Preparation method of antibacterial yarn

A yarn and preparation device technology, applied in the field of antibacterial yarn preparation, can solve problems such as inability to charge and absorb antibacterial liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

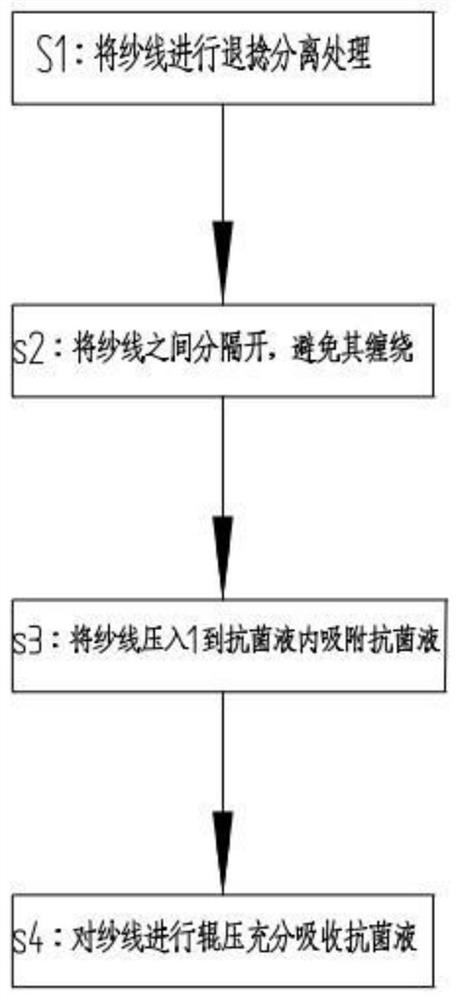

[0037] A kind of antibacterial yarn preparation method, this method comprises the following steps:

[0038] s1: Untwisting the stranded yarn formed by twisting and entwining each other, so that the multiple yarns are no longer entangled and entangled together;

[0039] s2: Separate multiple yarns so that there is a certain distance between multiple yarns;

[0040] s3: Press multiple yarns into the antibacterial solution, immerse the yarns in the antibacterial solution, and cover the surface of the yarn with an antibacterial layer;

[0041] s4: rolling the yarn so that the inside of the yarn also fully absorbs the antibacterial solution.

[0042] The antibacterial solution used in s3 contains 25 parts of nano-bamboo carbon fiber, 25 parts of nano-silver fiber and 75 parts of natural fabric fiber.

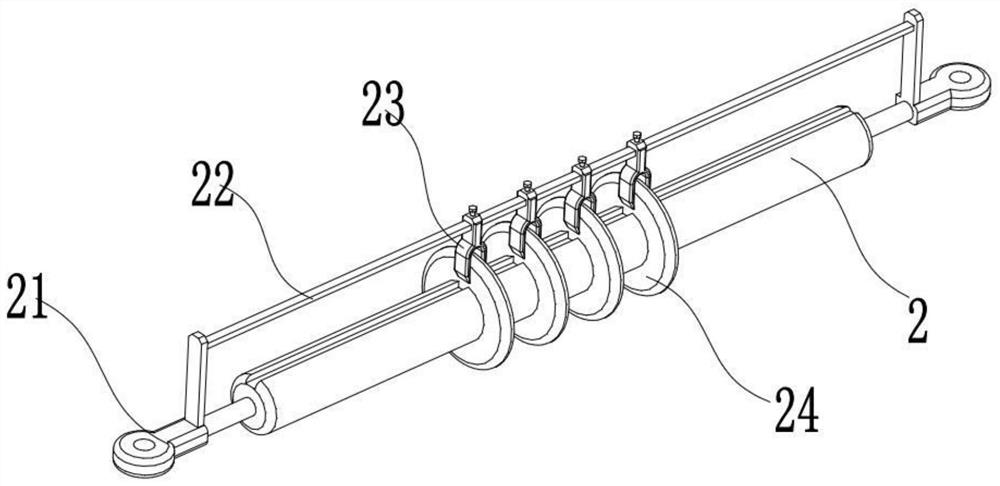

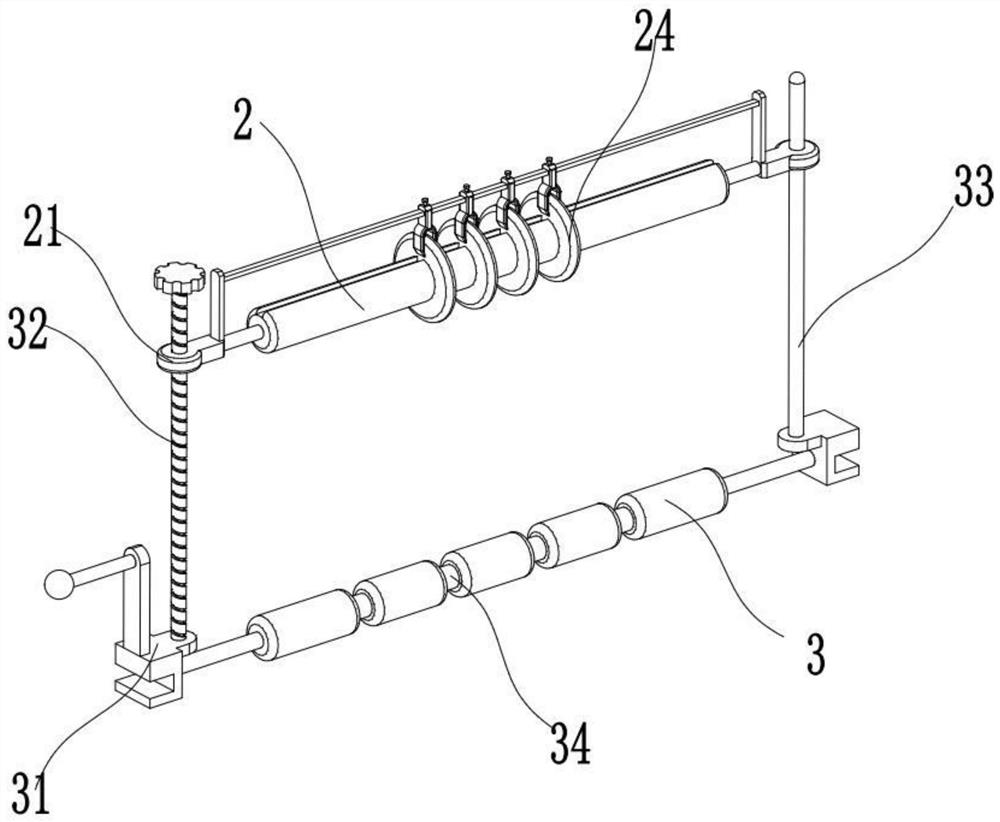

[0043] An antibacterial yarn preparation device is also used in the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com