Patents

Literature

168results about How to "Achieve narrow borders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

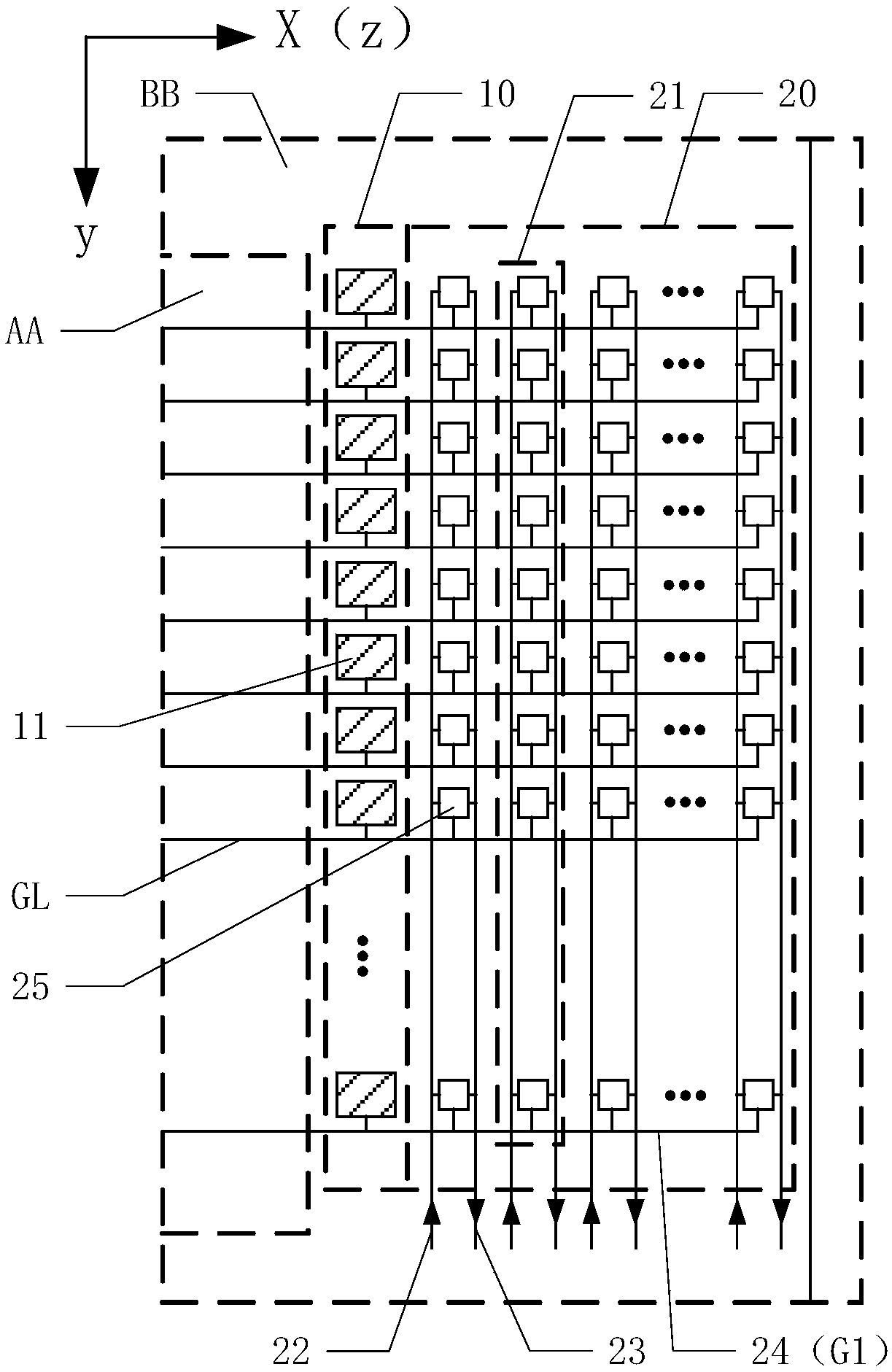

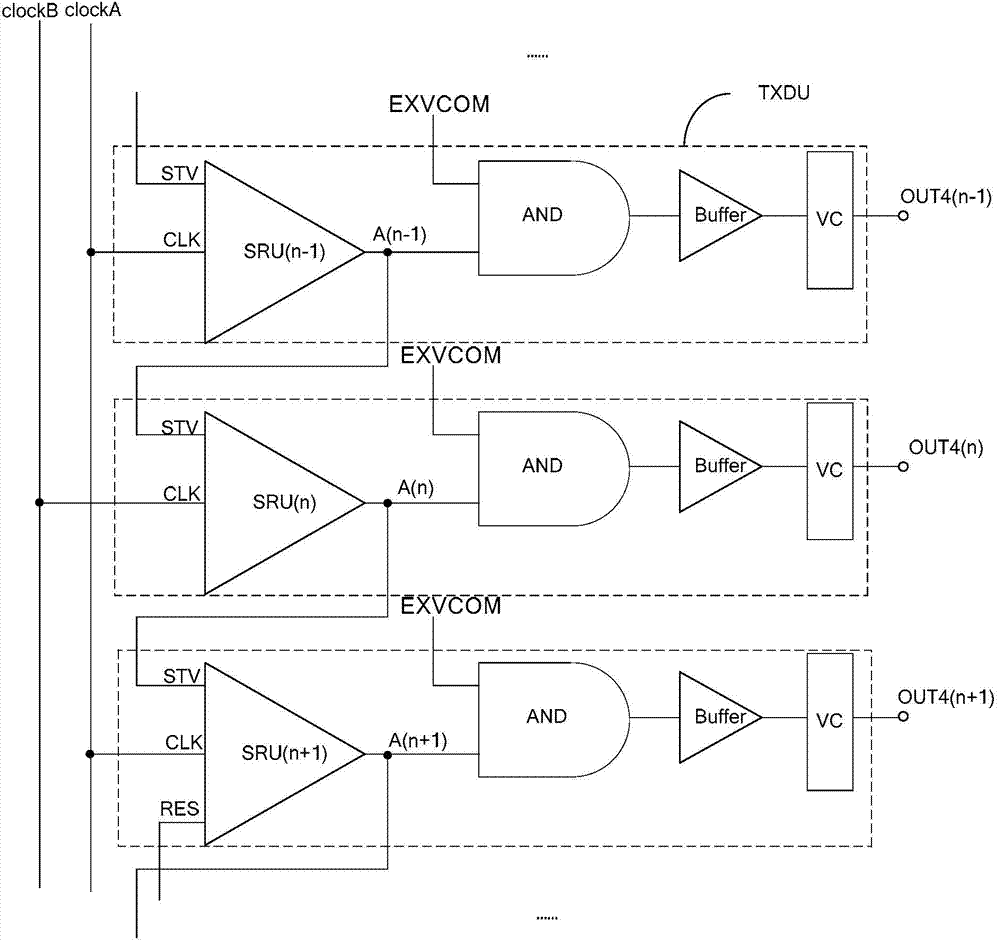

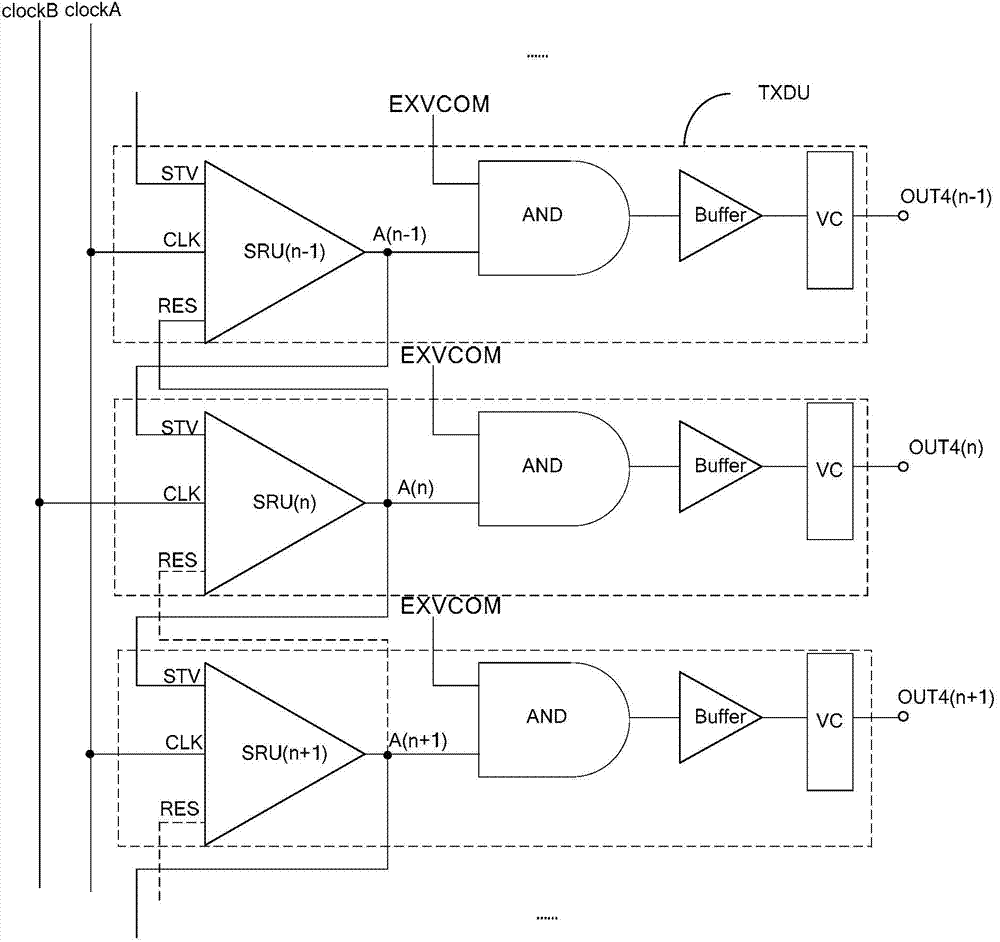

Grid driving circuit and driving method thereof and display device

ActiveCN102881248AReduce the numberAchieve narrow bordersStatic indicating devicesShift registerDisplay device

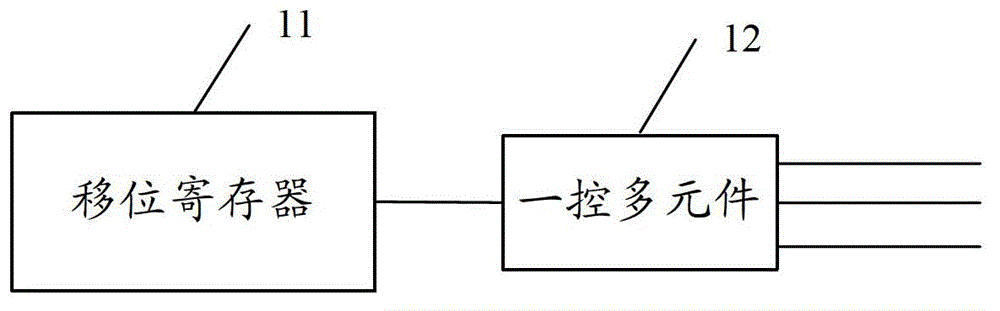

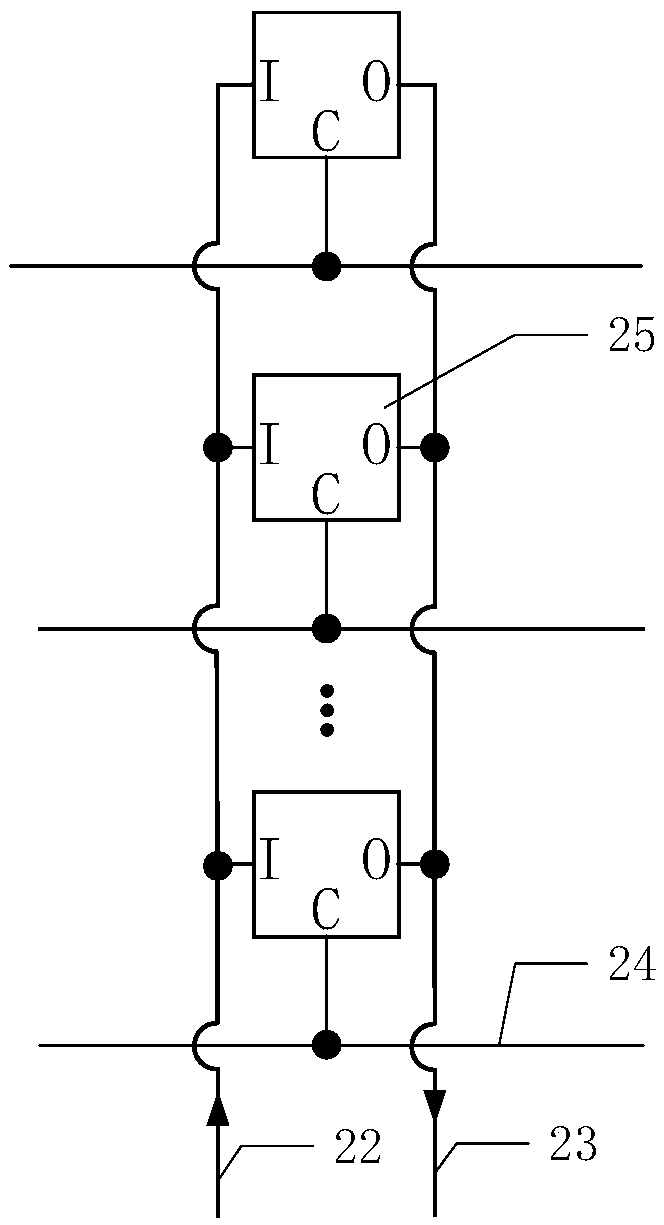

The invention discloses a grid driving circuit and a driving method thereof and a display device, and relates to the field of displaying. The grid driving circuit can reduce wiring space and realize frame narrowing of a panel and is particularly applicable to small-size panels. The grid driving circuit comprises a shifting register and a control unit, wherein the control unit is connected with an input end of the shifting register and used for converting first pulse signals output by the shifting register into multiple second pulse signals which are respectively used for driving a multiple grid lines.

Owner:BOE TECH GRP CO LTD +1

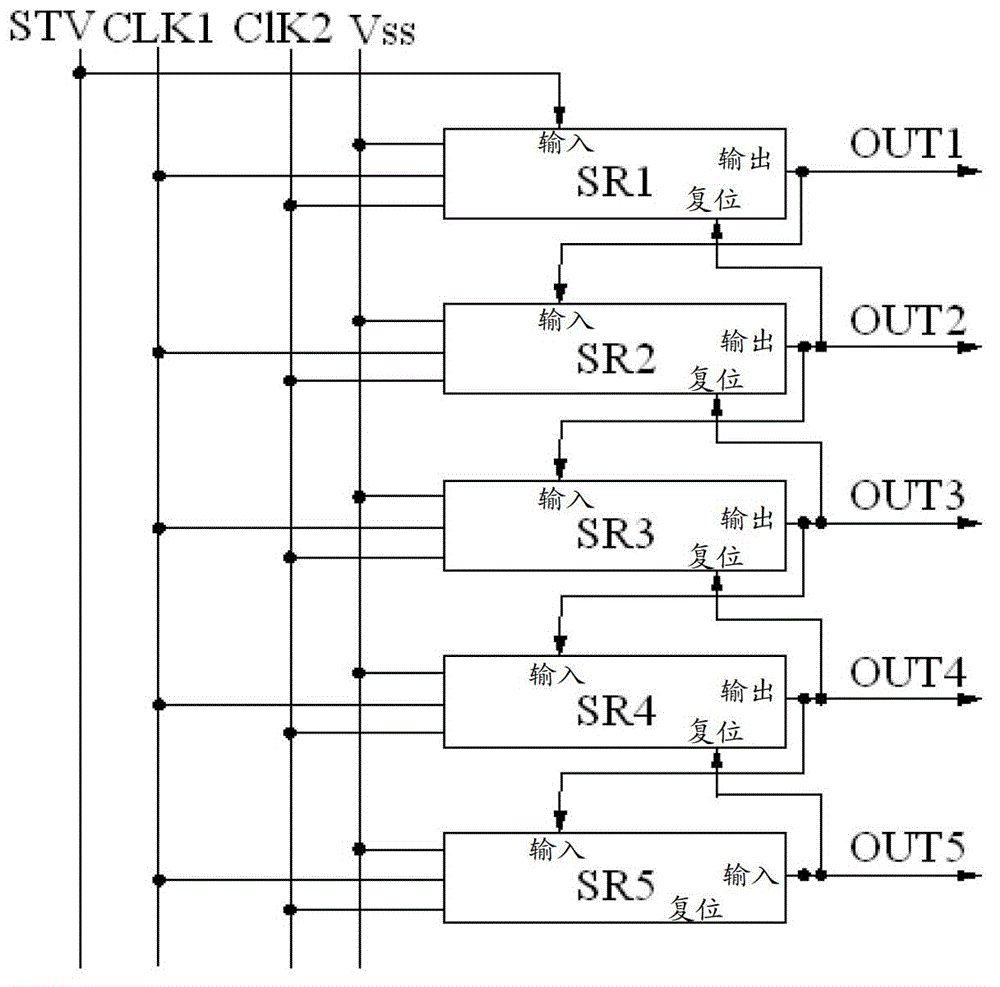

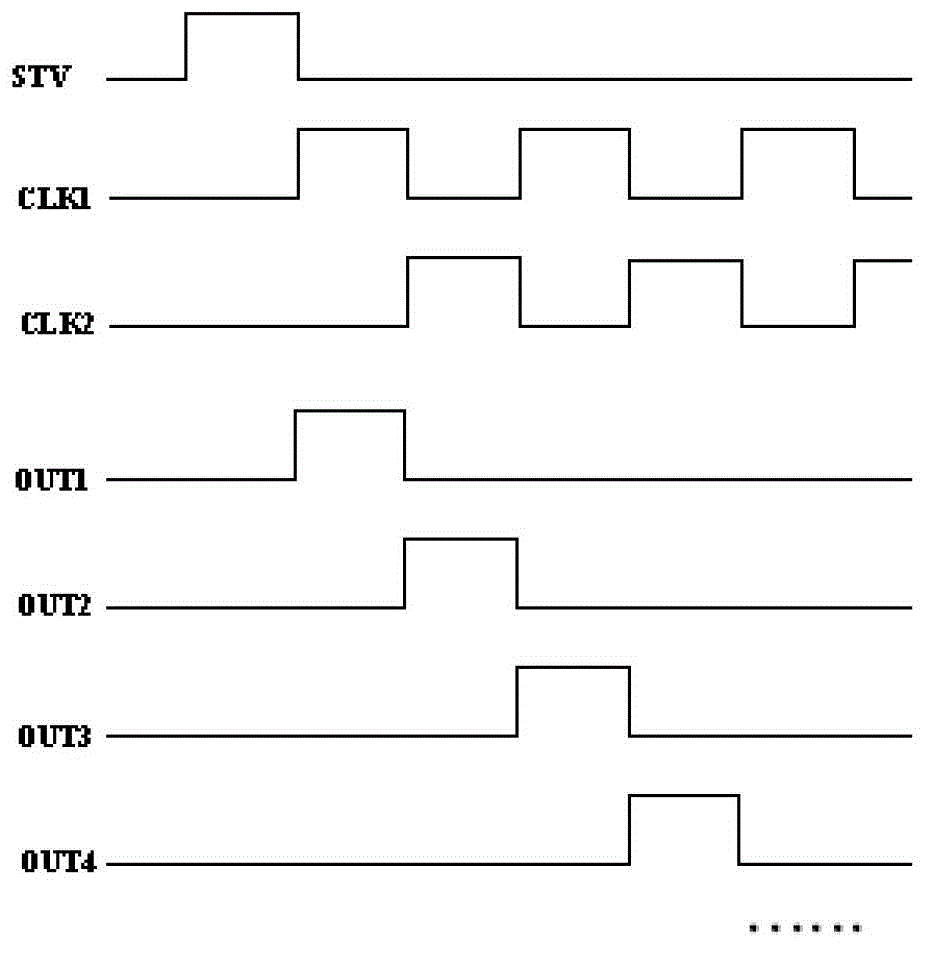

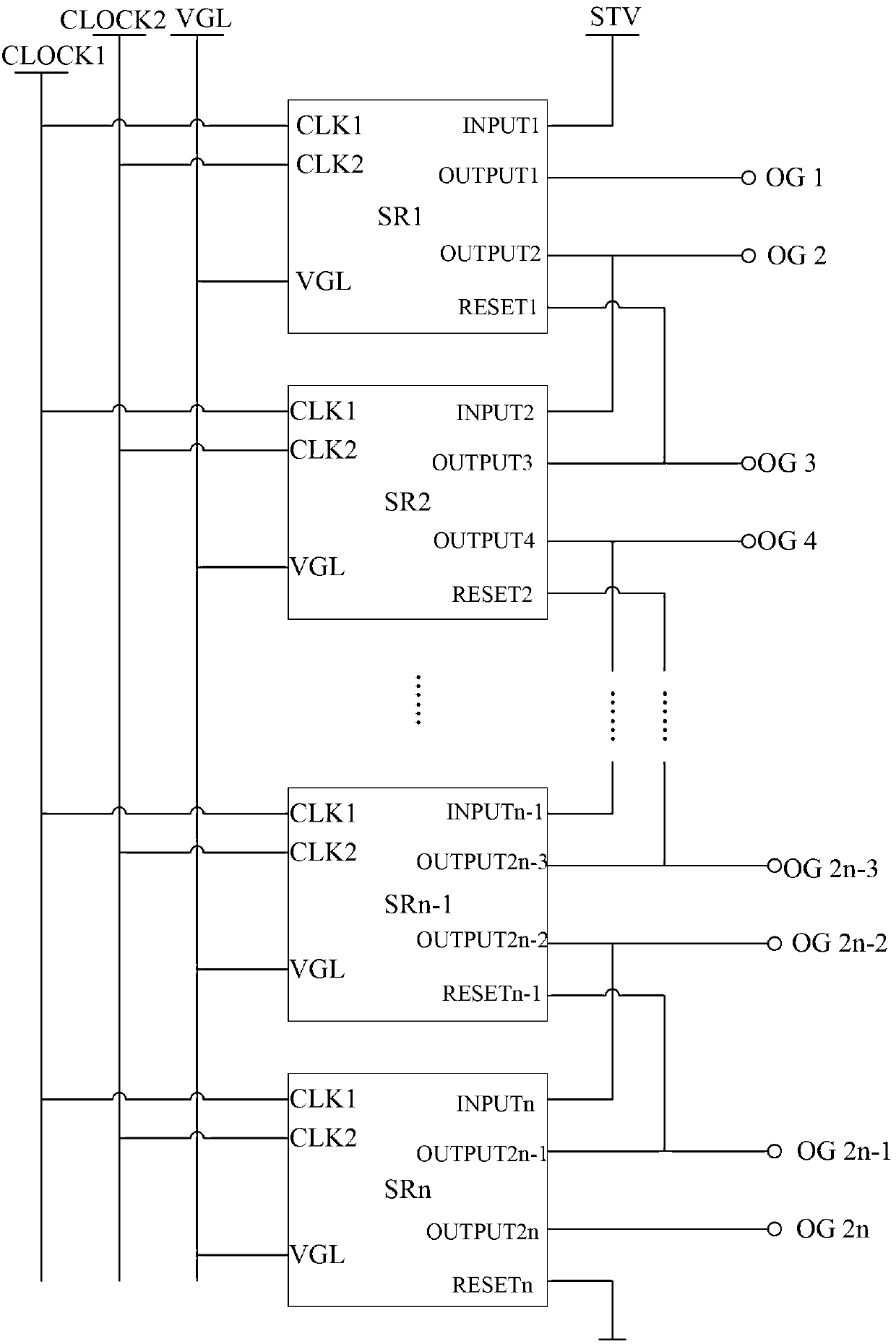

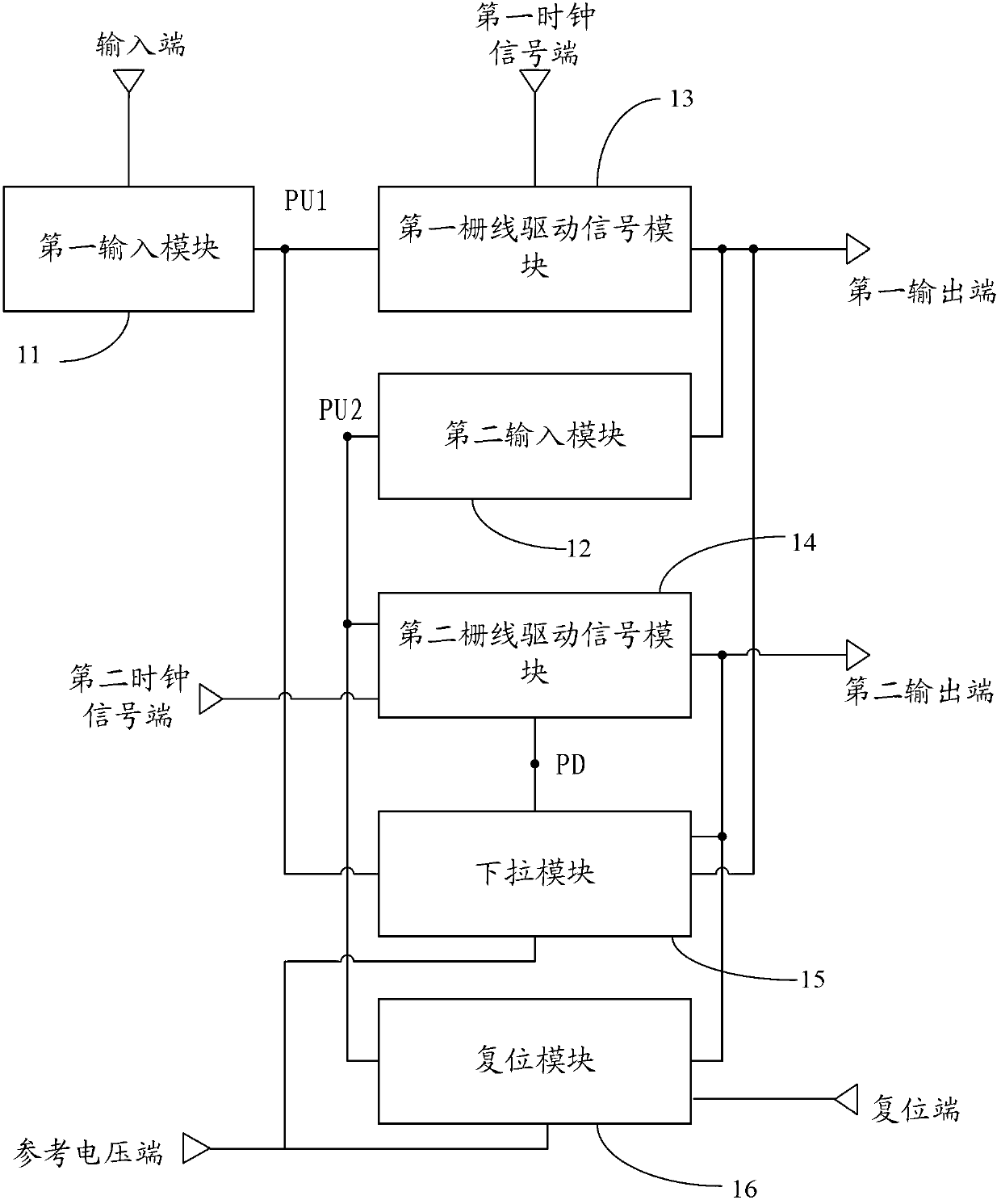

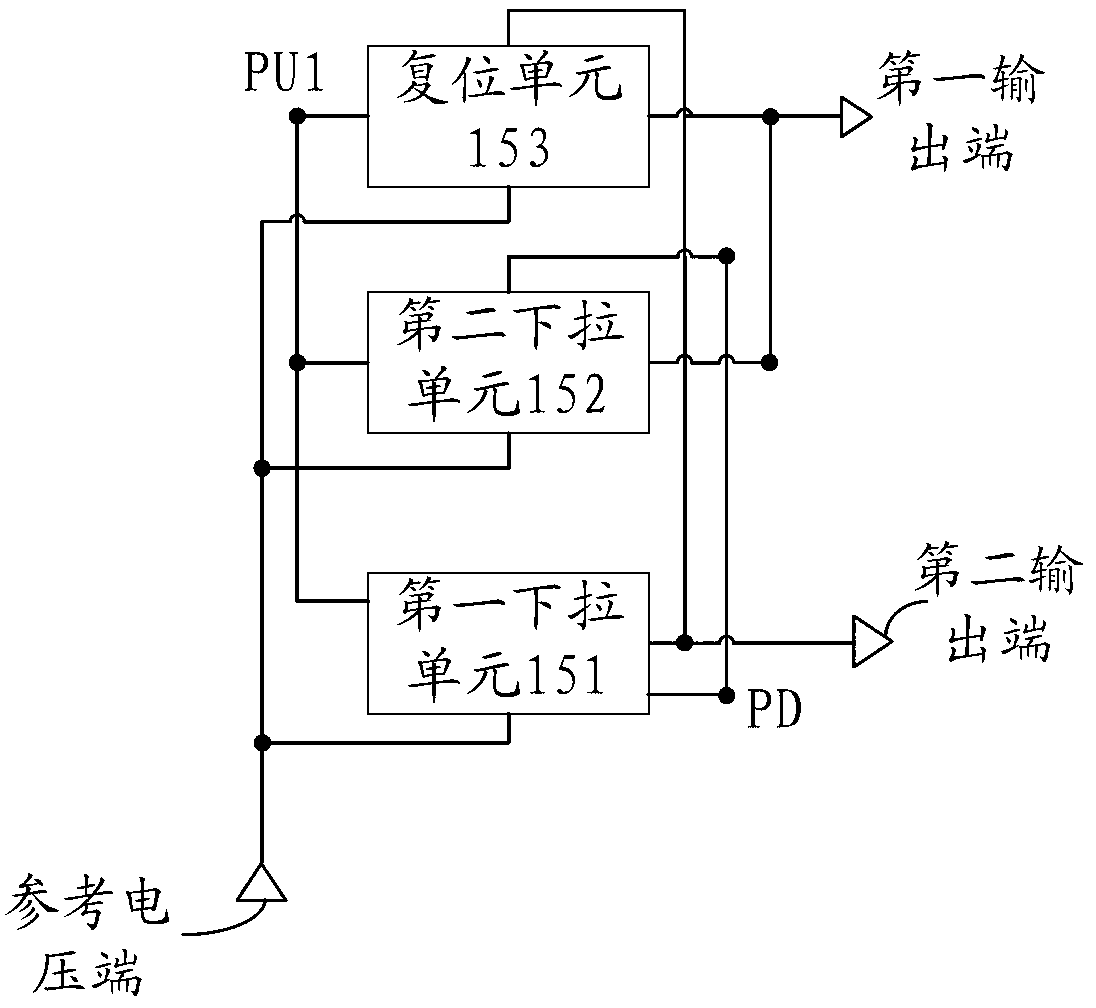

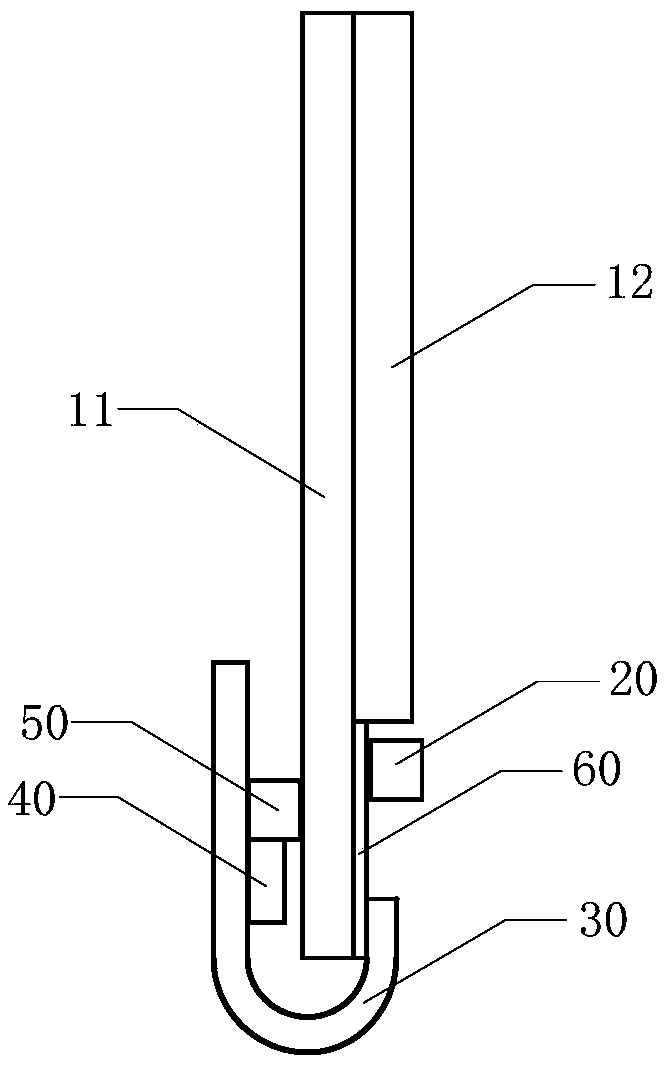

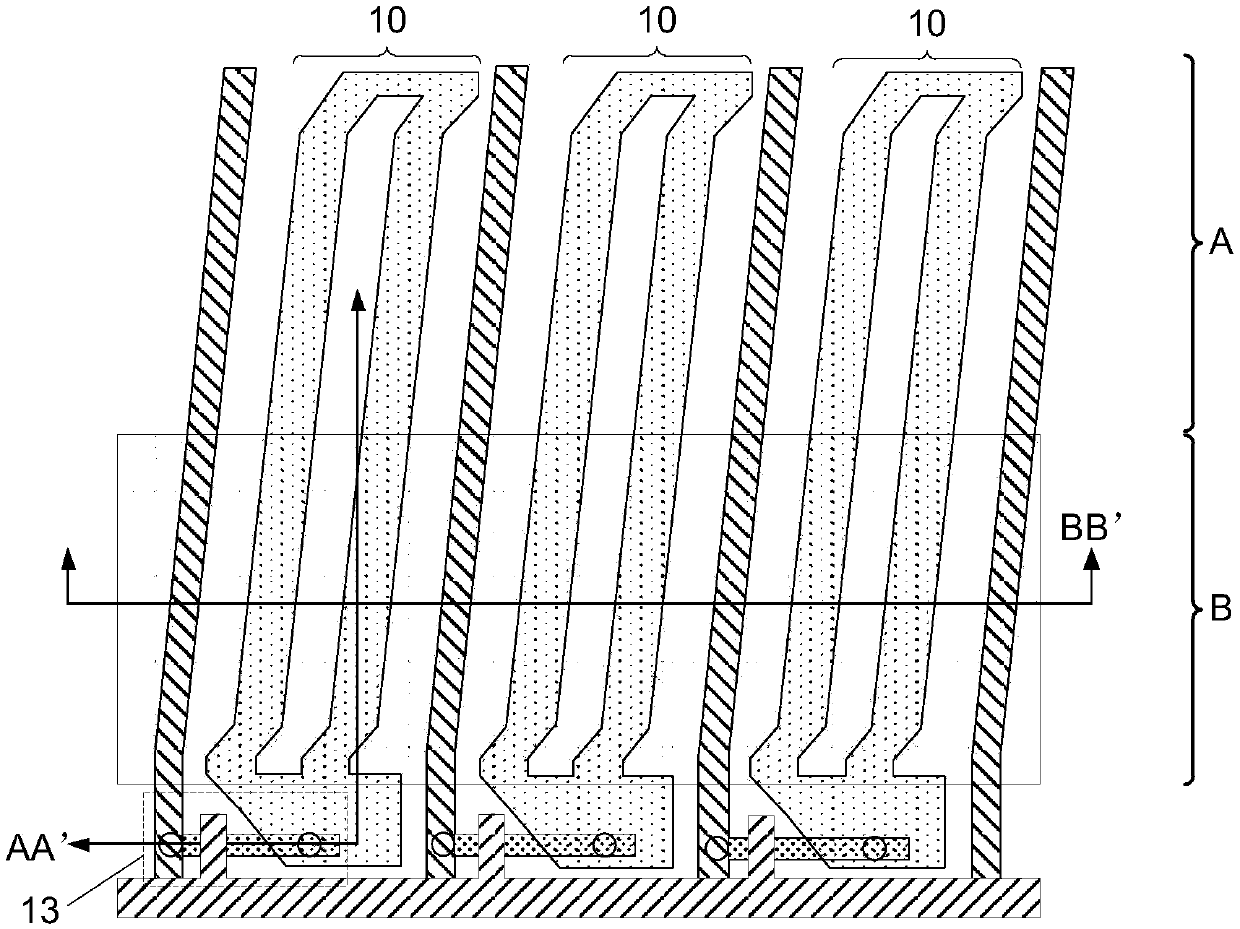

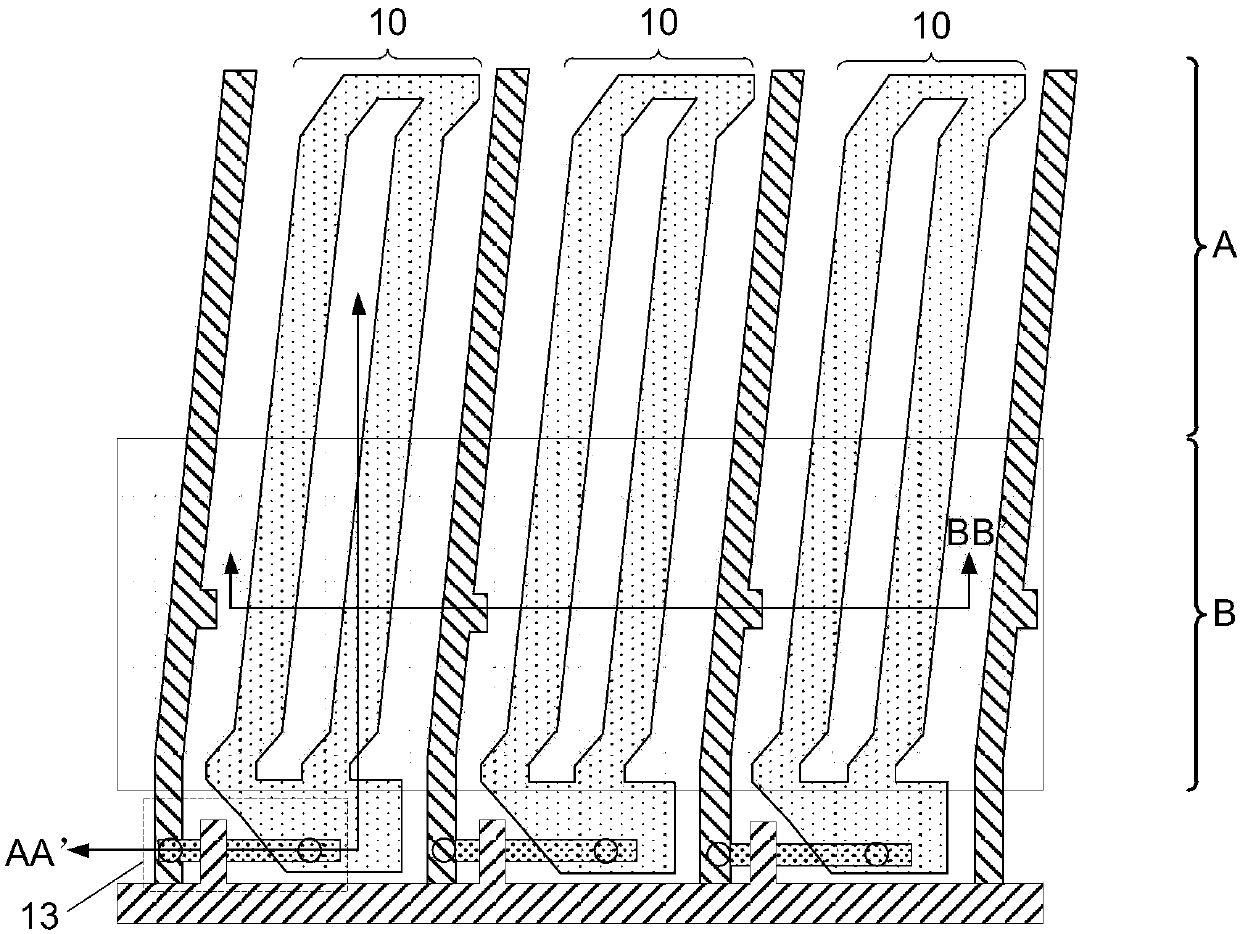

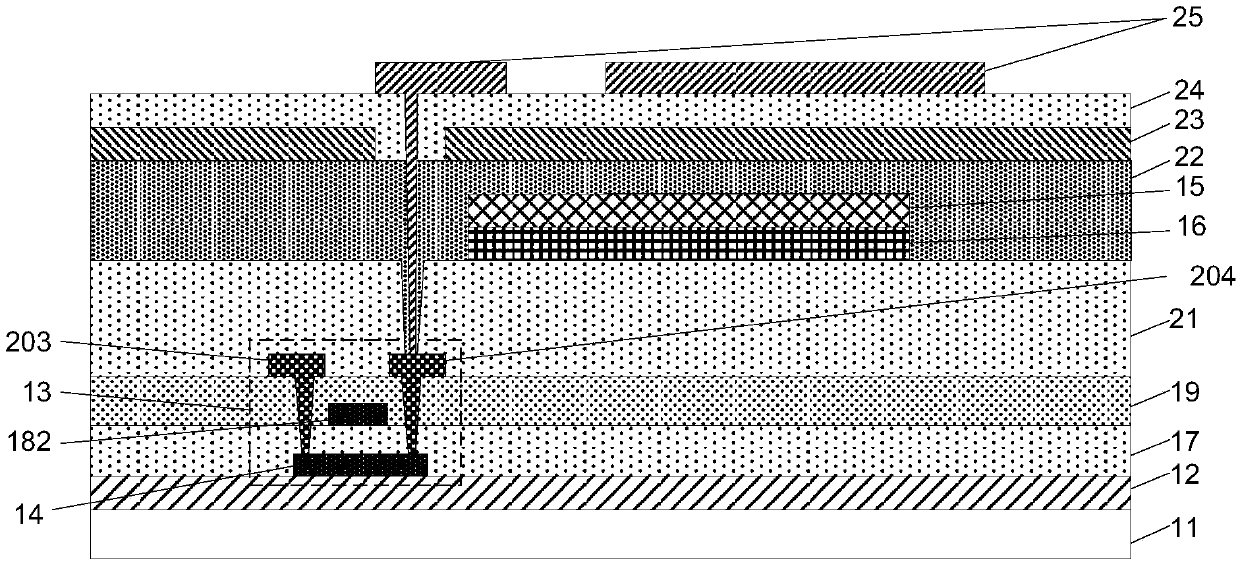

Shift register unit, drive method, shift register circuit and display device

ActiveCN103345941AConducive to integrated designAchieve narrow bordersStatic indicating devicesDigital storageShift registerProcessor register

The embodiment of the invention provides a shift register unit, a drive method, a shift register circuit and a display device, and relates to the field of manufacturing of the display. Output of two grid line signals can be achieved by one shift register unit, so that an integrated design of the circuit of a product is facilitated; and meanwhile, achievement of a narrow frame of the product is facilitated. The shift register unit comprises a first input module, a second input module, a first grid line drive signal module, a second grid line drive signal module, a pull-down module and a reset module. The embodiment of the invention is applied to manufacturing of the display.

Owner:BOE TECH GRP CO LTD

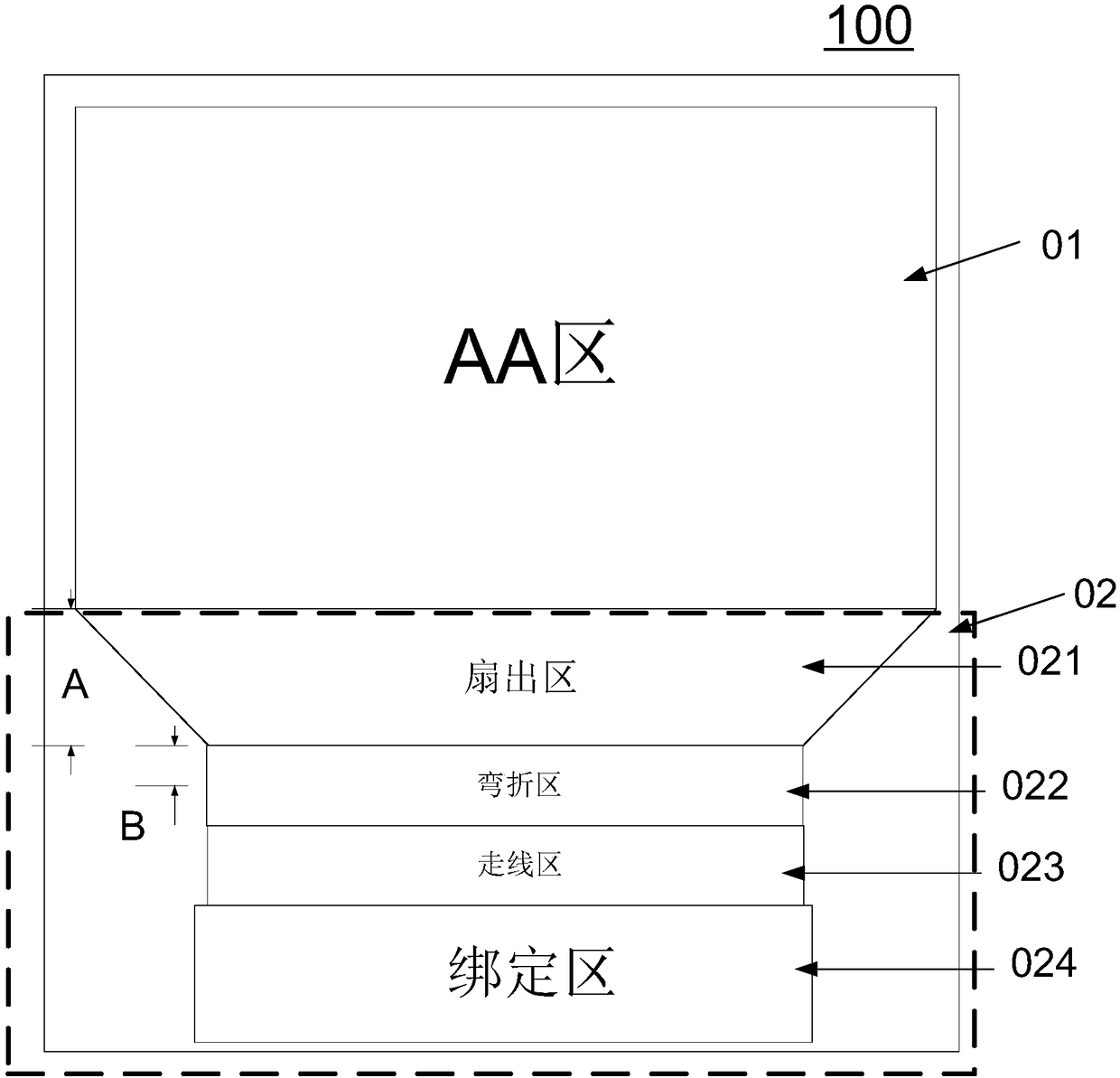

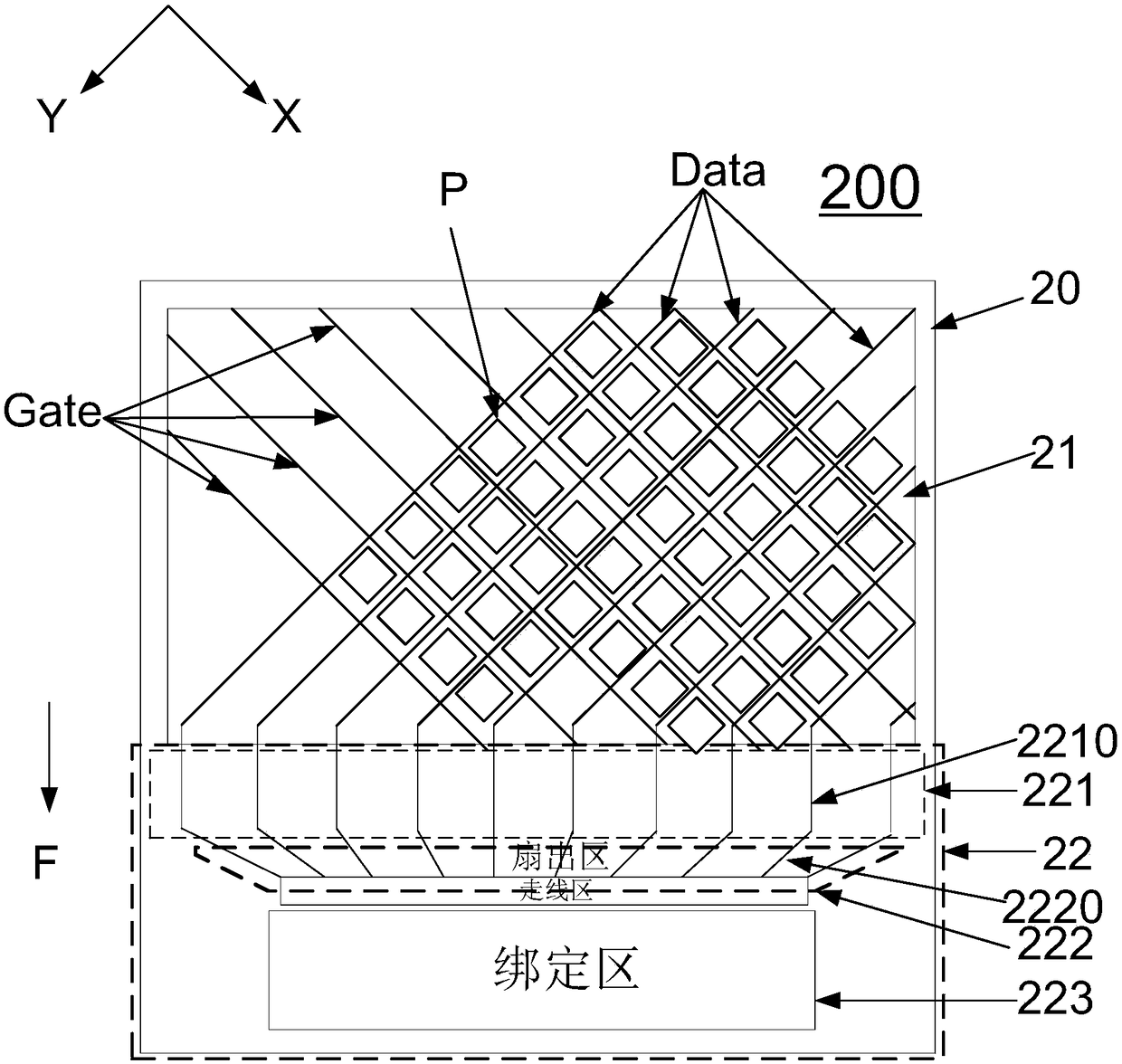

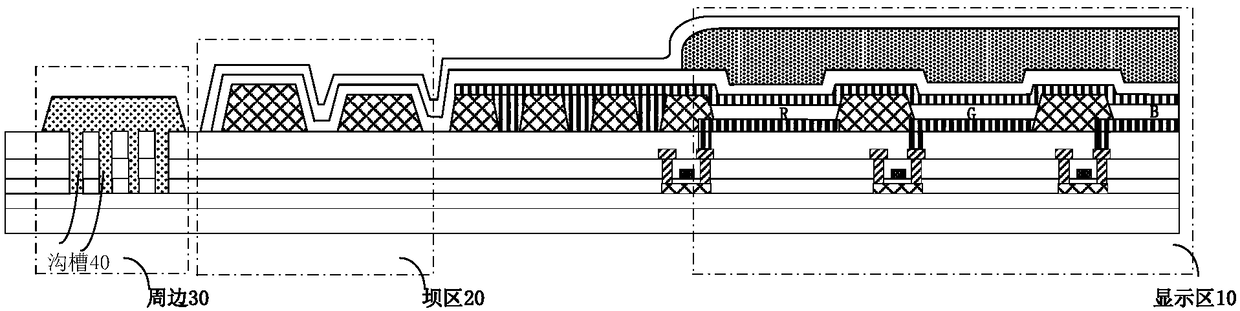

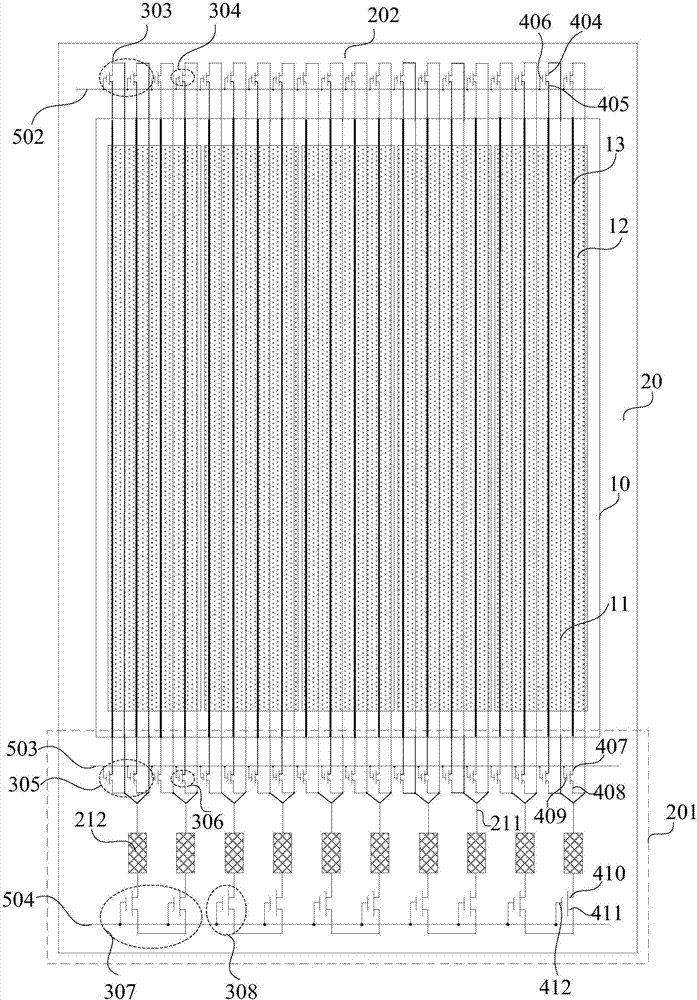

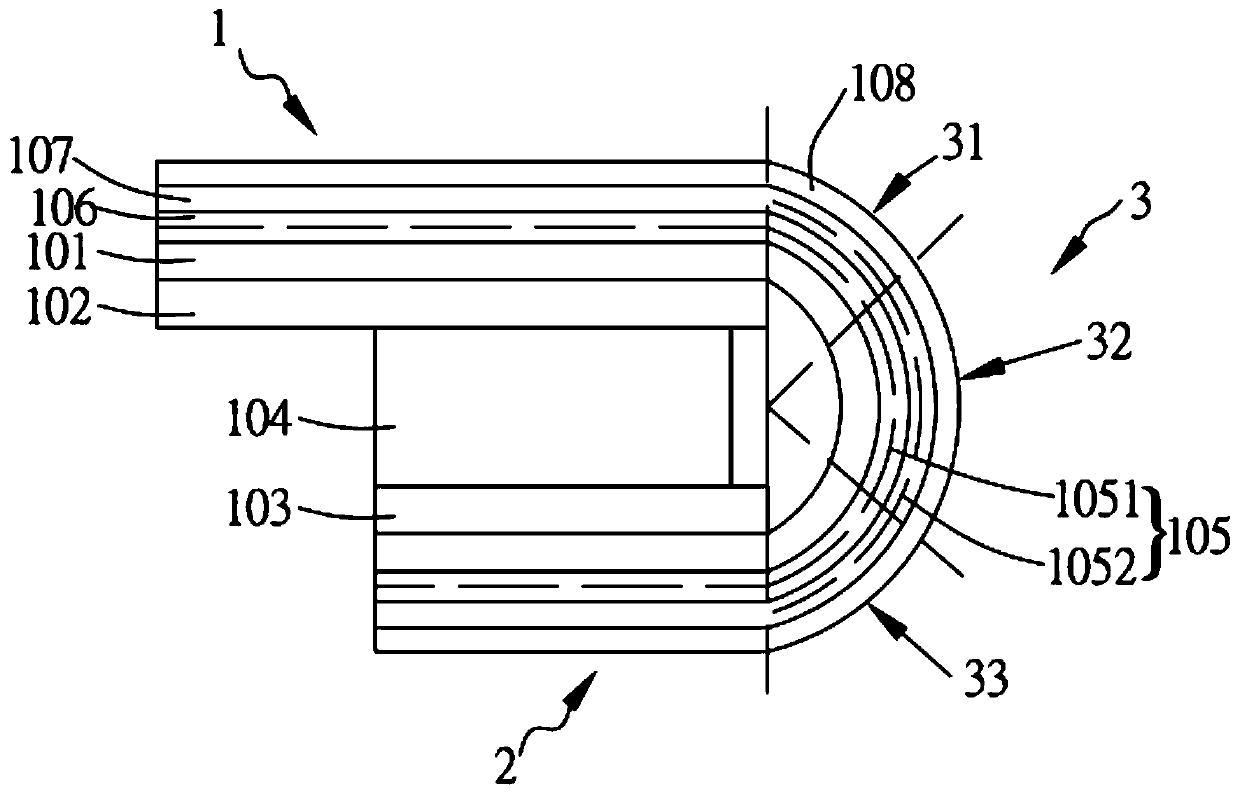

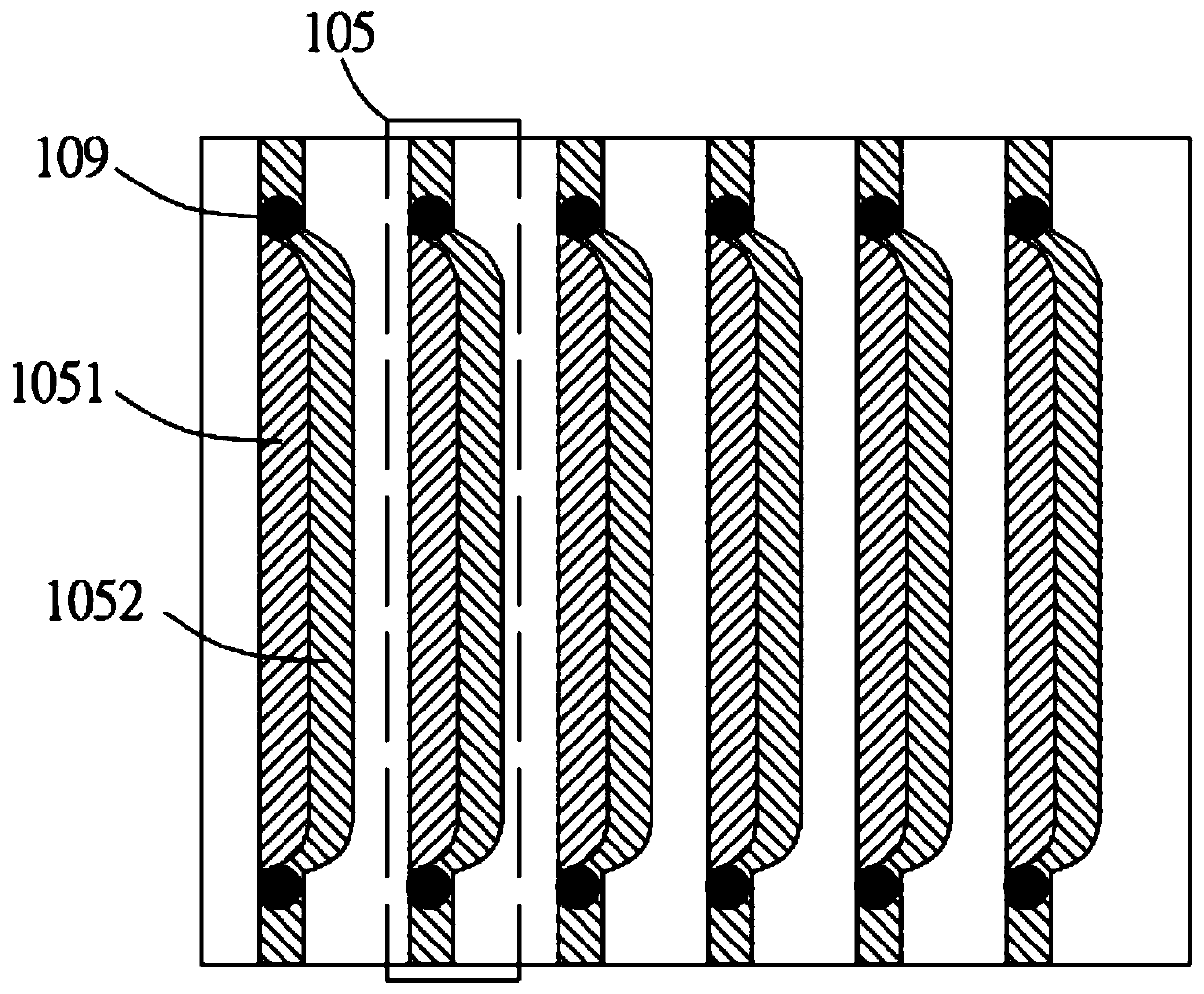

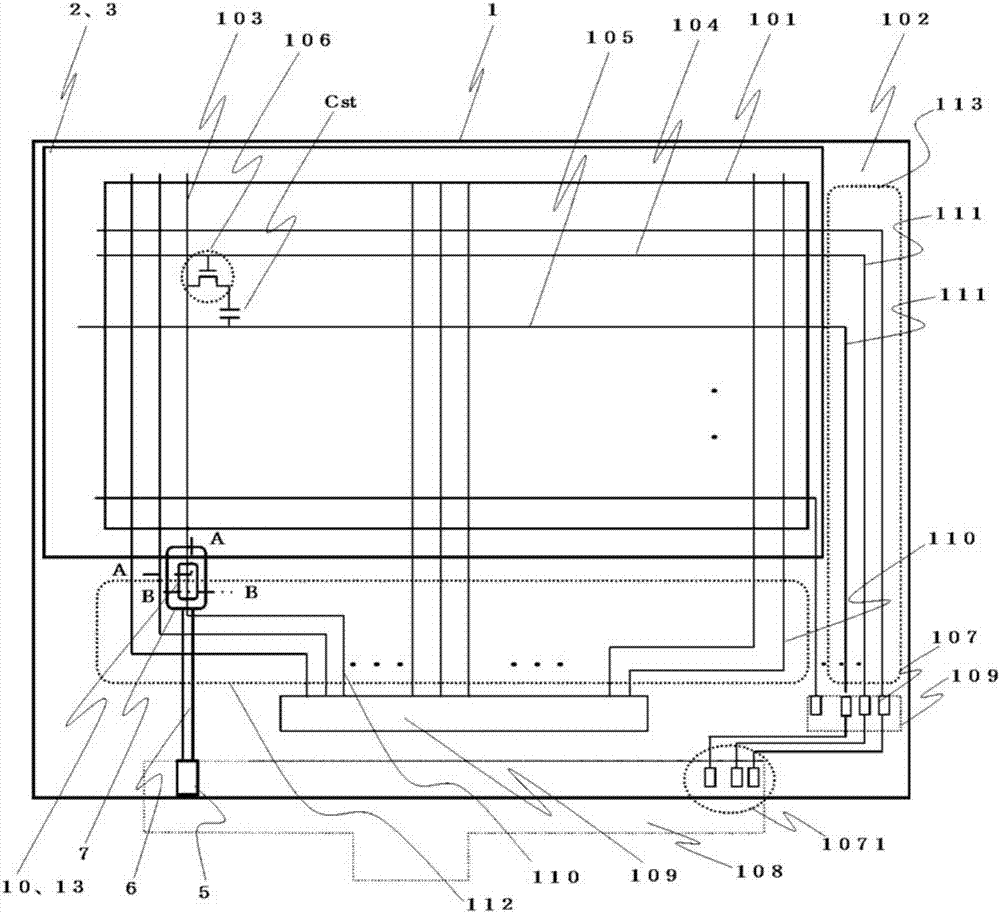

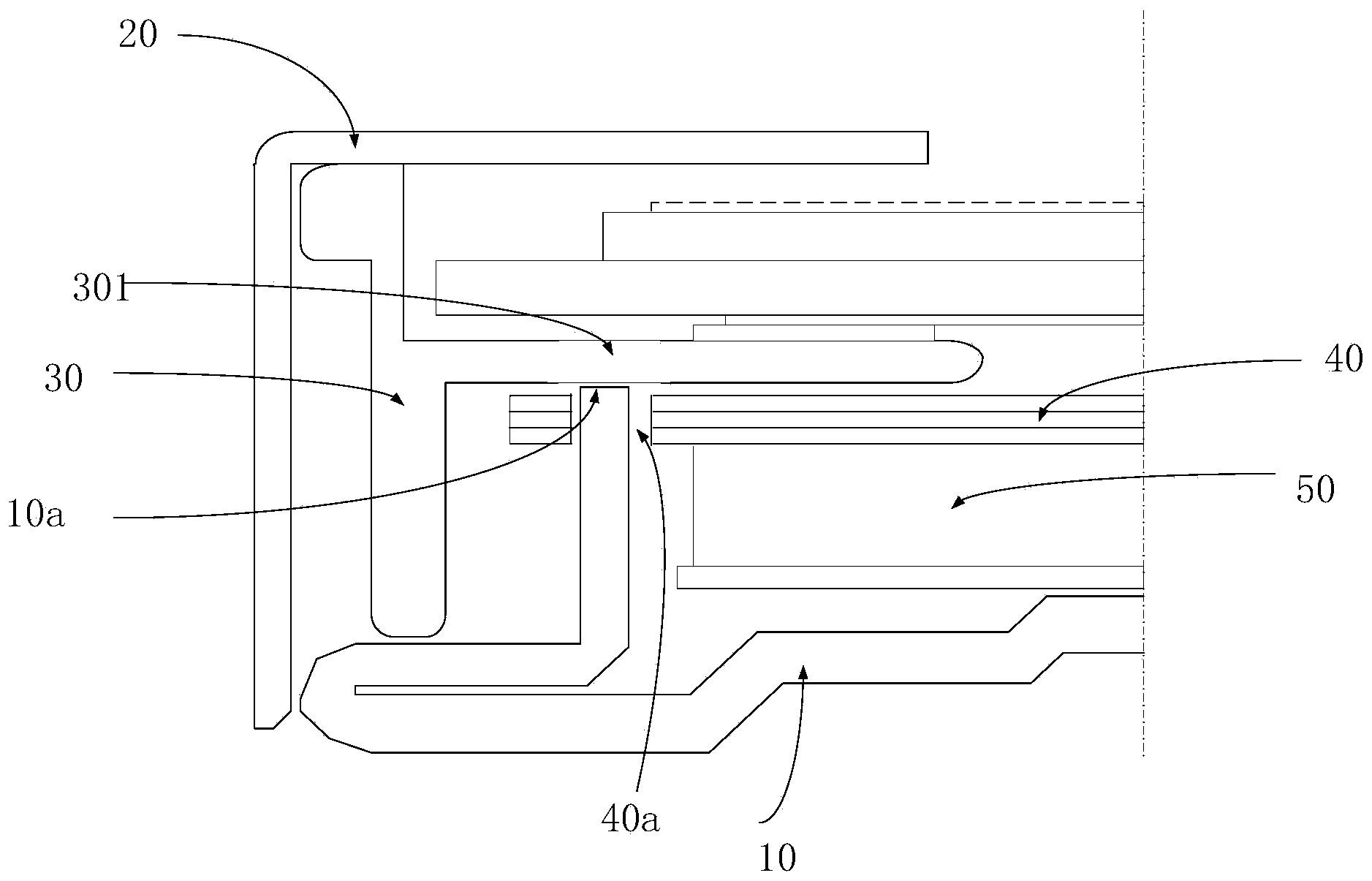

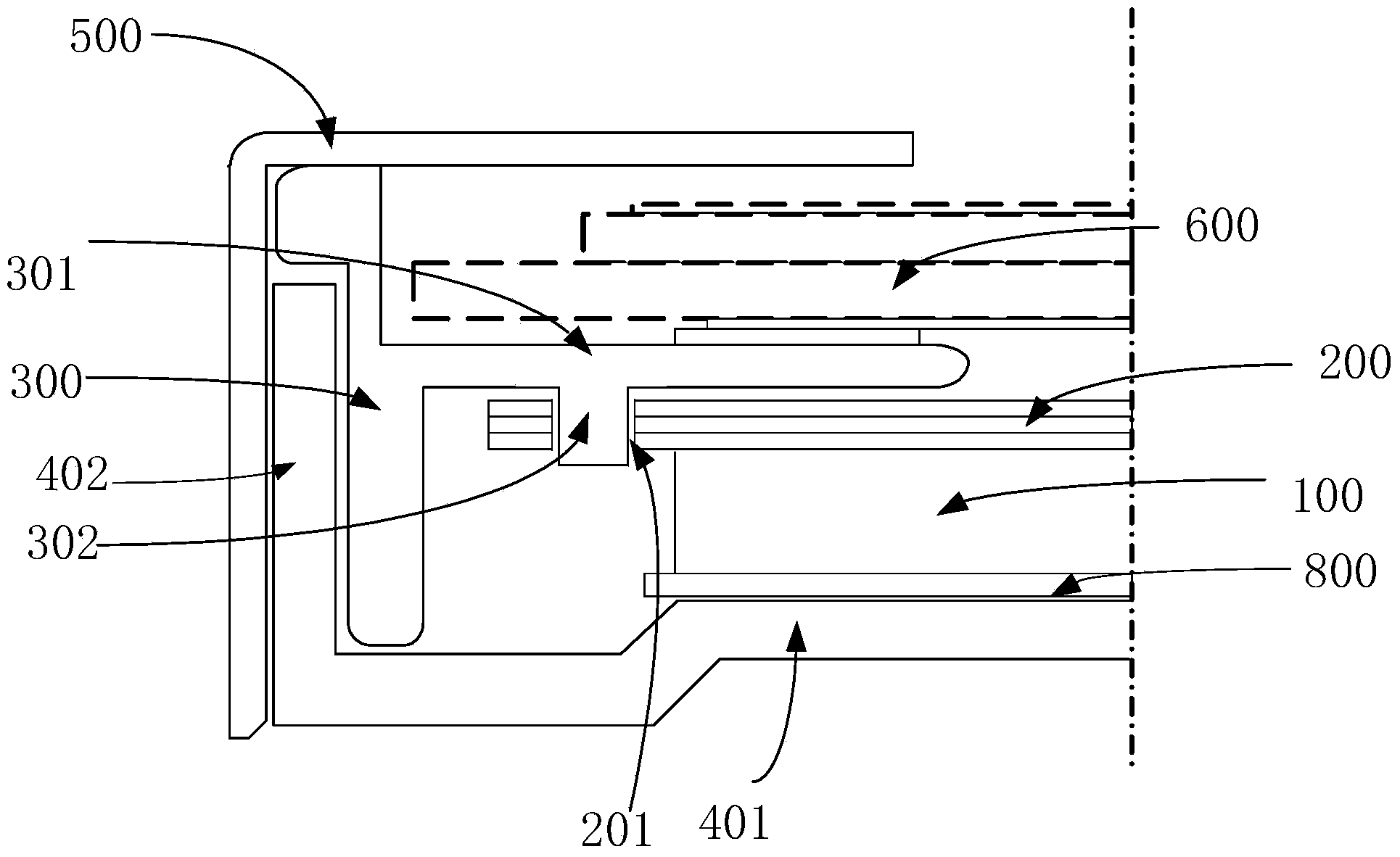

Flexible display substrate, flexible display panel and flexible display device

ActiveCN108598142AReduce widthAchieve narrow bordersSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

The invention provides a flexible display substrate, a flexible display panel and a flexible display device. The flexible display substrate comprises a substrate, wherein the substrate comprises a display region and a non-display region, the non-display region sequentially comprises a bending region, a fan-out region and a binding region along a direction pointing to the non-display region from the display region, namely, a bending region, a fan-out region and a binding region which are included in a frame region of the flexible display substrate provided by the invention, the bending region is arranged among the display region, the fan-out region and the binding region, so that the narrow edge framing process is achieved by bending the bending region, the fan-out region also can be bent to a back surface of a display side of the display substrate by the bending region, the frame region only comprises the bending region and does not comprise the fan-out region, the width of the frame is further reduced compared with the prior art, and the narrow edge framing is further achieved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

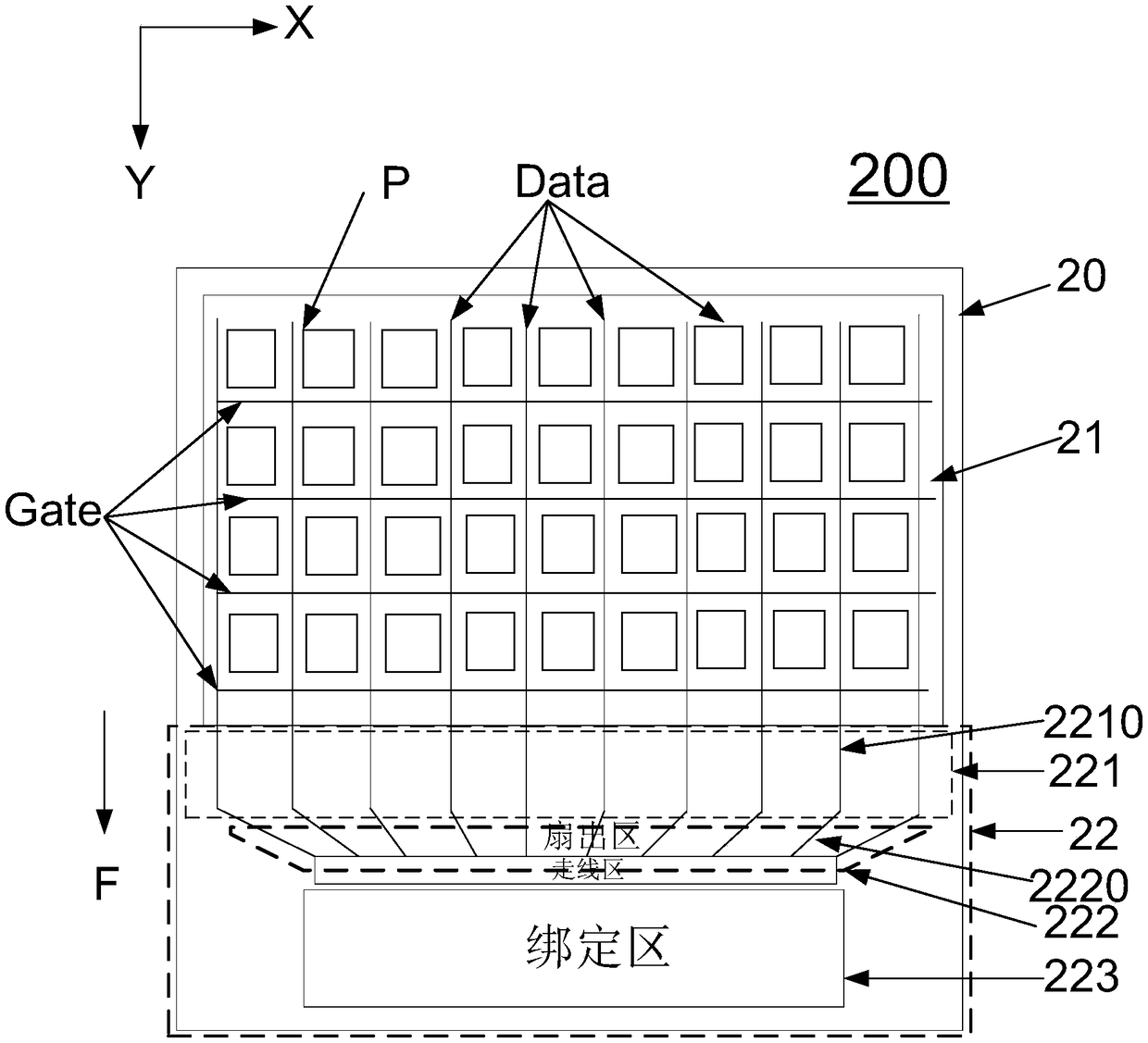

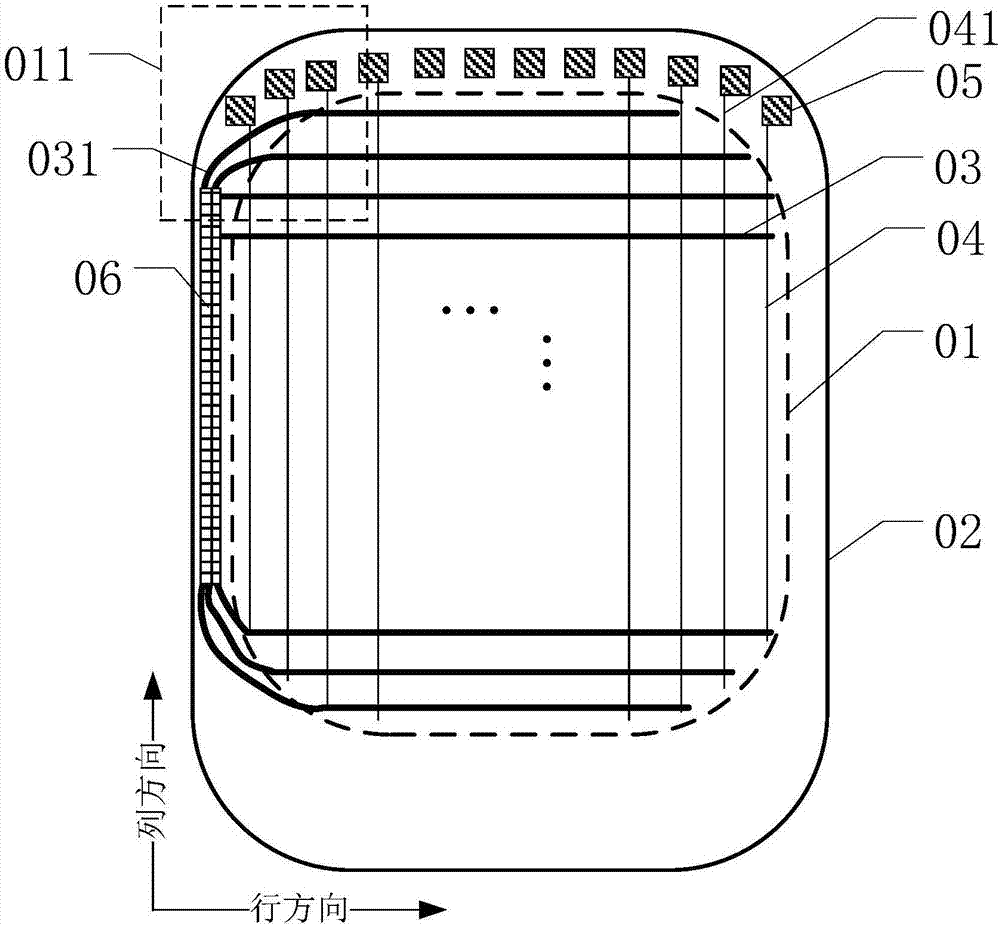

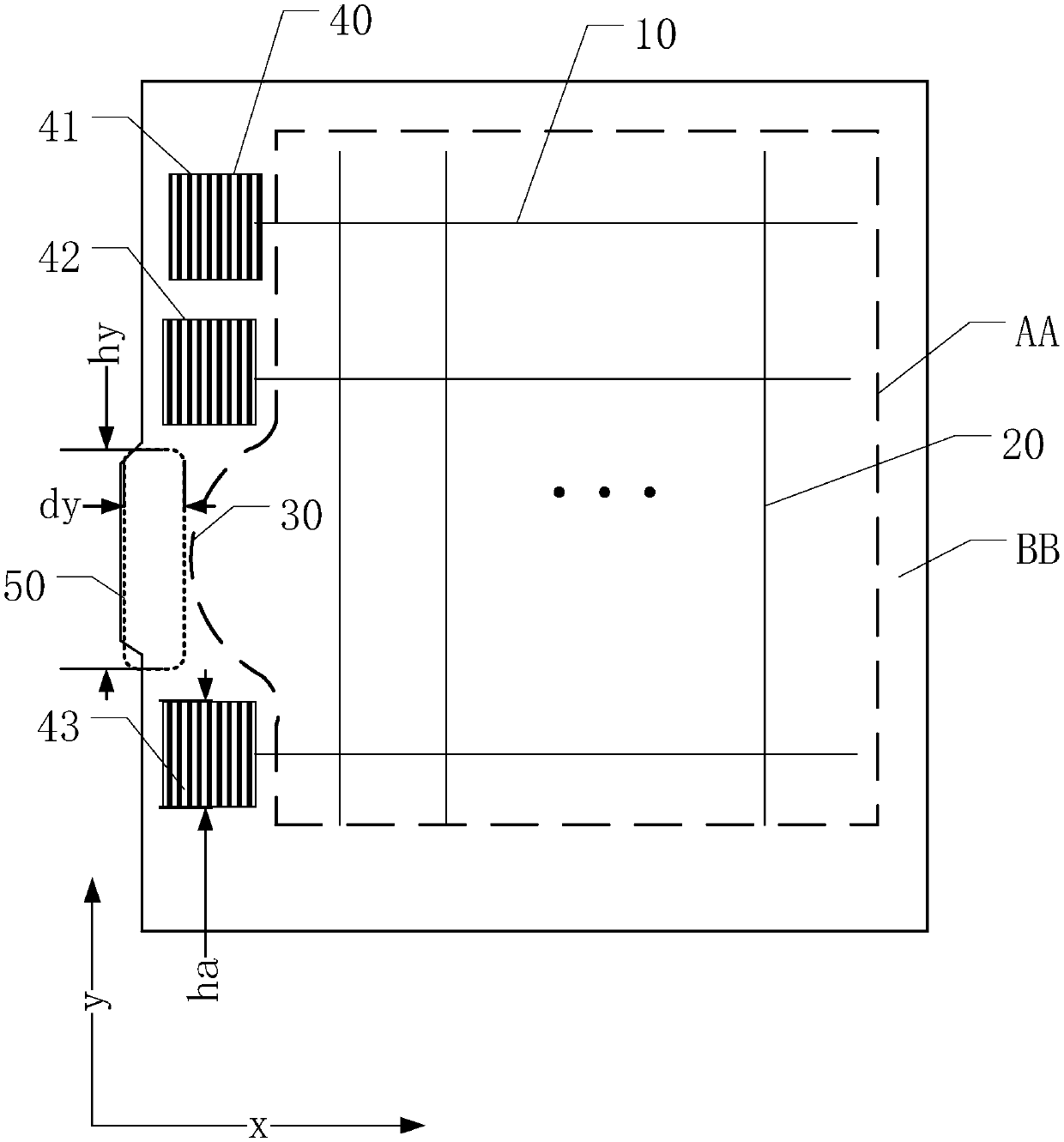

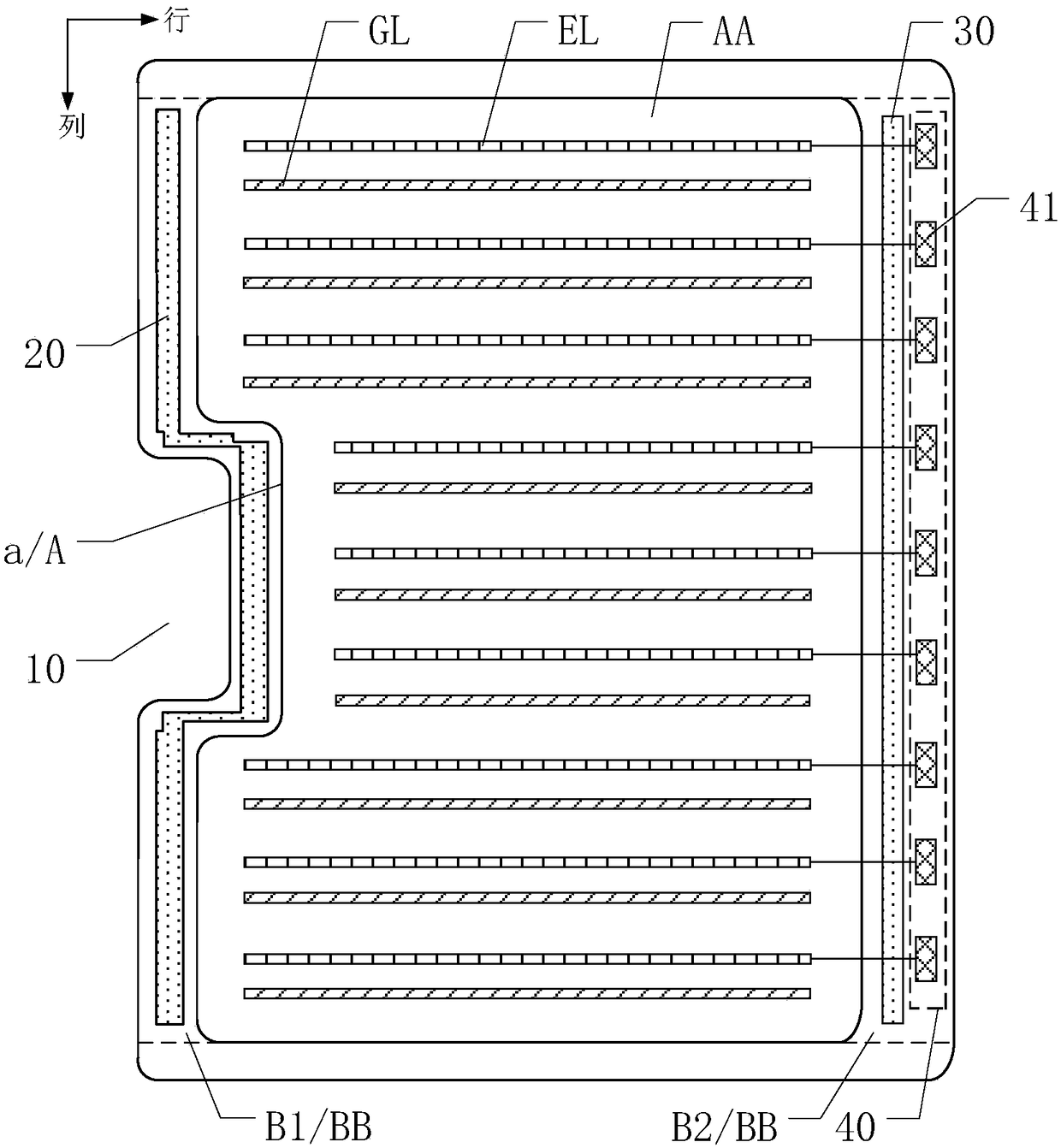

Special-shaped display panel and display device

ActiveCN107331297AAchieve narrow bordersAvoid settingNon-linear opticsIdentification meansElectricitySignal processing circuits

The invention discloses a special-shaped display panel and display device. The display panel includes a display area and a non-display area around the display area, wherein the display area includes a plurality of gate lines which are arranged side by side and extend in the row direction, and a plurality of data lines which are arranged side by side and extend in the column direction; the non-display area includes a binding area, and a signal processing circuit is arranged in the binding area; the non-display area includes a plurality of electrostatic release circuits, and the electrostatic release circuits are electrically connected with the data lines; the display area comprises at least one special-shaped edge angle, and the special-shaped edge angle is a non-right angle, and is arranged on the side edge, away from the binding area, of the display area; the display area also includes a first sub side angle, and the first sub side angle is arranged on the side edge, close to the binding area, of the display area, wherein the electrostatic release circuits are adjacent to the first sub side angle. The special-shaped display panel and display device can achieve narrow border shaping of the special-shaped display panel.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

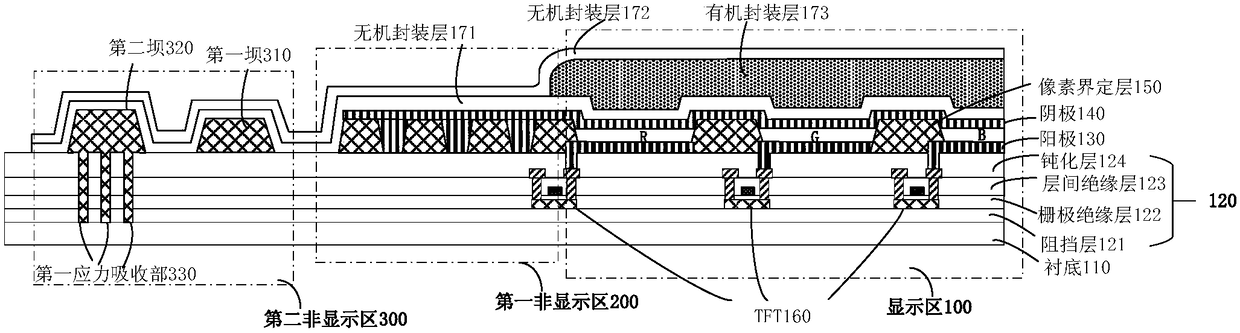

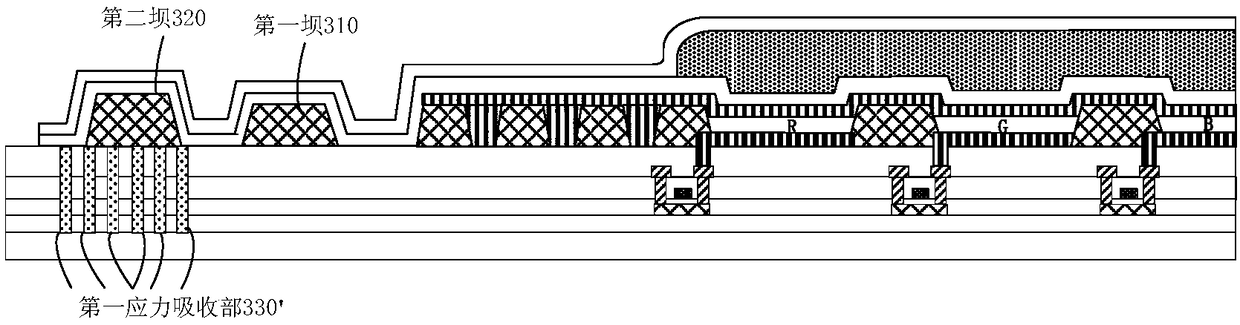

Display substrate, preparation method therefor, and display device

ActiveCN108364987AAvoid it happening againPrevent proliferationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer engineering

The invention relates to a display substrate, a preparation method therefor and a display device. The display substrate comprises a light-emitting part which is located in a display region of the display substrate; one or more dams which are located in a non-display region of the display substrate, wherein the non-display region surrounds the display region; and a first stress absorption part which disposed under at least one dam.

Owner:BOE TECH GRP CO LTD

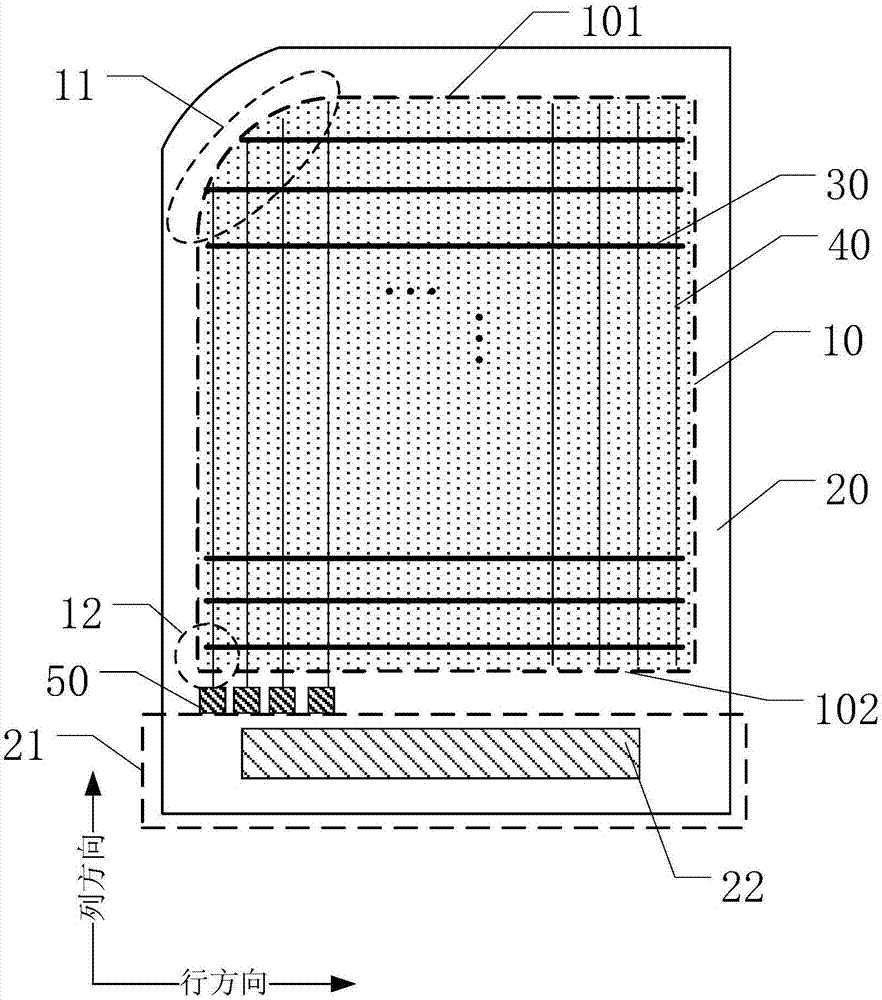

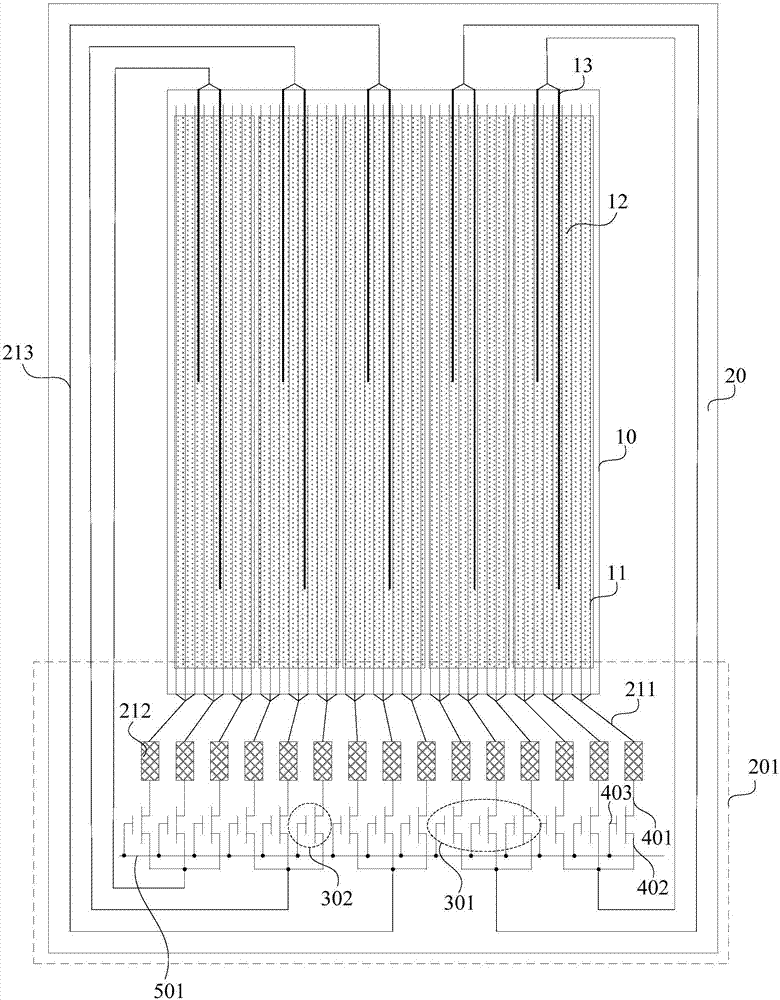

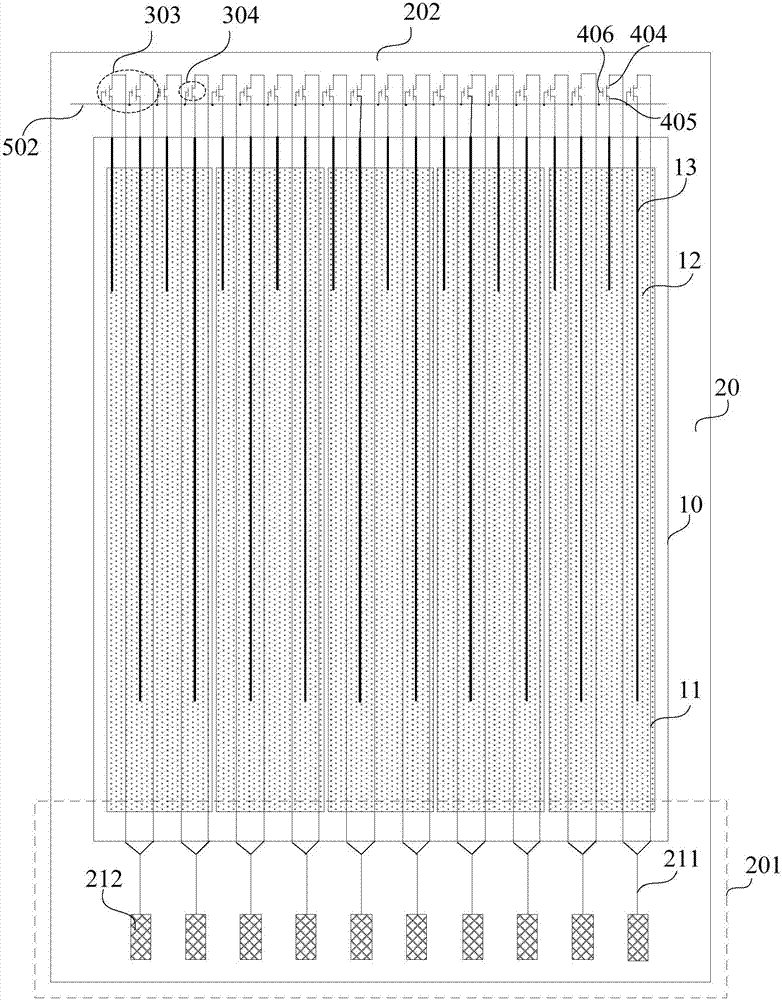

Array substrate, display panel and display device

ActiveCN107154218ARealize time-division multiplexingReduce in quantityStatic indicating devicesSolid-state devicesDisplay deviceData signal

The invention discloses an array substrate, a display panel and a display device. The array substrate comprises a display region and non-display regions arranged around the display region, wherein the display region comprises multiple data wires and multiple first touch electrodes; multiple data signal wires and multiple separate bonding pads are arranged in the first non-display region located on one side of the display region; each data signal wire is connected with at least one data wire; each bonding pad is electrically connected with one data signal wire; at least one bonding pad is electrically connected with one first touch electrode; the bonding pads are used for providing data signals for the data wires in a display stage and providing touch signals for the first touch electrodes in a touch stage. According to the array substrate provided by the invention, the bonding pads can provide corresponding signals in different stages, thus realizing time multiplexing of the bonding pads and reducing the quantity of the bonding pads; furthermore, no other functional circuits are arranged between the bonding disks and the data wires as well as the bonding disks and the touch electrodes, and narrowing of a lower rim of the display device can be realized favorably.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

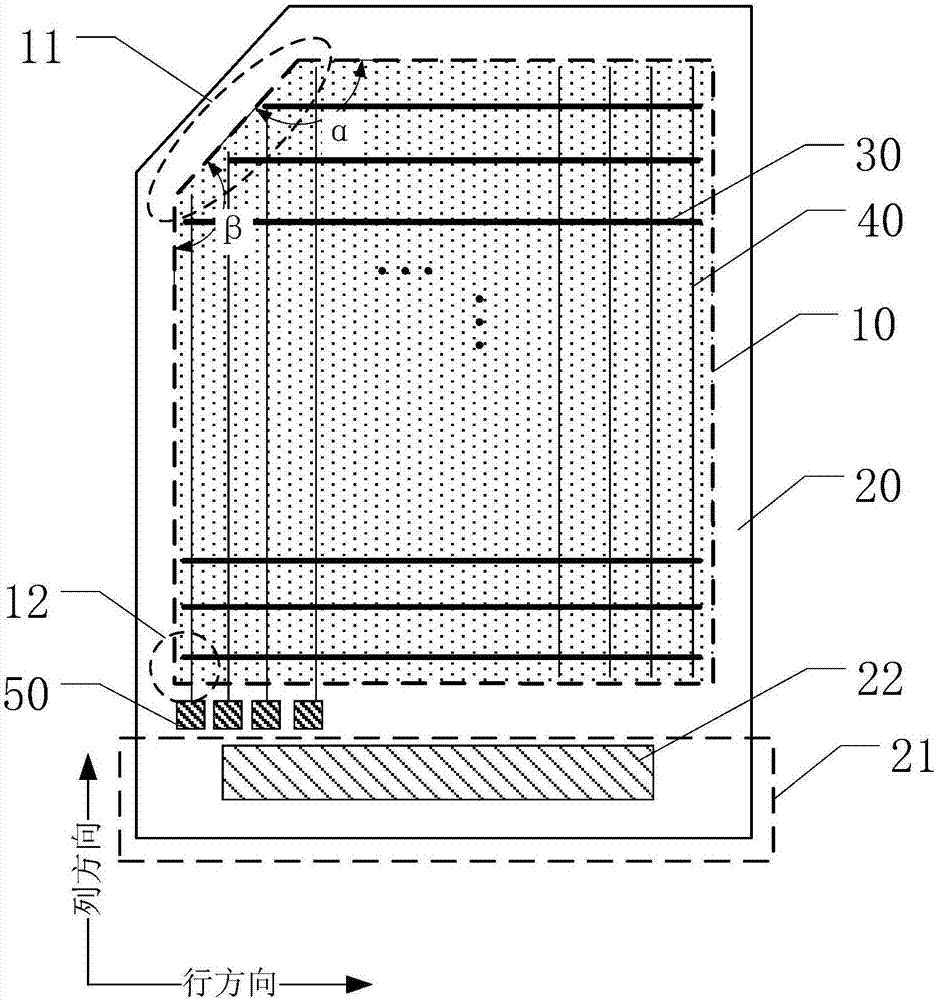

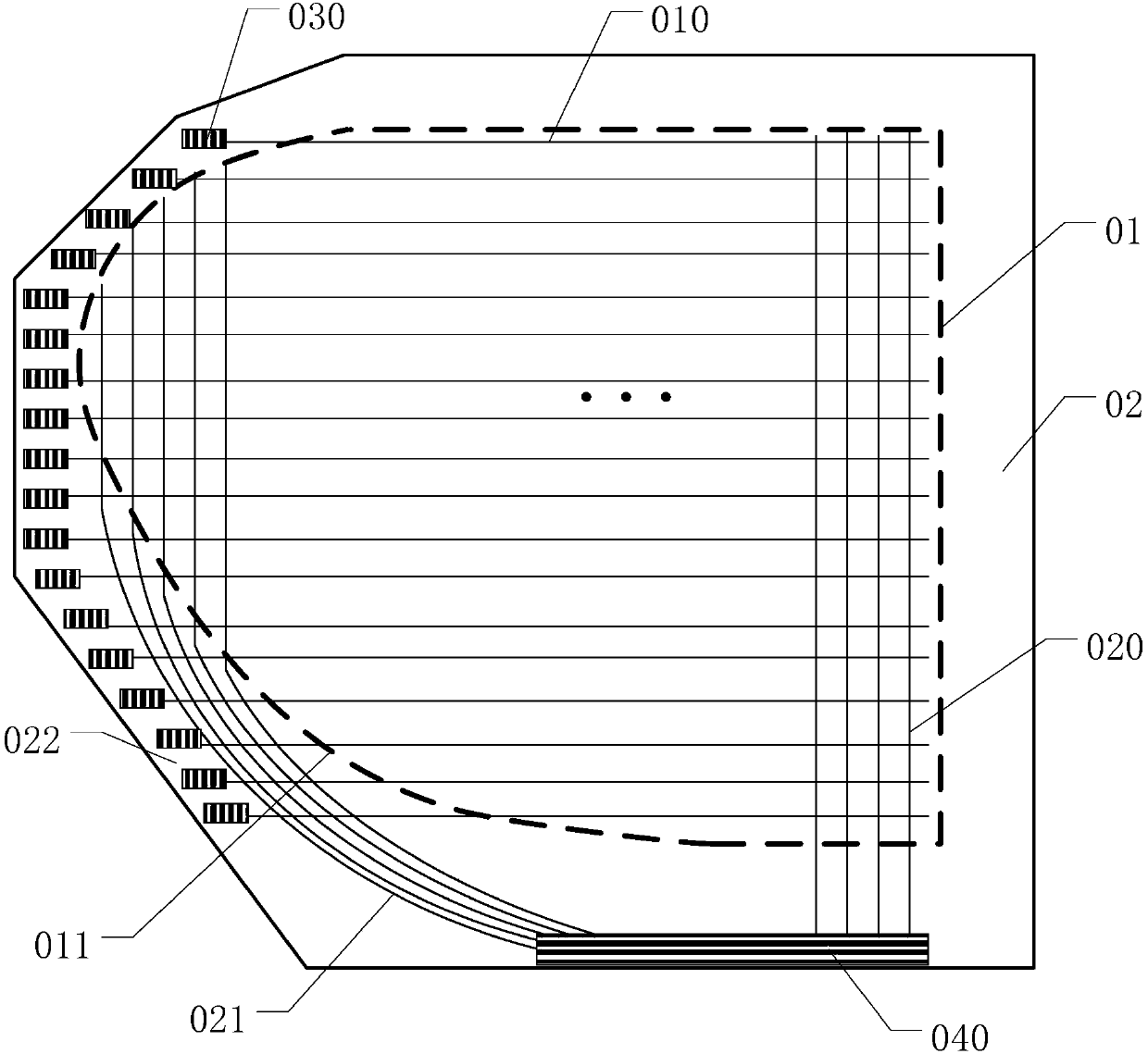

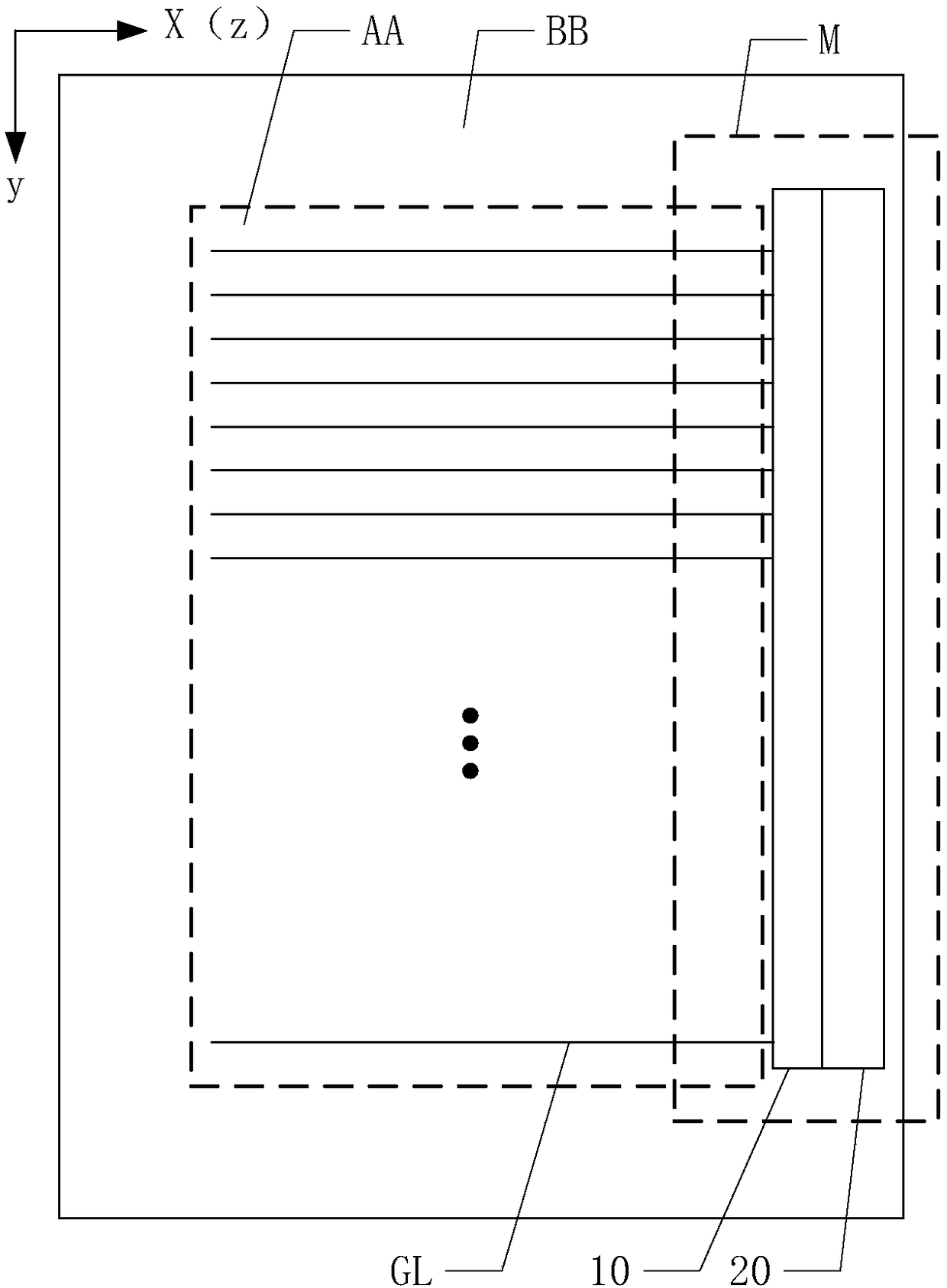

Array substrate, display panel and display device

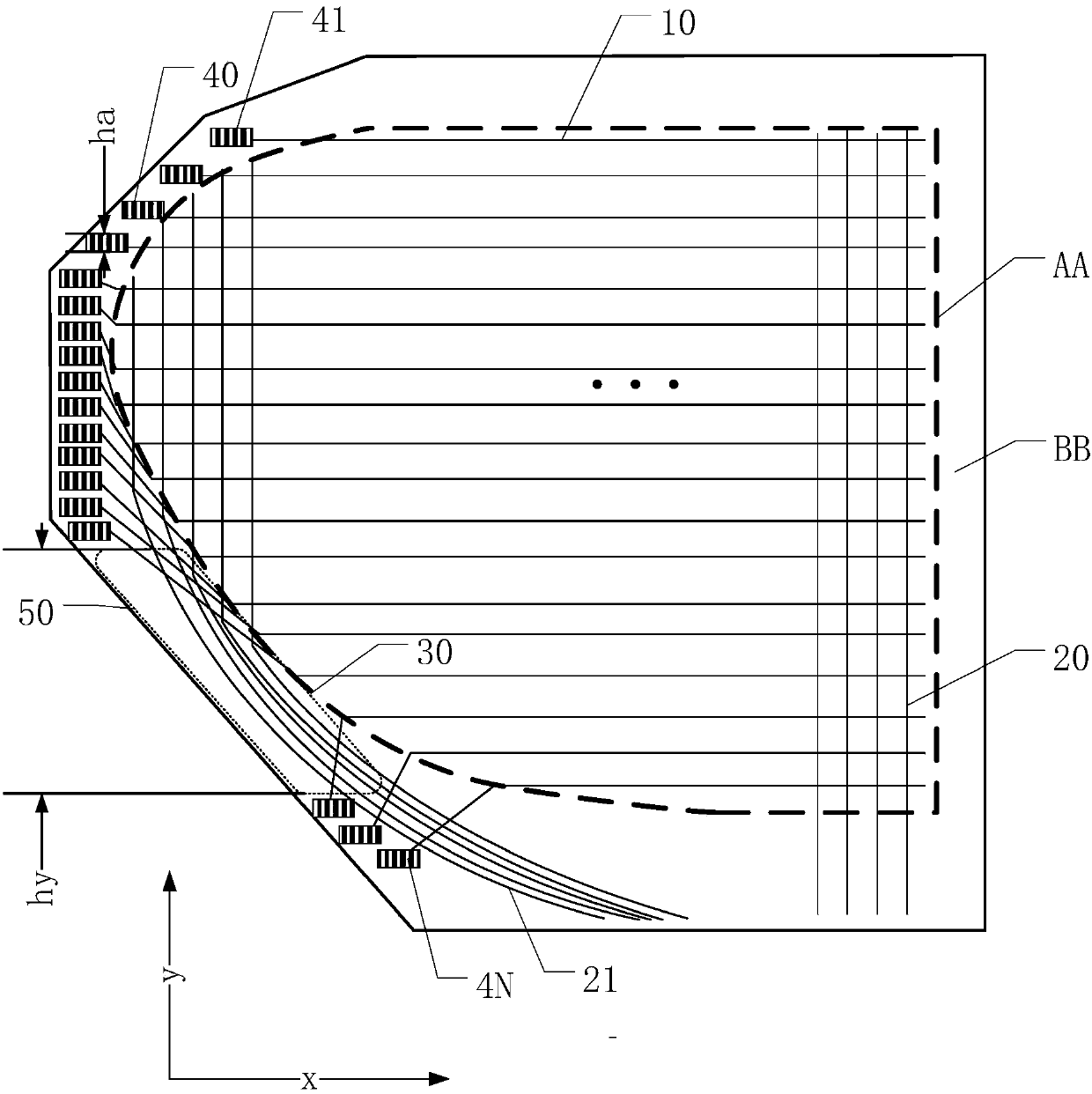

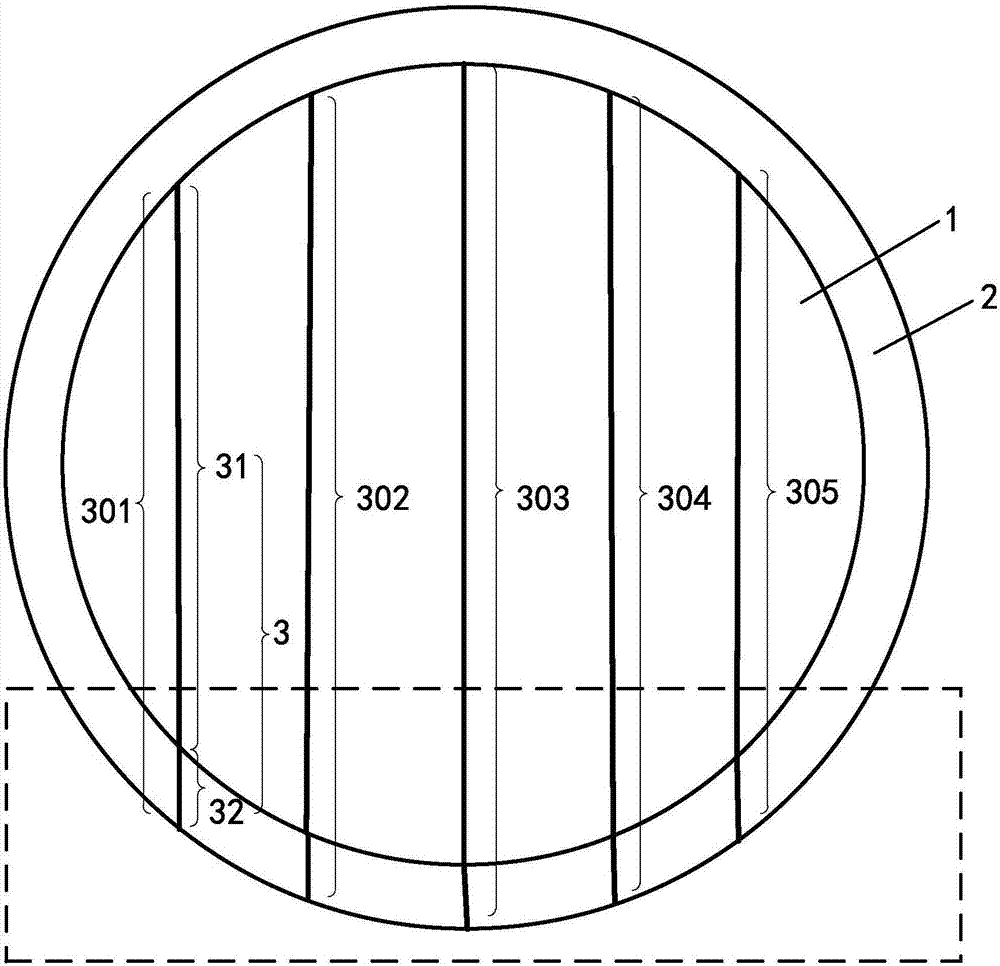

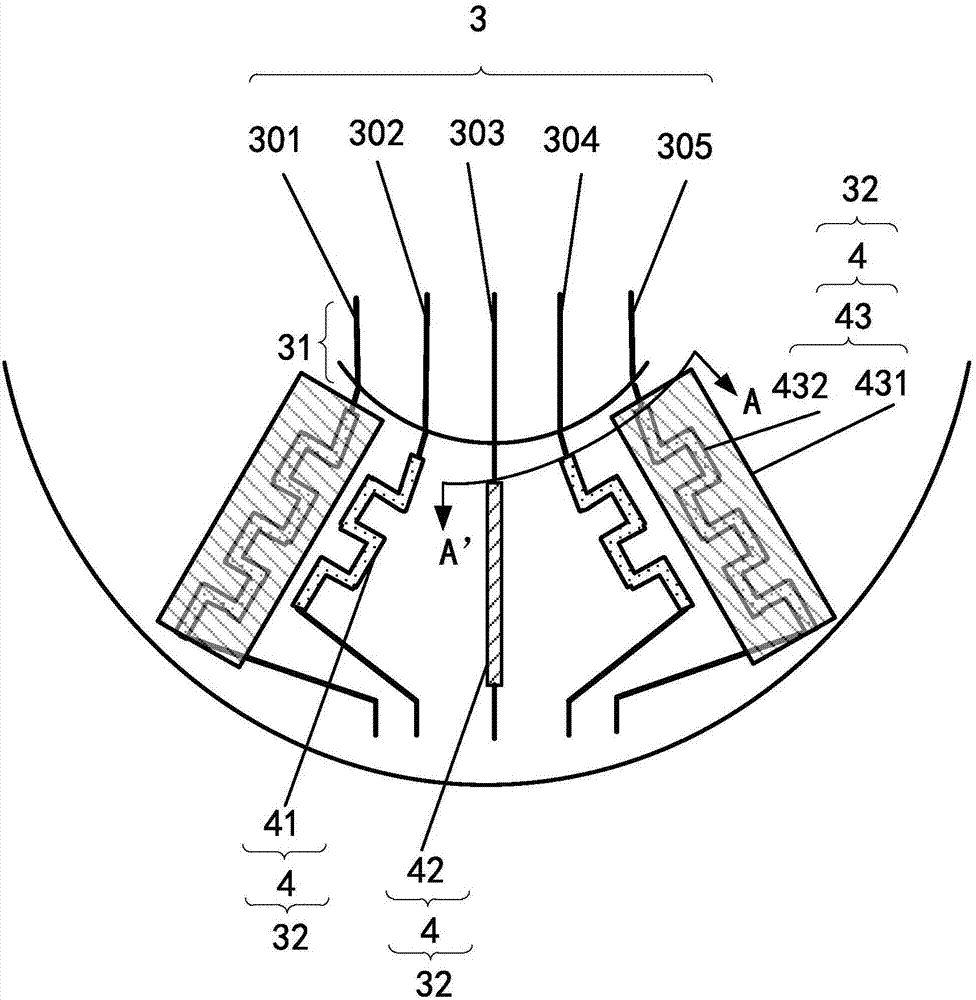

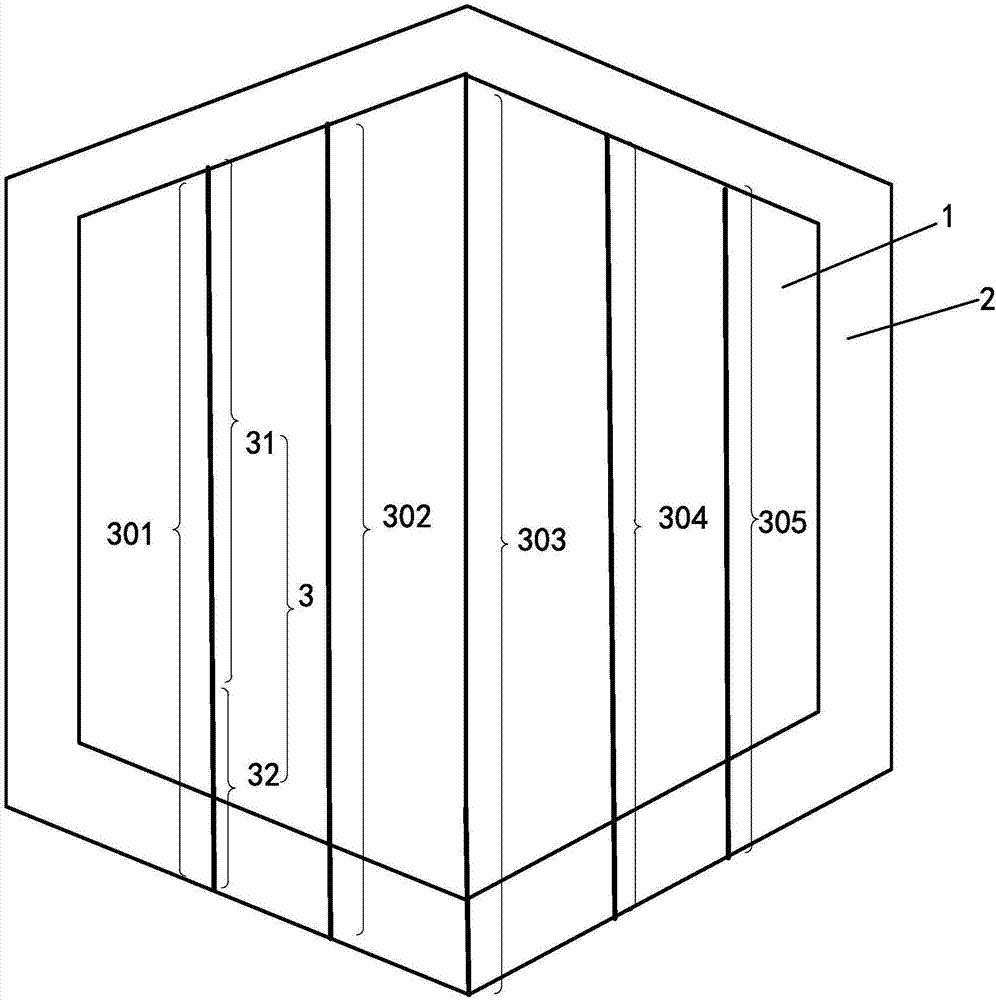

ActiveCN107644614AReduce borderAchieve narrow bordersStatic indicating devicesShift registerDisplay device

The invention discloses an array substrate, a display panel and a display device, which belongs to the technical field of display. A display area and a peripheral non-display area are comprised. The display area comprises a number of gate lines and a number of data lines. The display area comprises at least one special shaped edge. The non-display area comprises a gate driving circuit which comprises an N-stage shift register. The N-stage shift register comprises a first stage shift register to an N-th stage shift register; wherein N is an integer equal to or greater than 3. At least one virtual area exists between the first stage shift register and the N-th stage shift register. The virtual area is adjacent to the special shaped edge. No shift register is arranged in the virtual area. Thelength of the virtual area of the second direction is hy. The length of the shift register along the second direction is ha. hy is greater than 2ha. Compared with the prior art, the array substrate,the display panel and the display device have the advantages that the border of the array substrate can be reduced and the border of the array substrate can be narrow.

Owner:SHANGHAI AVIC OPTOELECTRONICS

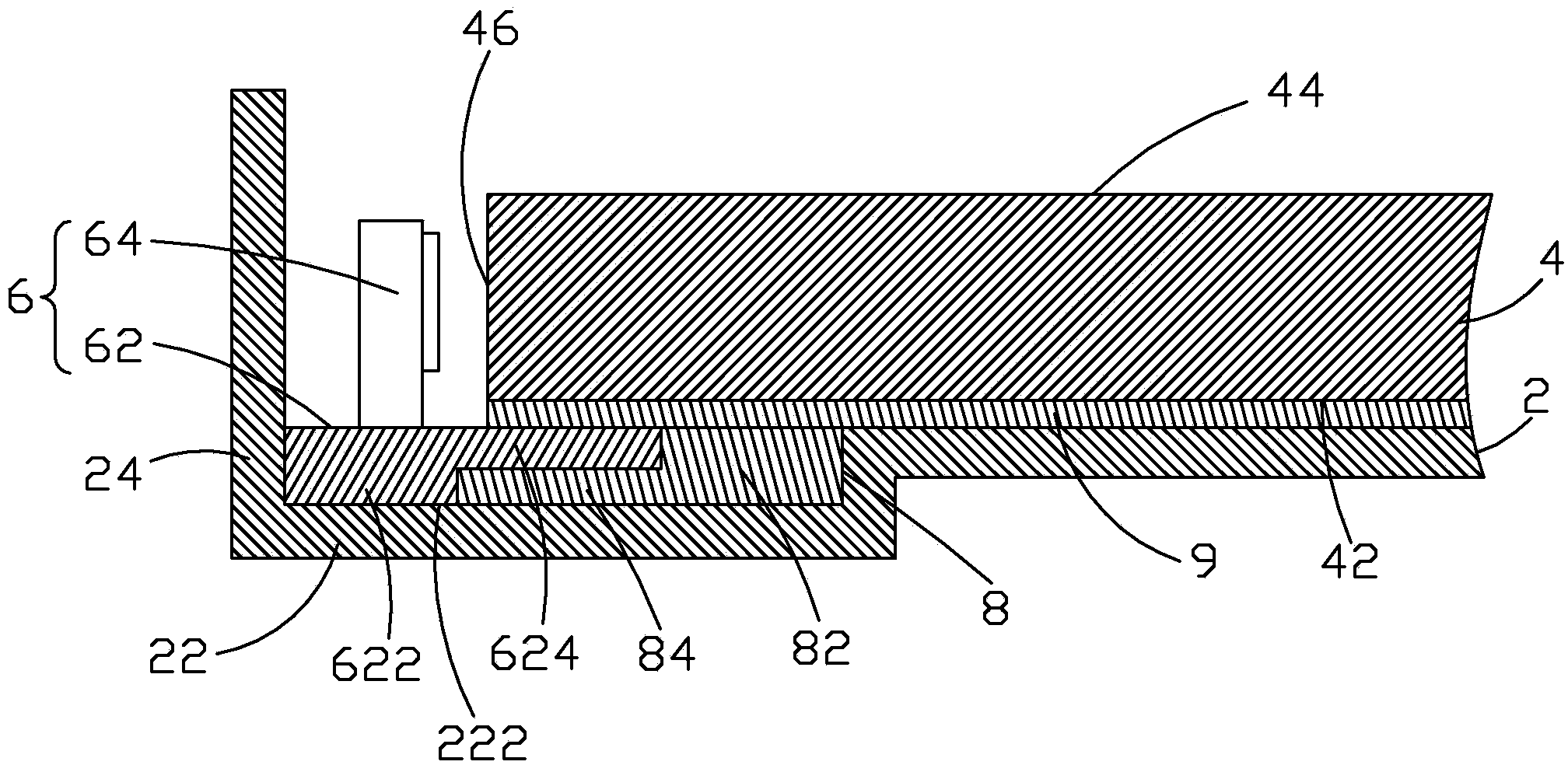

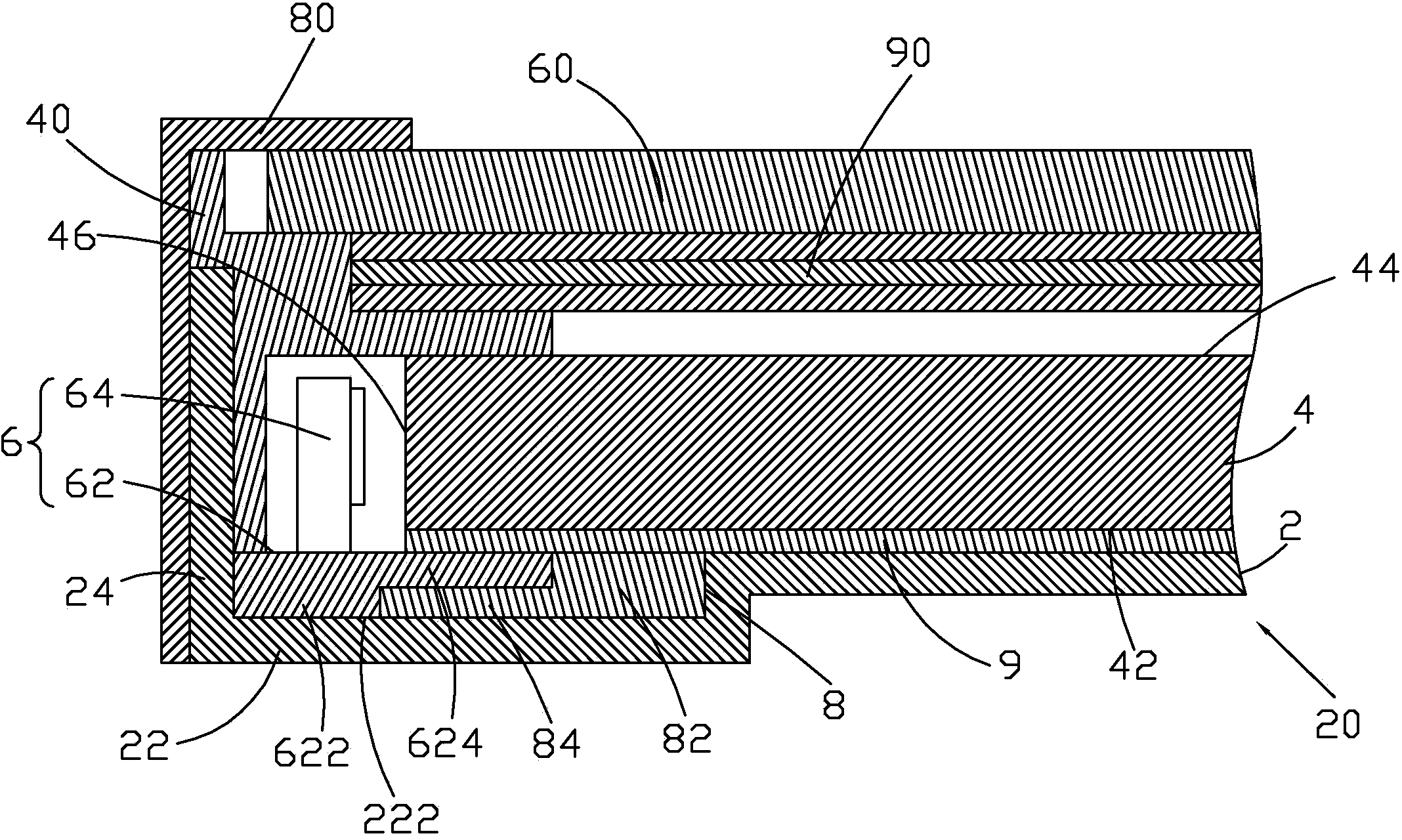

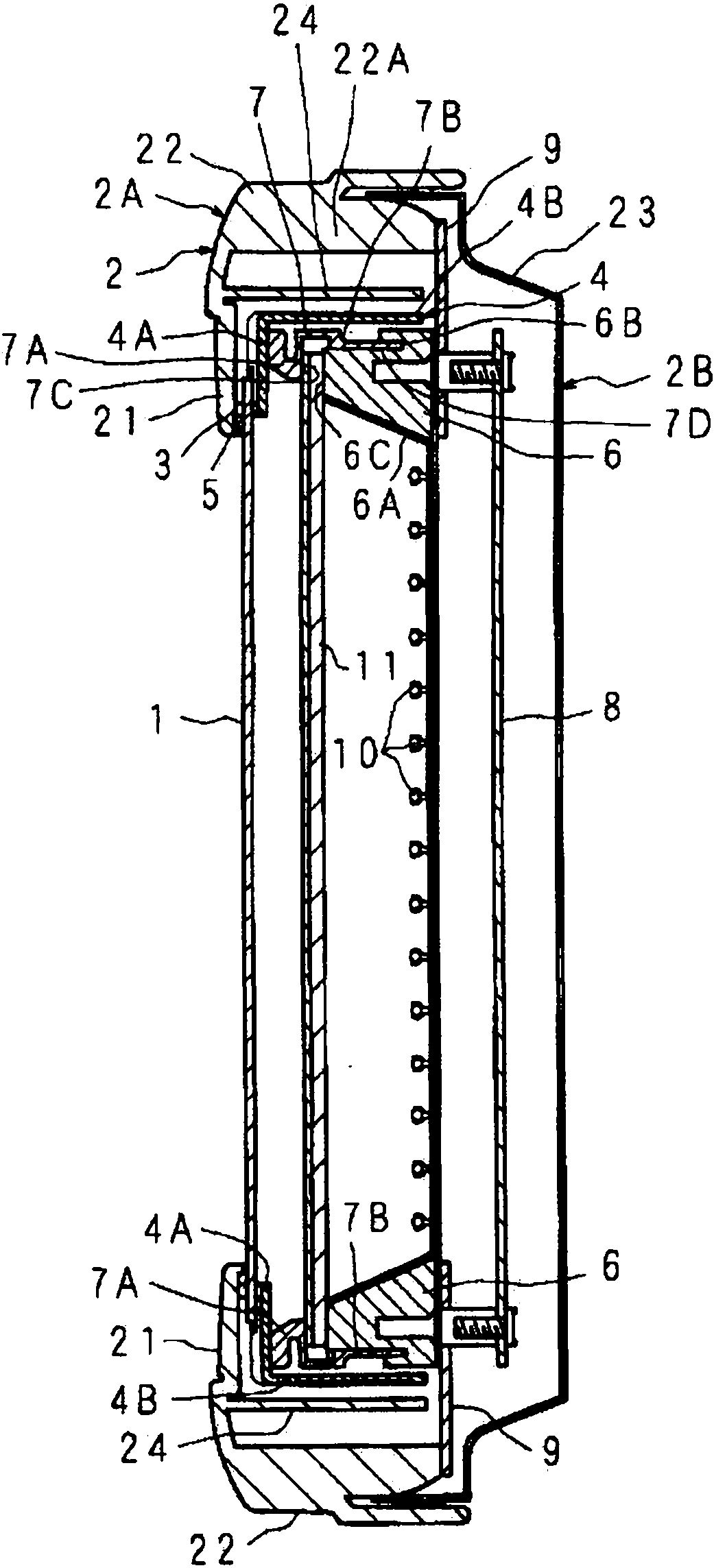

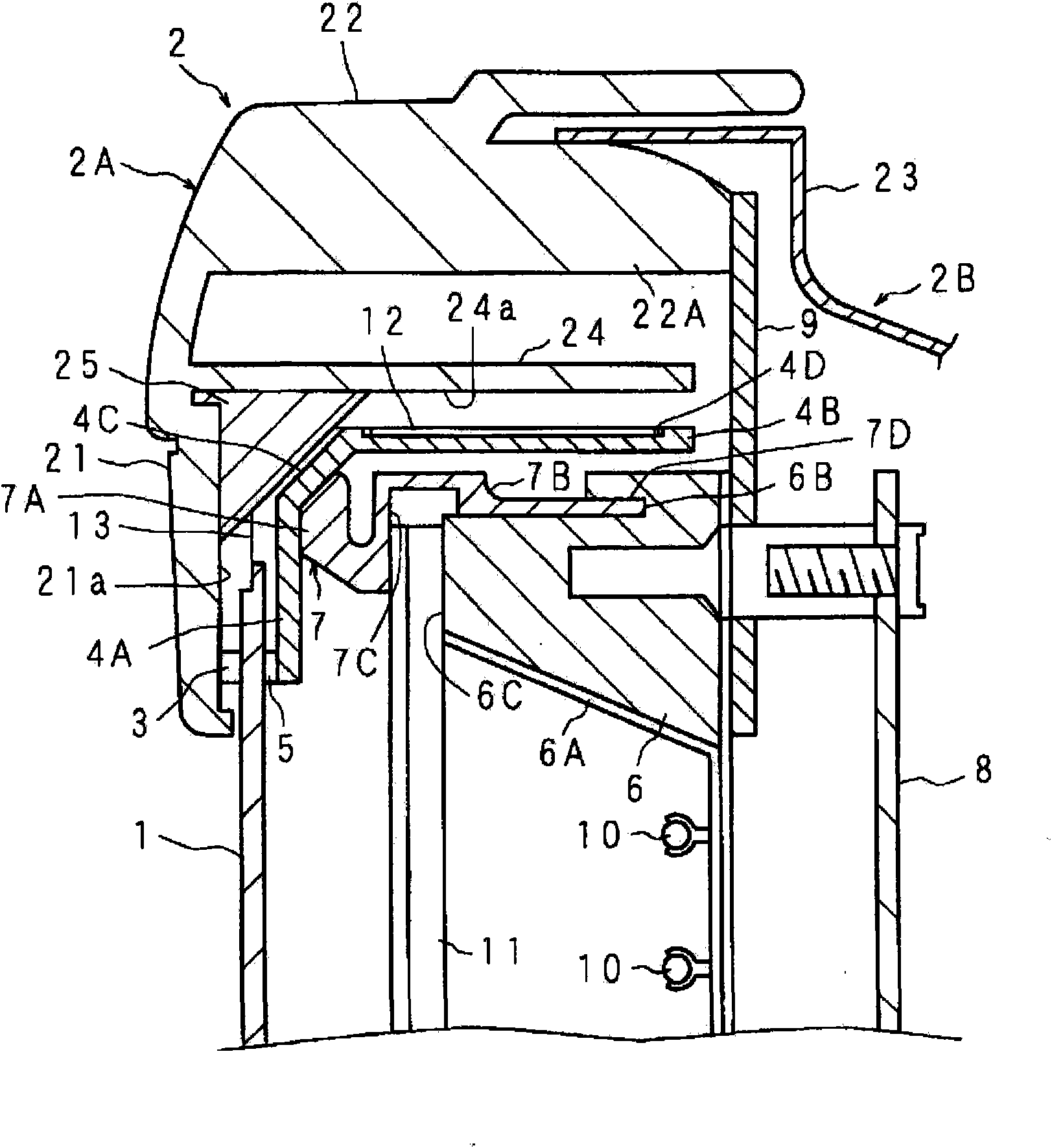

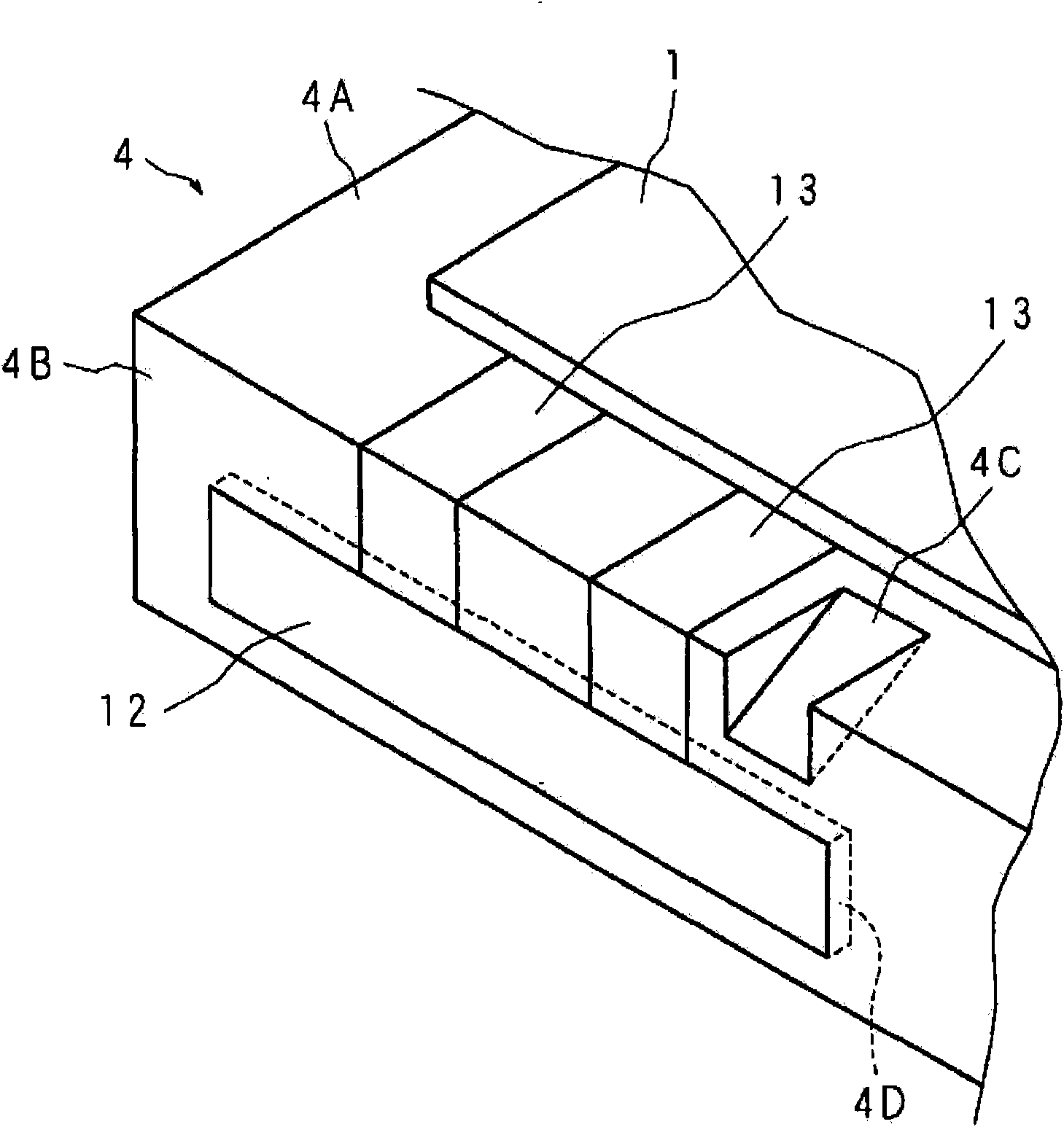

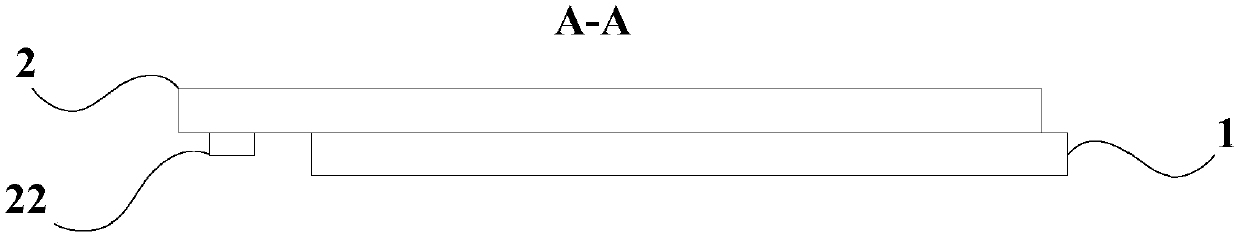

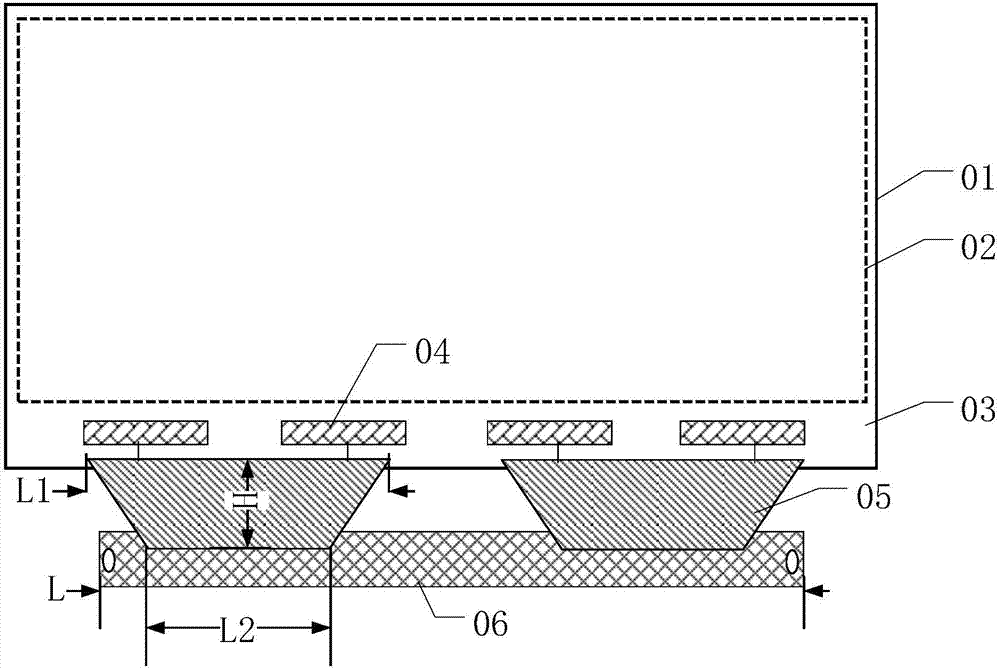

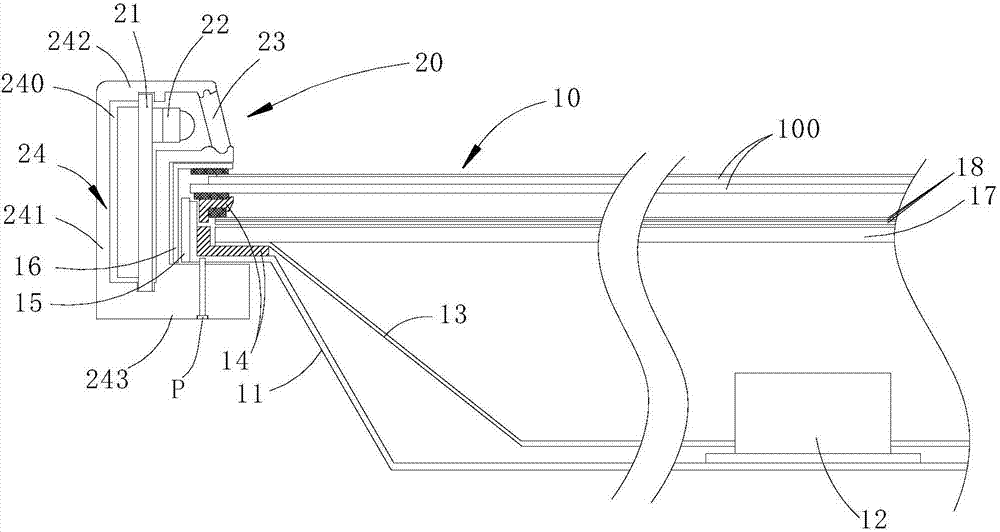

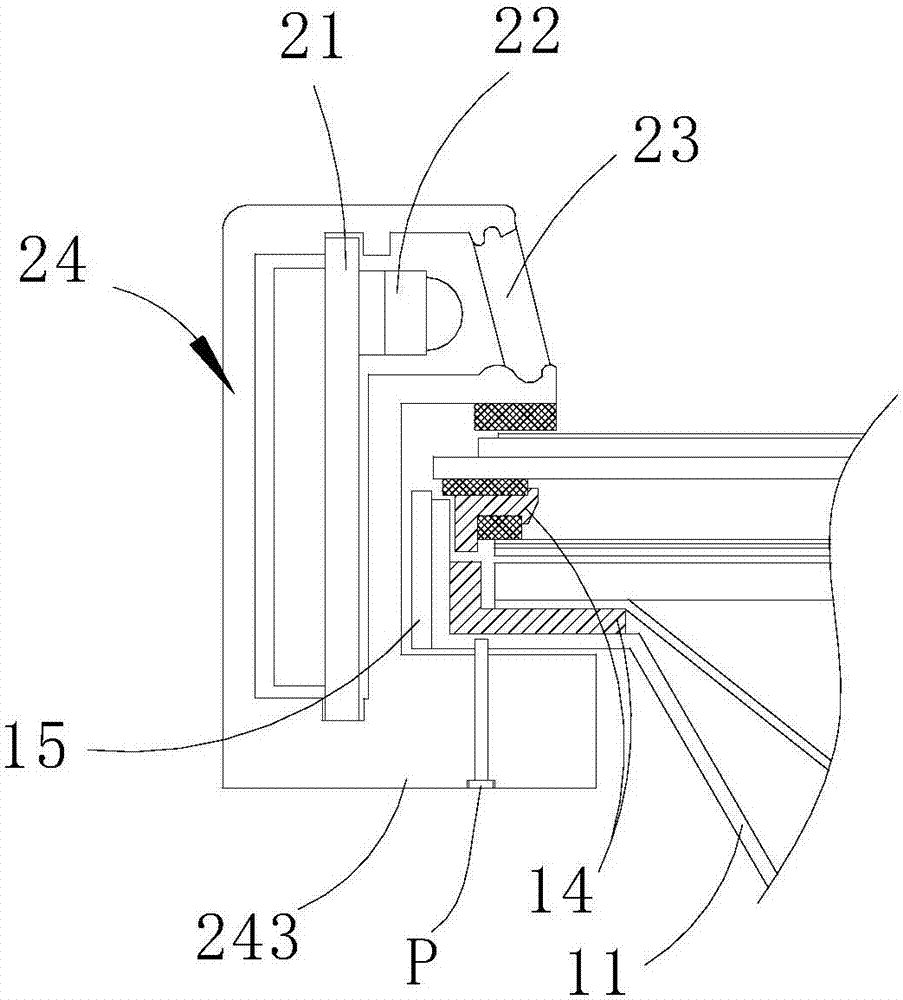

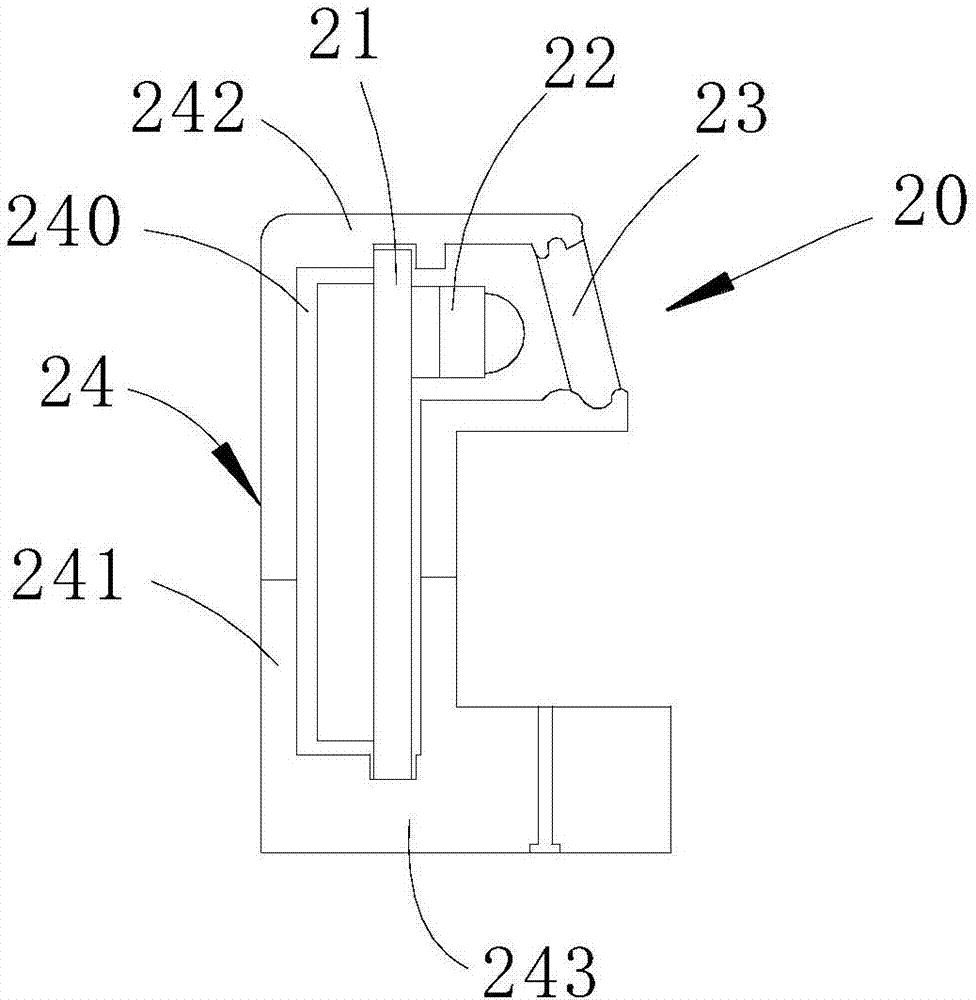

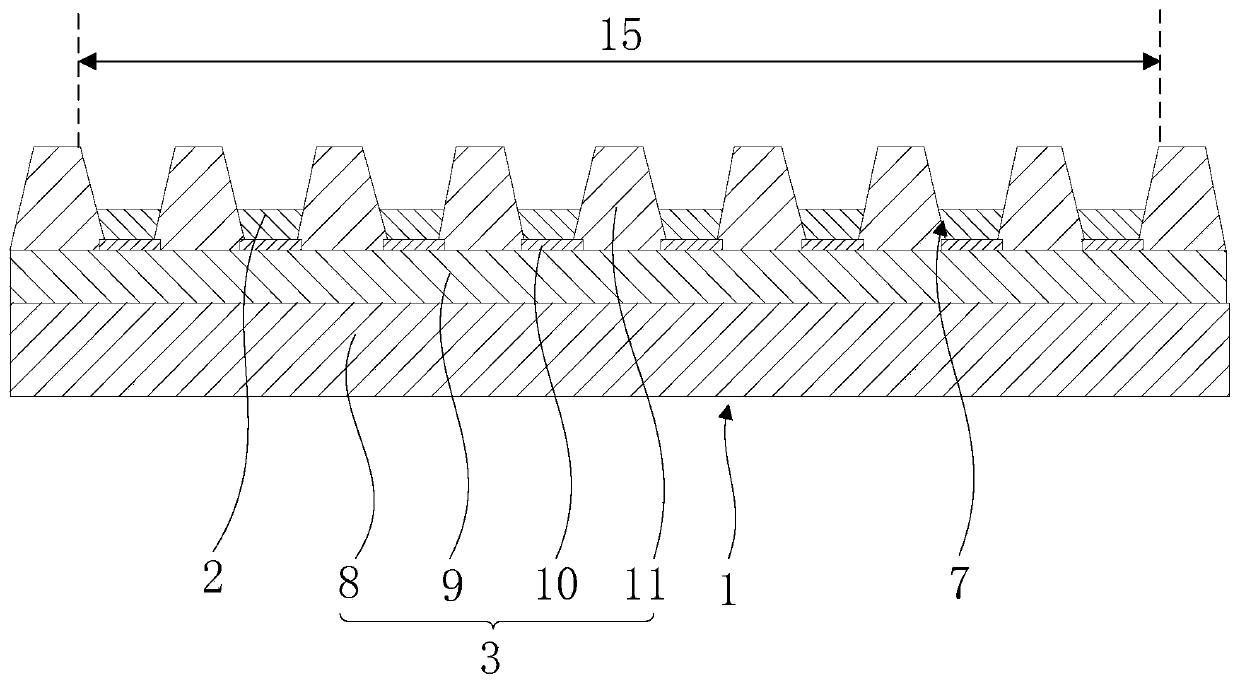

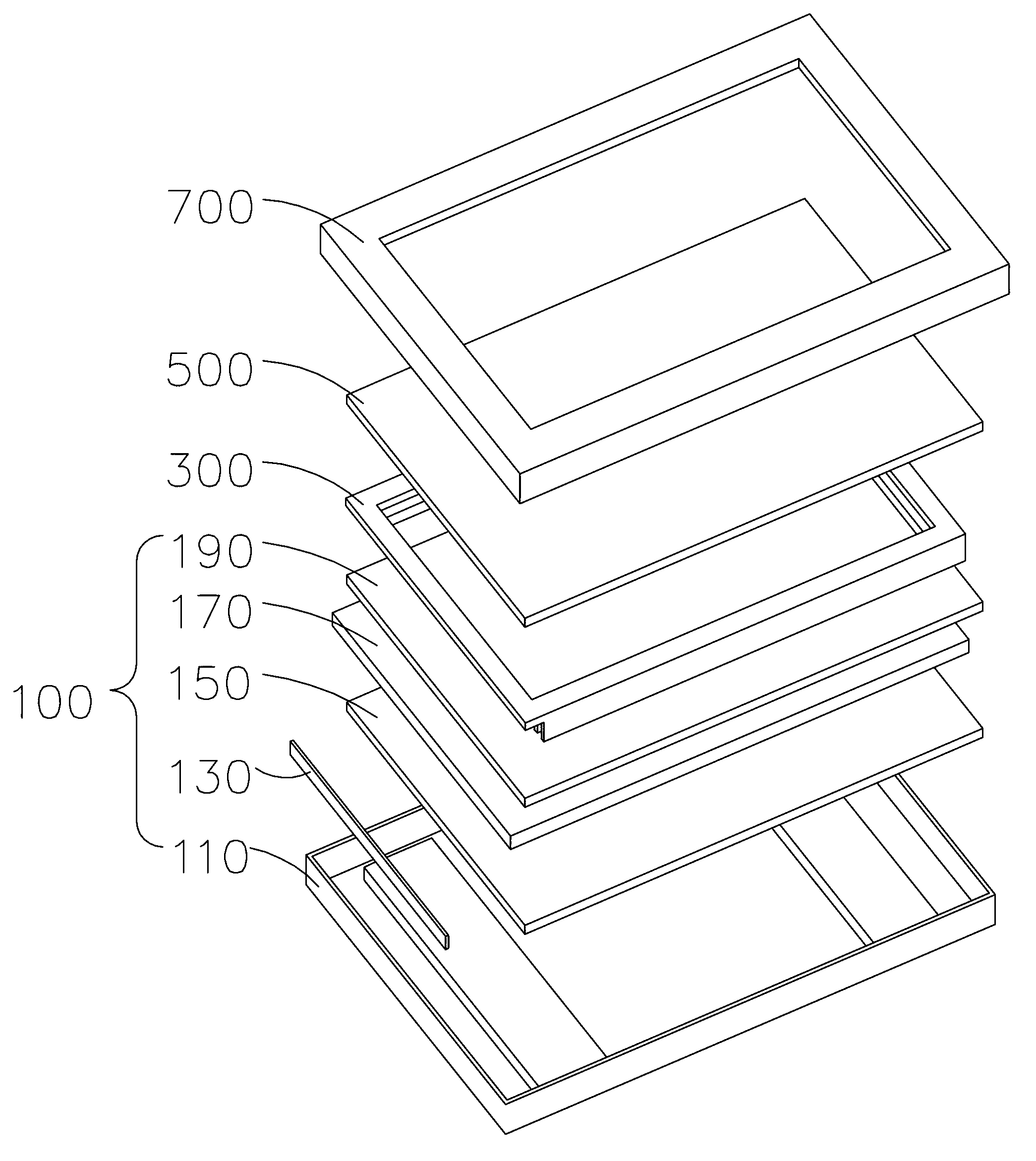

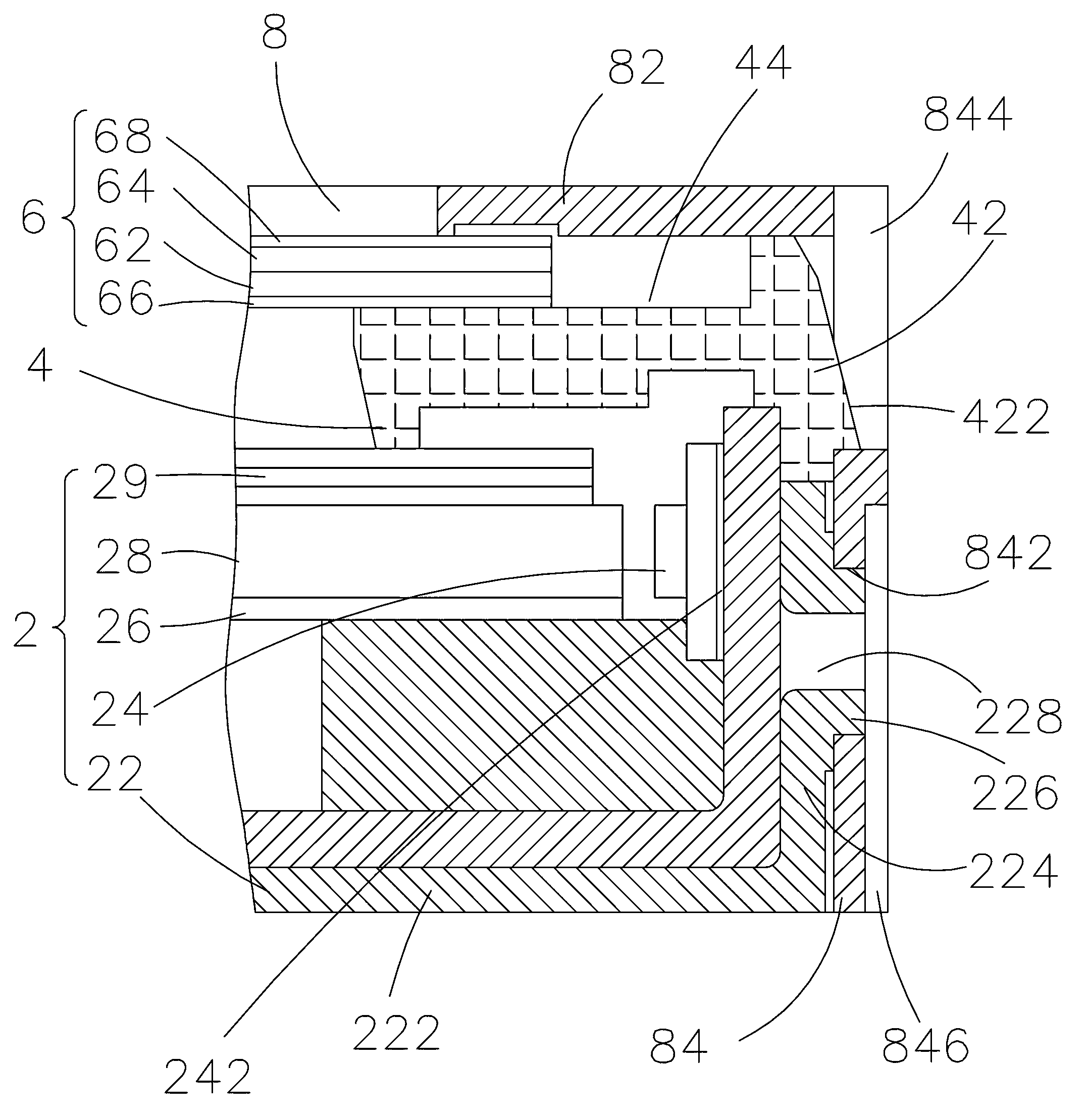

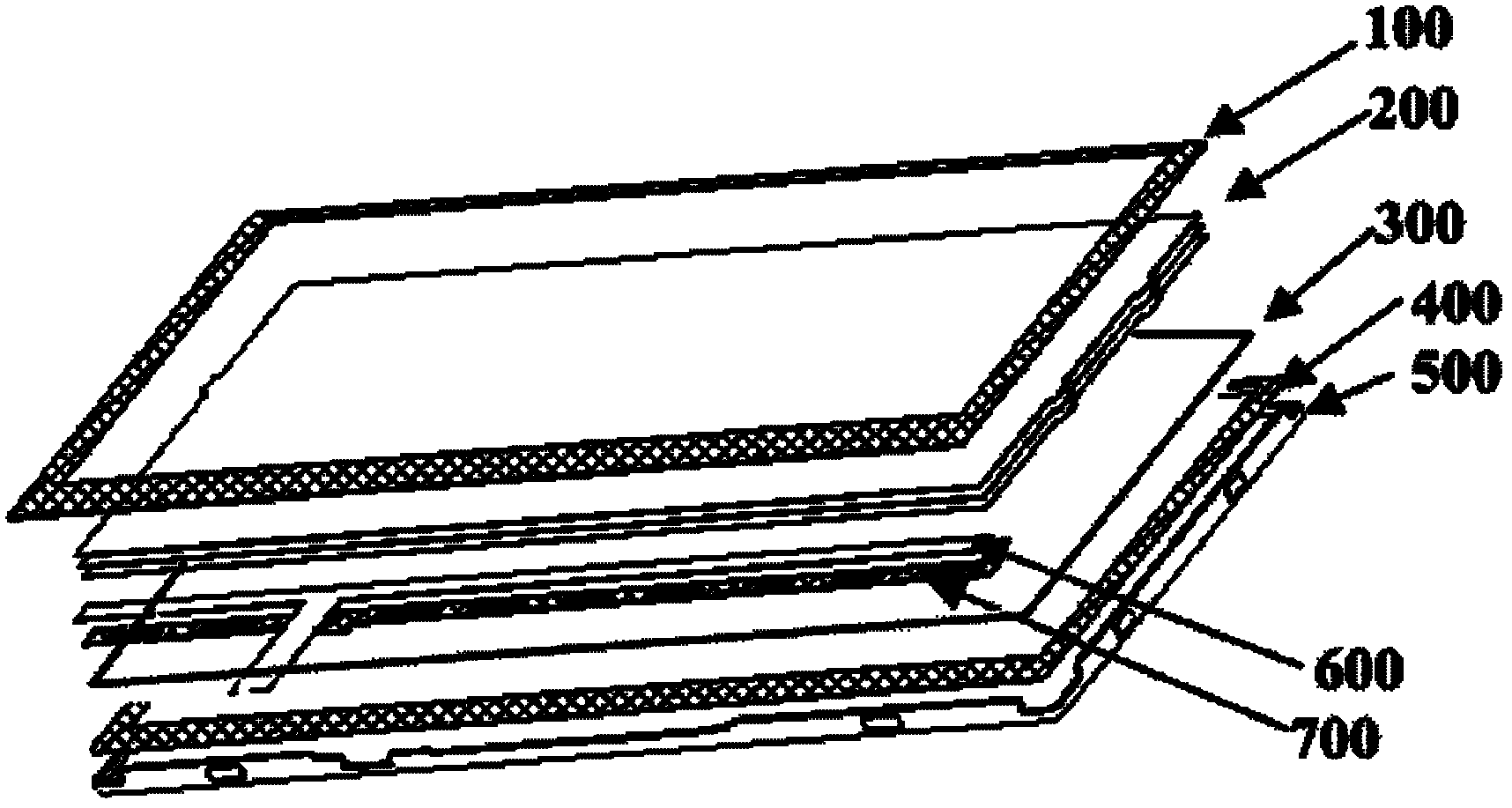

Backlight module and liquid crystal display device with same

ActiveCN103727467AReduce thicknessAchieve narrow bordersPoint-like light sourcePlanar/plate-like light guidesLiquid-crystal displayLight guide

The invention provides a backlight module and a liquid crystal display device with the backlight module. The backlight module comprises a back plate (2), a light guide plate (4) arranged in the back plate (2), a backlight source (6) arranged in the back plate (2), and a heat dissipation plate (8) arranged between the backlight source (6) and the back plate (2). The back plate (2) comprises a bottom plate (22) and side plates (24) perpendicularly connected with the bottom plate (22). The backlight source (6) comprises a PCB (62) and an LED chip (64) for positioning pieces on the PCB (62), wherein the PCB (62) is installed on the bottom plate (22) of the back plate (2) and the heat dissipation plate (8). The PCB (62) comprises an installation portion (622) and a lap joint portion (624) connected with the installation portion (622). The heat dissipation plate (8) comprises a supporting portion (82) and a bearing portion (84) connected with the supporting portion (82). The lap joint portion (624) is connected to the bearing portion (84) in a lap joint mode. The light guide plate (4) is borne by the supporting portion (82) and the lap joint portion (624).

Owner:CHANGSHA HKC OPTOELECTRONICS CO LTD

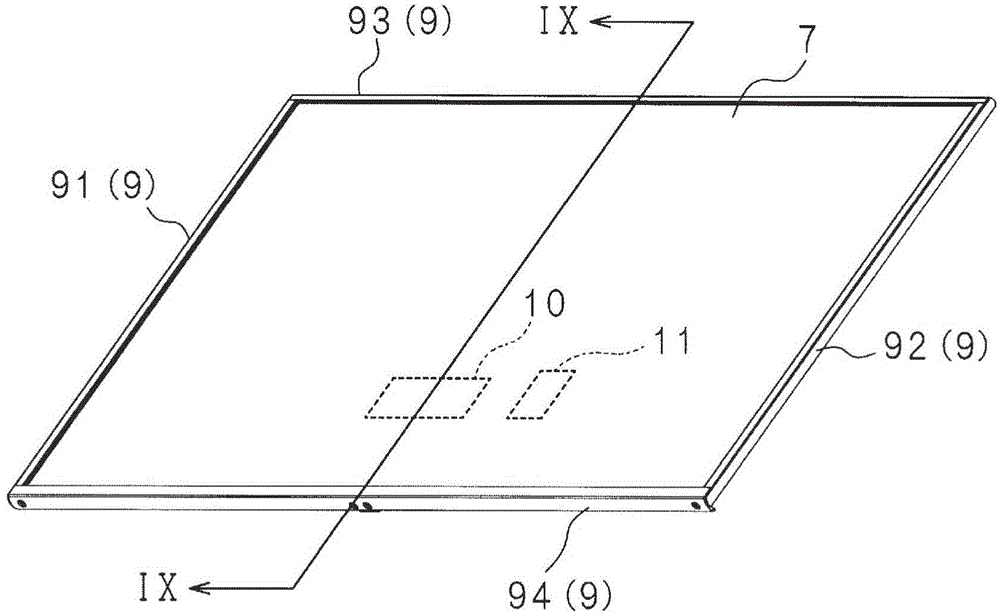

Display device

InactiveCN101842826AImprove rigidityImprove retentionNon-linear opticsIdentification meansDisplay deviceMechanical engineering

Owner:SHARP KK

Touch display panel and display device

InactiveCN107765919AAchieve narrow bordersLess squeezeInput/output processes for data processingDisplay deviceHuman–computer interaction

The invention relates to the field of display technology, and discloses a touch display panel and a display device for realizing frame narrowing of the touch display panel, and improving quality of the display device. The touch display panel includes an array baseplate and a touch baseplate disposed on one side of the array baseplate. The array baseplate includes a first substrate baseplate and adisplay function layer disposed on one side of the first substrate baseplate and close to the touch baseplate. A first side of the array baseplate is provided with a first gap. The touch baseplate includes a second substrate baseplate and touch electrodes, touch wires and a touch binding terminal disposed on the second substrate baseplate. Orthographic projection of the touch binding terminal on the first substrate baseplate is located in the first gap.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Display panel, display panel crack detection method and display device

ActiveCN109142447AGuaranteed display effectAchieve narrow bordersStatic indicating devicesMaterial analysis by electric/magnetic meansElectricityControl signal

The invention discloses a display panel, a display panel crack detection method and a display device. The display panel comprises a display area and a non-display area around the display area, and thenon-display area comprises a gate drive circuit and a crack detection circuit. The crack detection circuit comprises at least one detection unit. Each detection unit comprises an input signal line, an output signal line, multiple control signal lines extending along a third direction and a plurality of detection subunits distributed along a second direction. Each detection subunit comprises a control end, an input end and an output end, a control end of each detection subunit is electrically connected with one control signal line, each input end is electrically connected with the corresponding input signal line, and each output end is electrically connected with the corresponding output signal line. Compared with the prior art, the display panel, the display panel crack detection method and the display device have advantages that when input signals are provided for the detection subunits, positions of cracks in the non-display area can be determined according to acquired output signals of the output signal lines, and accordingly detection efficiency is improved while the crack detection rate is increased.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

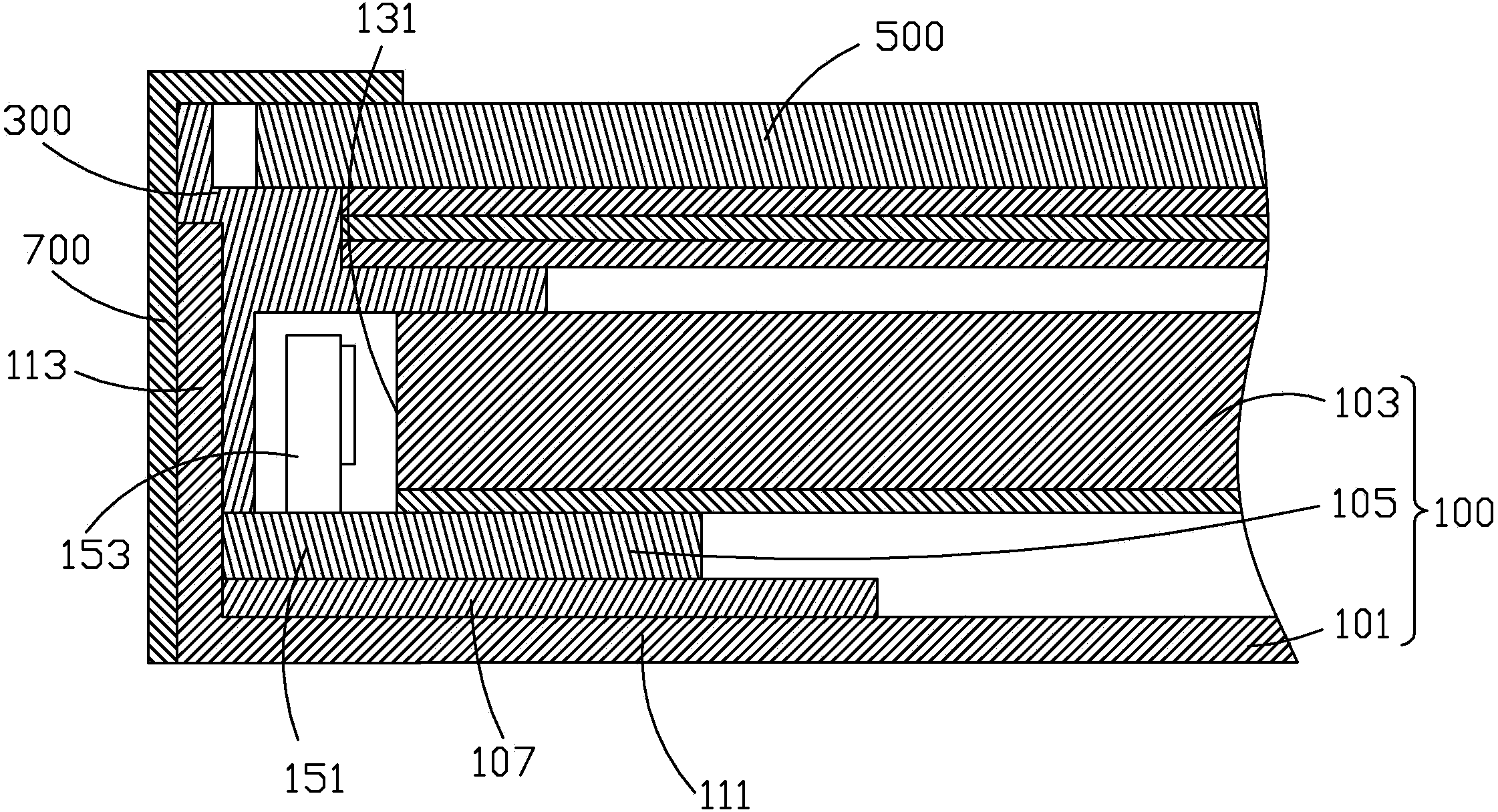

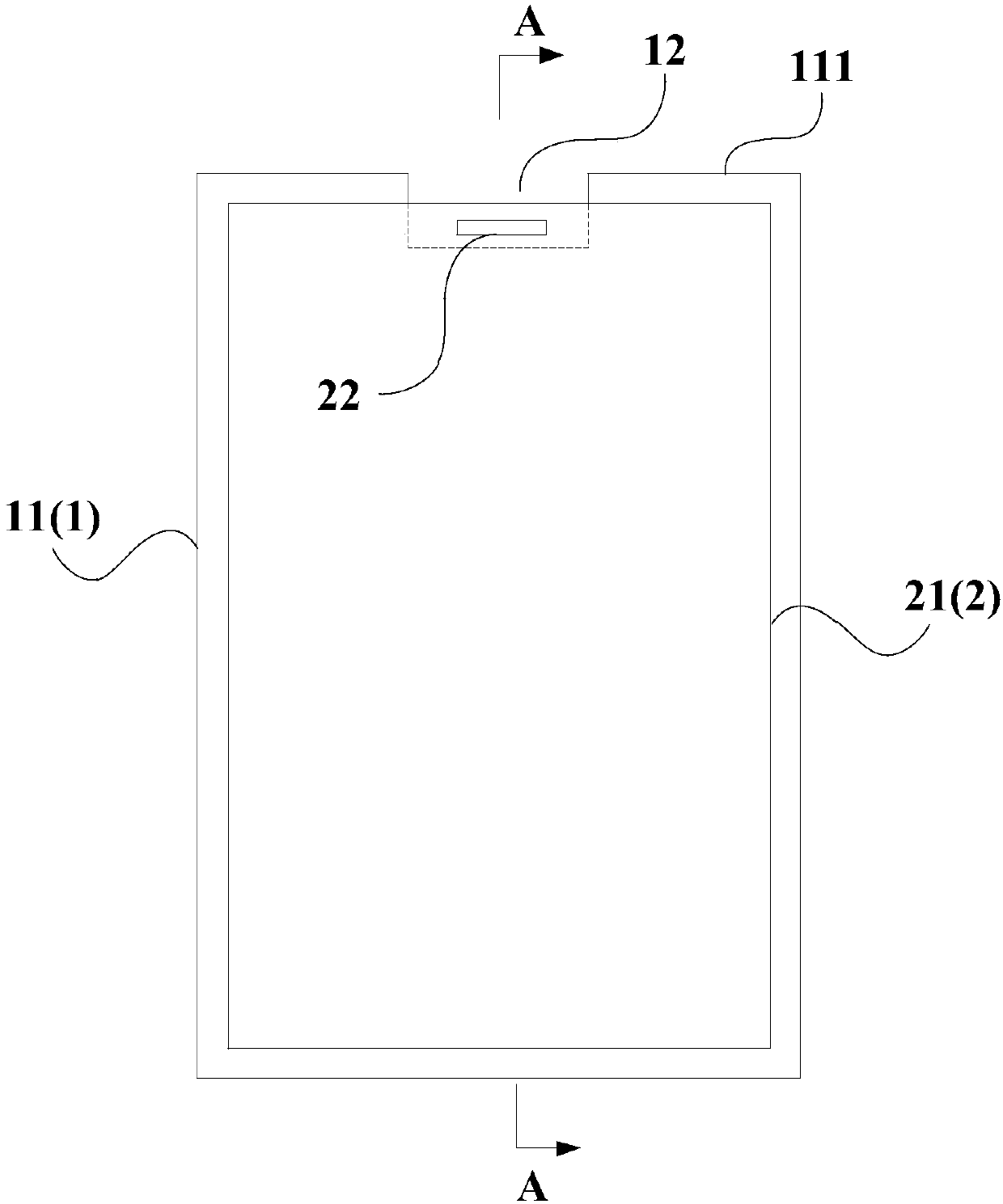

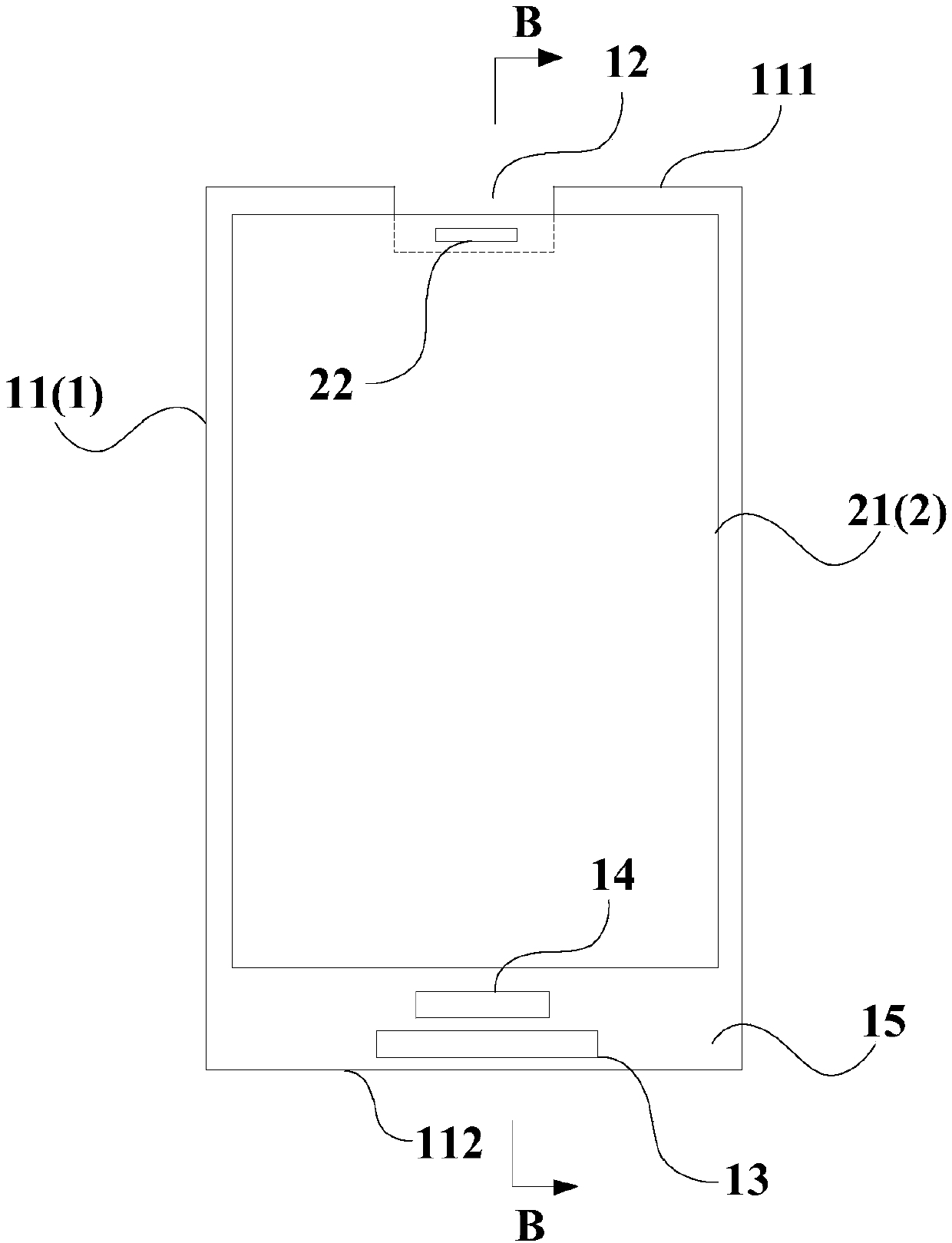

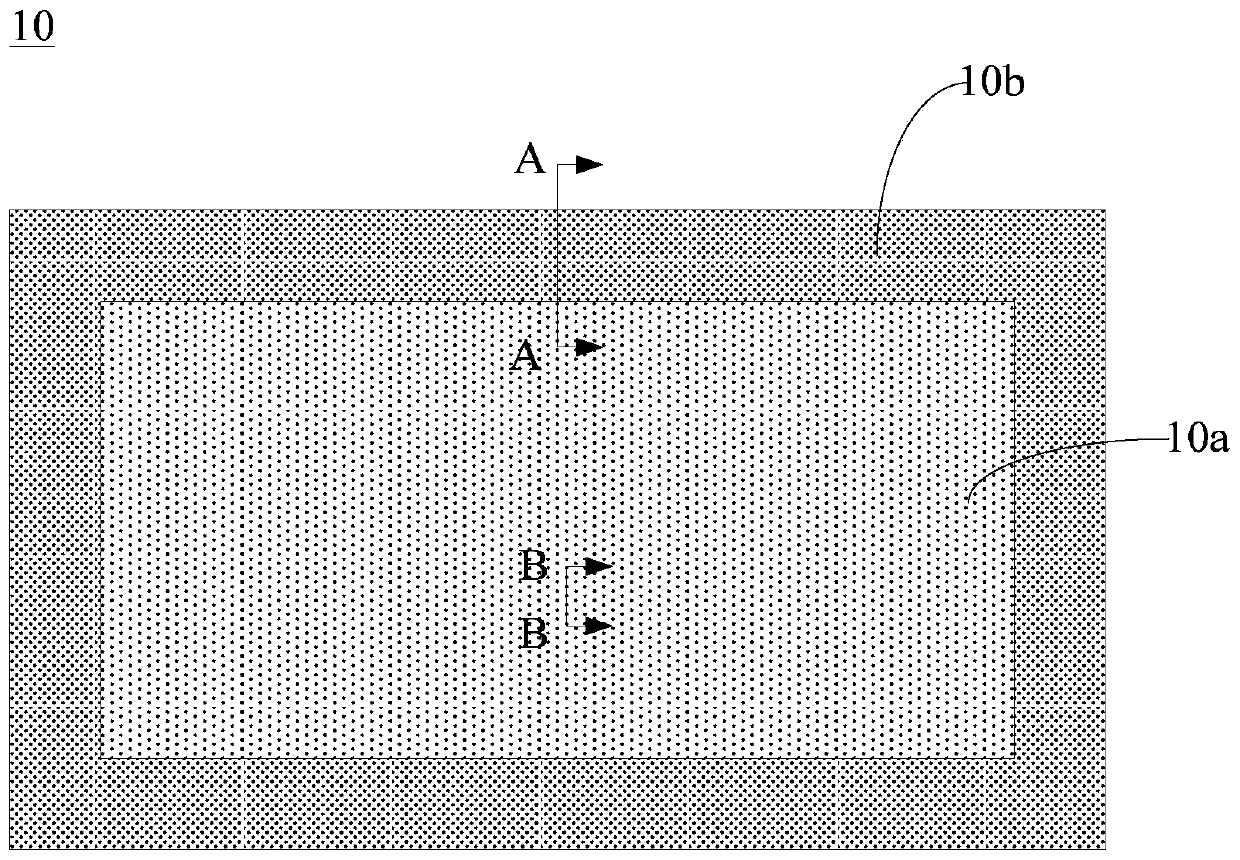

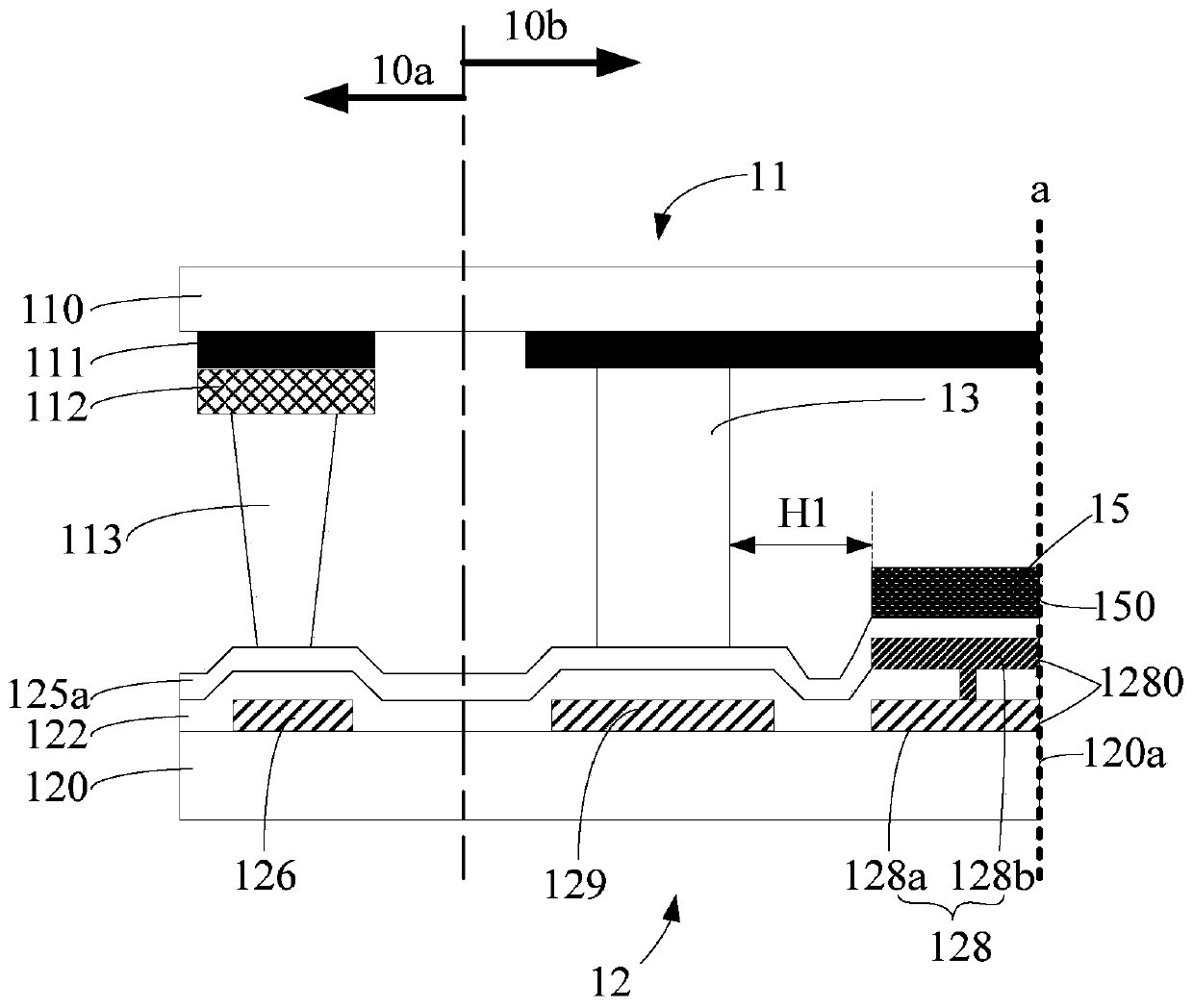

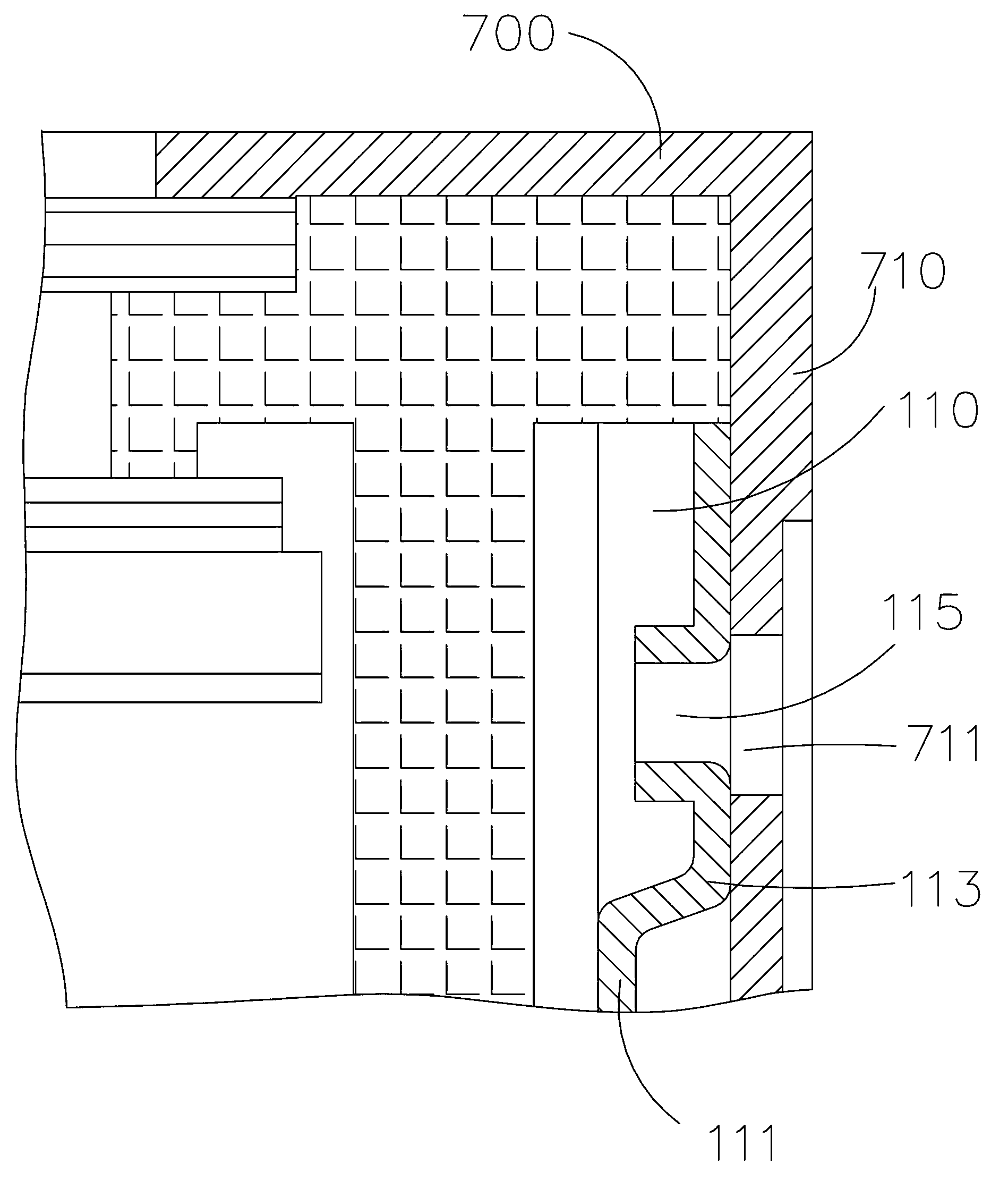

Backlight module and liquid crystal display

ActiveCN105223730APrevent leakageGuaranteed display effectNon-linear opticsLiquid-crystal displayLight guide

The invention provides a backlight module and a liquid crystal display. The backlight module comprises a backboard (11), a reflector plate (12), a light guide plate (13), and an optical film group (14). In the optical film group (14), the edge of an optical film (141) on the top is provided with a plurality of projections (142) extending outward. The backboard (11) comprises a bottom board (111), and a side plate (112). The side plate (112) is provided with a plurality of holes (113). The plurality of projections (142) respectively insert into the plurality of holes (113). The backlight module realizes a narrow frame, and prevents glue from leaking in gaps between the optical film group and the backboard when using a side edge glue dispensing method to fix the backlight module and a liquid crystal panel, thereby ensuring display effect and reliability of the liquid crystal display. The liquid crystal display is provided with the backlight module, and realizes a narrow frame, and prevents glue from leaking in gaps between the optical film group and the backboard, so the liquid crystal display has good display effect and reliability.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

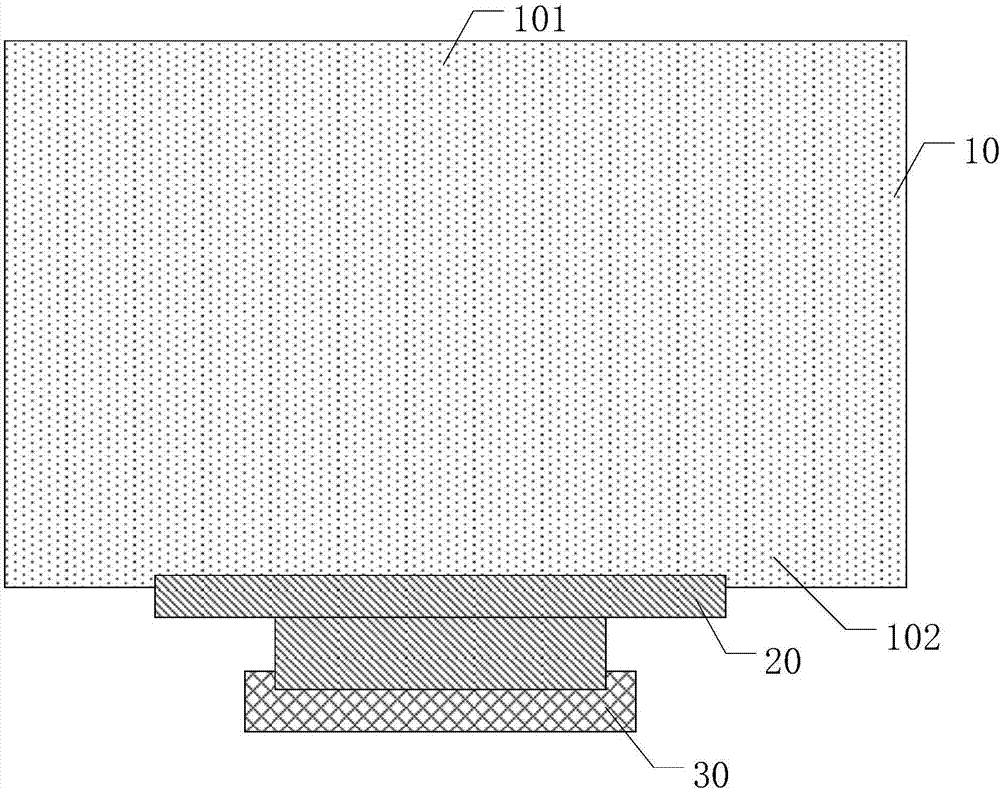

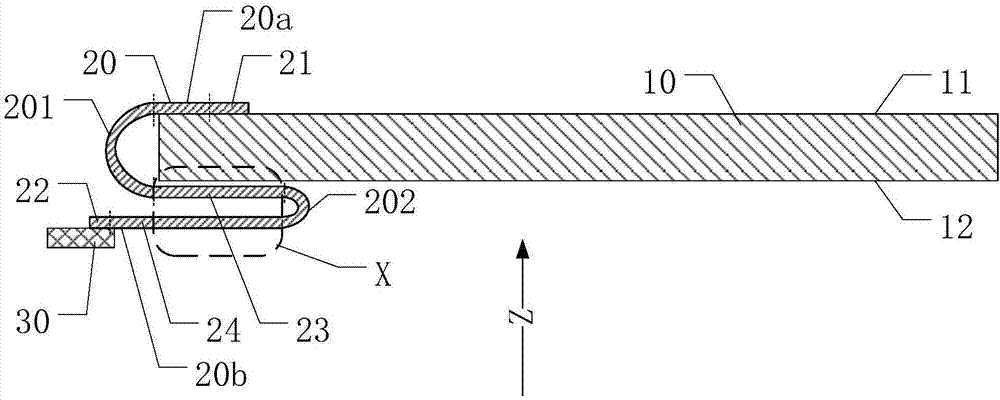

Display device

ActiveCN107484328AReduce the space taken upAchieve narrow bordersPrinted circuit detailsPrinted circuit non-printed electric components associationPrinted circuit boardSurface plate

The invention, which belongs to the technical field of display, discloses a display device comprising a display panel, at least one flexible circuit board and a printed circuit board. The flexible circuit board consists of a first connection area, a first bending area, a second bending area, a second connection area, a first routing area and a second routing area; the first connection area is electrically connected with the display panel; and the second connection area is electrically connected with the printed circuit board. When the first bending area of the flexible wiring board is in a bending state, at least part of orthographic projection of the first routing area on the display panel is located in the display panel; and when the second area of the flexible wiring board is in a bending state, the first routing area and the second routing area have an overlapped region and at least part of orthographic projection of the overlapped region on the display panel is located in the display panel, and the second routing area is arranged at one side, far away from the display panel, of the first routing area in a direction perpendicular to the display panel. Therefore, narrow framing of the display device is realized well.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

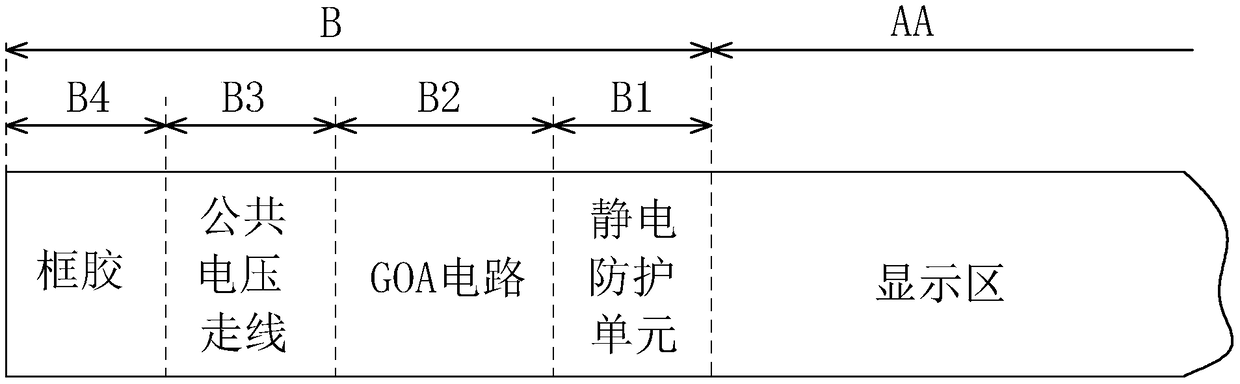

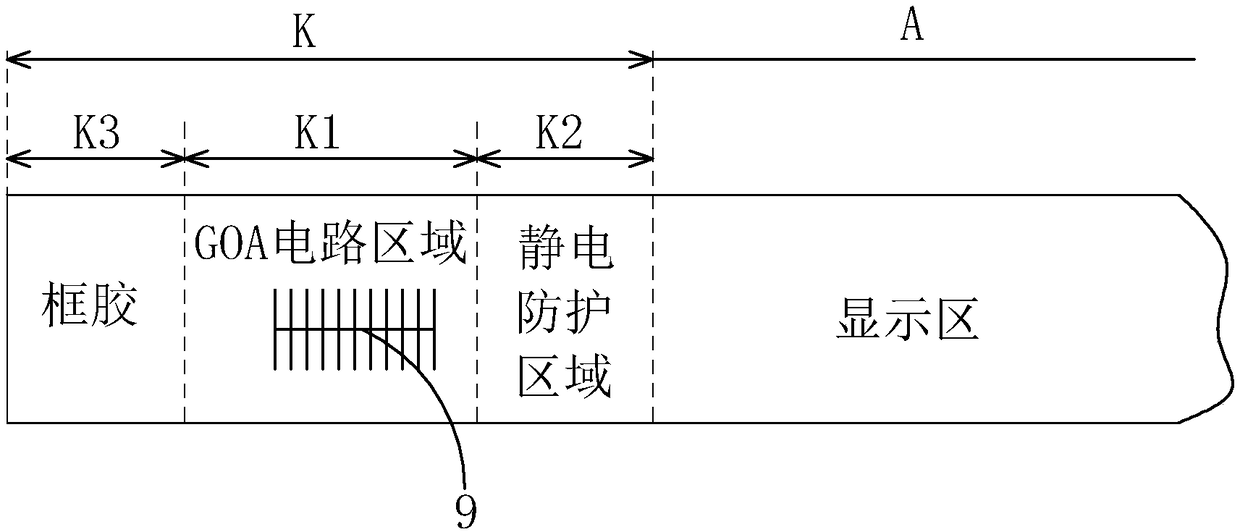

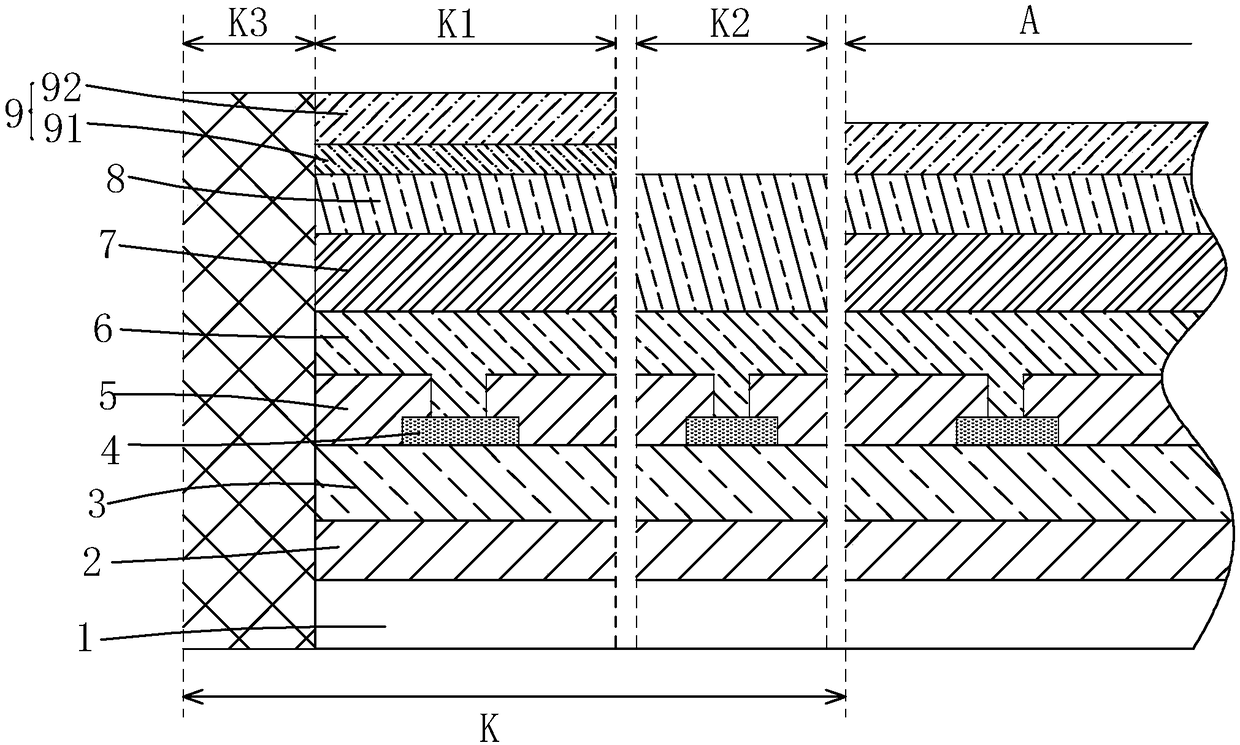

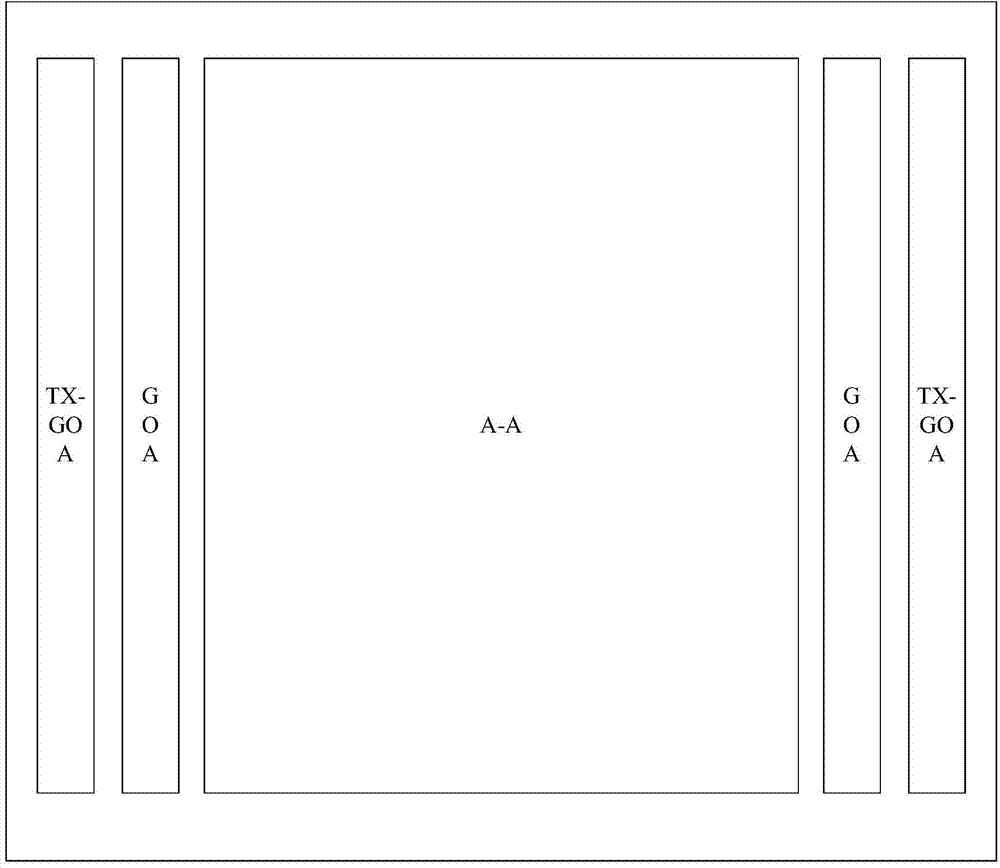

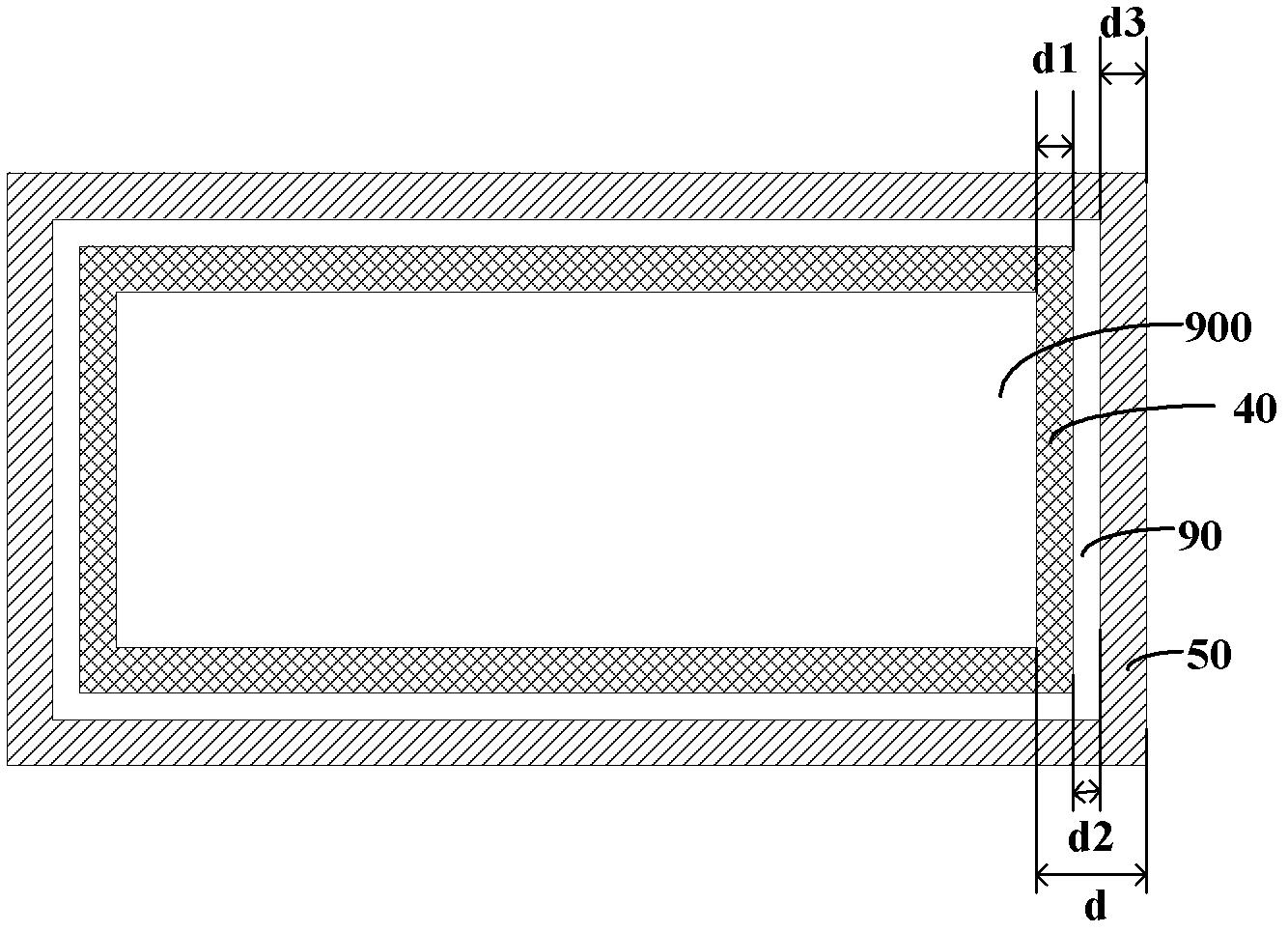

COA type liquid crystal display panel structure and manufacturing method of COA type liquid crystal display panel structure

ActiveCN108761941AReduce border widthAchieve narrow bordersNon-linear opticsLiquid-crystal displayEngineering

The invention provides a COA type liquid crystal display panel structure and a manufacturing method of a COA type liquid crystal display panel structure. The COA type liquid crystal display panel structure sets a color barrier layer (7) in the GOA circuit region (K1) of a peripheral zone (K) and sets a common voltage line (9) above the color barrier (7), the existing the common voltage line paralleling to the GOA circuit region in the peripheral zone of the existing liquid crystal display panel is moved to the top of the GOA circuit, so that the common voltage line no longer occupies the widthof the display border, so that the border width of LCD panel can be reduced which helps to realize the narrow borders of LCD panel products.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Touch driving unit and circuit, display panel and display device

ActiveCN104777936AAchieve narrow bordersCost controlStatic indicating devicesInput/output processes for data processingElectricityDisplay device

The embodiment of the invention provides a touch driving unit and a circuit, a display panel and a display device, which relate to the technical field of display and are favorable for realization of narrow side framing of the display panel and realization of effective control on the cost. The touch driving unit comprises a shift control module, a selecting module, a buffer module and an amplitude control module, wherein the shift control module comprises an initial signal end, an output port and at least one clock signal end; the selecting module comprises a first input end, a second input end and an output end; the buffer module comprises an input end and an output end; the amplitude control module comprises an input end, a first level end, a second level end and an output end. The touch driving unit and the circuit, the display panel and the display device of the embodiment are used for manufacturing displays.

Owner:BOE TECH GRP CO LTD

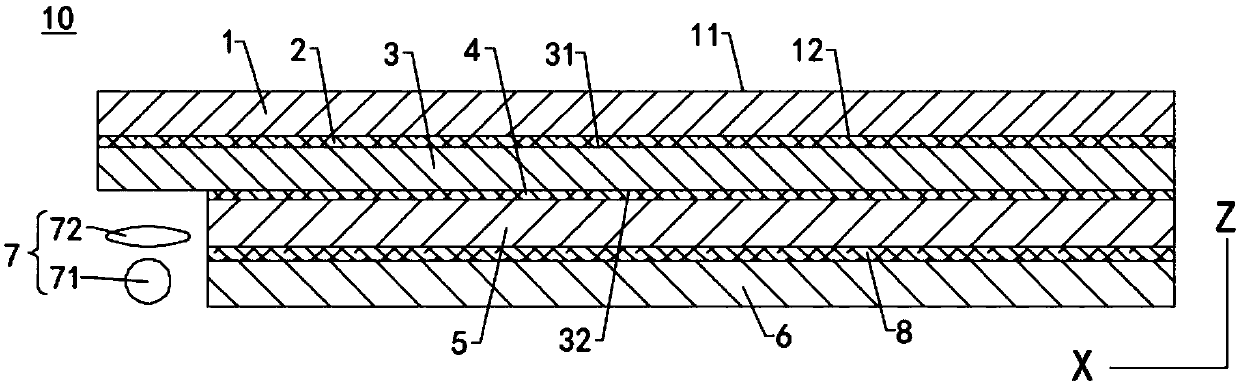

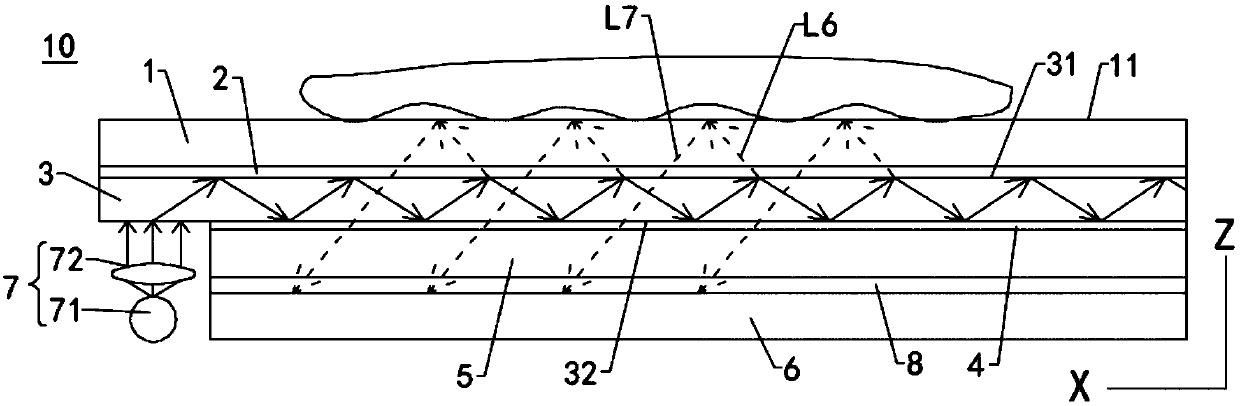

Eelectronic equipment with a line detection function

ActiveCN109948410AImprove light energy utilizationImprove recognition accuracyPlanar/plate-like light guidesPrint image acquisitionGratingLight guide

The embodiment of the invention discloses electronic equipment with a line detection function. The electronic equipment comprises a cover plate, a first bonding layer, a light guide plate, a second bonding layer and a display panel which are sequentially stacked. The refractive index of the first bonding layer and the refractive index of the second bonding layer are both smaller than the refractive index of the light guide plate. The electronic equipment also includes an image sensor and a light source. Each grating group of the light guide plate comprises a first grating part, a second grating part and a third grating part, and the area of the emergent surface of the third grating part is larger than that of the incident surface of the first grating part. The emitted light of the light source can enter the first grating part through the light incident surface of the first grating part, passes through the second grating part and the third grating part and then is emitted out through the light emergent surface of the third grating part, and the emitted light enters the cover plate and is totally reflected by the top surface of the cover plate or reflected by lines to be measured toform reflected light. The image sensor is used for receiving the reflected light to form image data of the to-be-detected lines. The electronic equipment is relatively high in identification precision.

Owner:HUAWEI TECH CO LTD

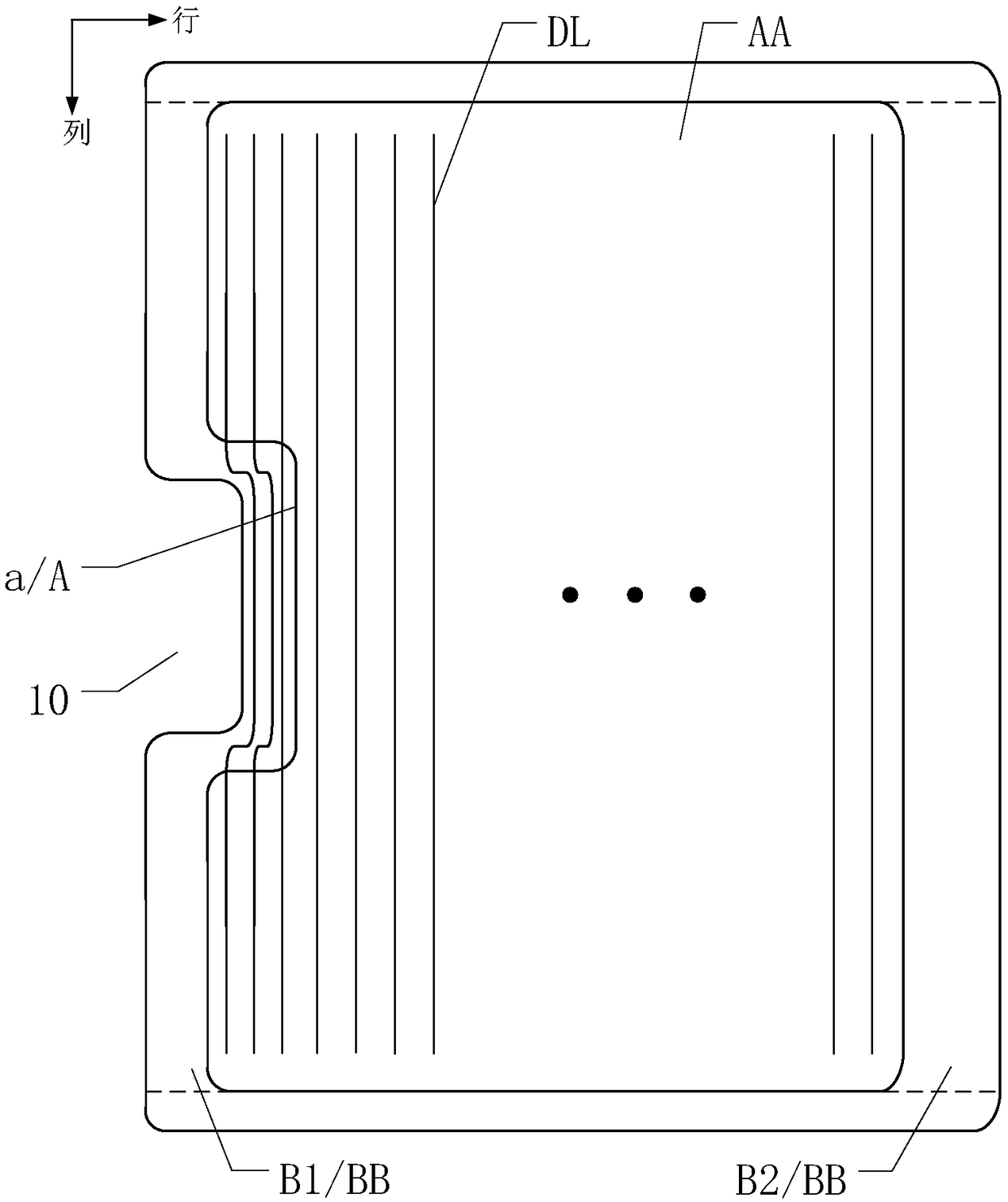

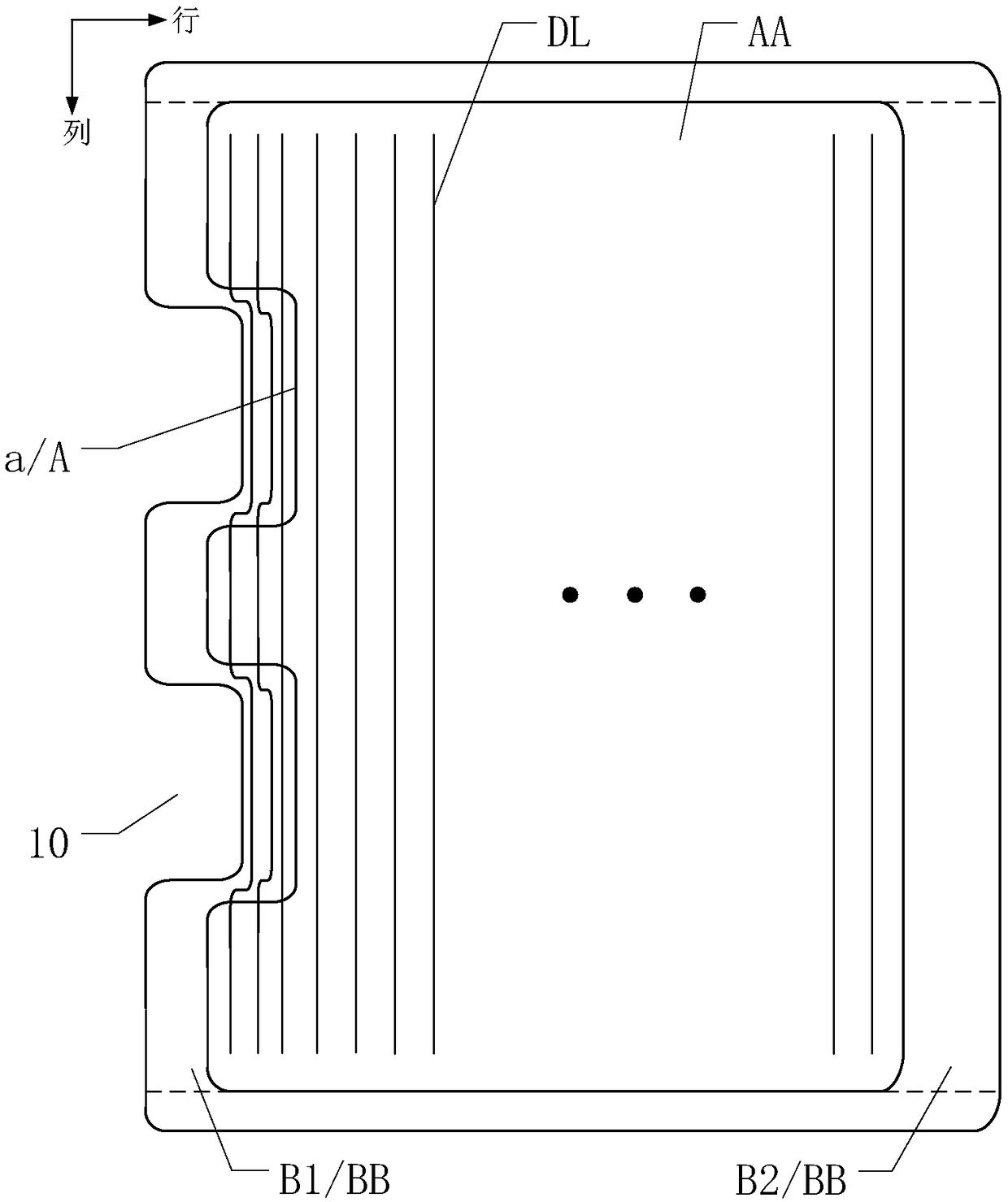

Array substrate, display panel and display device

ActiveCN107544189AImprove the display effectThe load gap is reducedNon-linear opticsIdentification meansLeg lengthDisplay device

The embodiment of the invention provides an array substrate, a display panel, and a display device. The array substrate includes a plurality of data lines, wherein the data lines of which the first portions have the same line length belong to the same data line group, the second portion of each data line includes a load regulation portion, the load structure of the load regulation portion of eachdata line comprises one of a first structure, a second structure, and a third structure, and the load structure of at least one data line is different from the load structures of the remaining data lines, thus the gap between the loads corresponding to any two data lines is reduced, the difference in the uniformity of the images displayed by the area corresponding to any two data lines is small when the images are displayed by the display panel, and the images displayed by the display panel are less affected, thereby enhancing the display effect of the display panel.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Infrared touch module and infrared touch-type display device

ActiveCN107390957AGuaranteed fixed reliabilityNarrow widthInput/output processes for data processingInfraredDisplay device

The invention discloses an infrared touch module. The infrared touch module comprises a circuit board, an infrared point light source, an optical lens and a shell body, wherein the infrared point light source is mounted on the circuit board, the shell body is of a frame structure and comprises one side frame, a first frame edge and a second frame edge, and the first frame edge and the second frame edge are bent from the upper end and the lower end of the side frame to the middle of the frame structure; the shell body is internally provided with a groove penetrates through the the end surface of the first frame edge, and the circuit board and the infrared point light source are contained in the groove; the infrared point light source faces the outlet of the groove, and an insertion slot for inserting the end part of a display device is formed between the first frame edge and the second frame edge. The invention also discloses the infrared touch-type display device. The circumstance of the display device is inserted into the insertion slot of the infrared touch module, and is fixed relative to the infrared touch module so as to ensure the reliability of fixing of the infrared touch module, and meanwhile using of various fixing structures for fixing is avoided; besides, the number of structural parts is reduced, and the design of a narrow bezel of the infrared touch-type display device is facilitated through the circuit board vertically mounted in the infrared touch module.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display panel, manufacturing method thereof, and liquid crystal display device

ActiveCN111352270AAchieve narrow bordersAvoid long and shortNon-linear opticsPhysicsLiquid-crystal display

The invention relates to the technical field of display, and concretely relates to a liquid crystal display panel, a manufacturing method thereof, and a liquid crystal display device. The liquid crystal display panel is provided with a display area and a non-display area surrounding the display area, the liquid crystal display panel comprises a color film substrate, an array substrate and a framesealing glue, the color film substrate and the array substrate are arranged in a box-to-box mode, the frame sealing glue is located between the color film substrate and the array substrate, and the frame sealing glue is located in the non-display area. The array substrate comprises: a first base with a substrate section; an extraction electrode, wherein the extraction electrode is formed on the first base, is located in the non-display area and is located on the side, away from the display area, of the frame sealing glue, and the extraction electrode is provided with a binding section away from the display area; and a protective film layer formed on the side, away from the first base, of the extraction electrode, wherein the protective film layer has a film layer section away from the display area, and the binding section, the substrate section and the film layer section are located in the same plane. According to the liquid crystal display panel, a narrow frame is achieved, and meanwhile the product yield can be increased.

Owner:BOE TECH GRP CO LTD +1

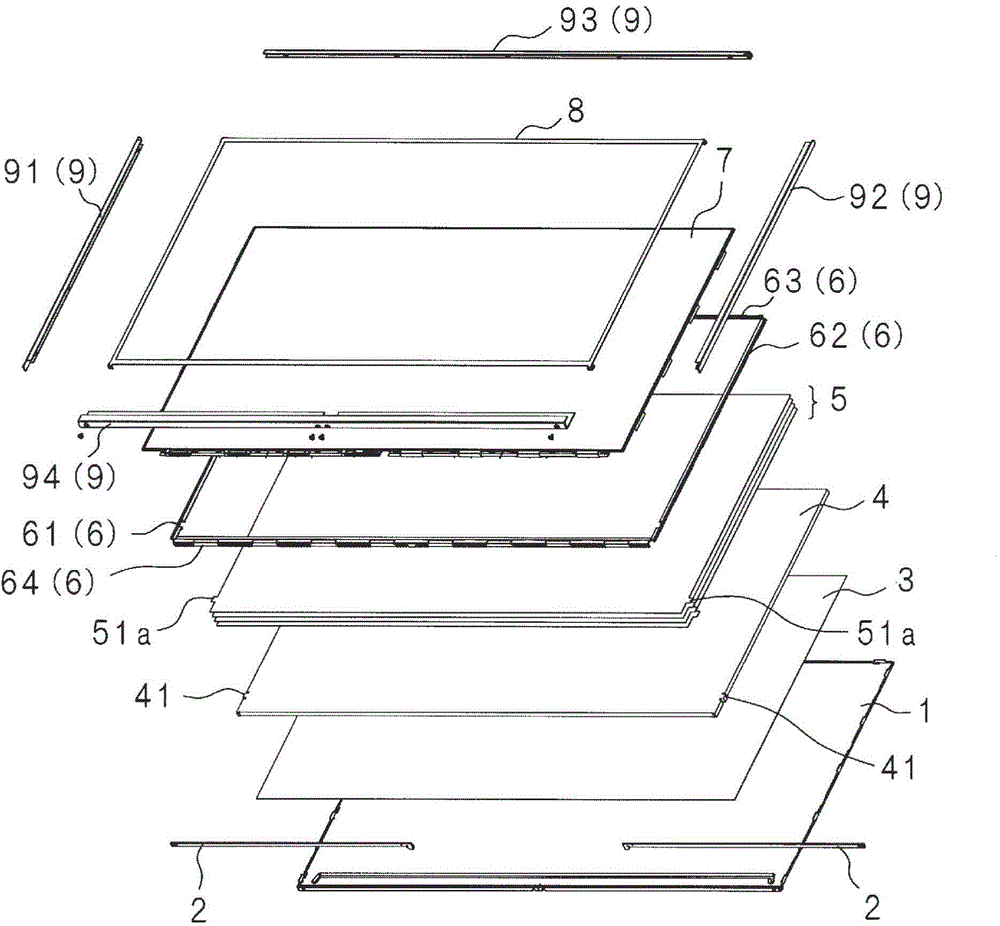

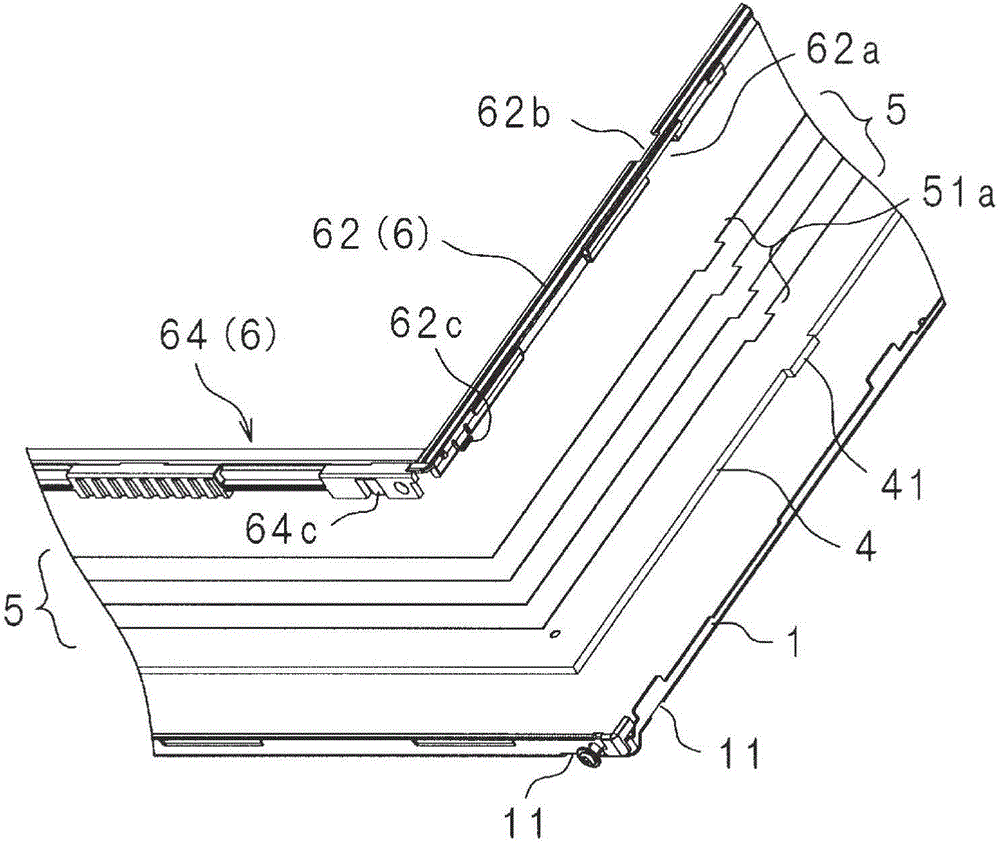

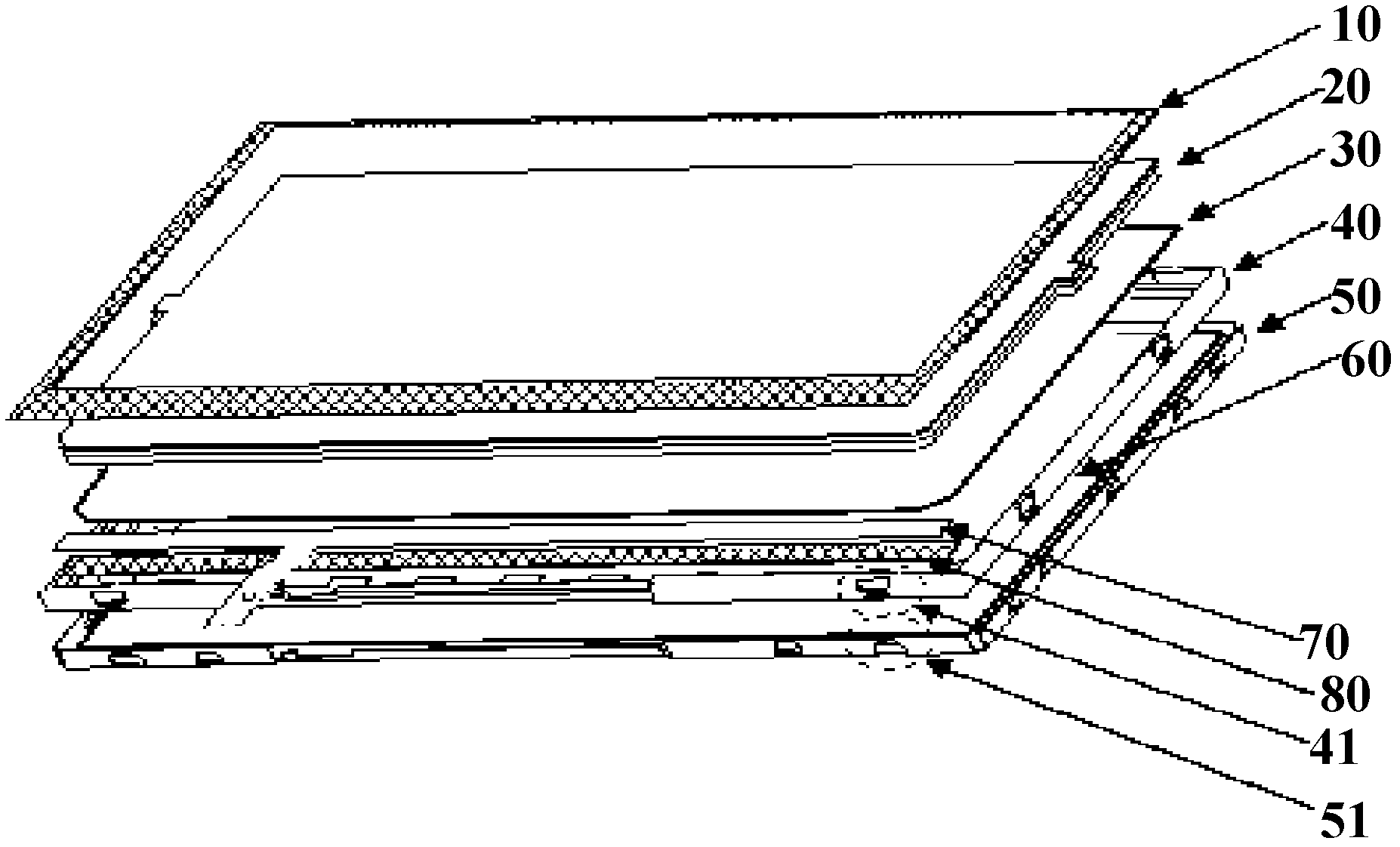

Display device and liquid crystal display device

InactiveCN104685555AAvoid temperature risePrevent leakagePoint-like light sourceElectric lightingLiquid-crystal displayDisplay device

Provided is a display device in which an optical member is accurately positioned and is fixed to a back-light chassis without the addition of molding processing or the like and without screwing and fastening. The display device has the following: a display panel for displaying images on a front surface thereof; optical sheets (5) that are disposed on the rear surface side of the display panel, and that diffuse light and cause the light to be incident on the display panel; a support body (1) that is box-shaped and supports the rear and side surfaces of the display panel; and a positioning member (6) that performs positioning of the optical sheets (5) in the surface direction thereof, and that has a side plate part interposed between a side surface of the optical sheets (5) and the side surface of the support body (1), and a surface plate part that is parallel to the front surface of the display panel. The display device is characterized in that on the edges of the optical sheets (5) are disposed protrusions (51a) that protrude in the surface direction and are for positioning, and disposed on the surface plate part is a notch (62b) into which the protrusions (51a) are inserted loosely.

Owner:SHARP KK

Flexible display panel and manufacturing method thereof

InactiveCN111063257AAchieve narrow bordersAvoid breakingIdentification meansEngineeringStructural engineering

The invention provides a flexible display panel and a manufacturing method thereof. The flexible display panel is provided with a display area, a non-display area and a bending area arranged between the display area and the non-display area. The flexible display panel comprises a substrate base plate and at least one signal trace arranged on the substrate base plate. Each signal trace comprises atleast two metal layers and an insulating layer arranged between the two adjacent metal layers in the bending area; orthographic projections of the at least two metal layers on the substrate base plate are not overlapped with each other, and the insulating layer is made of a low-modulus organic material, so that the increase of rigidity can be effectively relieved, the signal trace is prevented from being broken, impedance is reduced, and a narrow bezel of the flexible display panel is favorably realized.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

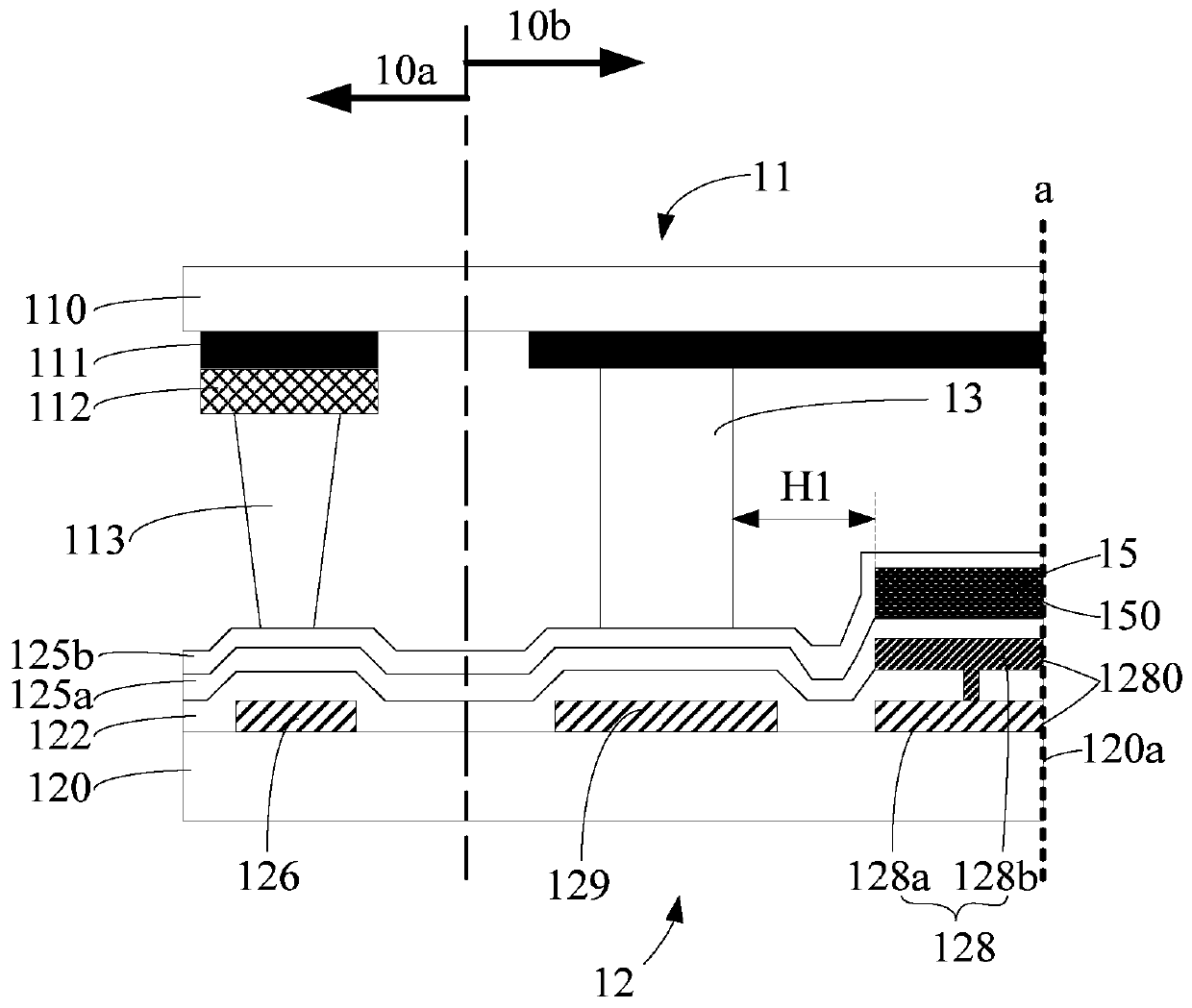

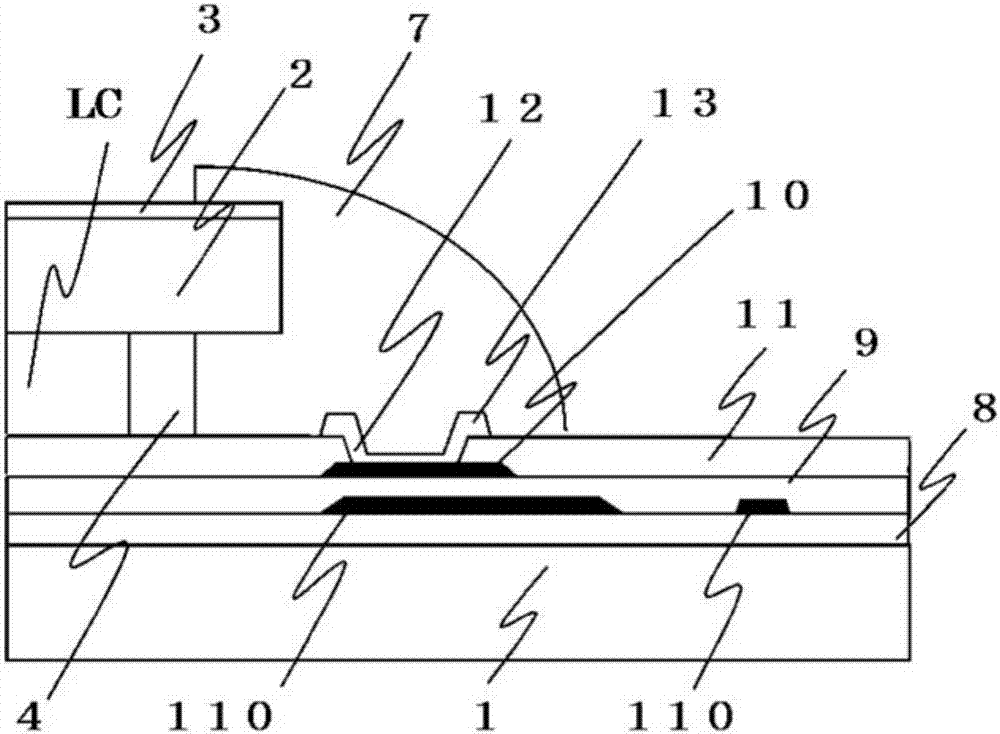

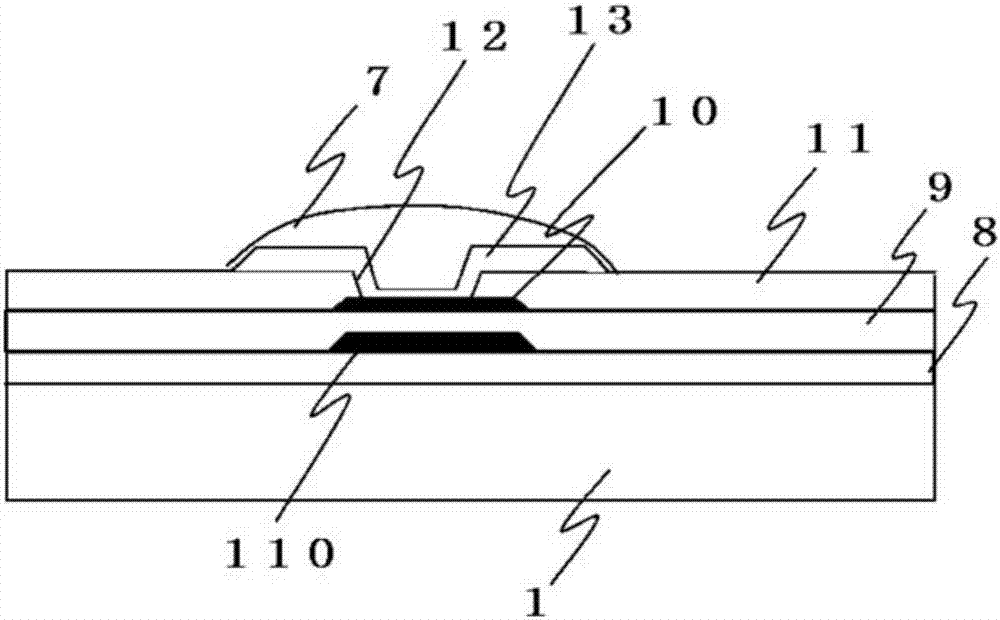

Liquid crystal display device

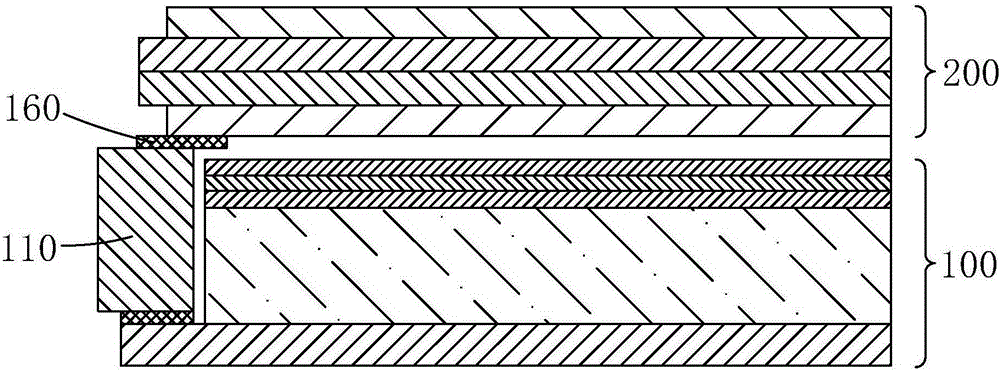

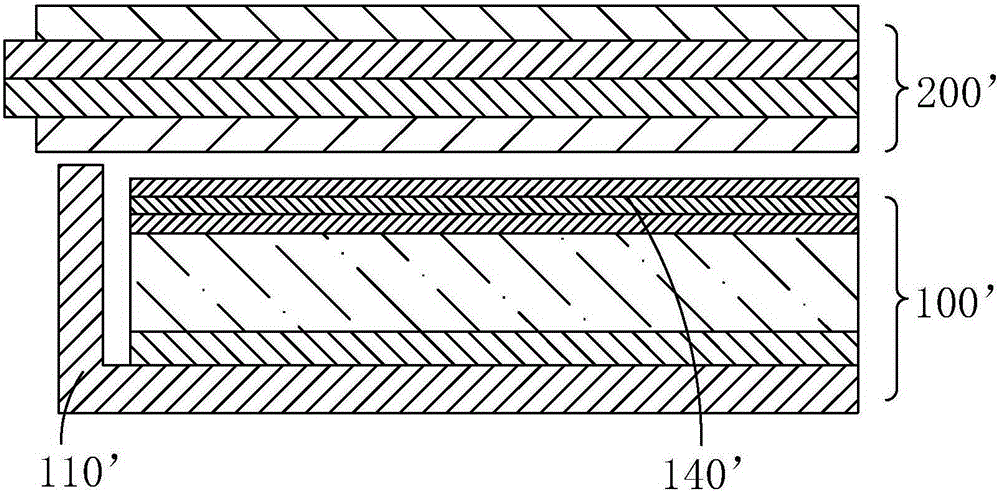

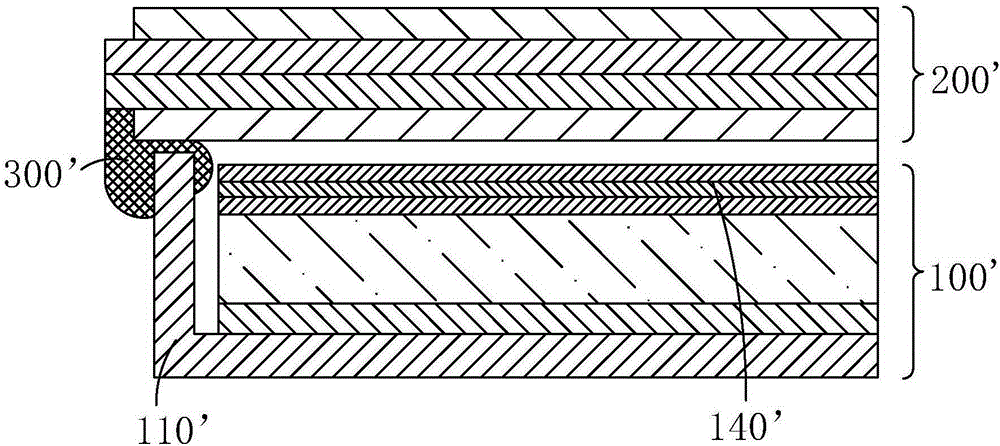

InactiveCN107065340ANo need to secure spaceAchieve narrow bordersNon-linear opticsLiquid-crystal displayTransparent conducting film

A liquid crystal display device includes: a first substrate which includes a display region, in which scan wirings and signal wirings intersecting with scan wirings are formed, and a frame region, which surrounds the display region, wherein a lead-out wiring 110 extending from at least one of the signal wiring and the scan wiring and a ground electrode 10 on an insulating layer covering the lead-out wiring are formed in the frame region 102; a second substrate, which faces the first substrate with interposing a seal, wherein a transparent conductive film is formed on a surface opposite to a side where the liquid crystal is provided; and a conductive member 7, which is formed to extend across the first substrate and the second substrate to electrically connect the transparent conductive film 7 with the ground electrode 10, wherein the ground electrode 10 overlaps with at least one of the lead-out wirings.

Owner:MITSUBISHI ELECTRIC CORP

Display panel and full screen display device

InactiveCN108682369AAchieve narrow bordersStatic indicating devicesNon-linear opticsData linesMultiplexer

The present application is applicable to the technical field of display and provides a display panel and a full screen display device. In the display panel and the full screen display device disclosedin an embodiment of the present application, a drive detection circuit electrically connected to a data line lead-out terminal of a display area is arranged on a first surface of the display area ofthe display panel. Whether the display area is good before a multiplexer and a driver IC are bound on the display area; the multiplexer and the driver IC are arranged on a flexible circuit board and reversed to a second surface opposite to a first surface of the display area, and a narrow frame of the display panel can be realized.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Array substrate, display panel and display device

InactiveCN107561763AAchieve narrow bordersReduce widthNon-linear opticsInput/output processes for data processingDisplay deviceActive layer

An embodiment of the invention relates to the technical field of display and provides an array substrate, a display panel and a display device. The array substrate comprises a display area and a non-display area surrounding the display area, and the display area comprises a plurality of sub-pixels. Each sub-pixel comprises a substrate, a buffer layer and a thin film transistor array, wherein the buffer layer is arranged above the substrate, and the thin film transistor array is arranged on one side, away from the substrate, of the buffer layer and comprises an active layer. Each sub-pixel comprises a transmission area and a reflection area, wherein the reflection area comprises a reflection electrode arranged on one side, away from the corresponding substrate, of the corresponding thin film transistor array. The reflection areas of part of the sub-pixels further comprise pressure sensors, and each pressure sensor is arranged between the corresponding reflection electrode and the corresponding buffer layer. By adoption of the technical scheme, convenience in realization of a narrow bezel of the display device is achieved, and heat radiation performances of the pressure sensors are improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

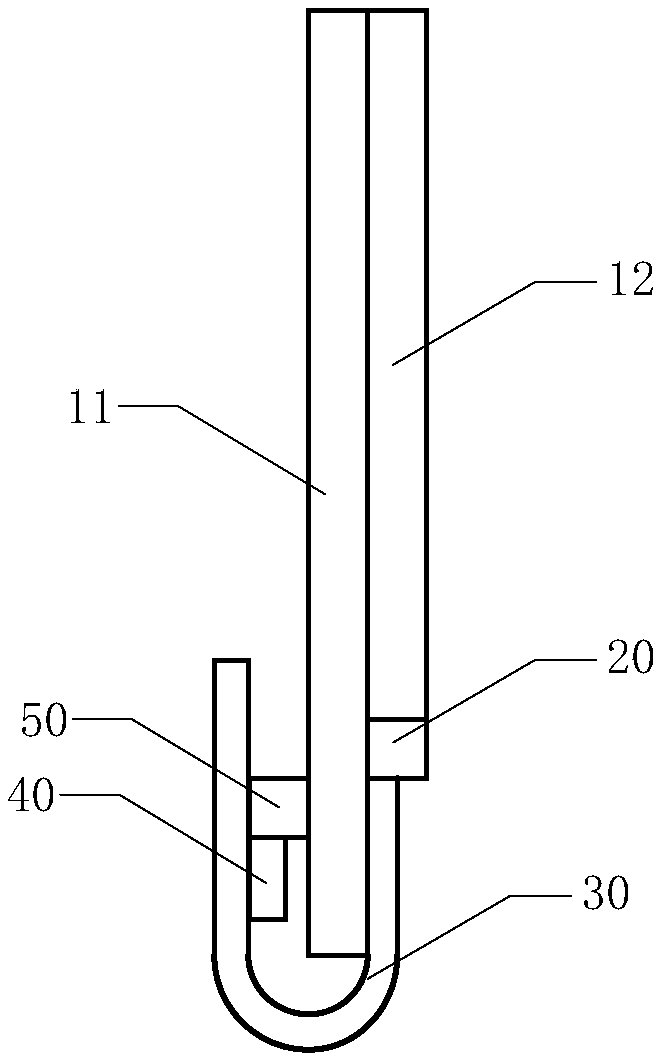

Backlight module and display device

InactiveCN104006332AReduce border widthAchieve narrow bordersOptical light guidesLight fasteningsLight guideDisplay device

The invention provides a backlight module and a display device. The backlight module comprises a light guide plate, an optical film material arranged on one side of the light guide plate and frame sealing glue arranged on the periphery of the light guide plate, wherein a first positioning part is arranged at the edge of the optical film material, the frame sealing glue comprises a covering part and a second positioning part, the covering part is located on one side, away from the light guide plate, of the optical film material, the edge of the optical film material is covered with the covering part, and the second positioning part is arranged on one face, towards the optical film material, of the covering part and matched with the first positioning part so as to positioning the optical film material. According to the backlight module, the positioning structures for positioning the optical film material are directly manufactured on the frame sealing glue, the width of a frame of the backlight module can be effectively reduced, and the frame of a displayed product can be narrow.

Owner:BOE TECH GRP CO LTD +1

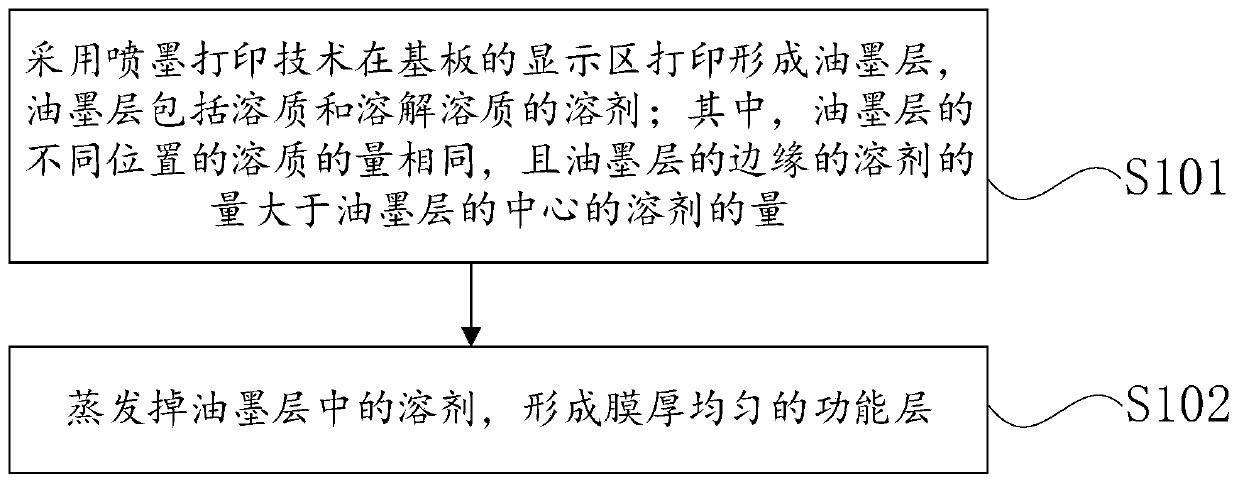

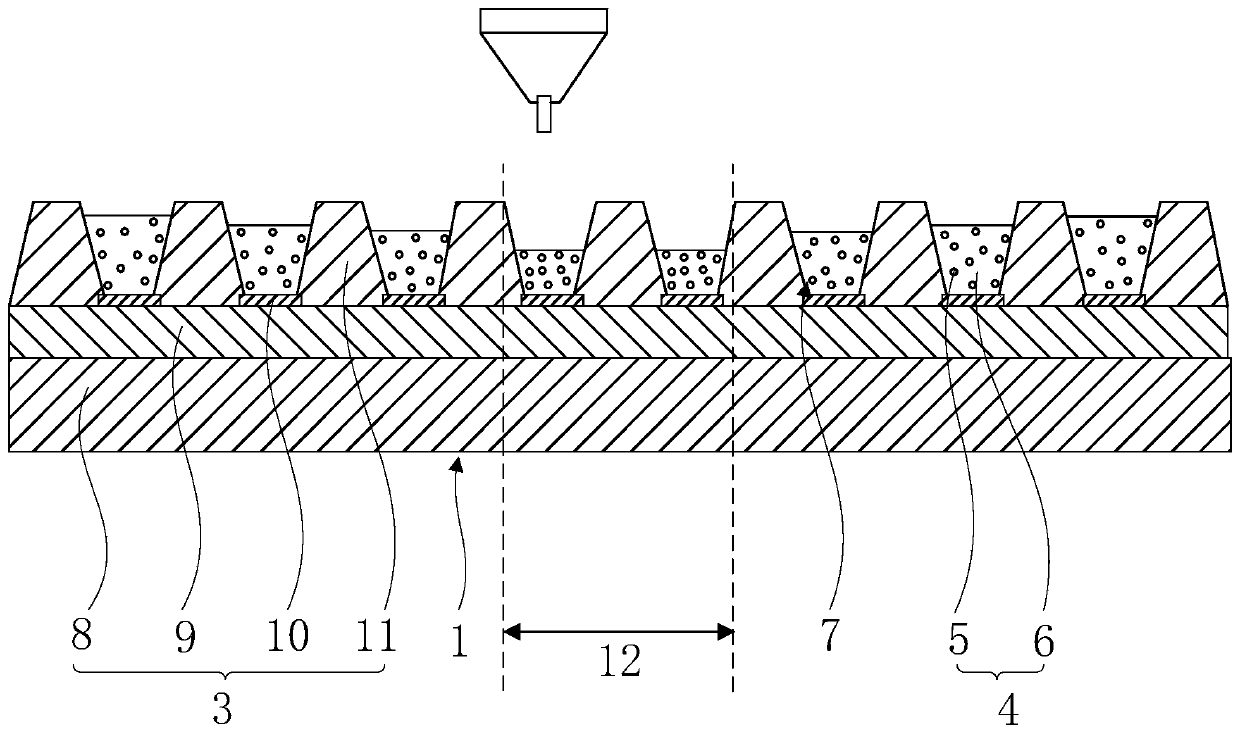

Preparation method for display panel and preparation method for functional layer thereof

ActiveCN110611053AAchieve narrow bordersAvoid taking awaySolid-state devicesSemiconductor/solid-state device manufacturingSolvent evaporationSolvent

The invention discloses a preparation method for a display panel and a preparation method for a functional layer thereof. The display panel comprises a substrate. The preparation method for the functional layer comprises the steps that an inkjet printing technology is used to print on a display area of the substrate to form an ink layer, wherein the ink layer comprises a solute and a solvent whichdissolves the solute; the amount of the solute at different positions of the ink layer is the same, and the amount of the solvent at the edge of the ink layer is greater than the amount of the solvent at the center of the ink layer; the solvent in the ink layer is evaporated to form the functional layer with uniform film thickness. The invention provides the method for preparing the functional layer with uniform film thickness. According to the invention, in the process of solvent evaporation, the solvent atmosphere above the display area of the substrate is substantially the same; the film thickness of the formed functional layer is uniform; and the design of the narrow frame of the display panel is realized.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Display panel and display device

ActiveCN109410771AReduce widthAchieve narrow bordersStatic indicating devicesHousing of computer displaysControl lineDisplay device

The invention discloses a display panel and a display device. The display panel comprises a display area, non-display areas surrounding the display area, and at least one groove, wherein the display area comprises a plurality of scanning lines, a plurality of light-emitting control lines and a plurality of data lines; the non-display areas comprise a first non-display area and a second non-displayarea, and the first non-display area and the second non-display area are positioned on two opposite sides along the row direction of the display area; the display area comprises a specially-shaped edge, and the specially-shaped edge is the common boundary of the display area and the first non-display areas; the specially-shaped edge comprises at least one sub edge, and the at least one sub edge sinks towards the inside of the display area, so that the groove is formed; the display panel further comprises a first scanning drive circuit, a second scanning drive circuit and a light-emitting control circuit, the first scanning drive circuit is positioned in the first non-display area, and the second scanning drive circuit and the light-emitting control circuit are positioned in the second non-display area. Compared with the prior art, the technical scheme has the advantages that the width along the row direction of the first non-display area can be greatly reduced, and thus the narrow frame of the display device is realized.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

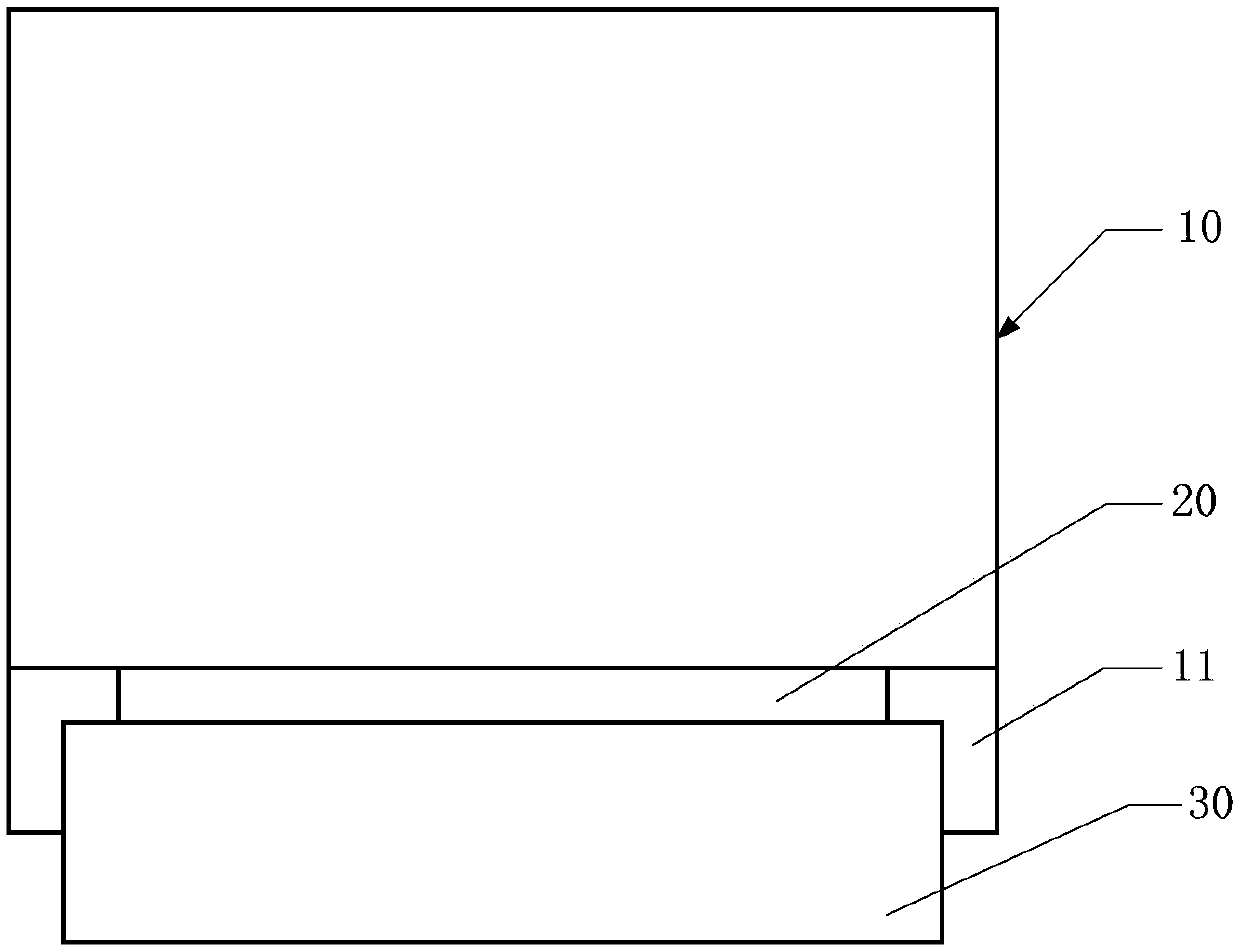

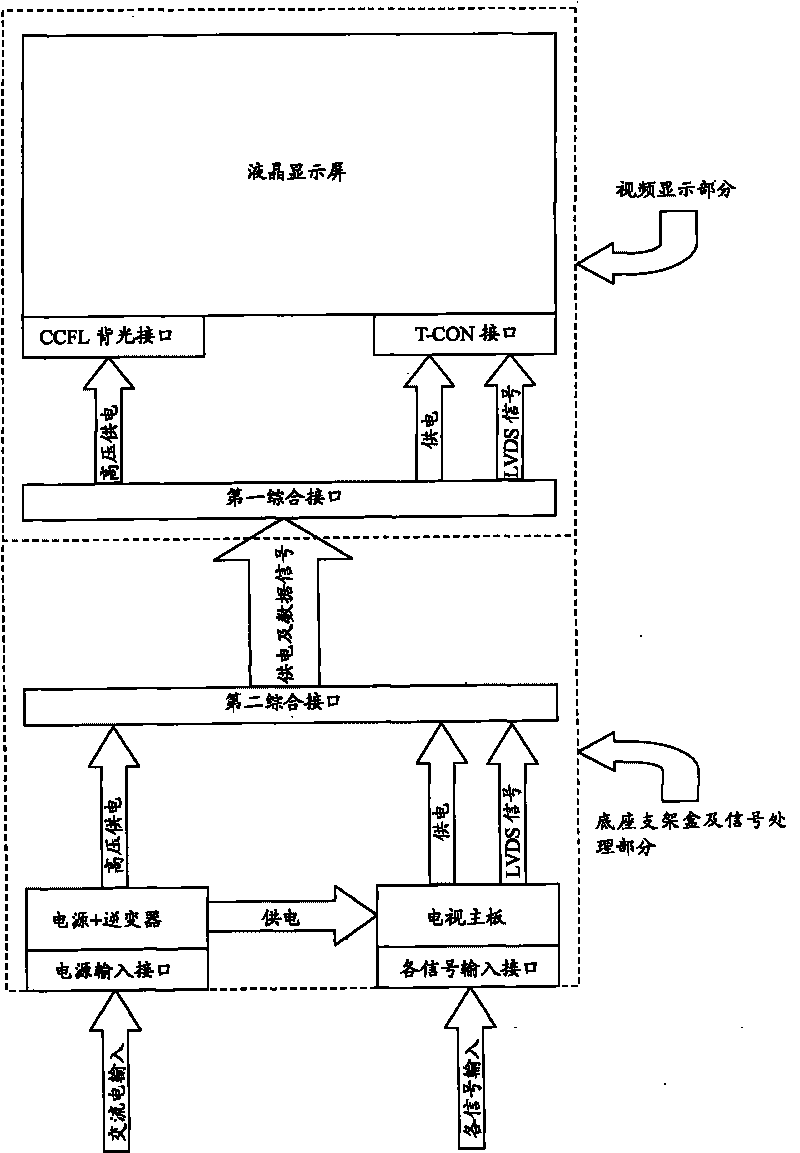

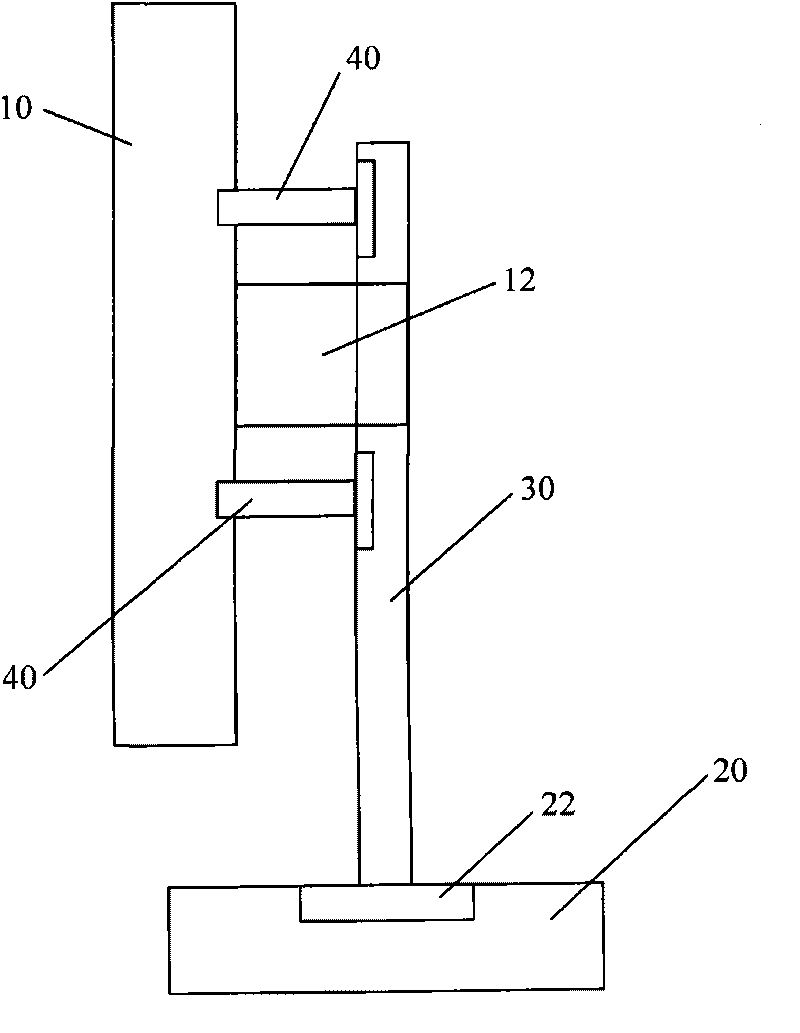

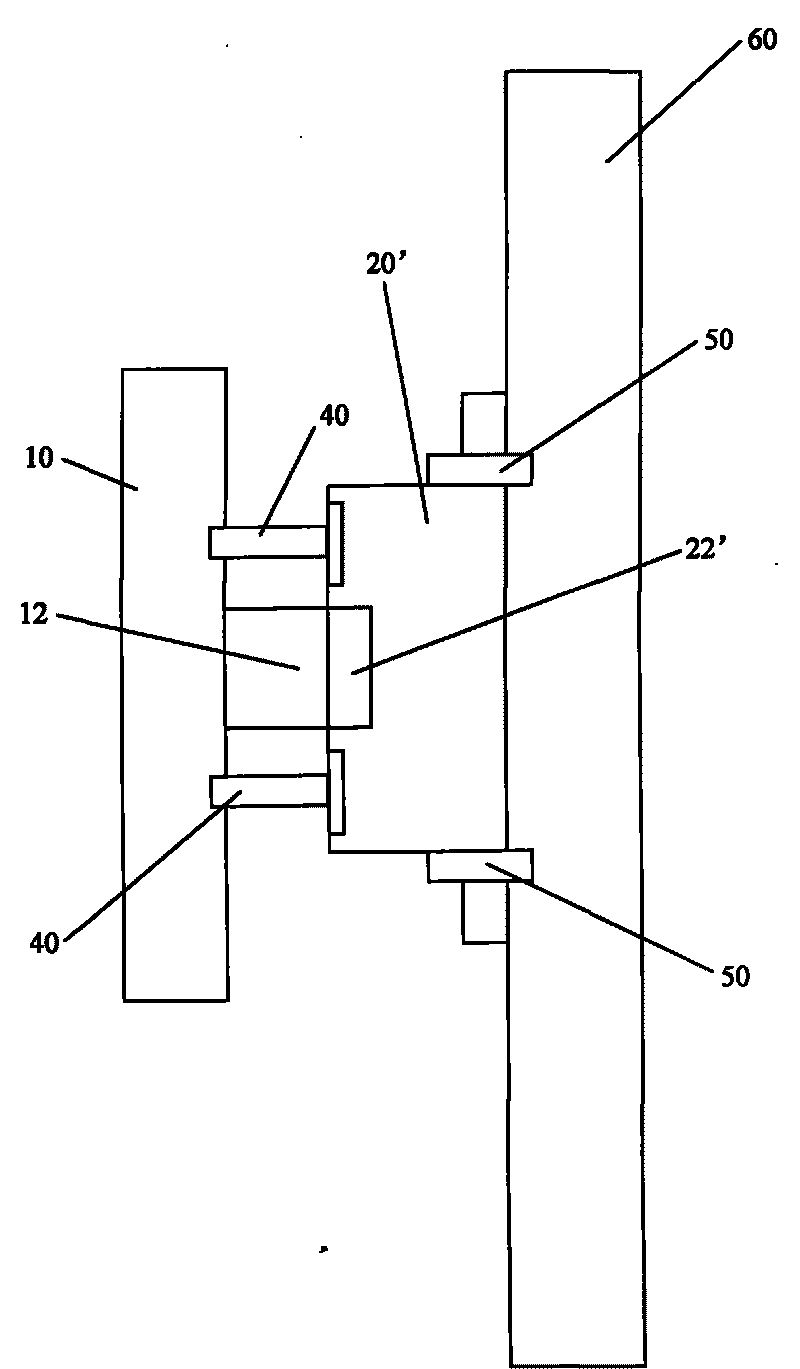

Method for realizing ultra-thin television and device thereof

InactiveCN101753930AAchieve ultra-thinAchieve narrow bordersTelevision system detailsColor television detailsEngineeringSignal processing

The invention relates to a method for realizing an ultra-thinned television and a device thereof. The ultra-thin television device comprises a television body, a base support case and a base support, wherein the base support case is arranged on the television body through the base support; a display screen and a first integrated interface are arranged on the television body, and the first integrated interface is connected with the display screen; a second integrated interface and a power supply, an inverter and a mainboard which are connected with the second integrated interface are arranged in the base support case; the first integrated interface is mutually connected with the second integrated interface; and the power supply, the inverter and the mainboard supply power and transmit data signals to the display screen through the connection of the first integrated interface and the second integrated interface. The television disassembles a video display part and signal processing parts reasonably, utilizes the thickness and space of the base support case reasonably, and transfers the signal process parts such as the power supply, the inverter, the mainboard and the like to the base support case, so that the ultra-thin and narrow border of the television can be realized simultaneously, and the television is convenient to assemble, disassemble and maintain.

Owner:KONKA GROUP

Liquid crystal display module

ActiveCN102799006AReduce thicknessAchieve narrow bordersNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display module, comprising a backlight module, a rubber frame which is arranged on the backlight module, a liquid crystal display panel which is arranged on the rubber frame, and a border frame which is arranged on the liquid crystal display panel and used for locking the backlight module, wherein the backlight module comprises a rear panel; the rear panel comprises a bottom plate and a lateral plate connected to the bottom plate; the border frame comprises a surface frame and a lateral frame connected to the surface frame; the lateral plate toward the lateral frame is provided with a lug boss; the lug boss is provided with a threaded hole; the lateral frame corresponding to the lug boss is provided with a holding hole; the lug boss is completely accommodated in the holding hole and locked together with the holding hole through a screw. According to the liquid crystal display module, the lateral plate of the rear panel of the backlight module is extracted and tapped outward to form the lug boss which is bumped toward the lateral frame and provided with the threaded hole; the lateral frame of the border frame corresponding to the lug boss is provided with the holding hole, so that the lug boss is completely accommodated in the holding hole; the lug boss is locked together with the holding hole through the screw, and the rear panel and the border frame is locked together, so that the thickness of the border frame is greatly reduced and the narrow border frame of the liquid crystal display device is favorably realized.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Backlight, production method thereof, backlight bottom frame and production method thereof

ActiveCN103075674AAchieve narrow bordersEasy to makeMechanical apparatusPoint-like light sourceLight guideMetallic materials

The invention relates to a backlight, a production method thereof, a backlight bottom frame and a production method thereof in the technical field of display. The backlight comprises an optical film, a light guide plate, a light source and the bottom frame, wherein the optical film is fixed on the top surface of the light guide plate, the light source is fixed on the side or bottom of the light guide plate, the bottom surface of the light guide plate is fixed on the bottom frame, the bottom frame comprises a reflective layer and a metal layer, and the reflective layer is in contact with the light guide plate. The production method of the backlight includes the following steps: composite materials, which are a reflective material and a metal material, are provided, and the reflective material and the metal material are stacked together; the composite materials are formed into the bottom frame, which comprises the reflective layer and the metal layer; the light guide plate is provided, and the bottom surface of the light guide plate is fixed on the reflective layer; the optical film is provided, and is placed on the top surface of the light guide plate; and the light source is provided, and is arranged on the side or bottom of the light guide plate. The frame of the backlight can be narrow, the production steps are simplified, and the production cost is reduced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com