Yarn sizing device

A yarn and yarn tube technology, applied in the field of textile equipment, can solve the problem of yarn sticking together and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

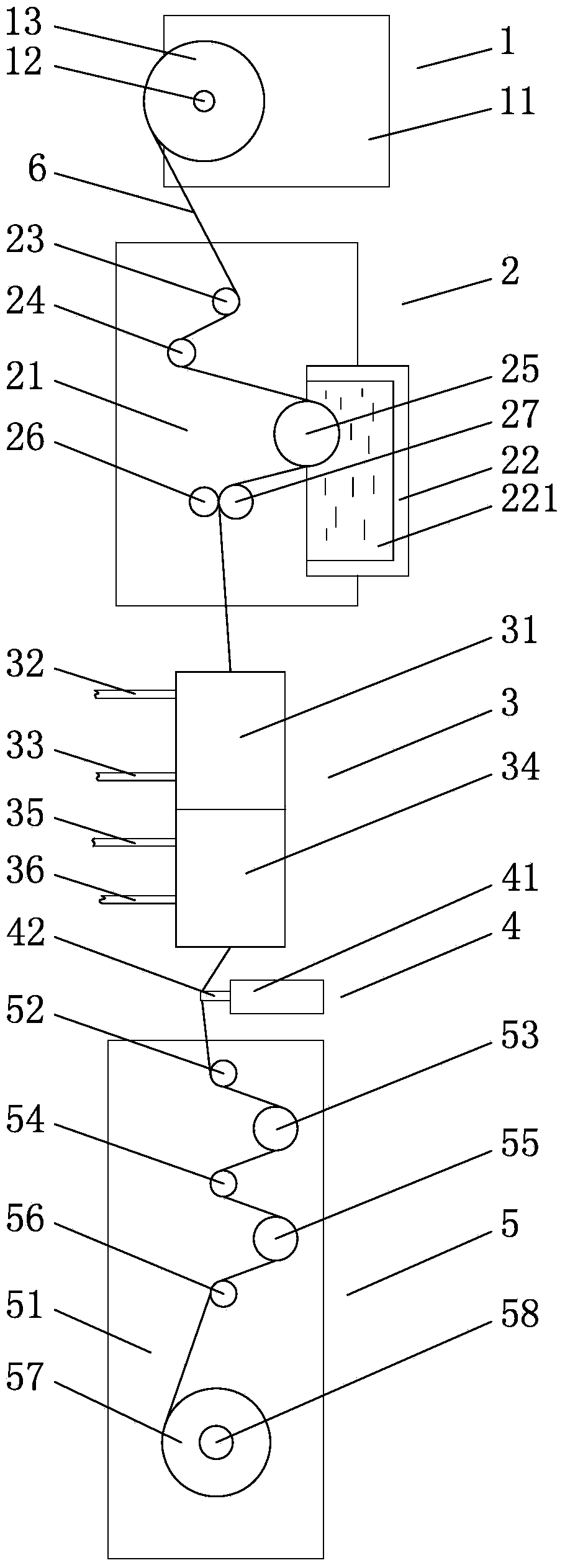

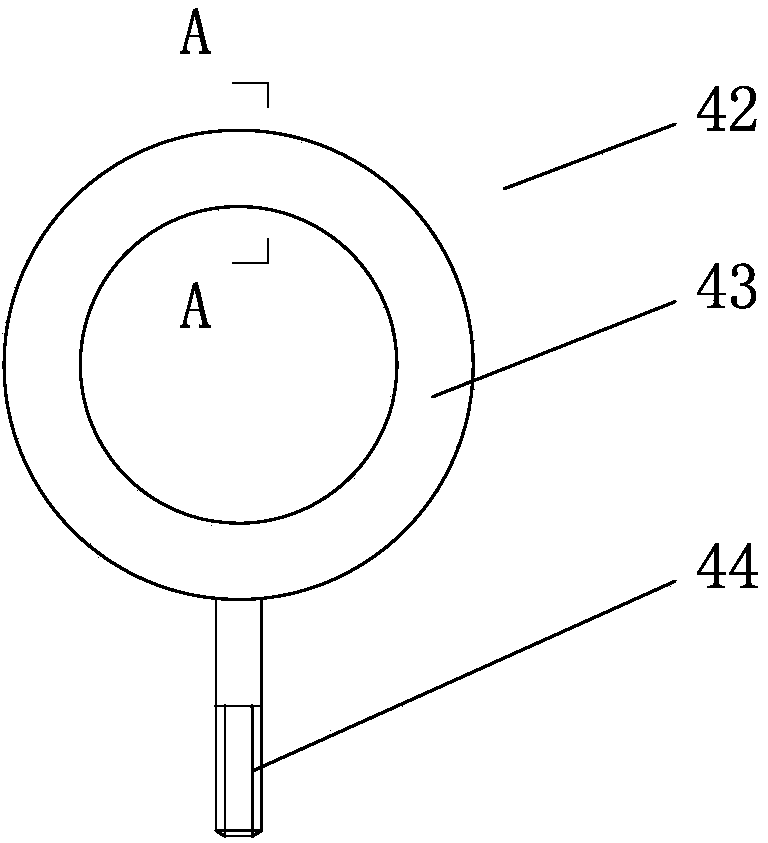

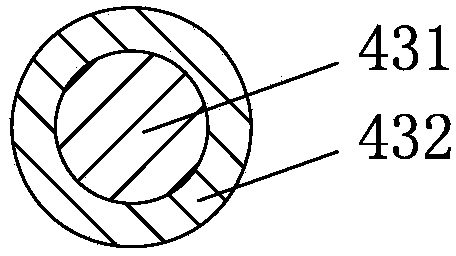

[0020] refer to figure 1 , a yarn sizing device, comprising a discharging device 1, a sizing device 2, a drying device 3, a yarn dividing device 4 and a yarn receiving device 5 arranged in sequence. refer to figure 2 and Figure 4 The yarn dividing device 4 comprises a yarn dividing frame 41 and a circular ring 43 arranged on the upper end surface of the yarn dividing frame 41, the lower end surface of the circular ring 43 is provided with a threaded rod 44 extending to the outside of the circular ring 43, and the circular ring 43 is connected with the threaded rod 44 Spinning frame 41 is threadedly connected. Each yarn 6 coming out of the drying device 3 passes through different rings 43, so as to prevent adjacent yarns 6 from sticking together. refer to image 3 The ring 43 includes a ring body 431 and a flexible tube 432 sleeved on the ring body 431. The flexible tube 432 can be a rubber tube or a paper tube.

[0021] In the present invention, the yarn dividing elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com