Eelectronic equipment with a line detection function

A technology of electronic equipment and texture, applied in the direction of light guide of lighting system, acquisition/organization of fingerprints/palmprints, instruments, etc., can solve the problems of insufficient fingerprint recognition accuracy, insufficient collection, recognition errors, etc., and achieve sufficient detection light intensity. , the effect of high signal-to-noise ratio and high utilization of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

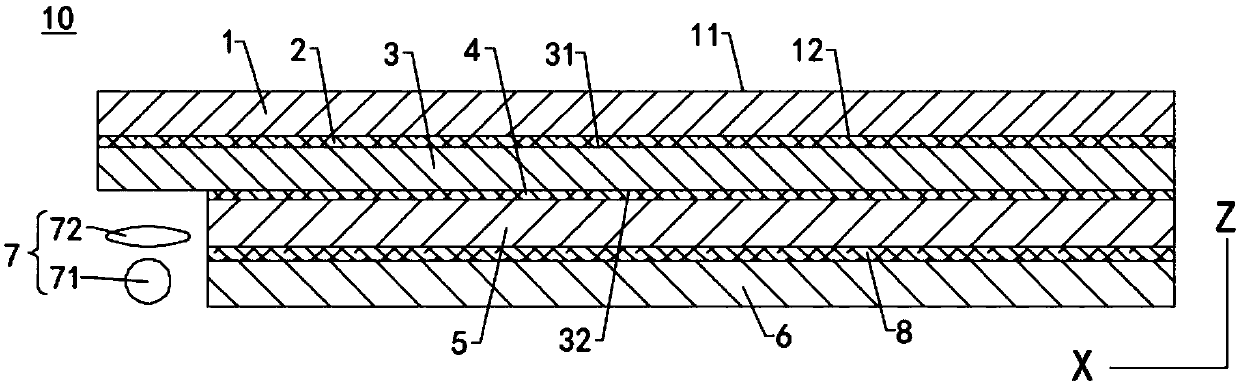

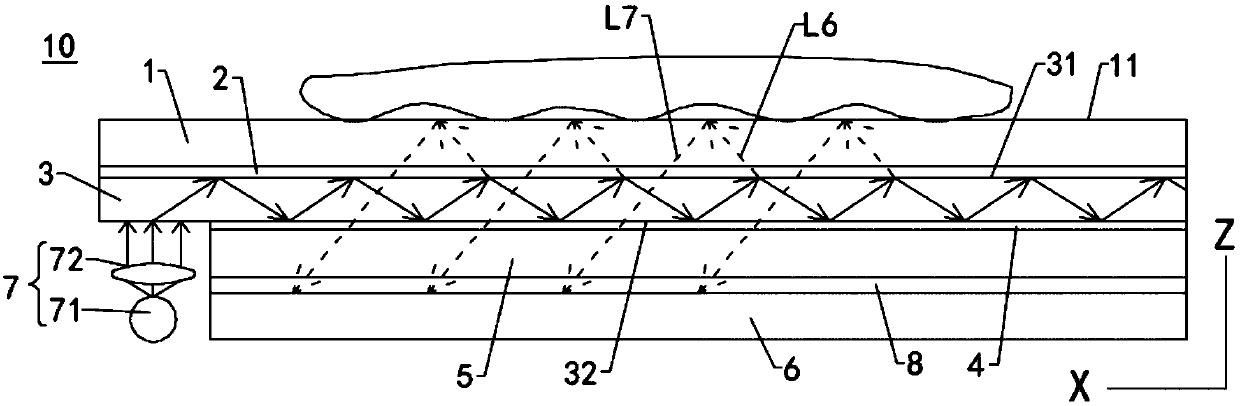

[0136]In one implementation manner, grating grooves of a plurality of first gratings 331 are processed on the base of the light guide plate 3 to form grating teeth of a plurality of first gratings 331 . The grating teeth and the grating grooves of the first grating 331 are arranged alternately in the same layer. The first base 334 is the base of part of the light guide plate 3 laminated with the first grating 331 . Wherein, the grating grooves of the first grating 331 are filled with air. When the top surface 31 of the light guide plate 3 is connected to the cover plate 1 through the first adhesive layer 2 , part of the first adhesive layer 2 is filled in the grating grooves of the plurality of first gratings 331 . At this time, the processing method of the first grating 331 is relatively simple, which is also beneficial to reduce the processing cost of the light guide plate 3 .

[0137] In another embodiment, multiple grating grooves of the first grating 331 are processed o...

other Embodiment approach

[0185] In other embodiments, the first grating part 33 can also be placed corresponding to the lower left corner of the cover plate 1, the second grating part 34 can be placed corresponding to the left edge of the cover plate 1, and the third grating part 35 is located at the second grating part 34 or the first grating part 33 can also be placed corresponding to the upper right corner or lower right corner of the cover plate 1, the second grating part 34 can be placed corresponding to the right edge of the cover plate 1, and the third grating part 35 is located on the second The left side of the grating part 34 .

[0186] Optionally, in a direction parallel to the light-emitting surface 346 of the second grating portion 34 and away from the light-incident surface 345 of the second grating portion 34 (such as Figure 12 As indicated by the straight line with an arrow in the middle), the diffraction efficiency of the second grating portion 34 increases gradually. For example, t...

other Embodiment approach

[0212] In other embodiments, among the two groups of axisymmetric grating groups 30 , the first grating part 33 of one group of grating groups 30 is placed corresponding to the right edge (or left edge) of the middle part of the cover plate 1 . The second grating portion 34 is placed corresponding to the middle of the cover plate 1 . The first grating portion 33 is located between the second grating portion 34 and the first long side 122 (or the second long side 124 ). The third grating portion 35 is located on the top side of the second grating portion 34 . The third grating portion 35 is located between the second grating portion 34 and the first short side 121 .

[0213] The first grating part 33 of the other grating group 30 is placed corresponding to the right edge (or left edge) of the middle part of the cover plate 1 . The second grating portion 34 is placed corresponding to the middle of the cover plate 1 . The first grating portion 33 is located between the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com