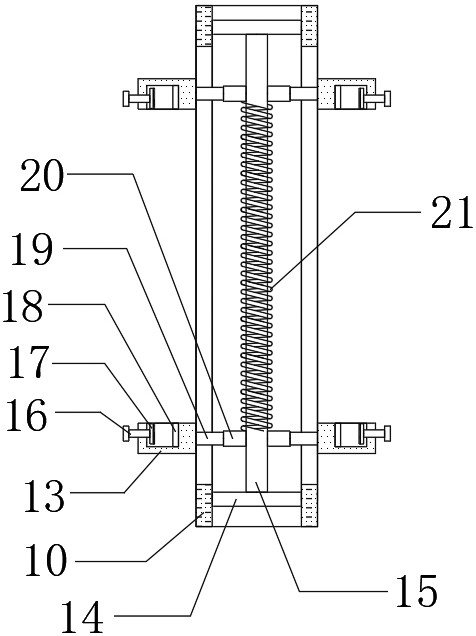

Splitting shaping device and splitting shaping method of ultrathin carbon fiber bundle

ActiveCN104674485AAchieve ultra-thinOnline continuous fastLiquid/gas/vapor removalTextile treatment machine arrangementsCarbon fibersFiber bundle

The invention discloses a splitting shaping device and a splitting shaping method of an ultrathin carbon fiber bundle. The splitting shaping device comprises a plurality of groups of filament spreading double-rollers, a heat roller and a levelness adjusting roller, which are sequentially arranged; each group of filament spreading double-rollers is provided with a hydraulic lifting machine, each hydraulic lifting machine is fixed on a support, two ends of the heat roller are fixedly connected to the support, and two ends of a rotating shaft of the levelness adjusting roller are also fixedly connected to the support; when the carbon fiber bundle is transported, the heat roller is fixed and does not rotate. The splitting and shaping method comprises the steps of enabling the carbon fiber bundle with serous fluid on the surface to sequentially pass through the filament spreading double-rollers, uniformly spreading the carbon fiber bundle under the extruding effect of the filament spreading double-rollers and the lubricating effect of the serous fluid, and pressing and flattening the fluctuated fibers in the carbon fiber bundle; enabling the carbon fiber bundle to pass through the heat roller, enabling the heat roller to be fixed and not to rotate, drying the carbon fiber bundle by virtue of the heat roller, and enabling the carbon fiber bundle to maintain the filament width after he carbon fiber bundle is spread. After the splitting shaping device and the splitting shaping method is applied to the carbon fiber production process, the ultrathin and online continuous and rapid production of the carbon fiber bundle can be realized, and the development of a downstream ultralight ultrathin product can be satisfied.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

Intermittent sizing device for dyed yarns and sizing technology thereof

InactiveCN102899835AIncrease the gapGuarantee the quality of dyeingTextile treatment carriersTextile treatment guiding meansYarnPolymer science

The invention relates to a spinning and sizing device and a sizing technology in the textile industry, in particular to an intermittent sizing device for dyed yarns and a sizing technology of the intermittent sizing device of the dyed yarns. The intermittent sizing device for the dyed yarns comprises a beam creel part, a size box part, a drying room part and a dried lease part. A yarn dividing roller is arranged between a beam in the beam creel part and a guide roller and is provided with multiple yarn dividing comb teeth for respectively guiding deep and light yarns. The sizing technological process for the dyed yarns, which adopts the intermittent sizing device for the dyed yarns, comprises the steps of: arranging the multiple yarn dividing comb teeth in front of the guide roller, enabling the yarns with the different colors to pass through the different yarn dividing comb teeth, dividing the yarns by the yarn dividing comb teeth, enabling the yarns to enter the different sizing tanks through the guide roller, sizing the yarns through the sizing tanks, then drying, and winding the yarns on a beam according to the set positions. The invention improves the production efficiency of sizing the multicolor warps, improves the quality of the dyed yarns, and maintains the elasticity of the yarns, thereby being beneficial for the improvement of the gray fabric quality.

Owner:山东宏诚集团有限公司

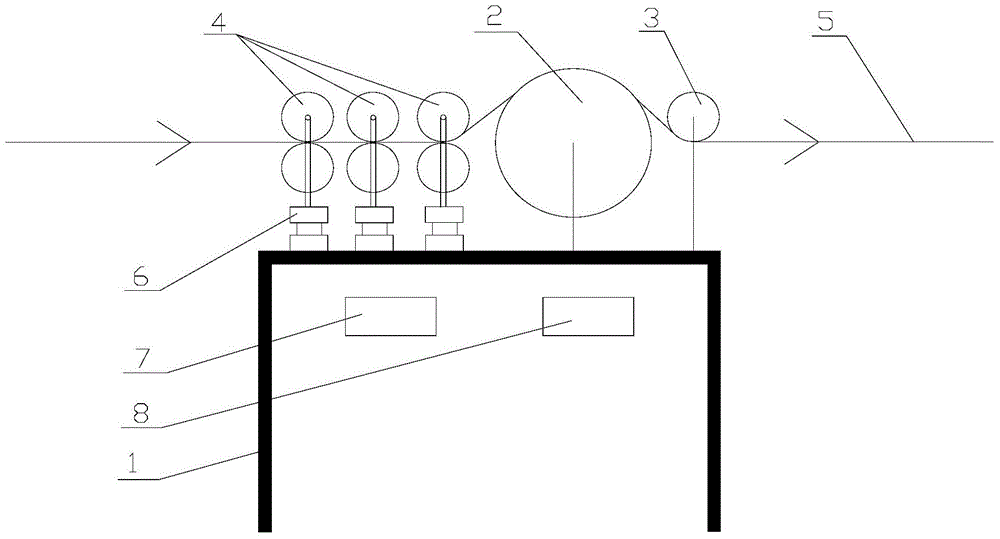

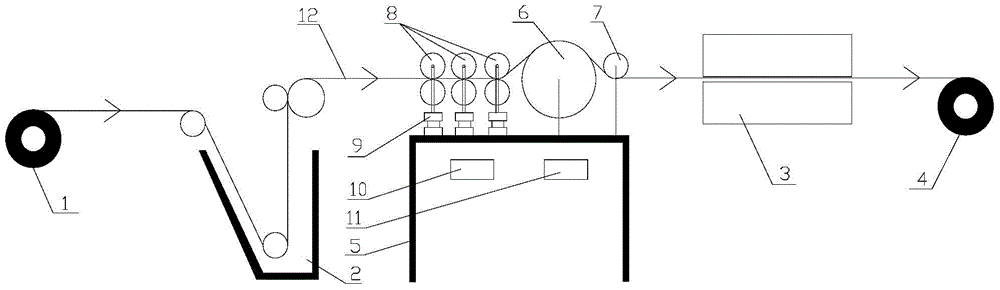

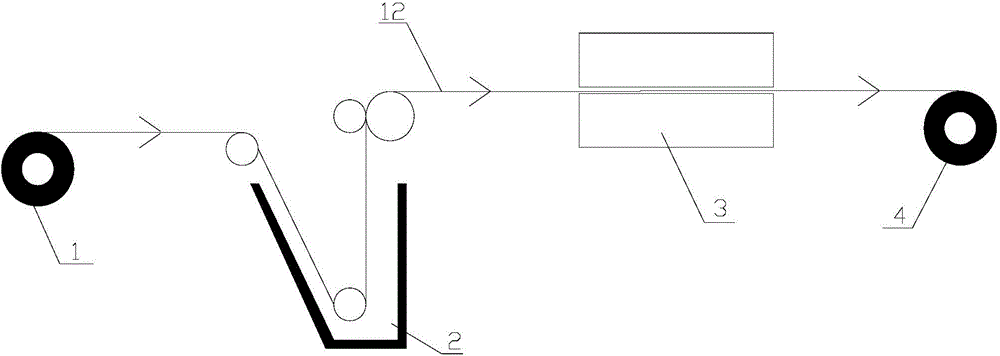

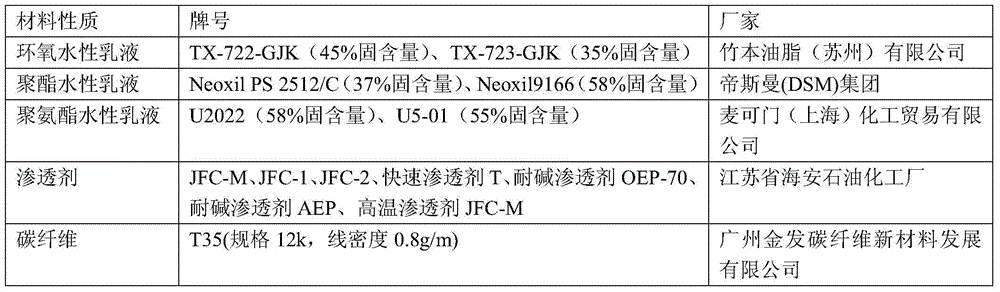

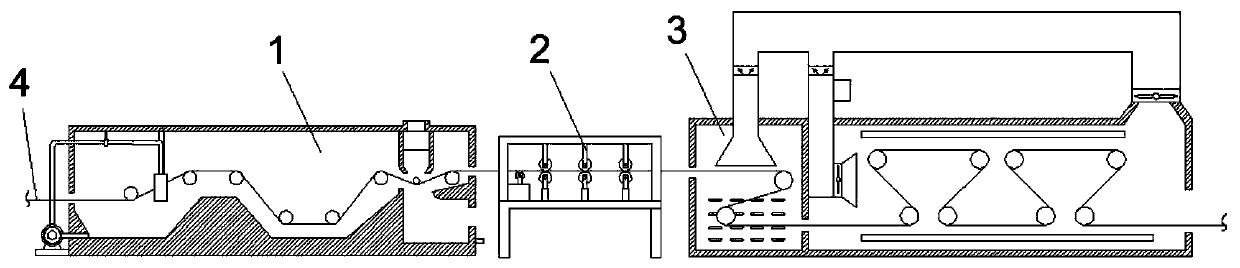

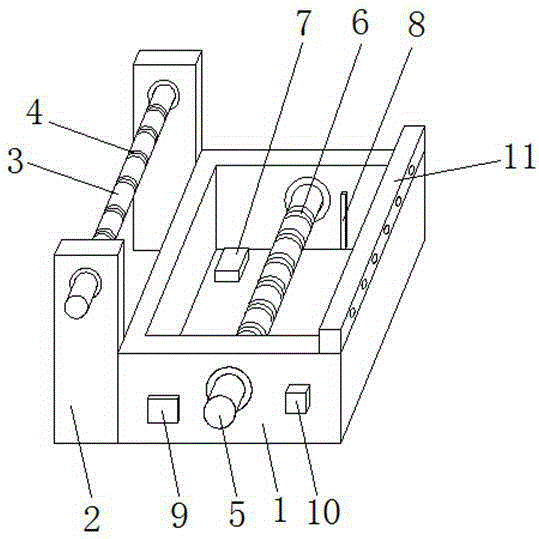

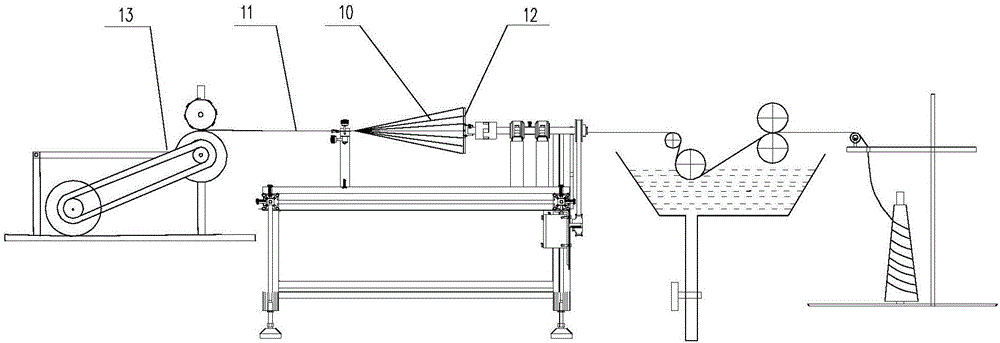

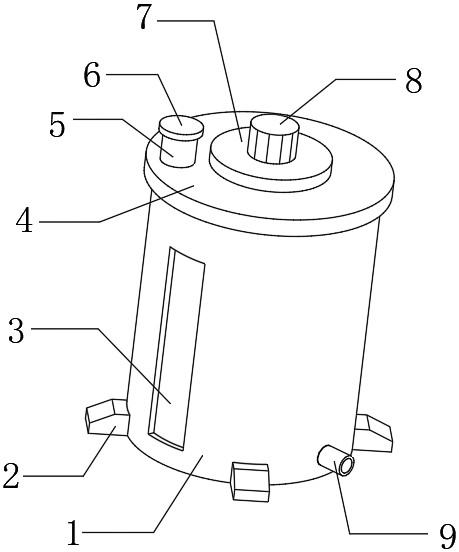

Test carbon fiber sizing apparatus

ActiveCN105525466ASolve the disadvantages of cumbersome process adjustment and affecting industrial productionEffective sizing testLiquid/gas/vapor removalTextile treatment guiding meansCarbon fibersMetallurgy

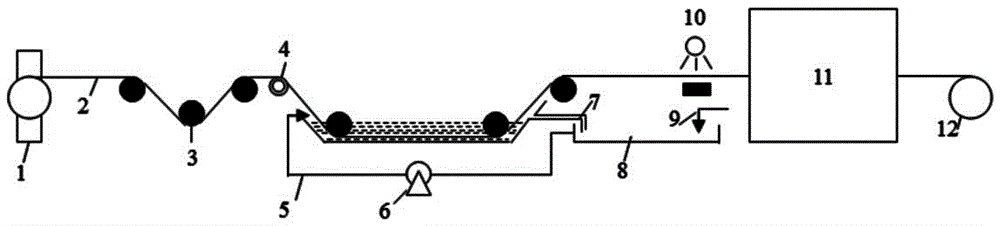

The invention discloses a test carbon fiber sizing apparatus, comprising a creel, guide rollers, an ultrasonic spreader, a sizing tank, a blower, an infrared heater and a carbon fiber winding device. Carbon fibers are placed on the creel and pass through multiple guide holes of the creel and sequentially through the guide rollers, the ultrasonic spreader, the sizing tank, the blower and the infrared heater, the carbon fibers are winded into a spindle at the carbon fiber winding device, the ultrasonic spreader is located at an inlet of the sizing tank, the sizing tank is located laterally below the ultrasonic spreader, the blower is located at one end of the sizing tank, the infrared heater is located at the right end of the blower, and the fiber winding device is located at the right end of the infrared heater. The test carbon fiber sizing apparatus provides uniform sizing and high sizing agent content and enables effective sizing test for carbon fibers and reduction in scientific research cost.

Owner:竺铝涛

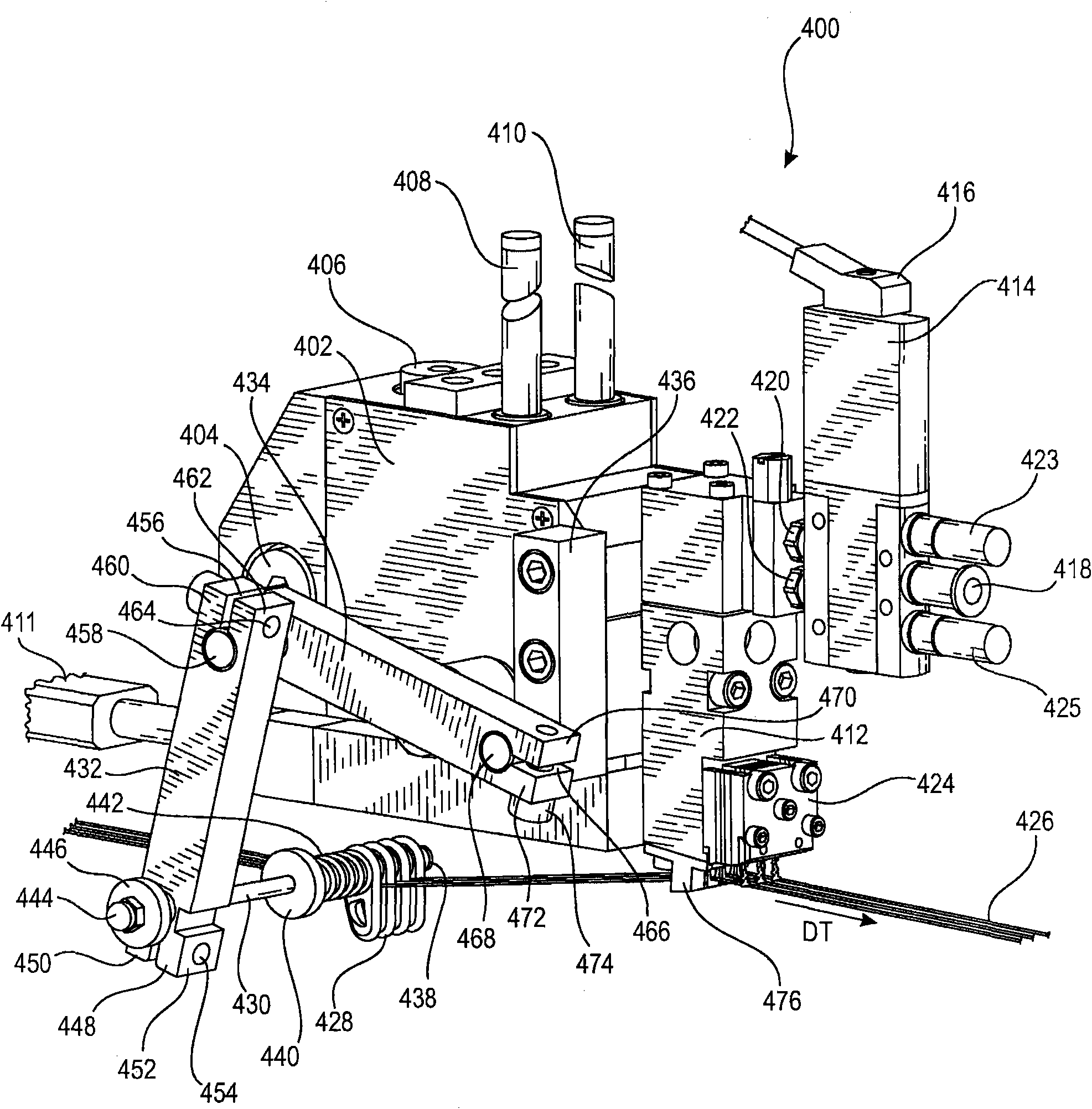

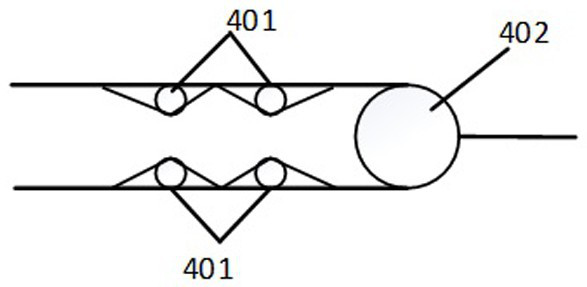

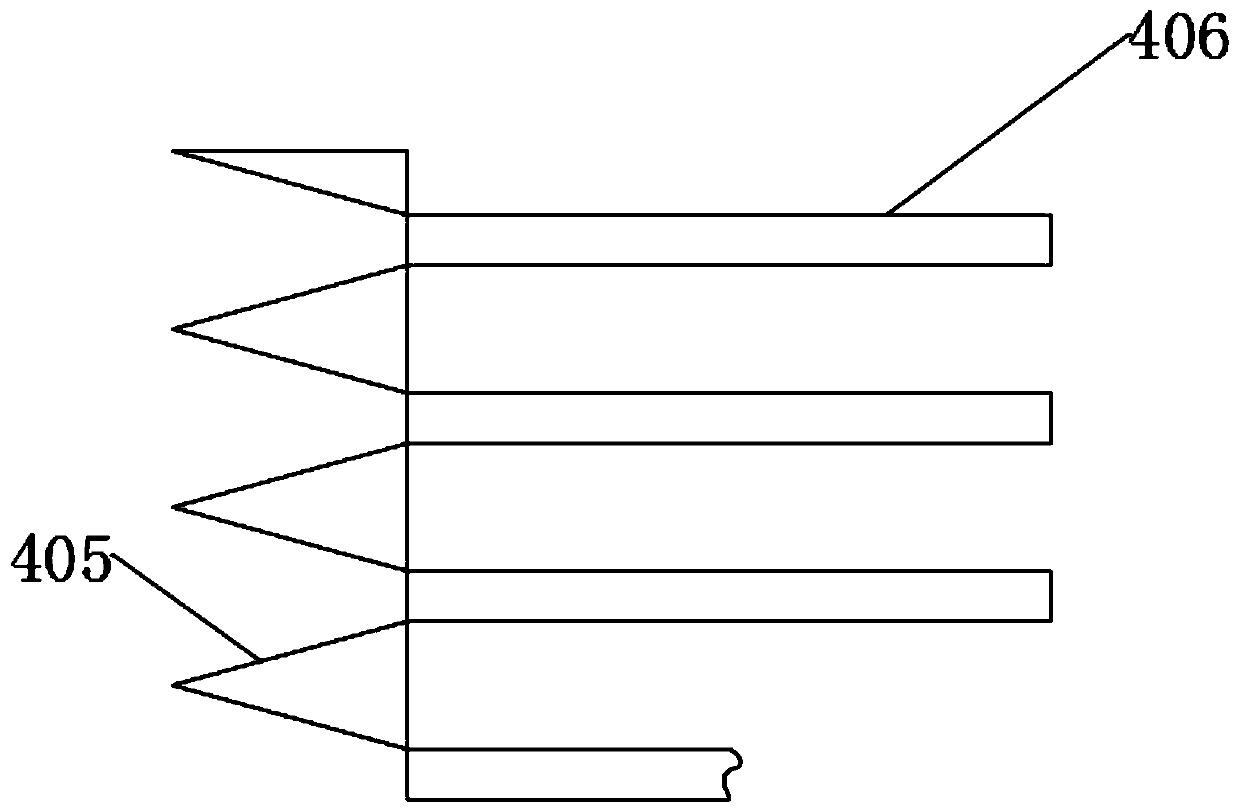

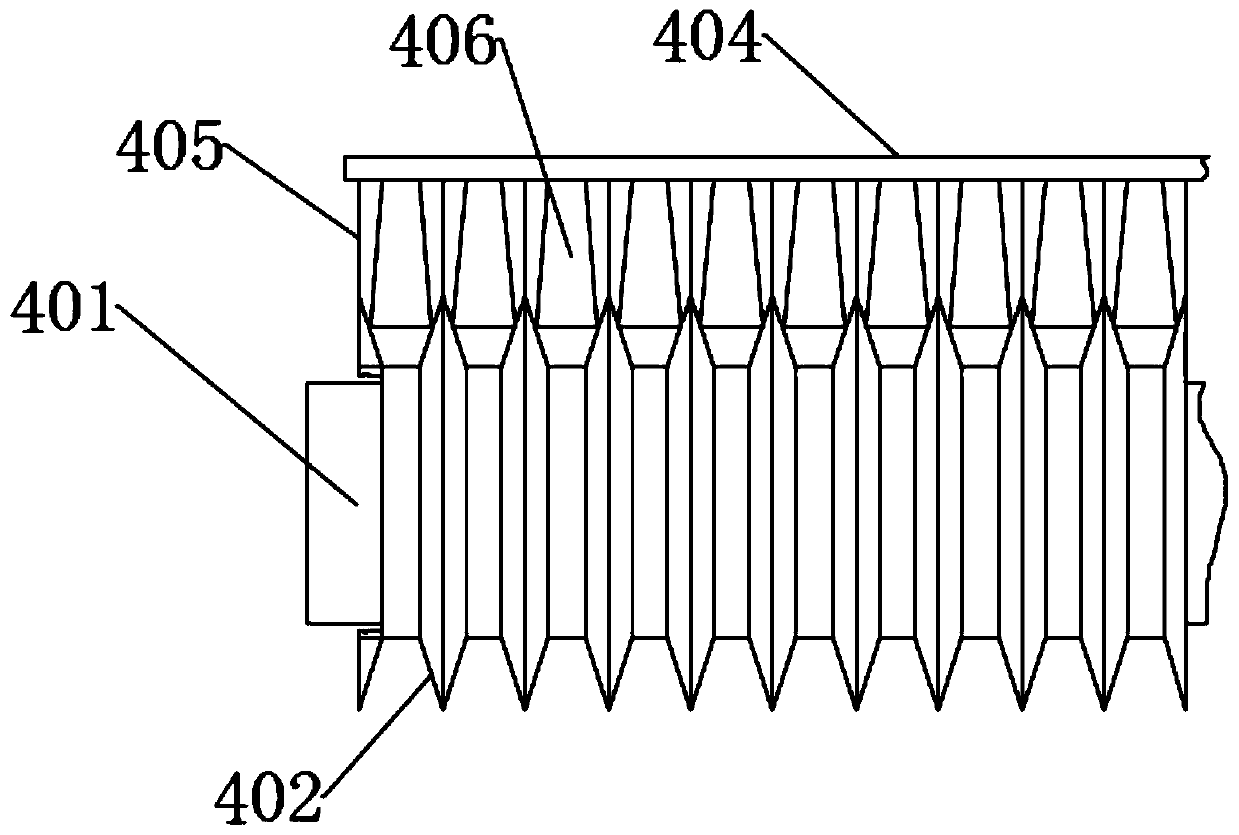

Strand positioning guide having reversely oriented v-shaped slots for use in connection with strand coating applicators

Strand positional guide implements, for use in connection with hot melt adhesive strand coating applicator assemblies, comprise a plurality of V-shaped strand guide slots wherein the apex portions areoriented outwardly away from the hot melt adhesive material dispensing nozzles. Accordingly, an enlarged air space is effectively defined between the plurality of elongated strands and its respectivehot melt adhesive material dispensing nozzle such that the plurality of elongated strands are not adversely affected by the heat or thermal radiation generated by or emanating from the hot melt adhesive material dispensing nozzles thereof.

Owner:ILLINOIS TOOL WORKS INC

Method and device for preparing ultrathin carbon fiber bundle

ActiveCN104695154AOnline continuous rapid productionEasy to useCarbon fibresLiquid/gas/vapor removalYarnFiber bundle

The invention discloses a method and a device for preparing an ultrathin carbon fiber bundle. The method comprises the following steps: after starching a carbon fiber bundle, sequentially passing through yarn widening roller pairs and a hot roller of a splitting and sizing device to widen and size, putting the widened and sized carbon fiber bundle in a drying oven to dry, and obtaining a wound carbon fiber bundle, wherein the wound carbon fiber bundle keeps the widened width. The device comprises an unwinding roller, a starching tank, the splitting and sizing device, the drying oven and a winding roller, wherein the unwinding roller, the starching tank, the splitting and sizing device, the drying oven and the winding roller are sequentially arranged; multiple groups of yarn widening roller pairs, the hot roller and a horizontal regulating roller are sequentially arranged on the splitting and sizing device; a hydraulic lifting machine is arranged on each group of yarn widening roller pairs, each hydraulic lifting machine is fixed on a support, the two ends of the hot roller are fixedly connected with the support, and the two ends of a rotary shaft of the horizontal regulating roller are fixedly connected with the support; when the carbon fiber bundle is conveyed, the hot roller is fixed and does not rotate. According to the method and the device for preparing the ultrathin carbon fiber bundle, the ultra-thinning of the carbon fiber bundle and the online continuous fast production and the development of downstream ultra-light ultrathin products can be achieved.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

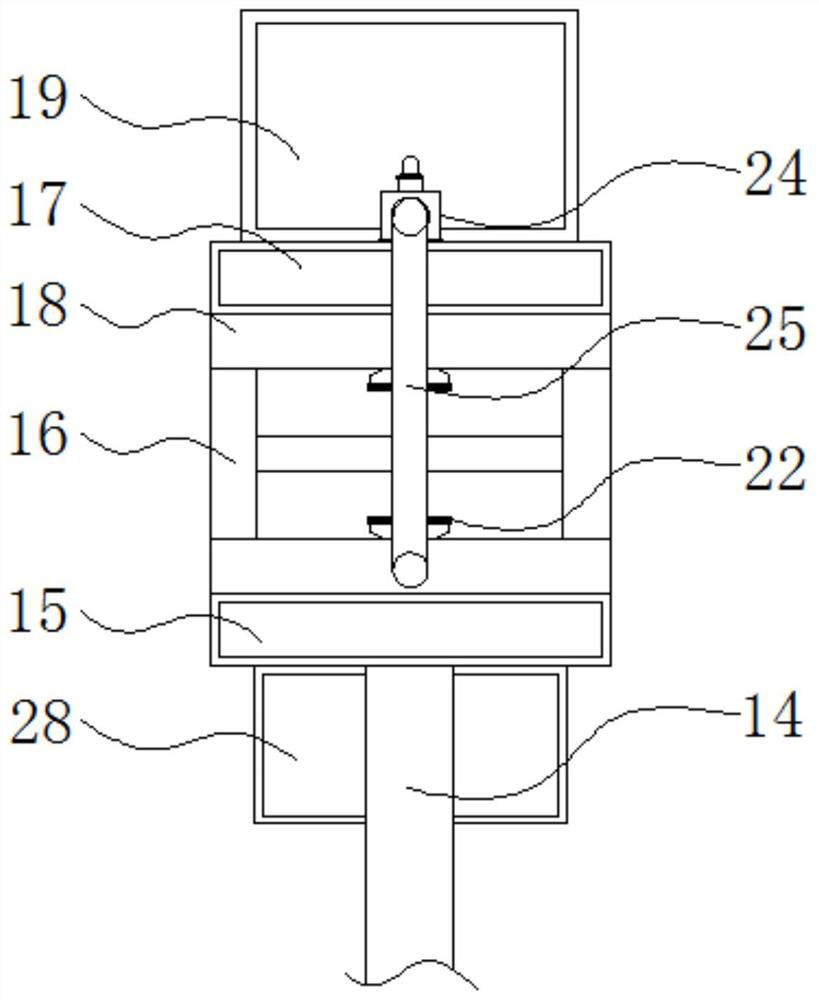

Slasher capable of realizing automatic pattern arrangement and automatic pattern arranging method

ActiveCN103046266AWith automatic flower arrangement functionImprove accuracyBeaming machinesTextile treatment carriersData processing systemYarn

The invention discloses a slasher capable of realizing automatic pattern arrangement and an automatic pattern arranging method. The slasher comprises a yarn distributing device and a headstock winding device, wherein the yarn distributing device is arranged in front of the headstock winding device, a compression roller device, an automatic pattern arranging device and an expansion reed are arranged between the yarn distributing device and the headstock winding device and are sequentially arranged along moving direction of yarns, and the automatic pattern arranging device is connected with a data processing system. By the aid of the automatic pattern arranging method, automatic pattern arranging function of the slasher is realized, thus labor force is saved, accuracy rating of sizing pattern arrangement is greatly increased, and producing efficiency and utilization rate of an automatic warp drafting machine during drafting process are greatly improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

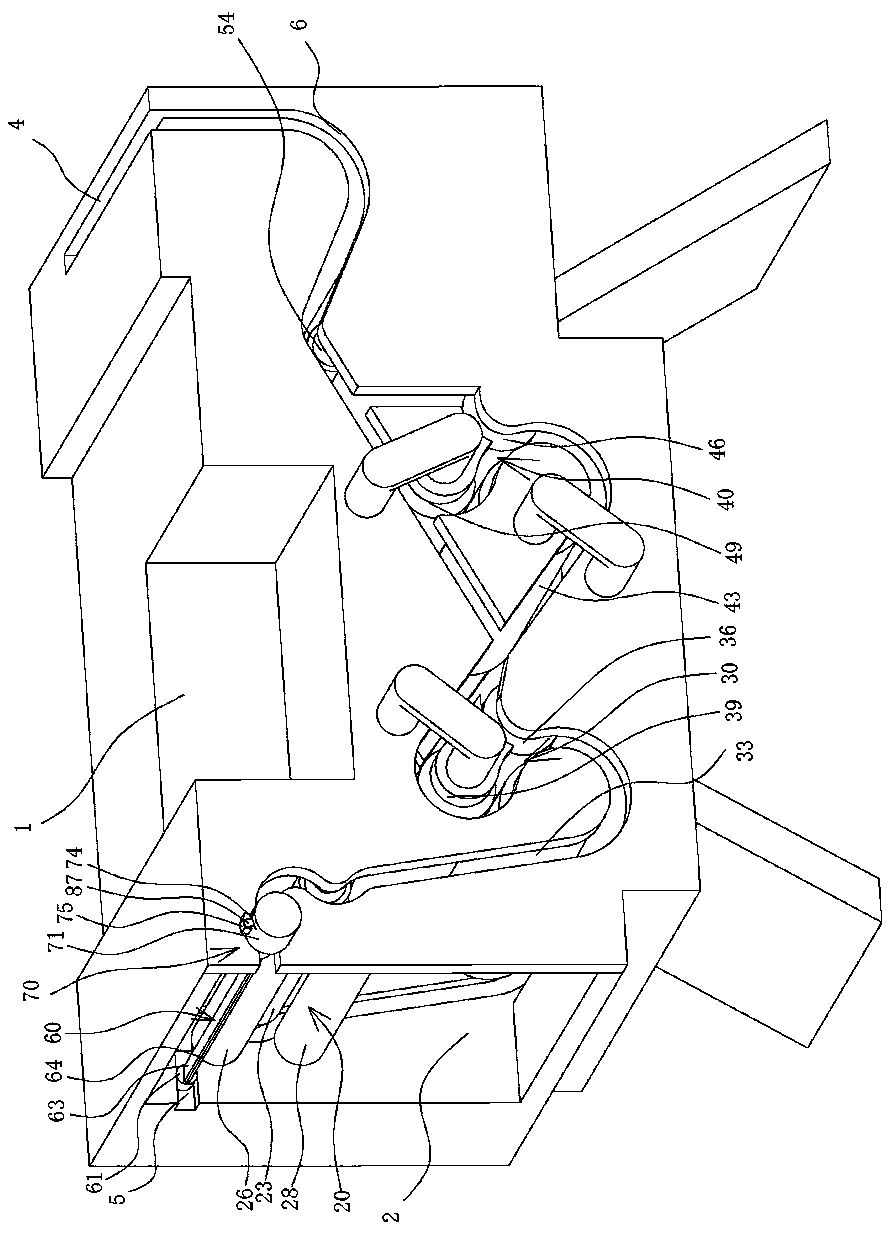

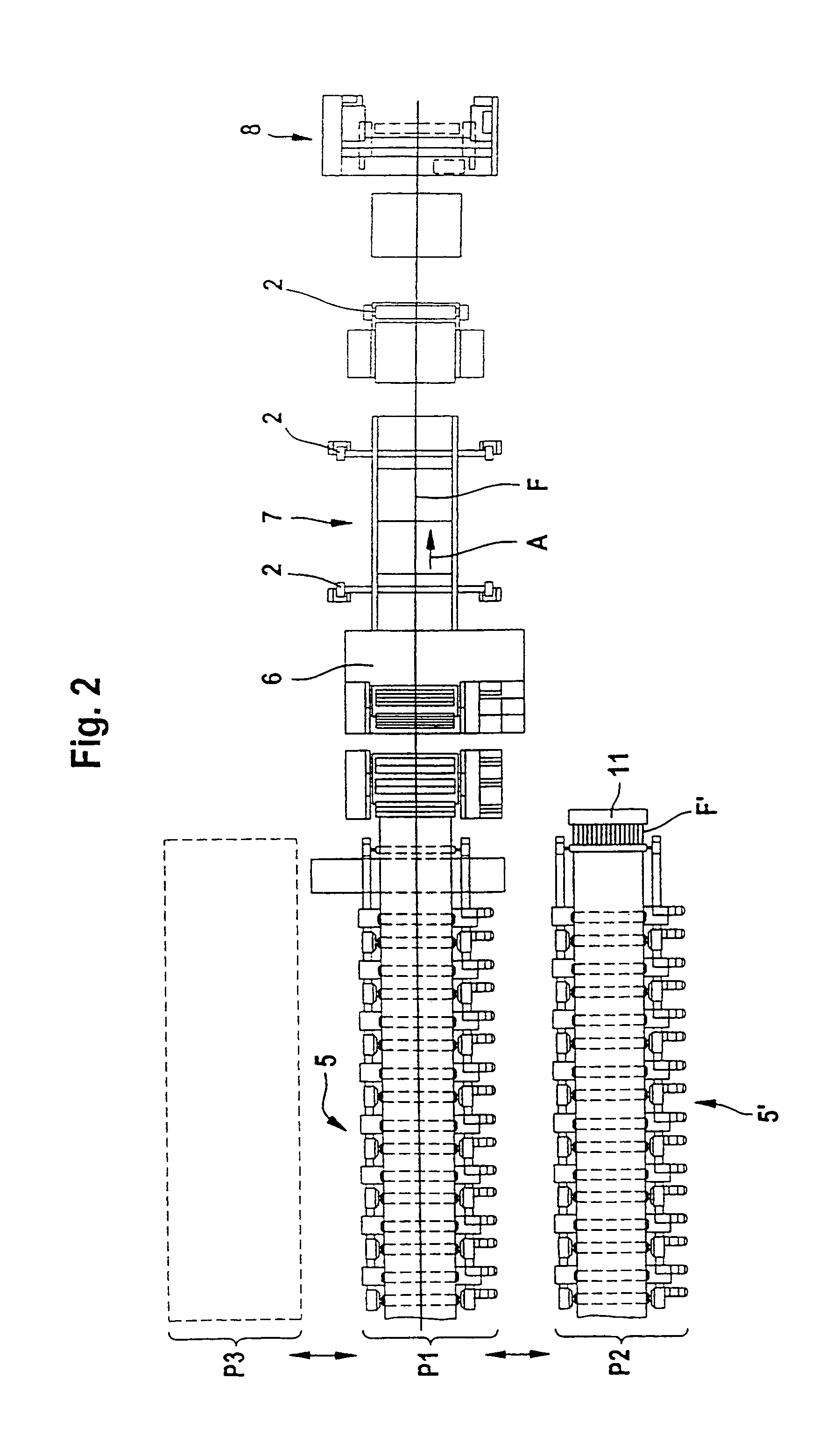

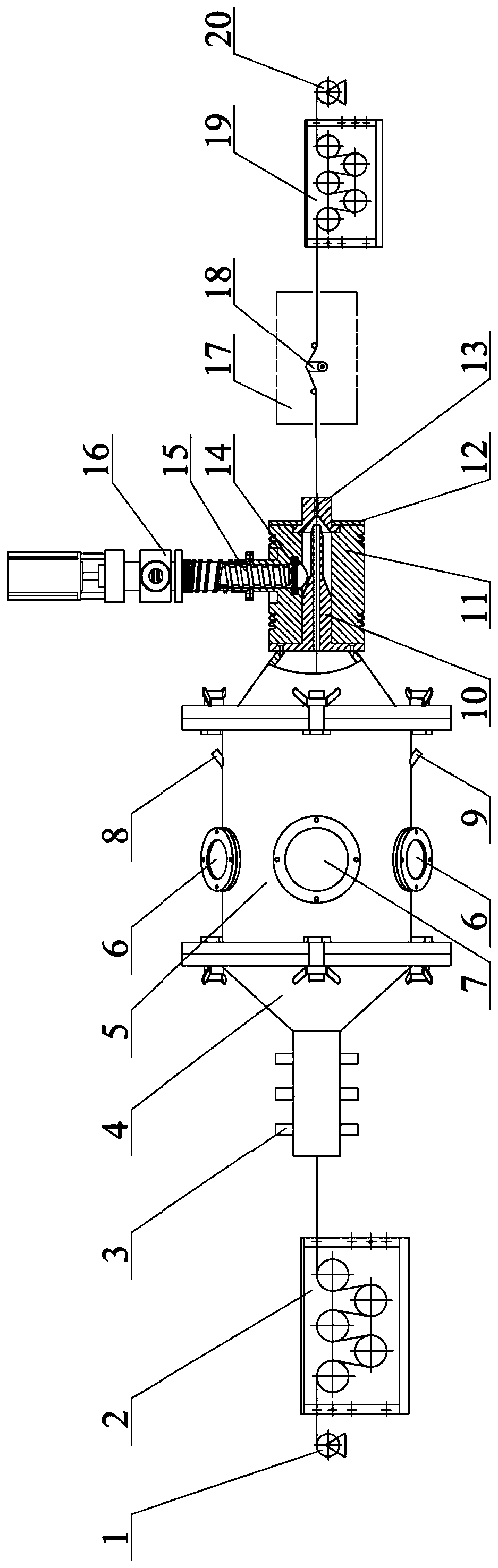

Special production tooling for high-strength carbon fiber

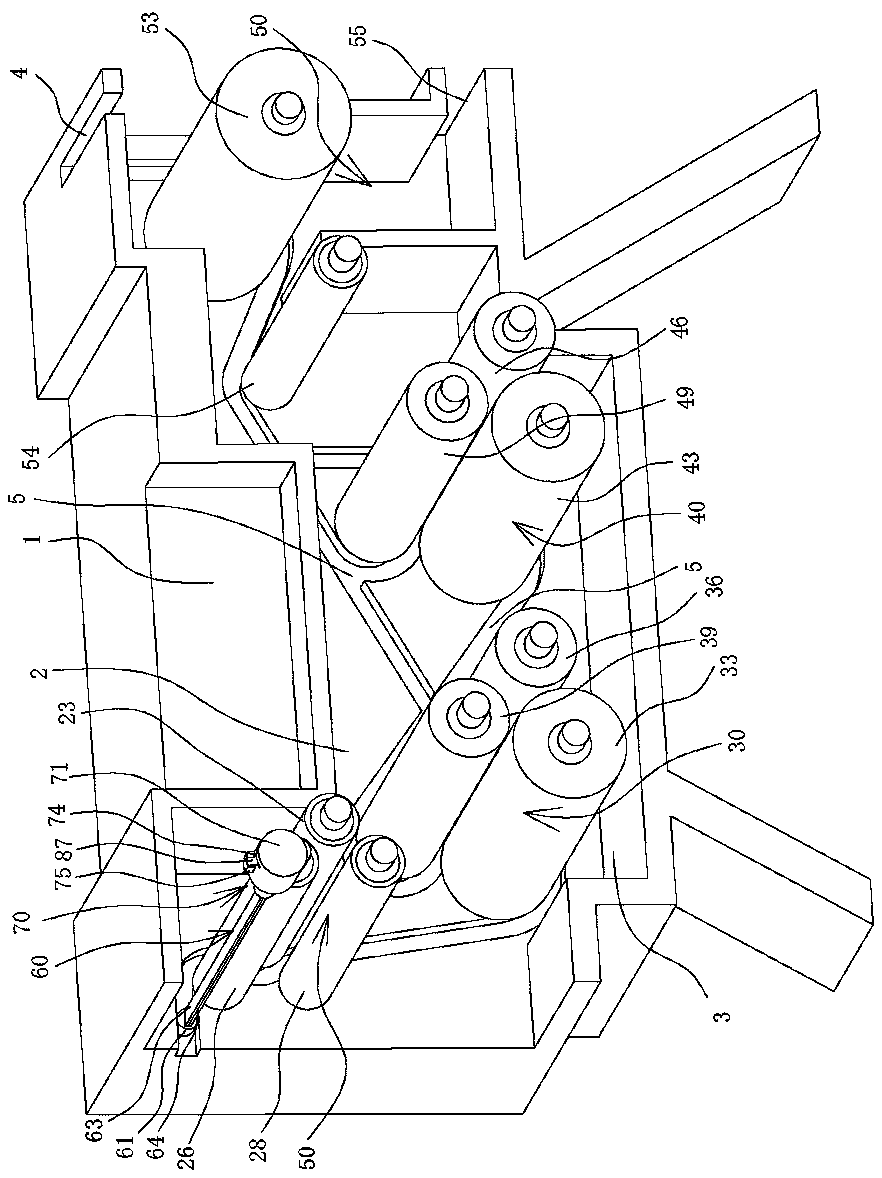

ActiveCN109972329AReasonable structural designFunctionalSucessive textile treatmentsTextile treatment machine arrangementsFiber bundleCarbon fibers

The invention provides a special production tooling for a high-strength carbon fiber. The special production tooling comprises sizing equipment, an opening and shaping device, a drying device and a carbon fiber bundle, wherein the sizing equipment comprises a sizing shell, a pre-spraying pump, a spraying pipe, a spraying pipe bracket, spray headers, an air inlet pipe, an air curtain machine, a waste liquid draining pipe, a first sizing roller, a second sizing roller, a third sizing roller, a first dipping roller, a second dipping roller, a fourth sizing roller, a fifth sizing roller and a positioning roller; the opening and shaping device comprises a workbench, a boss, guide roller brackets, guide rollers, a frame, paired roller brackets, upper paired rollers, hydraulic rods and lower paired rollers; the drying device comprises a drying shell, a partition plate, preheating section rollers, drying section rollers, heating pipes, a return air draught fan, a main air pipe, a preheating air pipe, a circulating air pipe, a fresh air pipe, a circulating draught fan and air valves. The special production tooling for the high-strength carbon fiber has the advantages that the carbon fiber bundle can be standardized, specialized and integrated, high-standard production requirements can be met, and the phenomenon that the carbon fiber bundle is disordered and broken is avoided systematically, and the system stability is strong.

Owner:北京百年初心科技有限公司

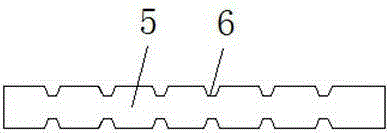

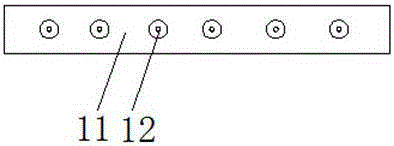

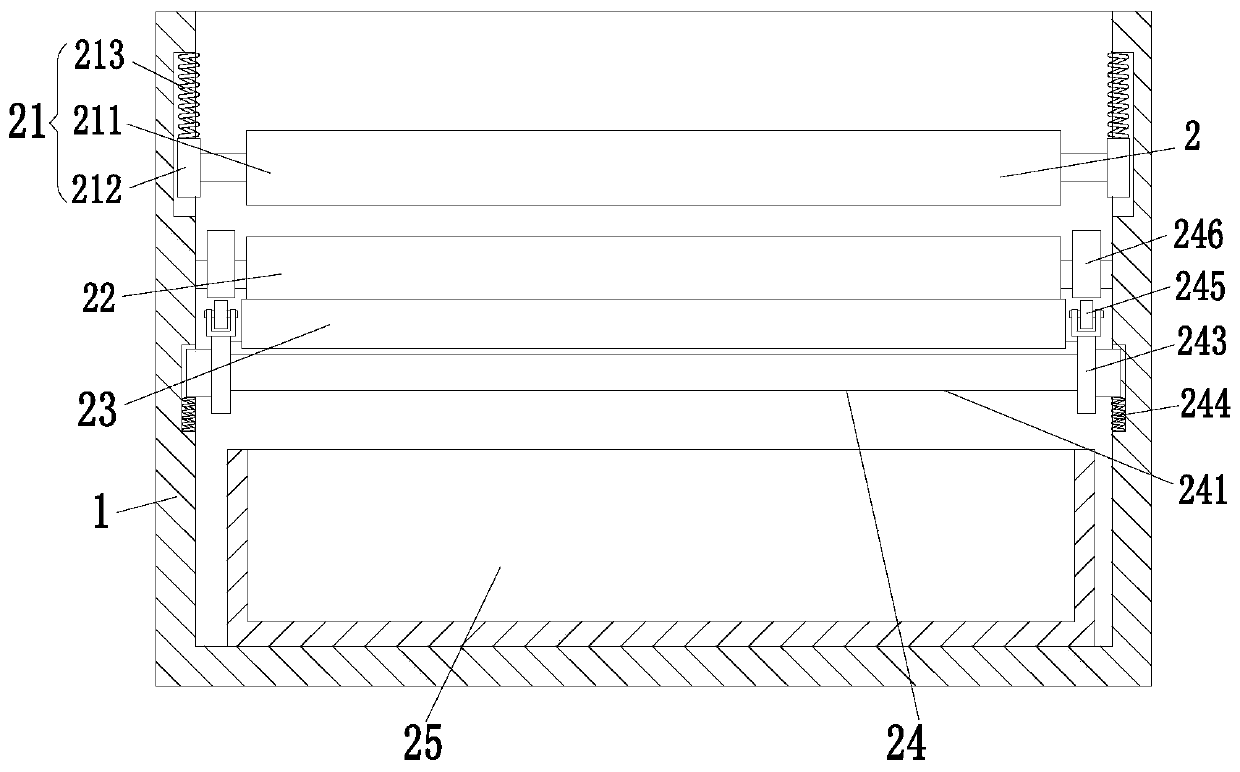

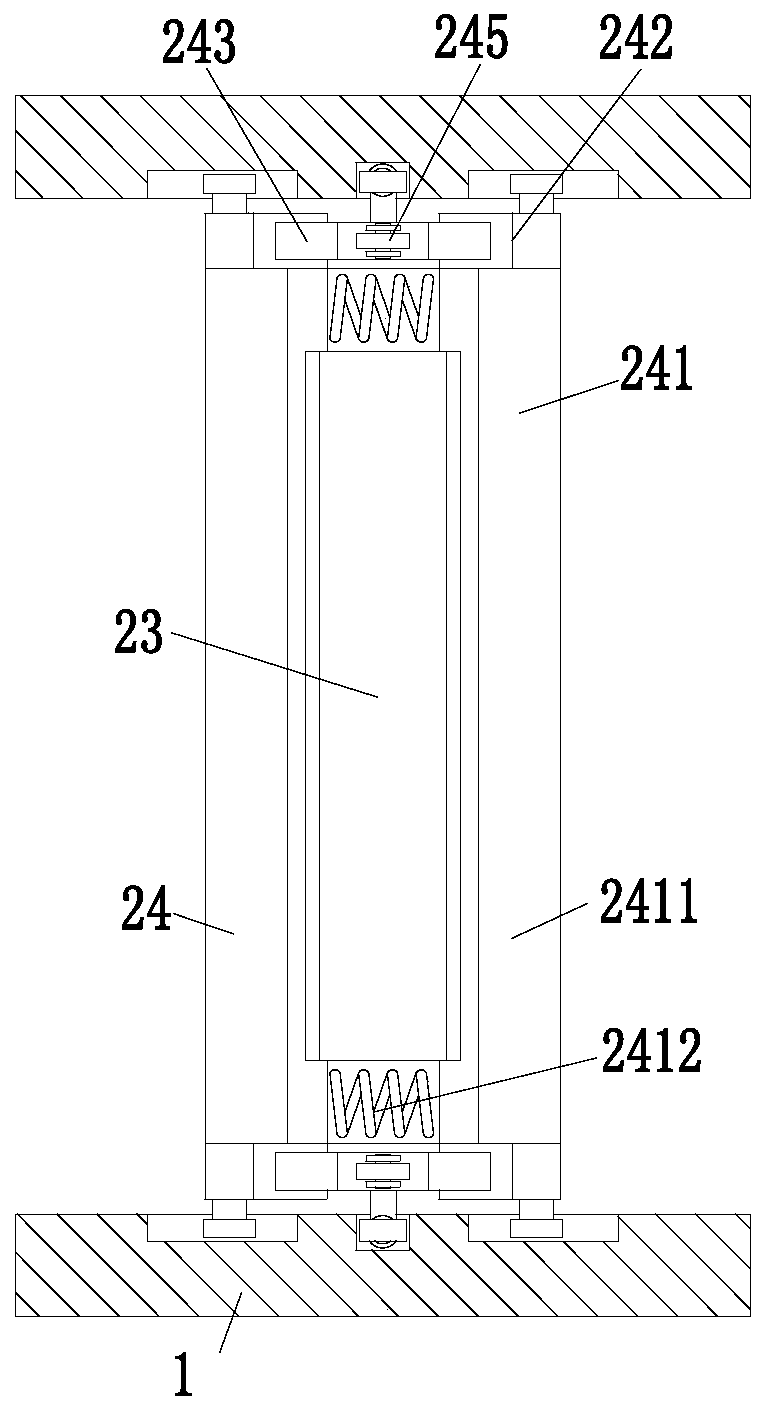

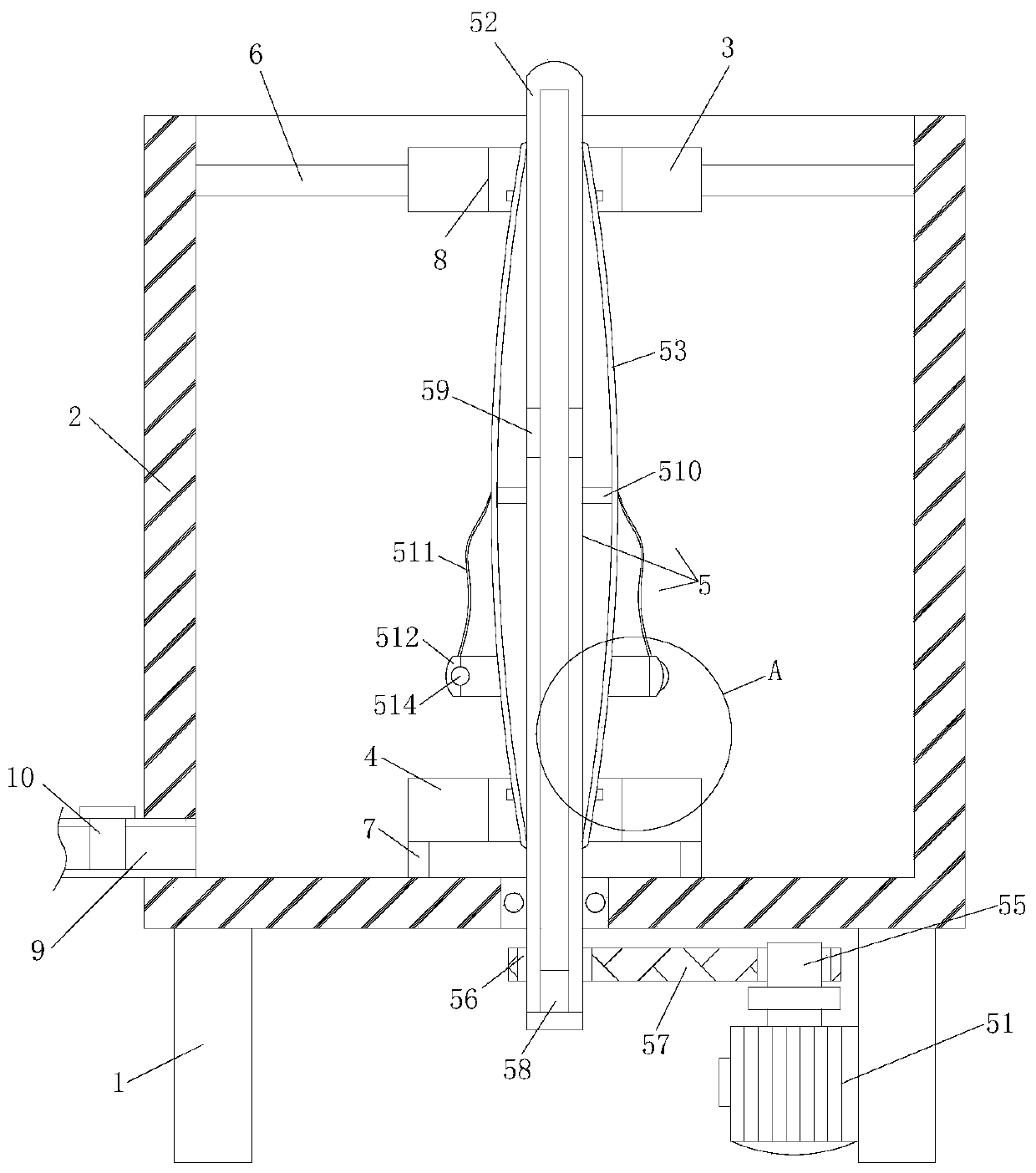

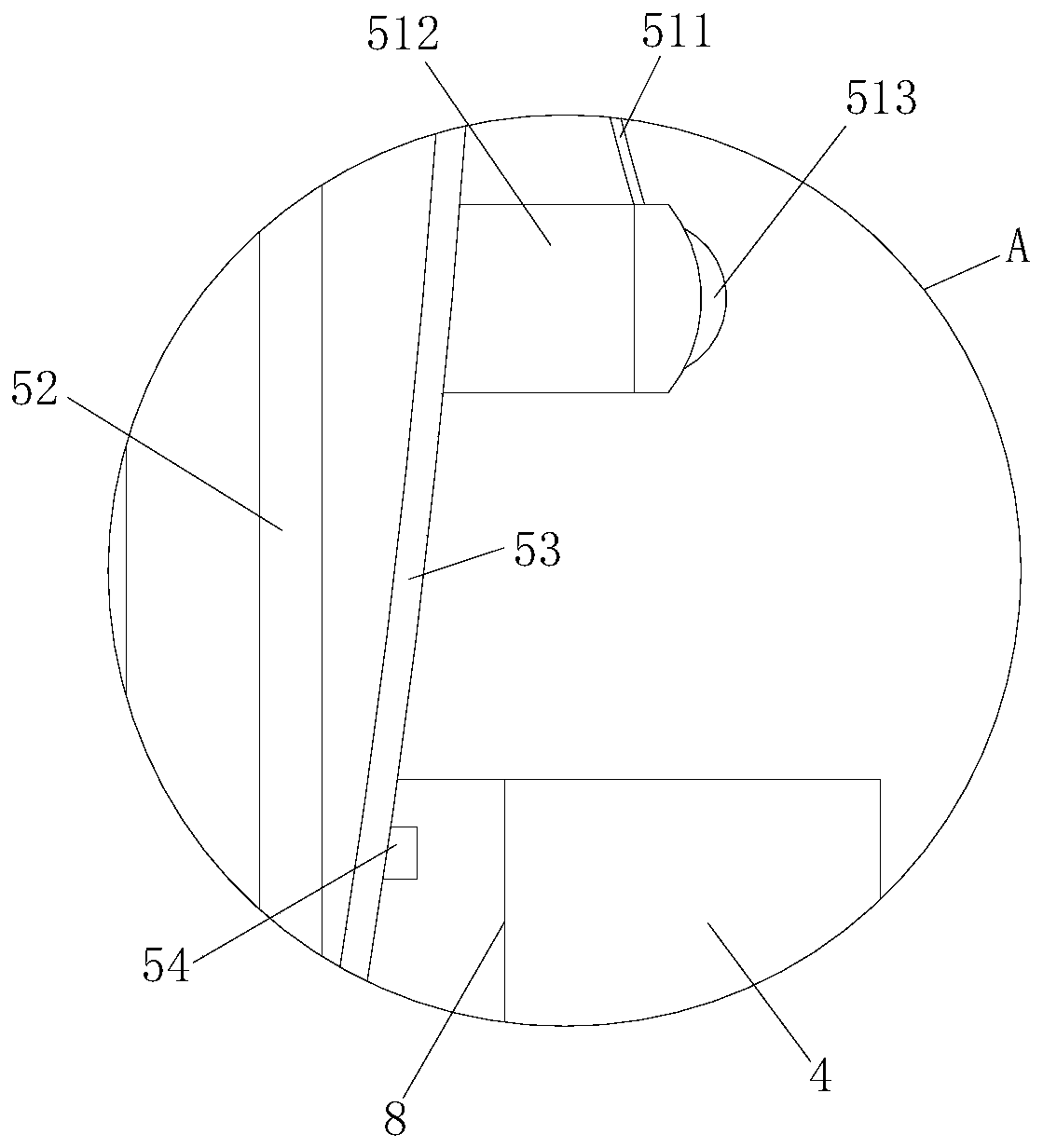

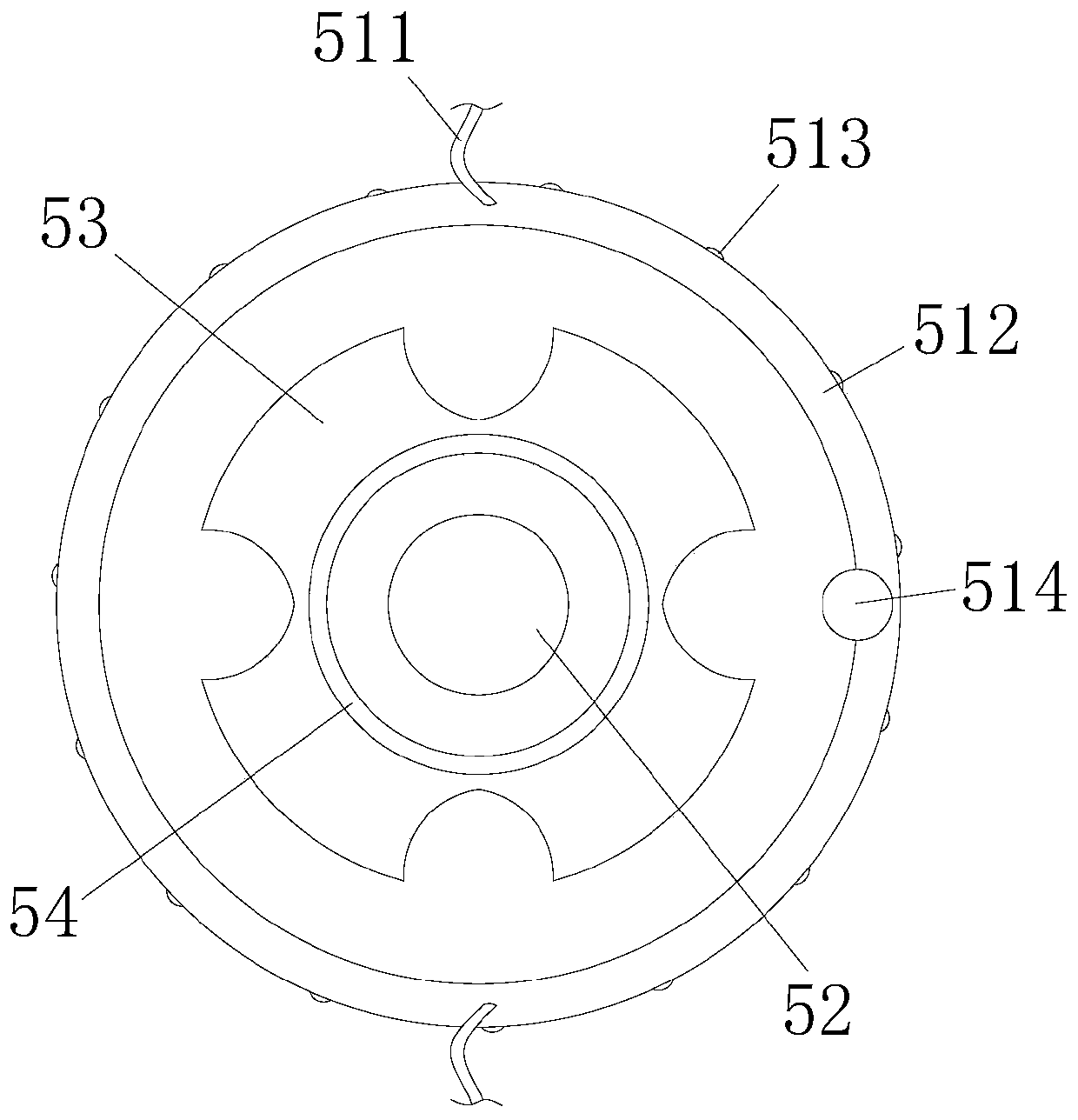

Textile yarn sizing equipment

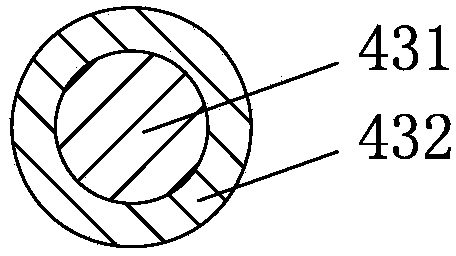

ActiveCN106381618AAvoid overlappingPrevent overlappingTextile treatment machine arrangementsTextile treatment guiding meansTextile yarnPulp and paper industry

The invention discloses textile yarn sizing equipment comprising a box body; the left side of the box body is provided with two parallel support plates; a transfer roller is arranged between the two support plates; two ends of the transfer roller are arranged on the support plates respectively through a bearing; one end of the transfer roller penetrates the support plate, and connected with a motor through a belt; the side face of the transfer roller is provided with a first limit groove; the surface of the box body is provided with an opening; a sizing roller penetrates the inner side of the box body; one end of the sizing roller penetrates the side face of the box body, and is connected with the motor through a belt; the side face of the sizing roller is provided with a second limit groove; one side edge, far away from the transfer roller, of the box body is provided with a yarn slurry filter plate having 6 mount holes arranged at equal intervals; filter blocks are arranged in the mount holes; the center of the filter block is provided with a yarn filter hole. The textile yarn sizing equipment is simple in structure, even in sizing, can prevent yarns from being stacked, thus improving yarn sizing efficiency.

Owner:佛山市高敦织染有限公司

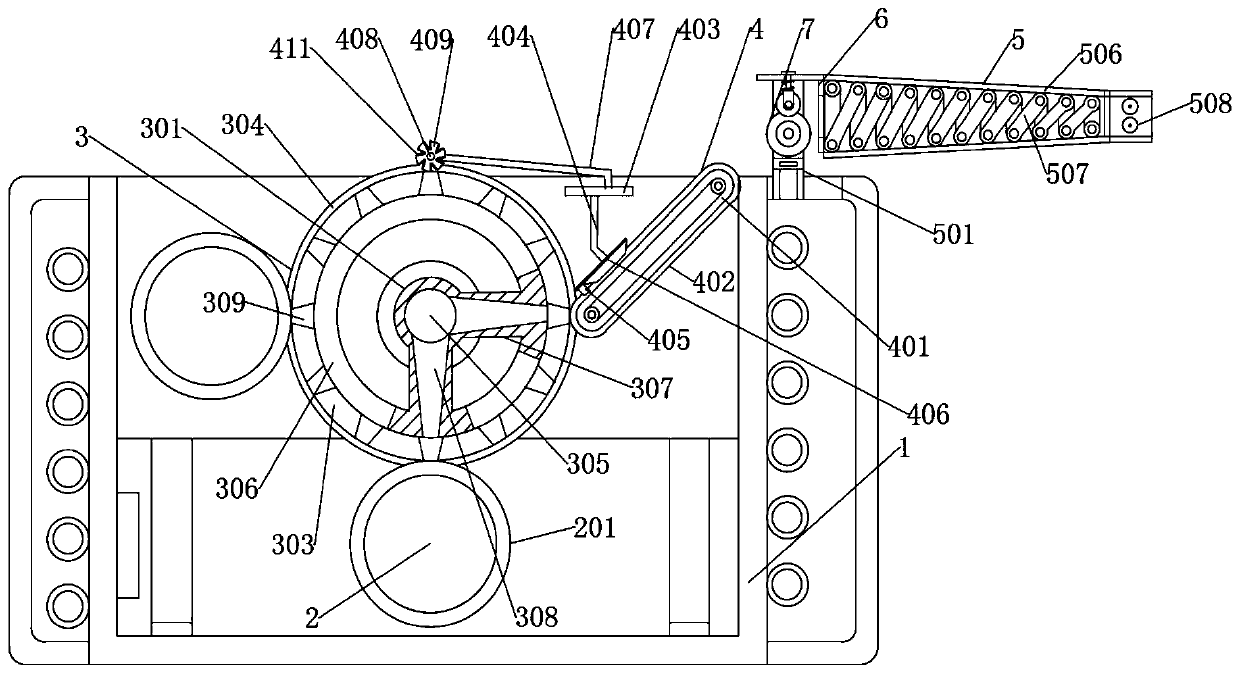

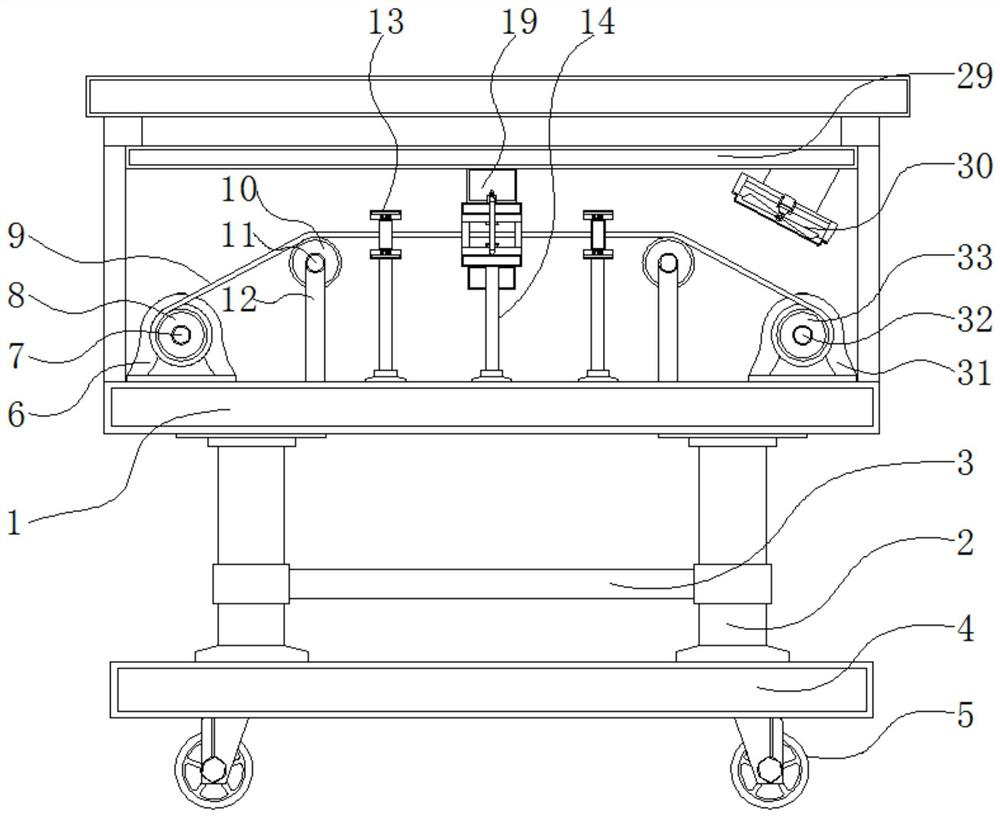

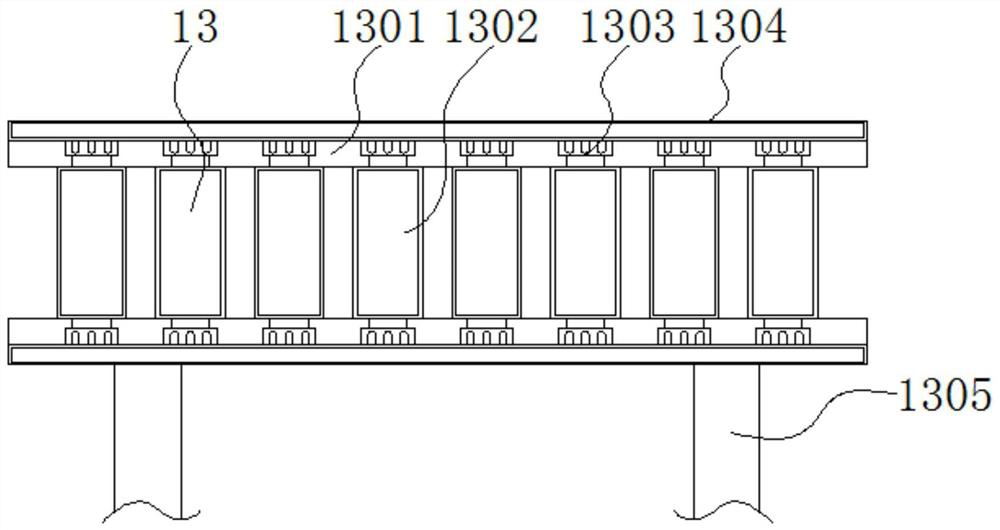

Automatic sizing machine

InactiveCN110894645AReduce labor intensityWork lessLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalYarnControl engineering

The invention discloses an automatic sizing machine. The automatic sizing machine comprises a machine case, wherein a discharge hole is formed in one side of the machine case; a power mechanism is arranged in the machine case; a carding machine is connected to one side of the power mechanism; a first sizing mechanism is connected to one side of the carding mechanism; a second sizing mechanism is connected to one side of the power mechanism; size slots are arranged on one side of the first sizing mechanism and one side of the second sizing mechanism; a drying mechanism is connected to one sideof the power mechanism; a first sliding slot is arranged on one side of the inner wall of the machine case; a second sliding slot corresponding to the first sliding slot is arranged on one side of themachine case; a clamping mechanism that can clamp yarn and move in the machine case is arranged in the first sliding slot; and the other end of the clamping mechanism extends to the outside of the machine case after passing through the second sliding slot. The automatic sizing machine has the beneficial effects that a sizing mode can be changed according to sizing requirements of different kindsof yarn, so that the automatic sizing machine is wider in application range, meanwhile, more convenient for yarn traction movement when the yarn is loading, and reduced in labor intensity of operatingpersonnel.

Owner:台州达邦贸易有限公司

Yarn sizing device

InactiveCN104074006AWon't leaveEasily brokenTextile treatment carriersTextile treatment guiding meansYarnSlurry

The invention relates to a yarn sizing device, belongs to the field of spinning equipment, and solves the problem of bonding of adjacent sized yarns due to the slurry effect. In order to solve the problem, the invention provides the following technical scheme: the yarn sizing device comprises an emptying device, a sizing device, a drying device and a yarn collecting device arranged in sequence, wherein a yarn separating device is arranged between the drying device and the yarn collecting device, and comprises a yarn separating frame and a yarn separating piece arranged on the upper end surface of the yarn separating frame; and the yarn separating piece is upwards projected.

Owner:CHANGXING ZHIHENG CLOTHING MATERIAL

Uniform sizing wet dividing device

ActiveCN103952883AApply evenlyTextile treatment machine arrangementsTextile treatment guiding meansYarnSlurry

The invention provides a uniform sizing wet dividing device, which comprises a sizing groove, a pulp soaking roller, a sizing roller, a wet dividing rod and a drying tube, wherein the pulp soaking roller, the sizing roller, the wet dividing rod and the drying tube are sequentially arranged in a yarn sheet sizing direction, the pulp soaking roller and the sizing roller are respectively soaked in the pulp groove, and a pulp pressing roller is arranged above the sizing roller. The uniform sizing wet dividing device is characterized by also comprising a water circulation system used for filling cold water into the wet dividing rod. The uniform sizing wet dividing device has the advantages that through filling cold water into the wet dividing rod, a layer of sufficient dew is constantly condensed on the surface of the rod, the influence by high-temperature in a drying room can be avoided, the soft yarn effect is better realized, and the coating of pulp on the surfaces of yarn sheets is more uniform.

Owner:WUJIANG LONGSHENG TEXTILE

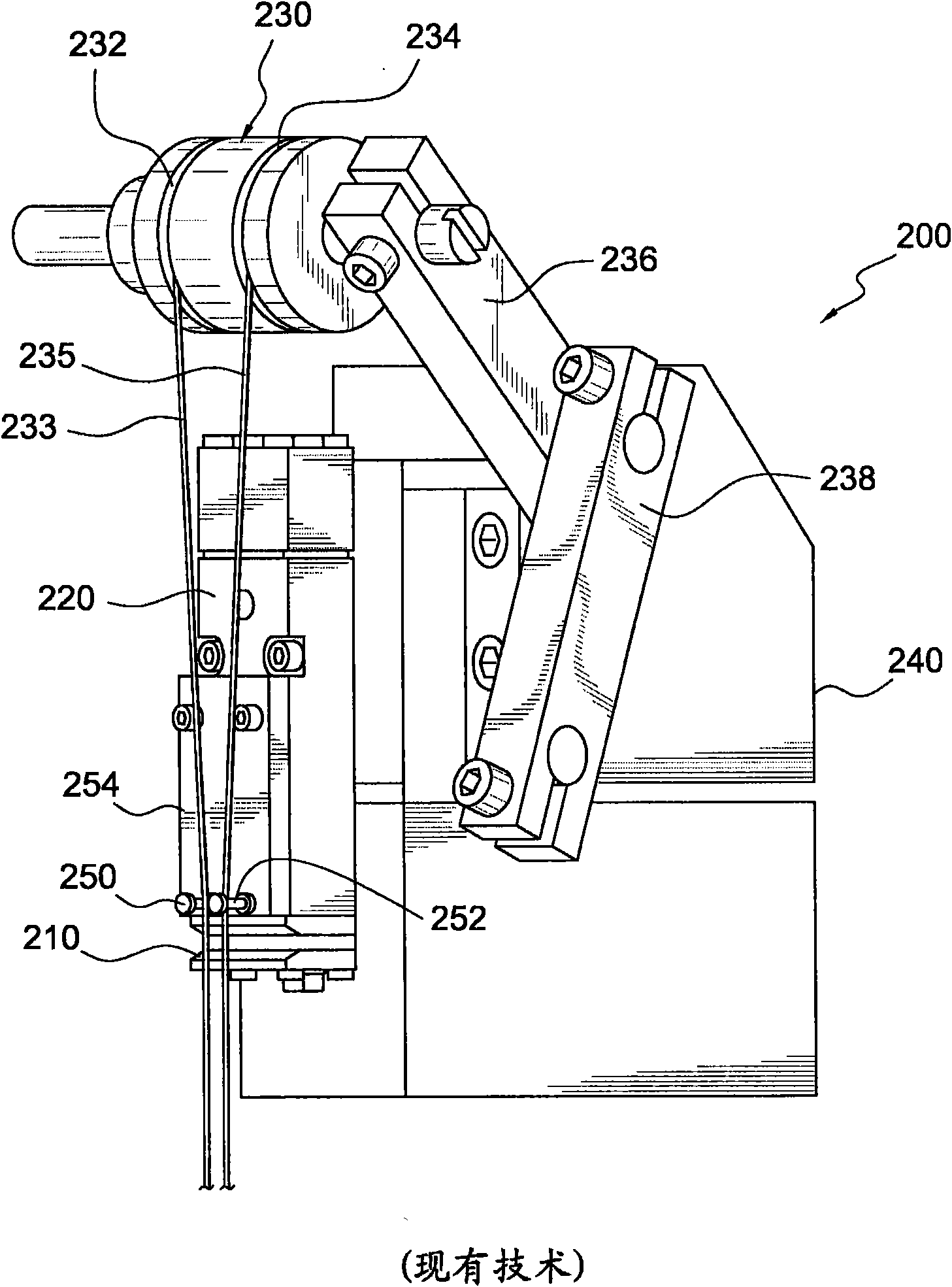

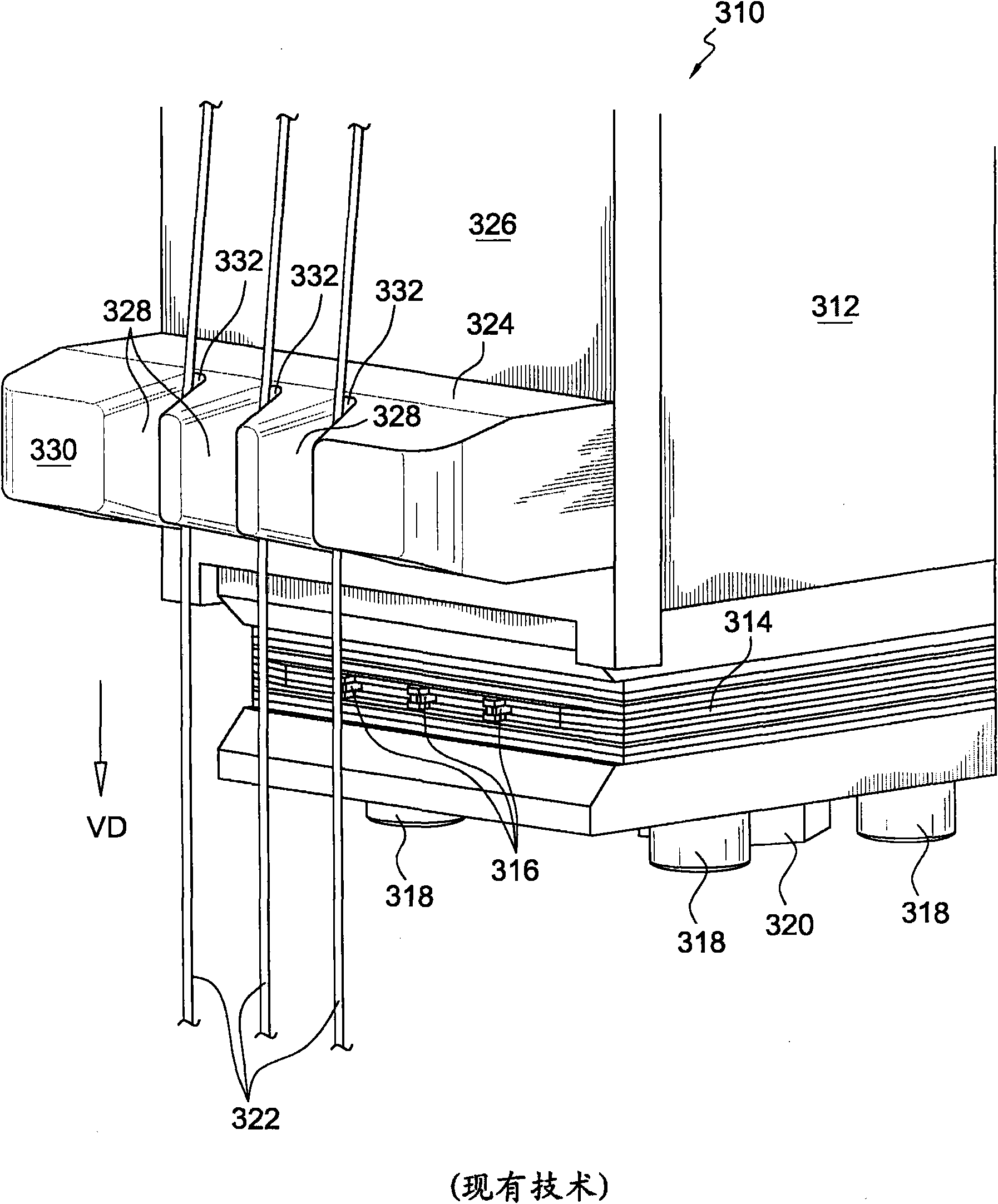

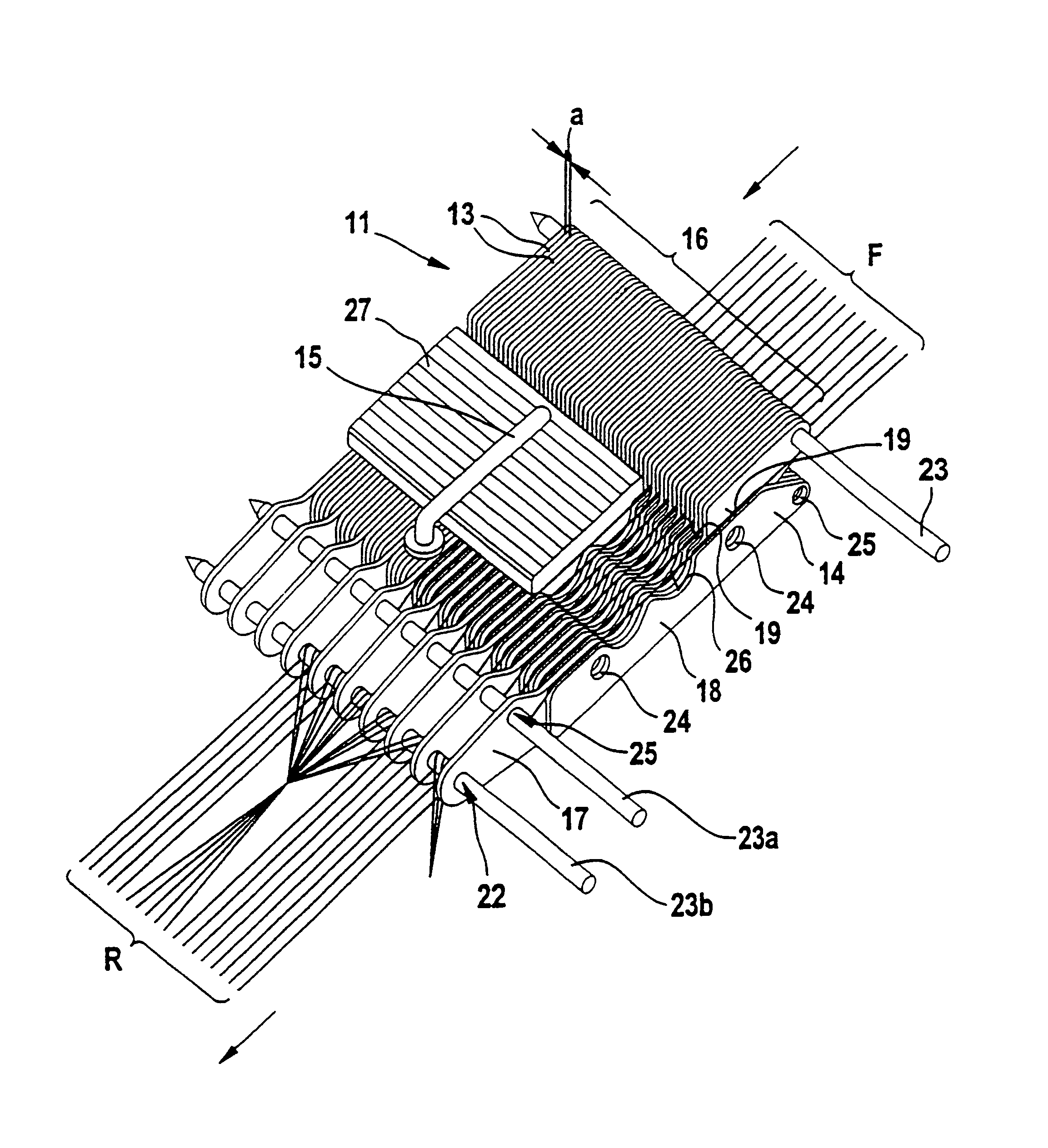

Method and auxiliary device for leasing threads into guide elements of a handling device for handling threads and a handling device of this type

InactiveUS7000296B1Rapid and secure leasingSimple and rapid leasingFilament handlingWarping machinesEngineering

Owner:MENSING HEINRICH JOHANN

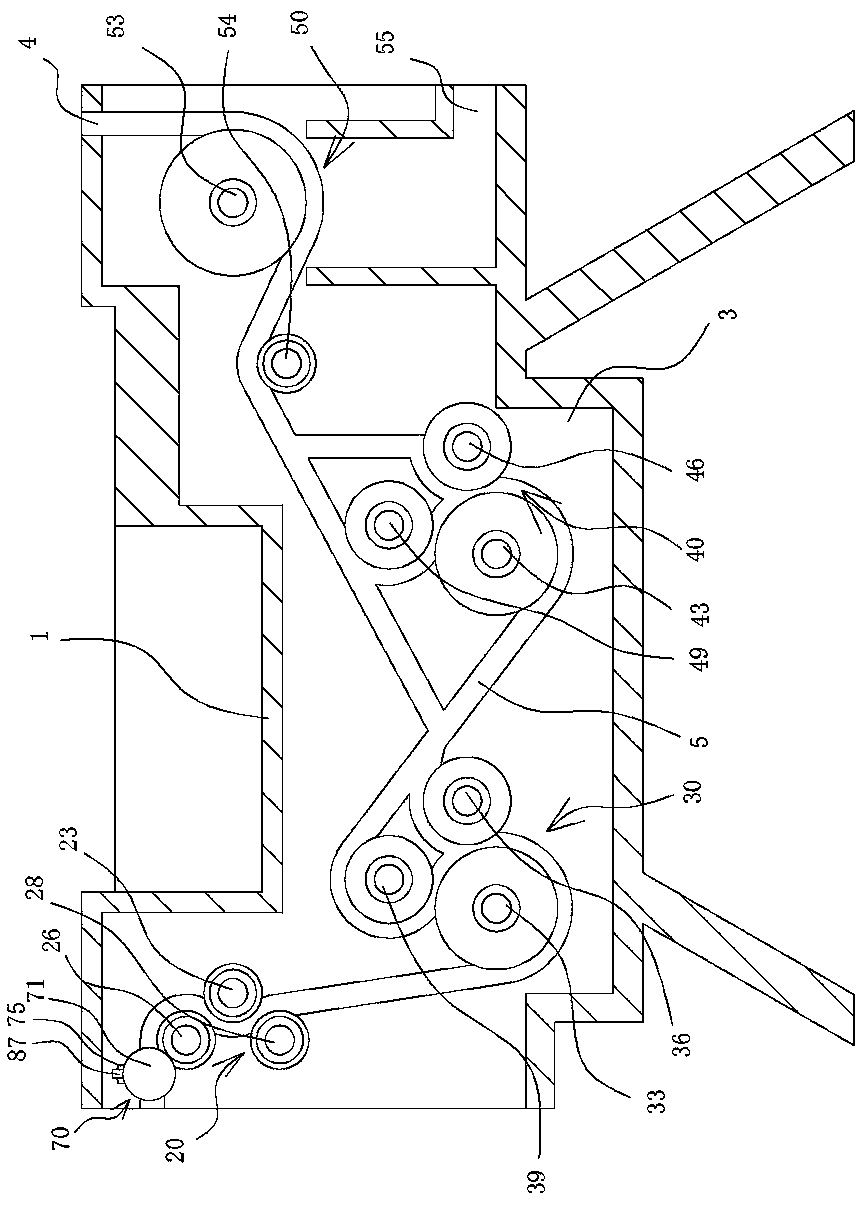

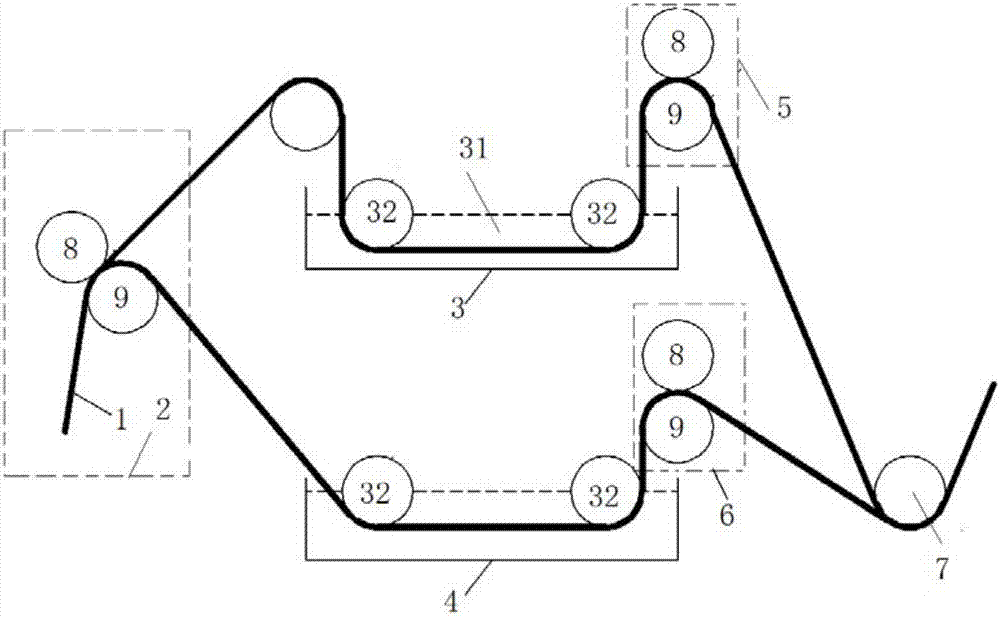

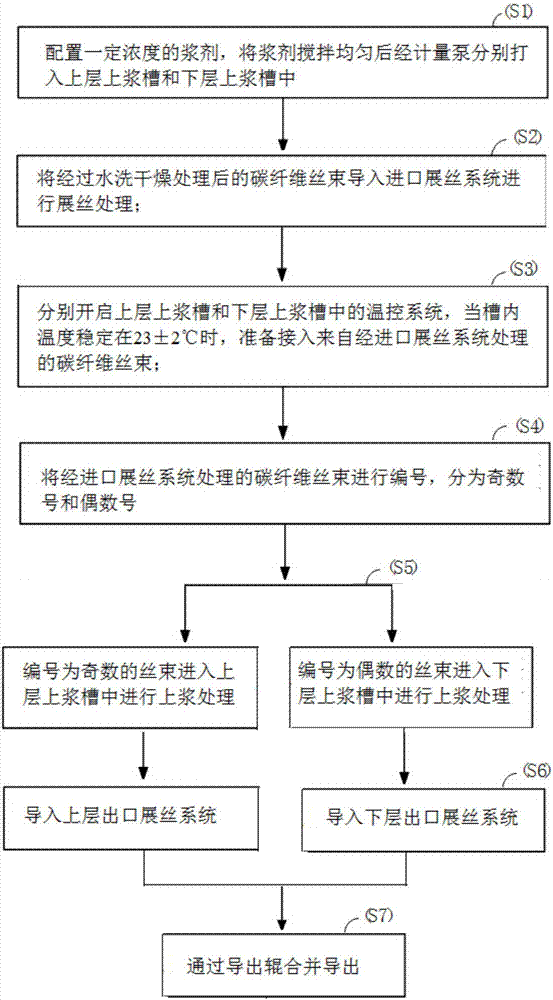

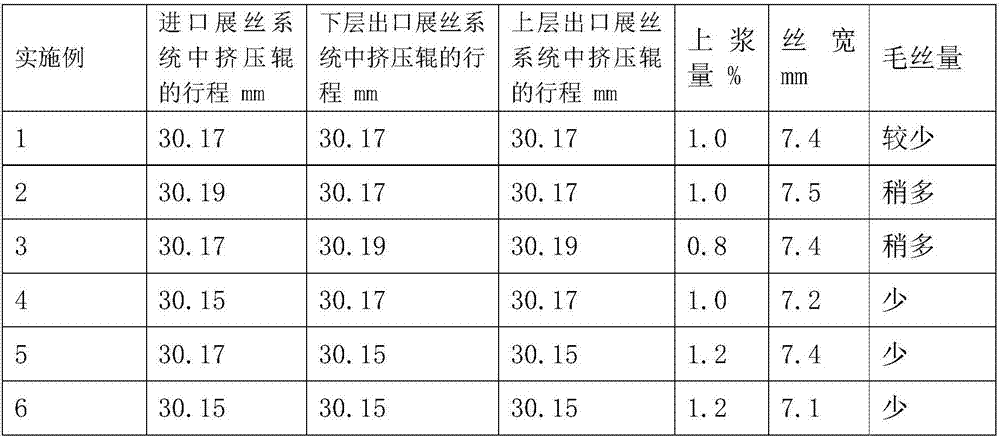

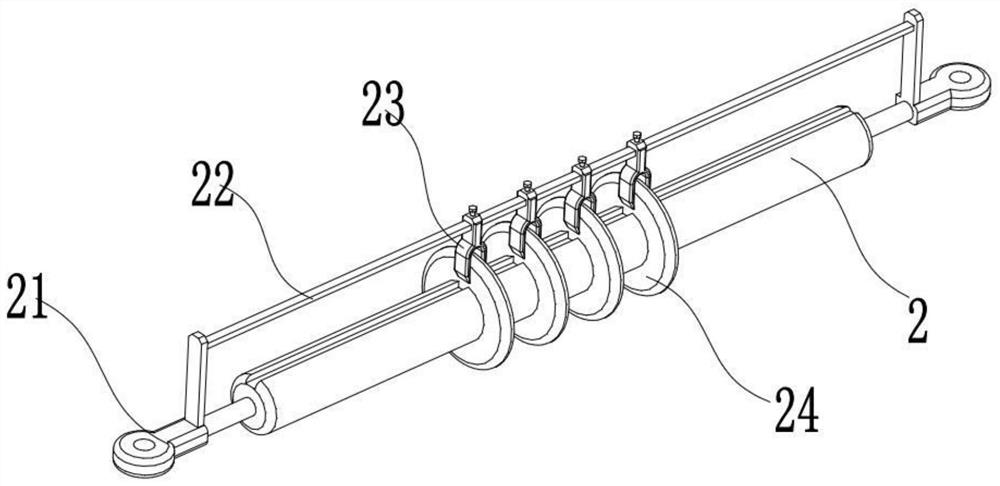

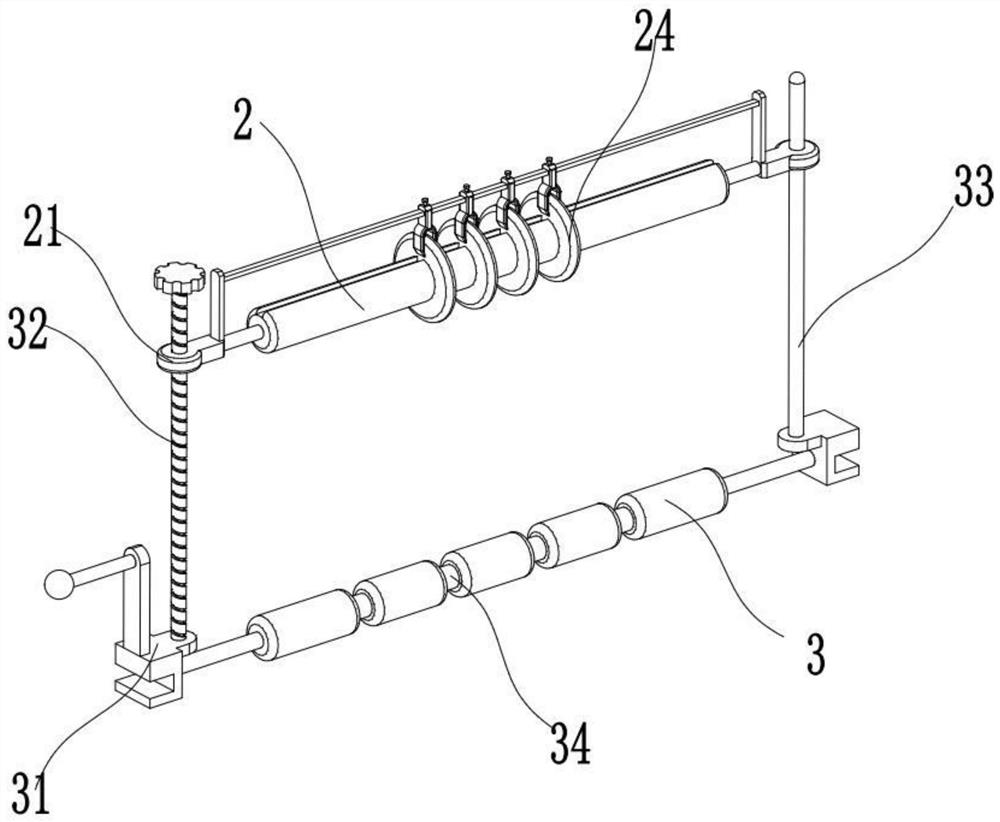

Novel sizing and shaping system for carbon fibers and sizing technology

ActiveCN107475945AReasonable structural designSave spaceLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsTemperature controlFiber

The invention discloses a novel sizing and shaping system for carbon fibers and a sizing technology. The sizing and shaping system comprises an upper layer sizing tank, a lower layer sizing tank, an inlet filament stretching system, an upper layer outlet filament stretching system and a lower outlet filament stretching system, wherein the upper layer sizing tank comprises a first temperature control system with a jacket, and two stainless steel polished rollers; the lower layer sizing tank is distributed in the vertical direction of the upper layer sizing tank, and the lower layer sizing tank comprises a second temperature control system with a jacket, and two stainless steel polished rollers; an inlet of the upper layer sizing tank and an inlet of the lower layer sizing tank are jointly connected with the inlet filament stretching system; the upper layer outlet filament stretching system is connected with an outlet of the upper layer sizing tank; the lower layer outlet filament stretching system is connected with an outlet of the lower layer sizing tank; the inlet filament stretching system, the upper layer outlet filament stretching system and the lower layer outlet filament stretching system each comprise two parallel supporting rollers, and bearings at the two ends of every two supporting rollers are arranged in same slide ways respectively. According to the sizing and sizing system and the sizing technology, adhesion of adjacent carbon filaments is avoided, so that the consistency of the width and sizing amount of the carbon fiber filaments is greatly improved.

Owner:ZHONG AN XIN TECH CO LTD

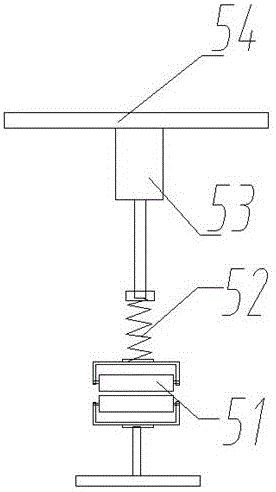

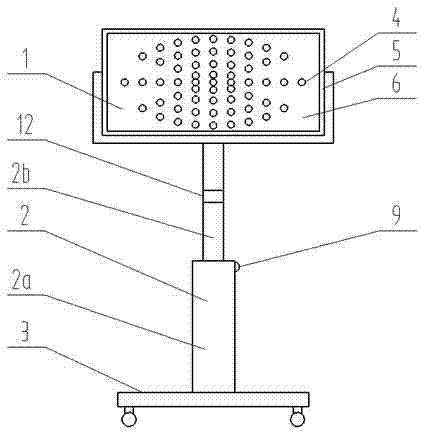

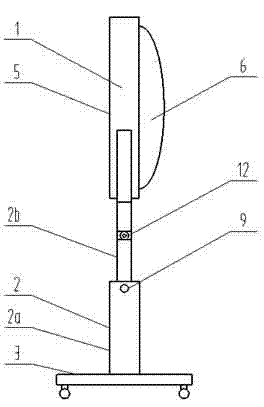

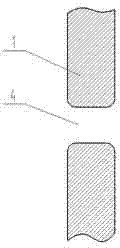

Multifunctional warp yarn tension equalizer

InactiveCN104499230AEasy fine-tuningPlay a role in focusingOther manufacturing equipments/toolsTextile treatment carriersBreakage probabilityBobbin

The invention provides a multifunctional warp yarn tension equalizer. A conventional yarn guide plate is modified to be an arc-shaped plate, and focusing effect is realized when yarn penetrates the yarn guide plate, so that big errors in yarn guide distance when yarn is guided from a bobbin creel to a yarn guide device are reduced to avoid big errors in yarn guide tension. Positions where two ends of yarn guide magnetic holes are connected with the surface of the yarn guide plate are arc-shaped, and contact face is smooth when the yarn penetrates the yarn guide magnetic holes, so that yarn breakage probability is reduced; a sliding rail is arranged on the upper surface of the base, a slider is arranged at the lower end of a support, and the sliding rail and the slider are in matched connection, so that convenience is brought to transverse fine adjusting of the yarn guide plate during use; the support comprises a support A and a support B arranged in a cavity inside the support A, so that convenience is brought to longitudinal fine adjusting of the yarn guide plate during use; a linear positioning groove is formed in the inner wall of the support A axially, and a linear clamping strip is arranged at a corresponding position of the outer wall of the support B, so that influence on yarn guide effect due to the fact that the support rotates under drawing of the yarn is avoided.

Owner:IANGSU COLLEGE OF ENG & TECH

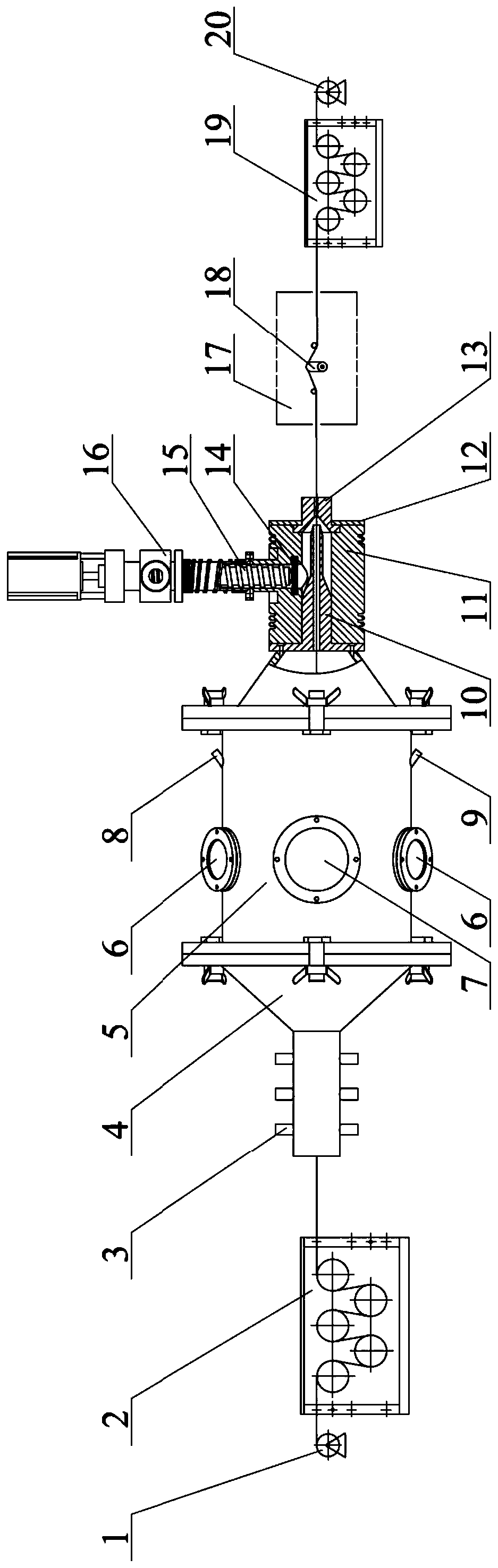

Carbon fiber laser graphitizing sizing equipment and method

ActiveCN110042583AGood fiber opening effectImprove wear resistancePhysical treatmentCarbon fibresCarbon fibersEngineering

The invention discloses carbon fiber laser graphitizing sizing equipment and method. The equipment is mainly composed of a silk releasing device, a drafting device A, a gas seal end cover, a graphitizing furnace body, a coating machine head, an extruder, a drying device, a drafting device B and a silk collecting device. The devices are sequentially arranged, the gas seal end cover is fixed to theleft end of the graphitizing furnace body through a bolt, the right end of the graphitizing furnace body is connected with the sizing coating machine head, the side face of the coating machine head isconnected with the small extruder, and the drying device, the drafting device B and the silk collecting device are sequentially mounted on the right side of the coating machine head. An outlet of a graphitizing furnace is directly connected with the coating machine head, inert gas sealing on the outlet is omitted, and the use amount of argon is saved. An extruded sizing agent has uniform and dense texture and is tightly attached to the surfaces of fibers, due to sizing in the pressure environment, the skinning performance of the sizing agent is better than the soaking effect in a sizing agenttank, skin films on the surfaces of the fibers are denser, and the performance of a prepared composite is improved.

Owner:BEIJING UNIV OF CHEM TECH +1

Sizing method and sizing equipment for preventing yarn from sizing bonding

ActiveCN111926489ASolve sticking problemsAvoid menopauseLiquid/gas/vapor removal by squeezing rollersTextile treatment cleaning apparatusYarnIndustrial engineering

The invention discloses a sizing method and sizing equipment for preventing yarn from sizing bonding. The sizing equipment for preventing the yarn from sizing bonding includes a placing device, a starching device, a drying device, a yarn separating device and a yarn receiving device. In order to prevent the bonding of the yarn at two ends of a grouting roll, and a scraping board is added in the starching device and a side yarn separating bar is added in the yarn separating device. The sizing method and equipment can solve the problem that the bonding of the yarn at two ends of the grouting roll still exists thoroughly, yarn breaking due to the bonding of the side yarn in the subsequent weaving process can be prevented, and the weaving production efficiency can be improved.

Owner:GUANGDONG FORWARD DENIM

Automated textile equipment and control system

ActiveCN111411464AThere will be no sticking phenomenonQuality impactLiquid/gas/vapor removalTextile treatment machine arrangementsYarnMaterials science

An embodiment of the invention discloses automated textile equipment which comprises a size storage cover and extrusion cylinders mounted at the inner wall of the bottom of the size storage cover, wherein a raw yarn immersion cylinder is connected to the upper parts of the extrusion cylinders; and a separation mechanism connected to the side wall of the raw yarn immersion cylinder is mounted at the inner wall of the size storage cover. The automated textile equipment can be used for separating yarn immersed in size liquid through separation strips and partition blocks, so that the adhesion ofthe adjacent yarn can be avoided. Even if the caked size liquid adheres to the surfaces of filaments resulting in the adhesion of the adjacent filaments, the filaments can be quickly separated when passing through the partition blocks, so that the quality of the yarn is not affected. Meanwhile, when the raw yarn immersion cylinder rolls, a scraping block can roll along with the raw yarn immersioncylinder and scrape the size liquid from the surface of the raw yarn immersion cylinder so as to avoid the non-uniformity of the size liquid on the surface of the yarn due to the fact that a size filmon the surface of the yarn is stuck away by the size liquid on the surface of the raw yarn immersion cylinder.

Owner:浙江荣莱纺织有限公司

Bamboo charcoal fiber home textile fabric

InactiveCN111691040AImprove drying efficiencyImprove drying effectLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsYarnPolymer science

The invention belongs to the technical field of textile fabrics, in particular to a bamboo charcoal fiber home textile fabric. The bamboo charcoal fiber home textile fabric is prepared from the following raw materials: bamboo charcoal fiber, cotton fiber and metal wires. A preparation method of the bamboo charcoal fiber home textile fabric comprises the following steps of: S1, blending white bamboo charcoal fiber, polyamide fiber and metal wires to obtain yarns and winding the yarns into yarn rolls; S2, dyeing and drying the yarns prepared in step S1 to obtain dyed yarns; mounting the yarn rolls onto a dyeing device, enabling the yarns on the yarn rolls to pass through the dyeing device, and dyeing the yarns in the dyeing device; and S3, making the dyed yarns obtained in step S2 into a fabric through textile equipment to obtain a finished product with bright colors. The bamboo charcoal fiber home textile fabric prepared is high in strength and good in dyeing effect.

Owner:吴闩闩

Yarn dip dyeing post-treatment device and method

InactiveCN111020941AGuaranteed Dip Dyeing EffectAvoid secondary wasteTextile treatment machine arrangementsLiquid/gas/vapor removal by squeezingYarnPolymer science

The invention relates to a yarn dip dyeing post-treatment device and a yarn dip dyeing post-treatment method. The yarn dip dyeing post-treatment device comprises a fixing frame, a draining device anda washing device, wherein the fixing frame is of a U-shaped structure, the draining device is mounted on the left side in the fixing frame, the washing device is arranged on the right side of the draining device, and the washing device is mounted on the right side in the fixing frame. With the device and the method, the problems that when an existing device is used for processing dip-dyed yarns, alarge amount of dye liquor adheres to the surfaces of the yarns generally, the dye liquor cannot be drained and collected effectively, then waste of the dye liquor is caused easily, meanwhile, the dye liquor has difficulty in immersing into the yarns, so that the dip-dyeing effect of the yarns is poor, moreover, when the existing device is used for washing the yarns, layered washing cannot be carried out on the yarns, so that the washing effect of the yarns is poor and the washing is incomplete, and then the subsequent processing effect of the yarns is influenced are solved.

Owner:卫平山

Method for preparing nanofiber aggregate and pretreatment device

InactiveCN106319647AQuality improvementImprove binding tightnessFilament/thread formingTextile treatment machine arrangementsFiberSpecific function

The invention relates to preparation of nanofiber aggregates and belongs to the textile field. A method for preparing the nanofiber aggregate is characterized by comprising the following steps: step one, a traction filament is immersed in a pretreatment liquid for certain time; step two, nanofibers are formed around the traction filament through electrostatic spinning with the traction filament as the central axis and are deposited between the traction filament and a receiver; step three, the receiver rotates and drives the nanofibers to rotate around the traction filament at certain rotation speed, the traction filament is dragged, the nanofibers wind around the outer layer of the traction filament, and the nanofiber aggregate is formed. When the traction filament is treated with different pretreatment liquids, the binding tightness of the nanofiber aggregate can be improved, a composition layer of a functional material can be even added, and the nanofiber aggregate is enabled to have specific functions. The invention further provides a pretreatment device for pretreating the traction filament.

Owner:SHANGHAI UNIV OF ENG SCI

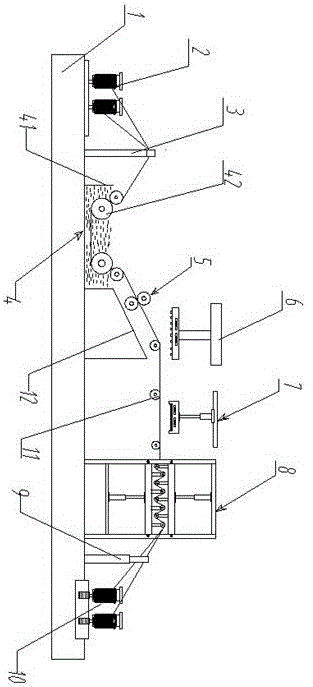

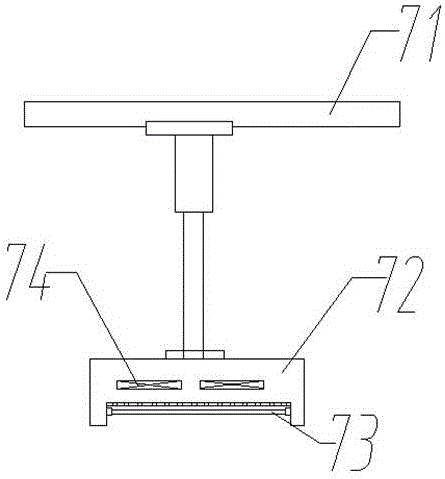

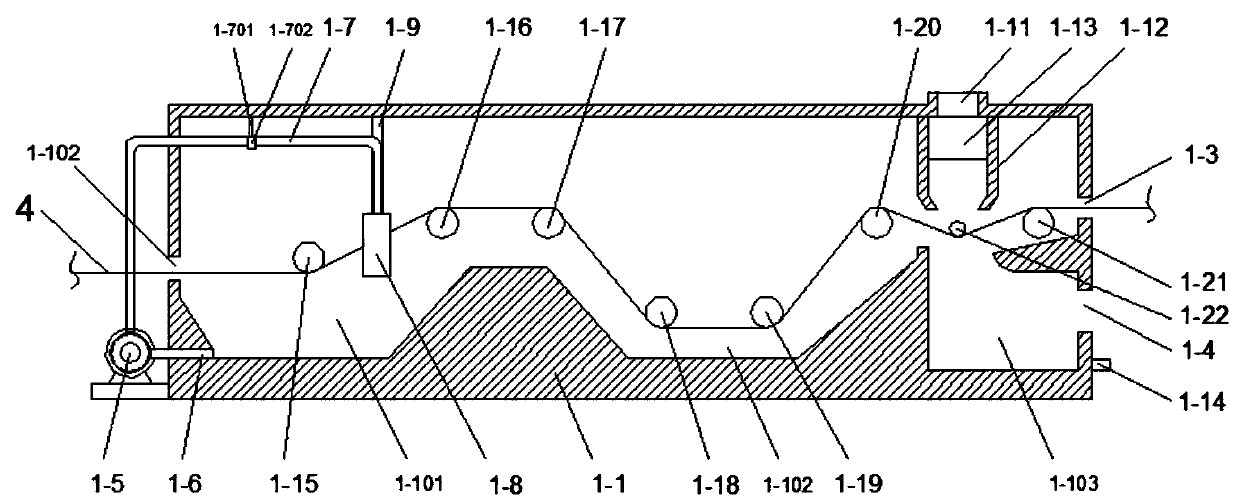

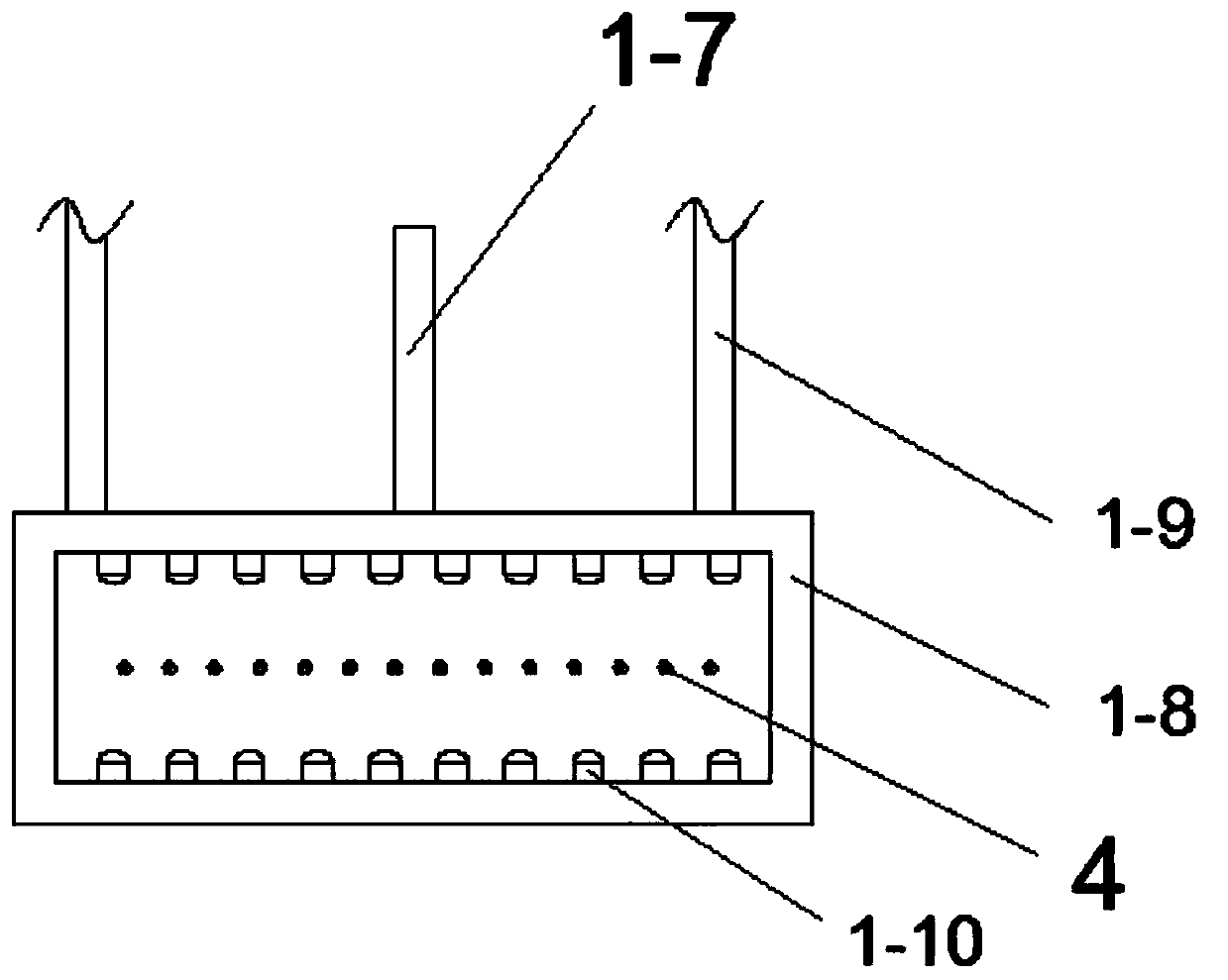

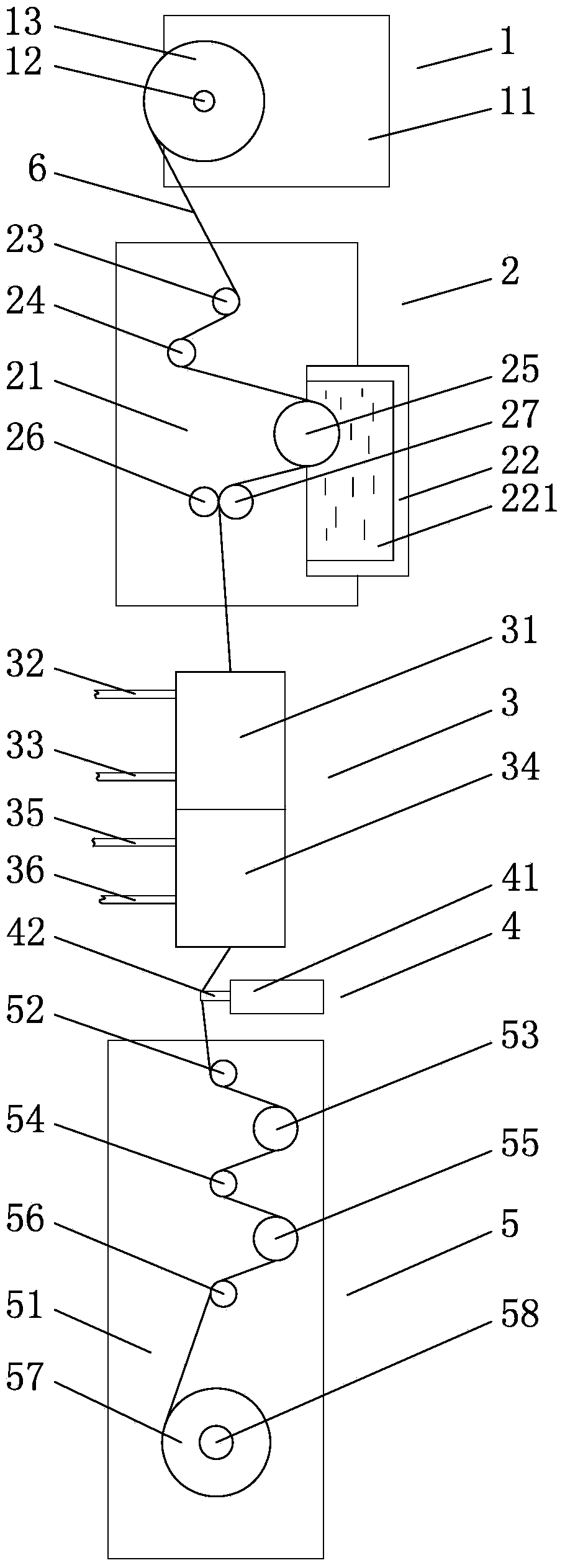

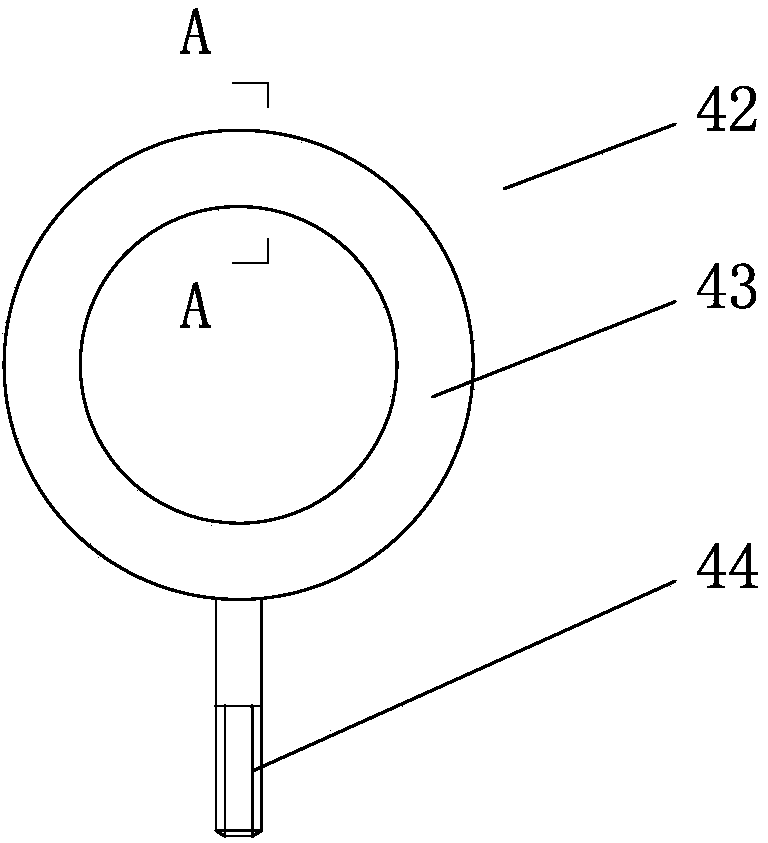

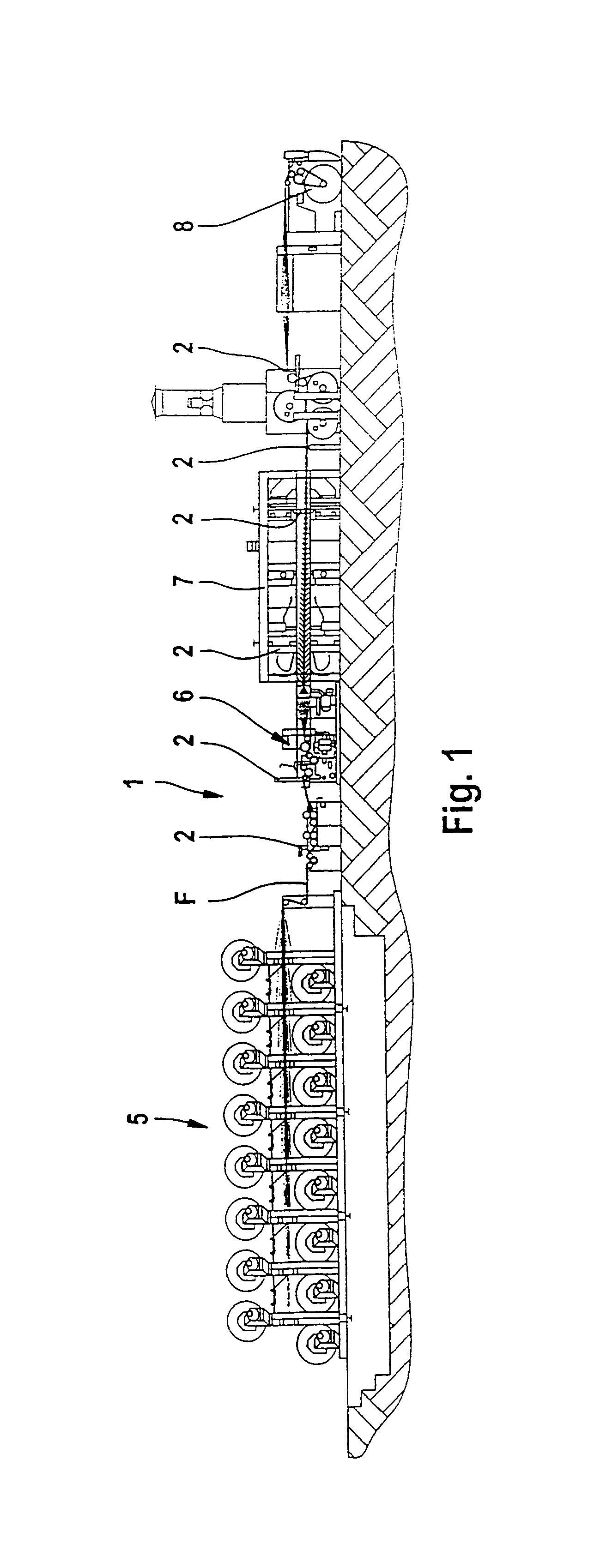

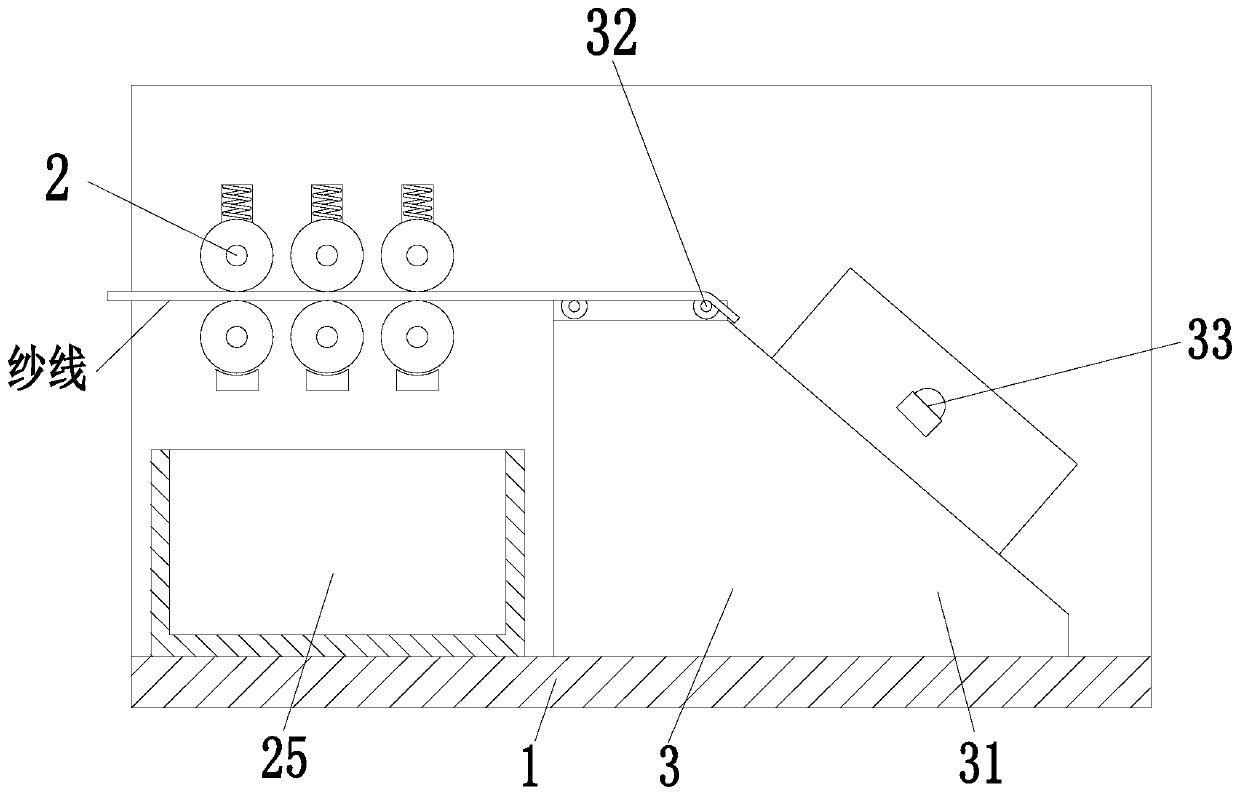

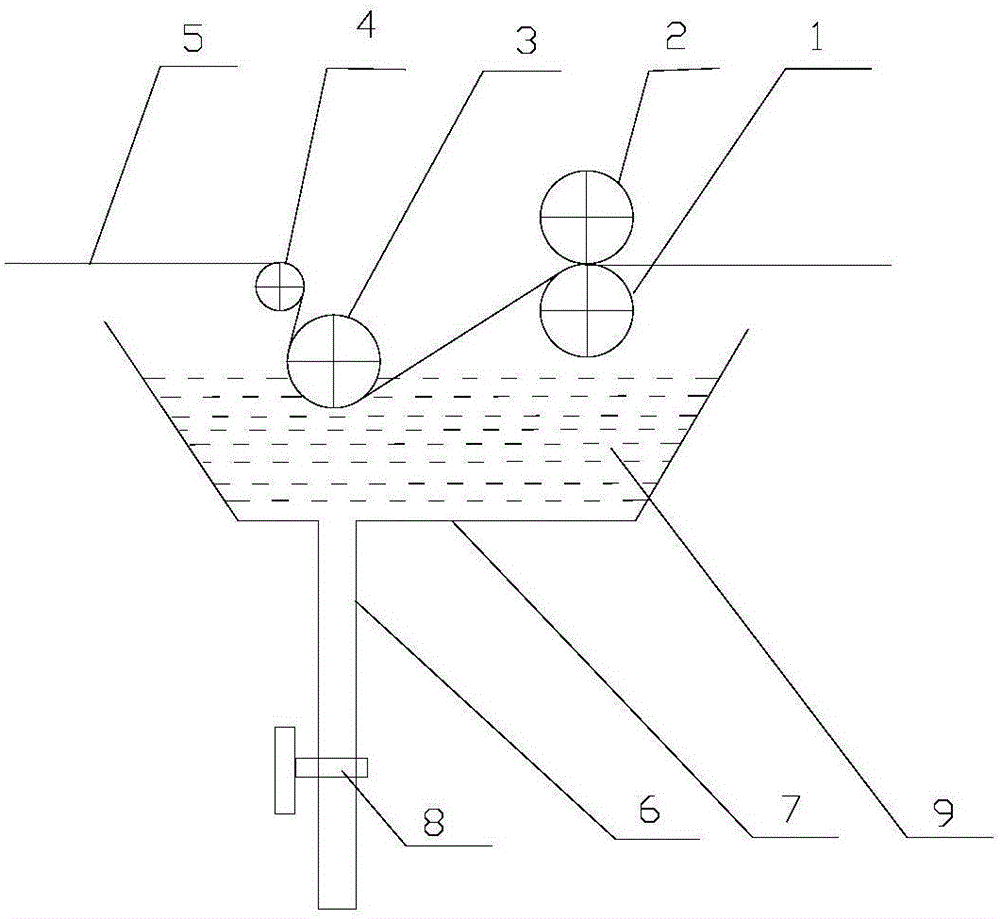

Warp sheet sizing machine for proofing press

ActiveCN104727041AImprove production automationImprove sizing effectTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentYarnPulp and paper industry

The invention discloses a warp sheet sizing machine for a proofing press. Through the cooperation of a lease reed, a sizing tank, a tension balance mechanism and a finishing mechanism, yarn is led into the warp sheet sizing machine, so that the warp sheet sizing machine is higher in production automation degree, good in sizing effect and broad in application prospect. According to the lease reed, a traditional yarn guide plate is refitted into an arc-shaped plate, so that the yarn is concentrated when passing through the yarn guide plate, the yarn interval is reduced, and large errors are avoided; because a support is movable, an operator can perform fine adjustment conveniently according to needs, and use is convenient; because an electric heater is fixedly arranged at the bottom of the sizing tank, sizing in the sizing tank can be heated, the temperature of the sizing can be kept, and the sizing efficiency can be improved. Meanwhile, through the coordinated leading of sizing rollers, a sizing squeezing roller and an immersing roller, the yarn can be sufficiently immersed into the sizing and make sufficient contact with the sizing, so that the sizing effect is effectively improved.

Owner:IANGSU COLLEGE OF ENG & TECH

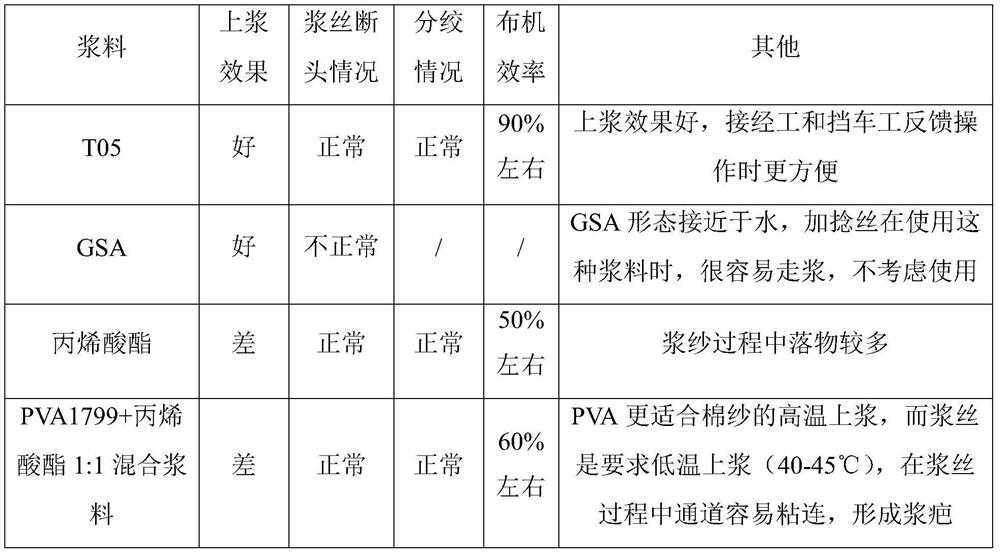

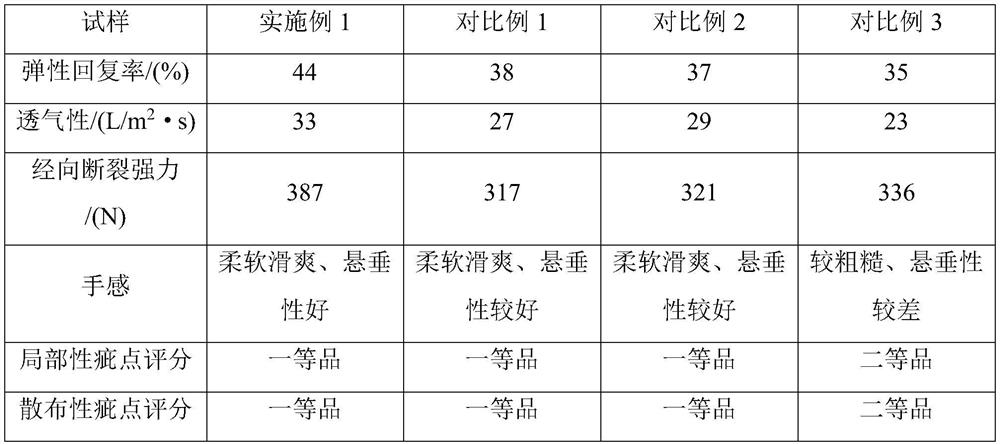

Acetate fiber fabric and production process thereof

ActiveCN112030309AFeel goodSoft and smoothWoven fabricsTextile treatment guiding meansFiberPolymer science

The invention provides an acetate fiber fabric and a production process thereof. According to the production process, bright acetate fiber filaments are selected as warp yarn, the acetate fiber filaments and cationic yarns are selected to form S twist piled twisted yarn and Z twist piled twisted yarn through plying and twisting to serve as weft yarn, and thus acetate fiber satin fabric is obtainedby satin weaving. In a warping process, a burr-free tension ring is used, and the tension difference of the single piece of yarn is controlled within 1g / piece; T05 slurry is selected for sizing, anda set of reed is additionally arranged between two drying ovens, so that the sizing effect is good, the end breakage phenomenon is avoided, and the cloth machine efficiency is up to 90%. When the weftyarn is put on a machine, a cover plate covers a weft yarn barrel, and a pineapple sleeve is further sleeved on the weft yarn barrel, so that the phenomena of twisting weft shrinkage and weft fallingin a weft yarn unwinding process are prevented. According to the acetate fiber fabric and the production process thereof, characteristics of the acetate fiber filaments and the composite acetate fiber plied twisted yarn are integrated, the acetate fiber fabric with good wearability and strength is obtained, and the application value of the acetate fiber fabric is improved.

Owner:武汉裕大华纺织有限公司

Spinning thread guiding lubrication jig

InactiveCN105332209AWalking smoothlyLimit the range of activitiesLiquid/gas/vapor textile treatmentTextile treatment guiding meansCrevasseEngineering

The invention relates to the technical field of textile equipment, and especially relates to a spinning thread guiding lubrication jig, comprising a guiding platform. The guiding platform is provided with a thread inlet end, a lead device, and a thread outgoing board. The thread inlet end is provided with a plurality of gaps. The thread outgoing board is provided with a plurality of grooves. The lead device is provided with a plurality of crevasses. A spinning thread is led into the guiding platform from the gap of the thread inlet end, and through the crevasses of the lead device, the spinning thread is led out of the guiding platform from the groove of the thread outgoing board. Thus, accurate guiding of the spinning thread is realized. The gaps, the crevasses, and the grooves are arranged correspondingly in a pairwise manner, and the bottom surfaces of the gaps, the crevasses, and the grooves pass through a same plane which has a certain upward inclination angle with a horizontal plane, so that the spinning threads travel tightly abutting against the gaps, the crevasses, and the grooves in a travelling process because of gravity. Slight friction of the spinning threads and the flexible layers on the outer walls of the gaps, the crevasses, and the grooves occurs, so as to reduce swing amplitude of the spinning threads in a travelling process. The lower part of the lead device is also provided with a lubrication roller which can lubricate the spinning threads.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

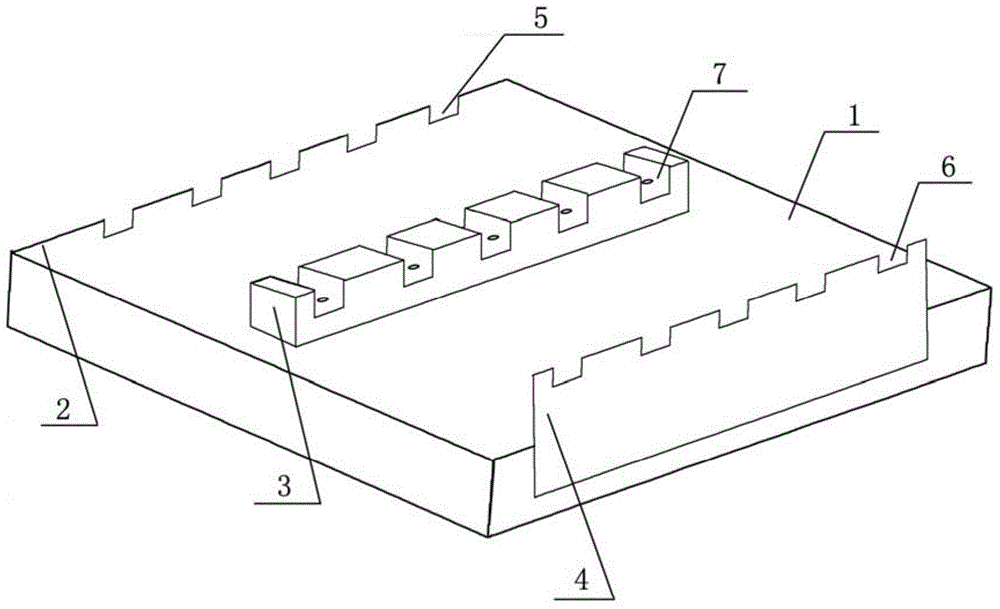

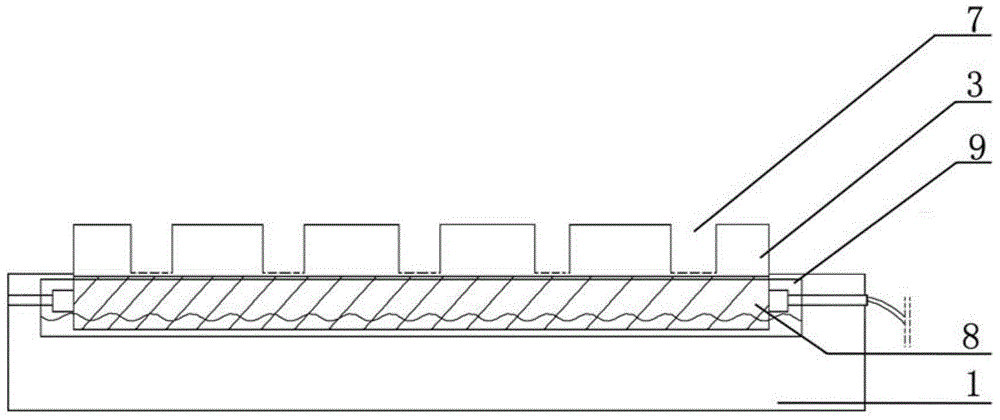

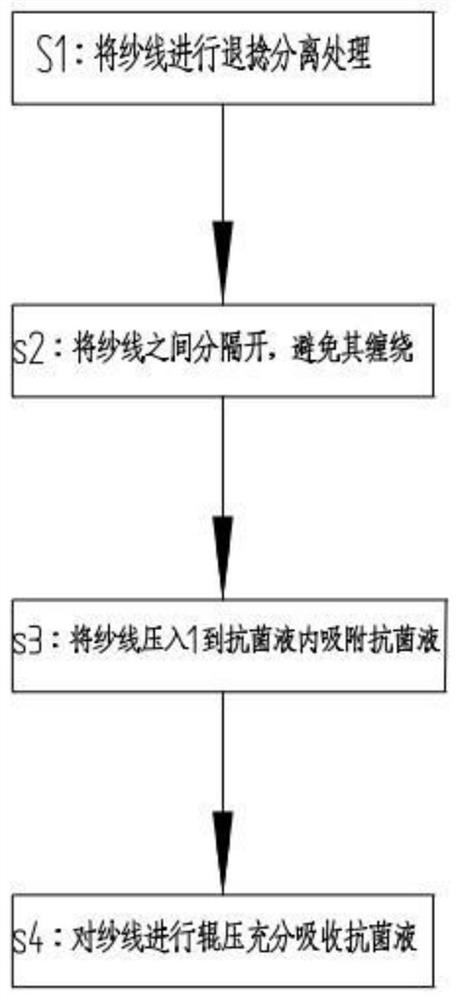

Preparation method of antibacterial yarn

InactiveCN113388982AImprove adsorption capacityFully adsorbedTextile treatment untwisting devicesTextile treatment guiding meansYarnFiber

The invention relates to the technical field of knitted fabrics, in particular to a preparation method of antibacterial yarn. The invention solves the problem that in the background technology, an antibacterial solution cannot be fully adsorbed in multiple twisted yarns which are wound together. The method comprises the following steps of s1, untwisting a plurality of stranded yarns which are formed by mutual cohesion after twisting, so that the plurality of yarns are not wound or cohered together; s2, separating the multiple yarns, so that the multiple yarns are spaced by a certain distance; s3, pressing the plurality of yarns into the antibacterial solution, so that the yarns are immersed into the antibacterial solution, and the surfaces of the yarns are coated with an antibacterial layer; and s4, rolling the yarns, so that the interiors of the yarns fully absorbs the antibacterial solution. The antibacterial solution used in the step s3 contains 25 parts of nano bamboo carbon fibers, 25 parts of nano silver fibers and 75 parts of natural fabric fibers.

Owner:哈尔滨嗨菲特健康管理有限公司

Antistatic treatment device for drying and shaping tow

PendingCN111910360AEasy towingReduce tensionTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsRotational axisElectric machinery

The invention discloses an antistatic treatment device for a drying and shaping tow, and relates to the technical field of tow antistatic treatment. The antistatic treatment device comprises a supporting table, an unwinding wheel and a winding wheel, supporting columns are fixed to the two sides of the lower portion of the supporting table, reinforcing rods are arranged between the supporting columns, and a base is installed below the supporting columns; moving wheels are arranged at the two sides of the lower portion of the base, a first motor is installed at the left side of the upper portion of the supporting table, a first motor shaft is arranged in front of the first motor, the unwinding wheel is installed in front of the first motor shaft, a tow body is arranged at the outer side ofthe unwinding wheel, and tensioning rollers are arranged at one side of the tow body; and rotating shafts are arranged at the two ends of the tensioning rollers. The device has the beneficial effectsthat the two sides of the outer portion of the tow body are conveniently pulled and tensioned through the two sets of symmetrical tensioning rollers, movable rotation between the tensioning rollers and a support is conveniently achieved through the rotating shafts, and therefore the tow body at the outer sides of the upper portions of the tensioning rollers can be conveniently pulled and moved ina matched manner.

Owner:ZHANGJIAGANG RONGCHANG POLYESTER TOPS

Line printing and dyeing device for textile processing

InactiveCN111945324AEffective vertical clampingImprove convenienceTextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forceAnnular arrayIndustrial engineering

The invention discloses a line printing and dyeing device for textile processing, and relates to the technical field of textile processing. The problem that existing printing and dyeing equipment is insufficient in line printing and dyeing is solved. The line printing and dyeing device specifically comprises a material storage box body, four supporting blocks distributed in an annular array mannerare fixedly installed at the outer wall of the circumferential bottom of the material storage box body, a top cover is fixedly installed at the outer wall of the top of the material storage box body,and a first opening is formed in the outer wall of the center of the top of the top cover. According to the line printing and dyeing device for textile processing, two annular supporting blocks are arranged, annular grooves are formed in the annular supporting blocks, and annular rubber pads, arc-shaped supporting plates and screws are arranged in the annular grooves, so that lines for textile processing can be placed at the inner walls of the annular grooves, the annular supporting plates are driven by the multiple screws to move, then multiple bundles of lines can be effectively and vertically clamped and fixed, and the convenience of textile line installation by the device is improved.

Owner:宣城红妆美人床上用品有限公司

Tow printing and dyeing device for textile processing

InactiveCN111254610AAvoid entanglementAvoid accumulationTextile treatment carriersTextile treatment guiding meansTextile printerPolymer science

The invention provides a tow printing and dyeing device for textile processing, and relates to the field of textiles. The tow printing and dyeing device for textile processing comprises support legs,a printing and dyeing box for textile printing and dyeing of tows, an upper limit block for fixing and limiting the tows, a lower limit block for fixing and limiting the tows and a movable printing and dyeing mechanism, wherein the printing and dyeing box is fixedly connected to the support legs, the inner wall of the printing and dyeing box is fixedly connected with a first supporting rod, the surface of the first supporting rod is fixedly connected with the surface of the upper limiting block, the inner bottom wall of the printing and dyeing box is fixedly connected with a second supportingrod, and the surface of the second supporting rod is fixedly connected with the surface of the lower limiting block. According to the tow printing and dyeing device for textile processing, special printing and dyeing equipment capable of avoiding tow entanglement and accumulation is designed according to the problems in existing tow printing and dyeing, so that the problem that working efficiencyis influenced to a certain extent due to the fact that common tows are in a static soaking state during the printing and dyeing process, tow printing and dyeing are uneven inside and outside and thatthe printing and dyeing time is long is solved.

Owner:黄春惠

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com