Acetate fiber fabric and production process thereof

A technology of acetate fiber and production process, applied in the field of acetate fiber fabric and its production process, can solve the problems such as failure of further research work, and achieve the effects of good hand feeling, improved performance uniformity, and good color fineness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

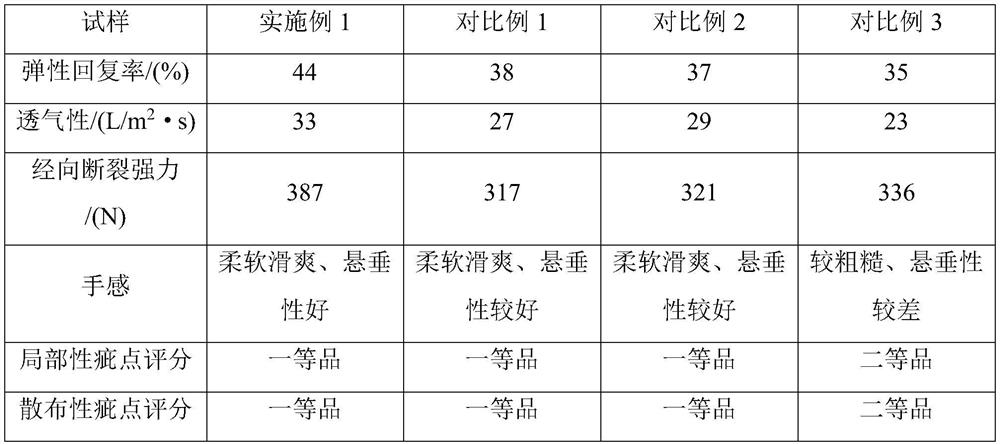

Embodiment 1

[0044] An acetate fiber fabric, the design specifications of the acetate fiber fabric are as follows:

[0045] Lower width: 65.5 inches;

[0046] Warp: 75D / 19F and 350T / M·S bright twisted acetate filament (to be sizing);

[0047] Weft yarn A: (75D / 19F acetate filament yarn + 75D / 36F cationic yarn)→900T / M·S×2 plied twist→Composite acetate plied twisted yarn 900T / M·S

[0048] Weft yarn B: (75D / 19F acetate filament yarn + 75D / 36F cationic yarn)→900T / M·Z×2 plied and twisted→composite acetate plied twisted yarn 900T / M·Z

[0049] Weft arrangement ratio: A:B=1:1

[0050] Off-machine warp and weft density: 254×66

[0051] Weave: 5 / 3 Satin

[0052] The production process of the acetate fiber fabric includes the steps: warping → sizing → spooling → splitting → warp knotting → fishing shaft → weaving, the details are as follows:

[0053] S1. Warping

[0054] Warping is the first process of weaving production. Before production, the cleaning and sanitation of each static eliminator,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com