Splitting shaping device and splitting shaping method of ultrathin carbon fiber bundle

A carbon fiber bundle and shaping device technology, which is applied to the yarn guide device for processing textile materials, the processing of textile materials, and the configuration of equipment for processing textile materials, can solve the problems of easy evaporation and shrinkage, hinder the development of carbon fiber products, etc. Stable quality, satisfying the effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

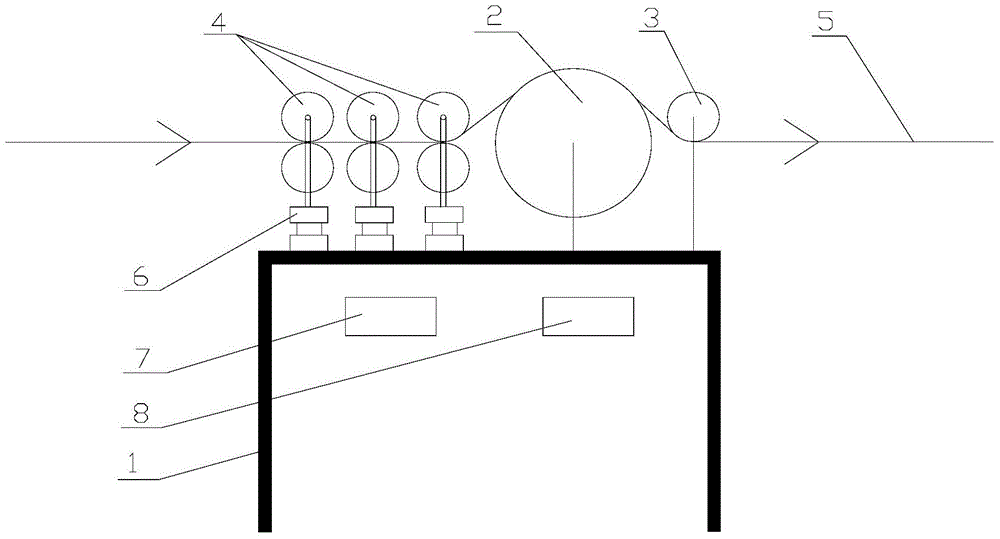

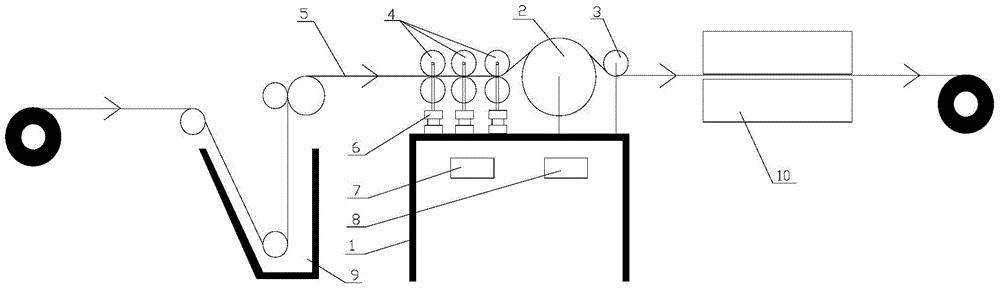

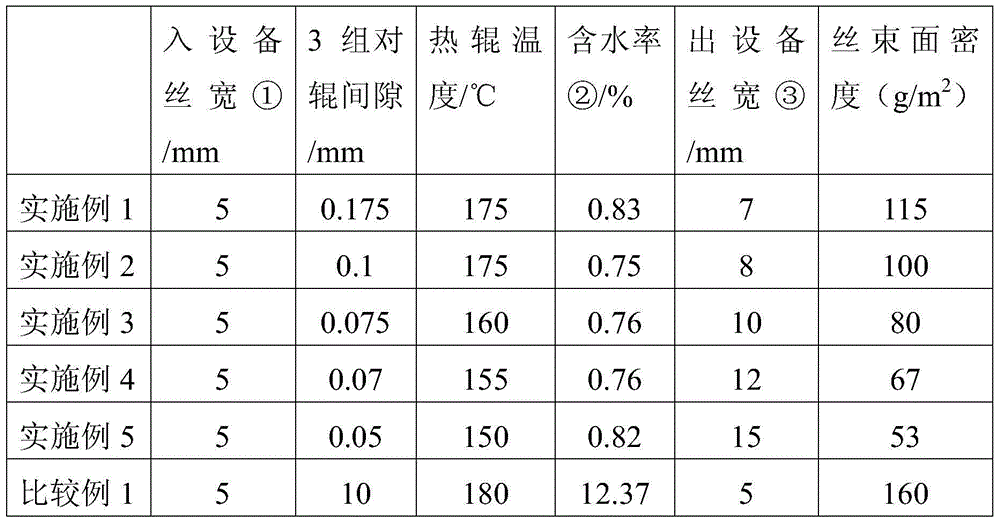

[0030] A kind of fiber opening and shaping device of the ultra-thin carbon fiber bundle of the present embodiment, such as figure 1 As shown, it includes a bracket 1, a heating roller 2, a horizontal adjustment roller 3 and three sets of spreading rollers 4. According to the conveying direction of the carbon fiber bundle 5, three sets of spreading rollers, heating rollers and horizontal adjusting rollers are arranged in sequence; each group There is a hydraulic lifter 6 for the yarn spreading rollers, and each hydraulic lifter is fixed on the support. Do not turn.

[0031] Spreading rollers include upper roller and lower roller with the same structure, the rotation direction of upper roller and lower roller is opposite, the two ends of the rotating shaft of upper roller and lower roller are respectively connected with hydraulic lift, and the upper roller is adjusted by hydraulic lift The gap between the roller and the lower roller is the conveying surface of the carbon fiber ...

Embodiment 2

[0047] Compared with Example 1, the fiber opening and shaping device and method of this embodiment differ in that:

[0048] In each pair of spreading rollers, the gap between the upper roller and the lower roller is 0.1 mm.

[0049] The carbon fiber bundle that present embodiment makes, the silk width before entering fiber opening and shaping device is 5mm, and the silk width when sending out fiber opening and shaping device is 8mm, and tow surface density is 100g / m 2 , the moisture content of carbon fiber bundles is 0.75%, see Table 1 for details.

Embodiment 3

[0051] Compared with Example 1, the fiber opening and shaping device and method of this embodiment differ in that:

[0052] In each spreading roller, the gap between the upper roller and the lower roller is 0.075mm;

[0053] The temperature of the heat roll was 160°C.

[0054] The carbon fiber bundle that present embodiment makes, the silk width before entering fiber opening and shaping device is 5mm, and the silk width when sending out fiber opening and shaping device is 10mm, and tow surface density is 80g / m 2 , the moisture content of carbon fiber bundles is 0.76%, see Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com