Test carbon fiber sizing apparatus

A carbon fiber and experimental technology, which is applied in the direction of processing textile material yarn guide devices, textiles and papermaking, textile processing machine accessories, etc., can solve the problems of increasing scientific research costs, cumbersome adjustments, and affecting industrial production, so as to reduce scientific research costs and sizing Uniform and stable sizing agent content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

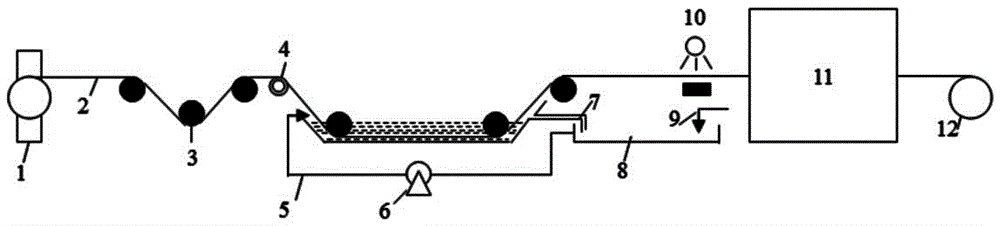

[0011] Such as figure 1 As shown, the test carbon fiber sizing device of the present invention comprises creel 1, guide roller 3, ultrasonic expansion device 4, sizing tank 5, blowing device 10, infrared heating device 11, carbon fiber winding device 12, and carbon fiber 2 is placed on the creel 1, the carbon fiber 2 comes out from multiple guide wire holes of the creel and passes through the guide roller 3, the ultrasonic expanding device 4, the sizing tank 5, the blowing device 10, the infrared heating device 11, and then winds up at the carbon fiber winding device 12 Winding into an ingot, the ultrasonic expanding device 4 is located at the entrance of the sizing tank 5, the sizing tank 5 is located under the side of the ultrasonic expanding device 4, the blowing device 10 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com