Liquid crystal display device

A technology of liquid crystal display device and display area, which is applied in the directions of instruments, nonlinear optics, optics, etc., can solve the problems of intrusion, disconnection of signal lines, damage of TFT elements of display pixels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

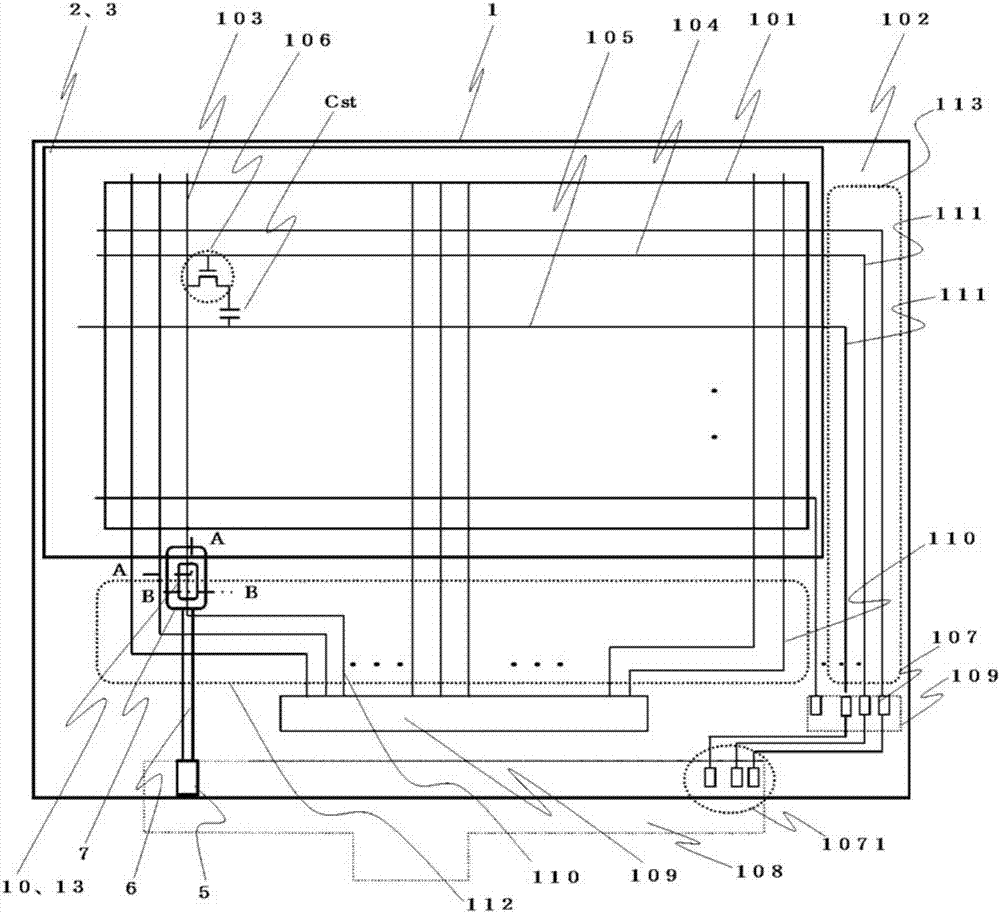

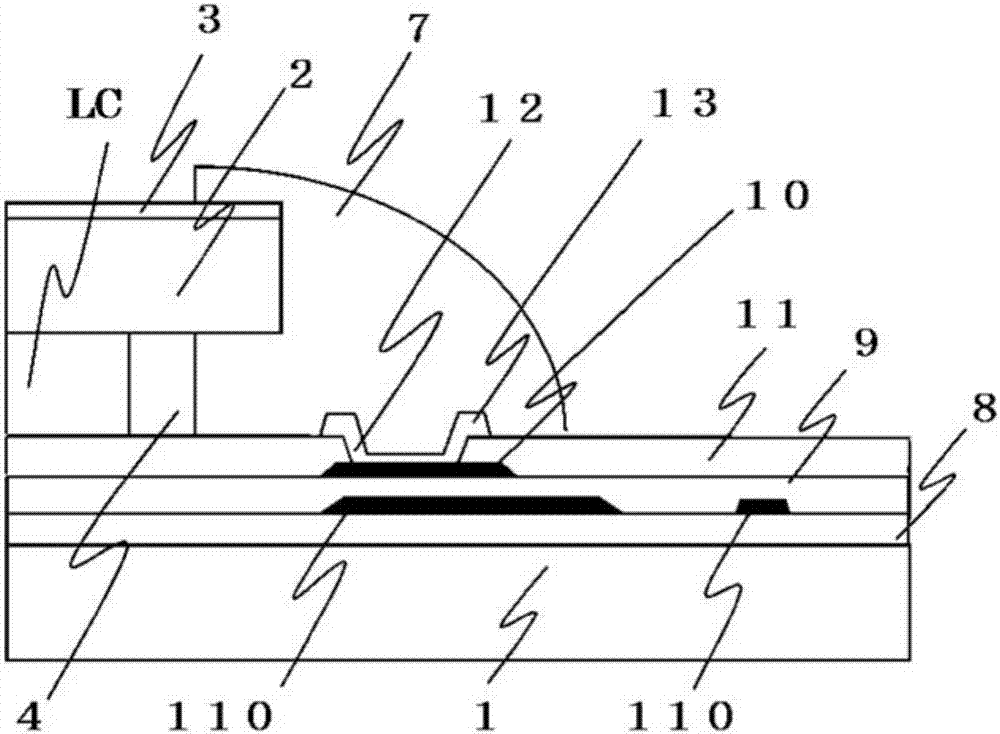

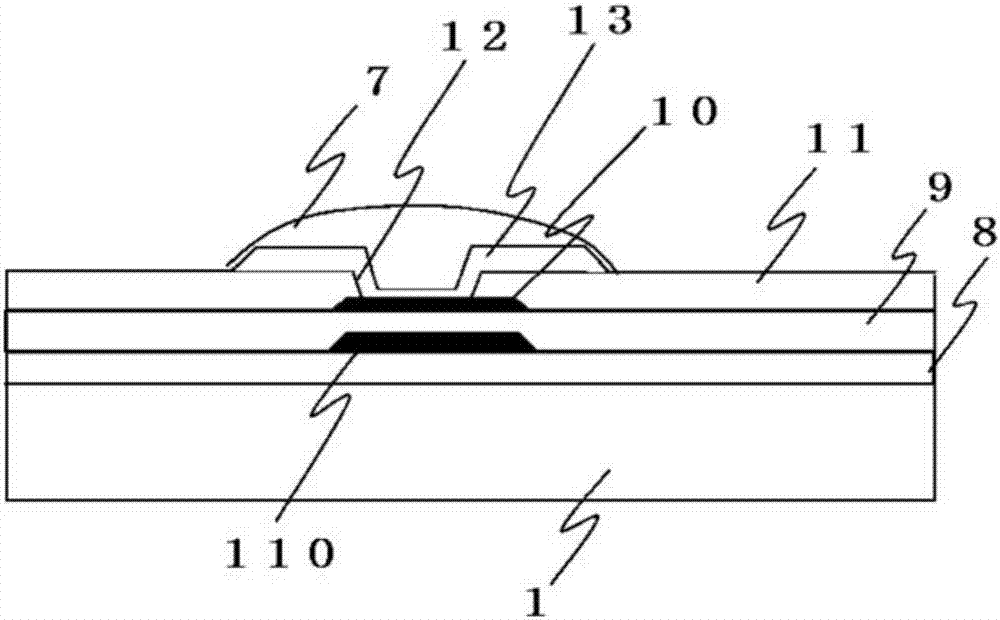

[0037] Hereinafter, embodiments of the present invention will be described using the drawings. figure 1 It is a plan view of the liquid crystal display panel of the liquid crystal display device according to the embodiment. in addition, figure 2 is a cross-sectional view of a liquid crystal display panel, specifically, a figure 1 Sectional view of the part shown in A-A. All the drawings are schematic diagrams, and do not reflect the exact size and the like of the illustrated components. In addition, omission of description, simplification of a part of the structure, etc. are suitably performed about the parts other than the main part of the invention for easy understanding of the drawings.

[0038] like figure 1 , 2 As shown, in the liquid crystal display panel 100, a TFT substrate 1, which is a first substrate on which wiring and the like are formed, and a CF (color filter) substrate 2, which is a second substrate opposite thereto, are used to encapsulate liquid crystal...

Embodiment approach 2

[0075] In the display area 101 of Embodiment 1, a new second common wiring (not shown) may be provided on the same layer as the scanning line 104, and the common wiring 105 on the capacitive insulating film 27 and the second 2. The common wiring is electrically connected through a contact hole (not shown) opened in the insulating film. With this structure, since the resistance of the common wiring can be reduced, there is an effect of improving the display quality. In addition, in this case, the lead-out wiring 111 may be formed by extending the second common wiring of the same layer as the scanning line 104 .

[0076] In the case where the common wiring 105 is directly led out to constitute the lead wiring 111 , if it is attempted to provide the ground electrode 10 thereon, it is necessary to further form an insulating film covering the common wiring 105 . However, if the second common wiring, the lead-out wiring 111 connected to the second common wiring, and the scanning li...

Embodiment approach 3

[0079] In Embodiment 2, the second common wiring is formed on the same layer as the scanning line, but the layer to which the second common wiring is added is not limited to the same layer as the scanning line 104 , and may be laminated with the common wiring 105 . And, as otherwise, except Figure 4 , Figure 5 In addition to the illustrated form, a second common wiring made of a metal film may be separately formed on the same layer as the pixel electrode. In this case, the second common wiring may be electrically connected to the common wiring on the capacitive insulating film via a contact hole. With this structure, since the resistance of the common wiring can be reduced, there is also an effect of improving the display quality.

[0080] In addition, in the case where the second common wiring is formed by a metal film, if it is formed so as to overlap with at least one of the scanning line 104 or the signal line 103, there is an effect that the use of the pixel portion w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com