Backlight, production method thereof, backlight bottom frame and production method thereof

A manufacturing method and backlight technology, which are applied to the backlight bottom frame and its manufacture, backlight and its manufacturing field, can solve the problems of complex assembly process of the plastic frame 40 and the iron frame 50, increase the production cost of the liquid crystal display, etc., so as to save Complicated matching process, saving production cost, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

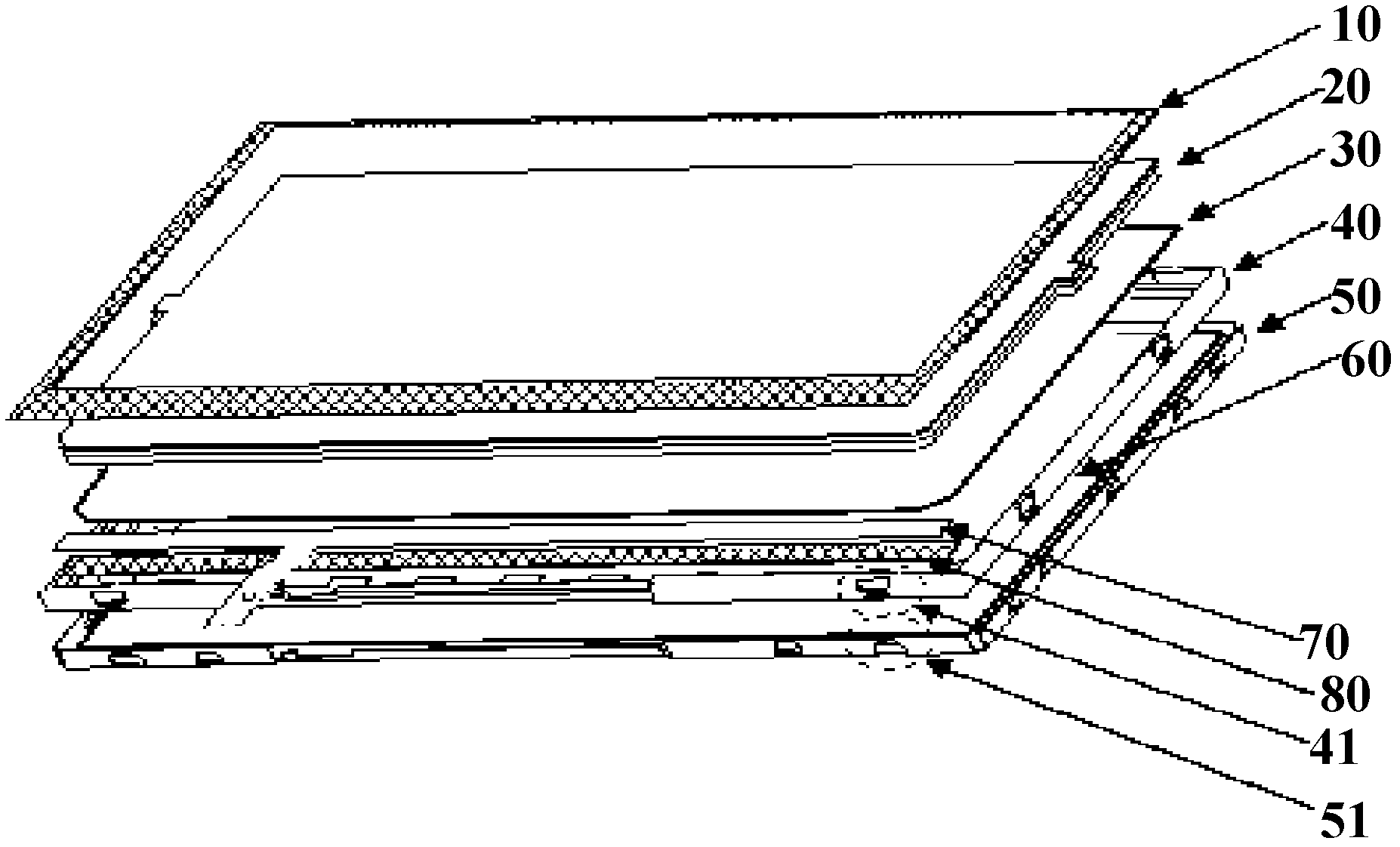

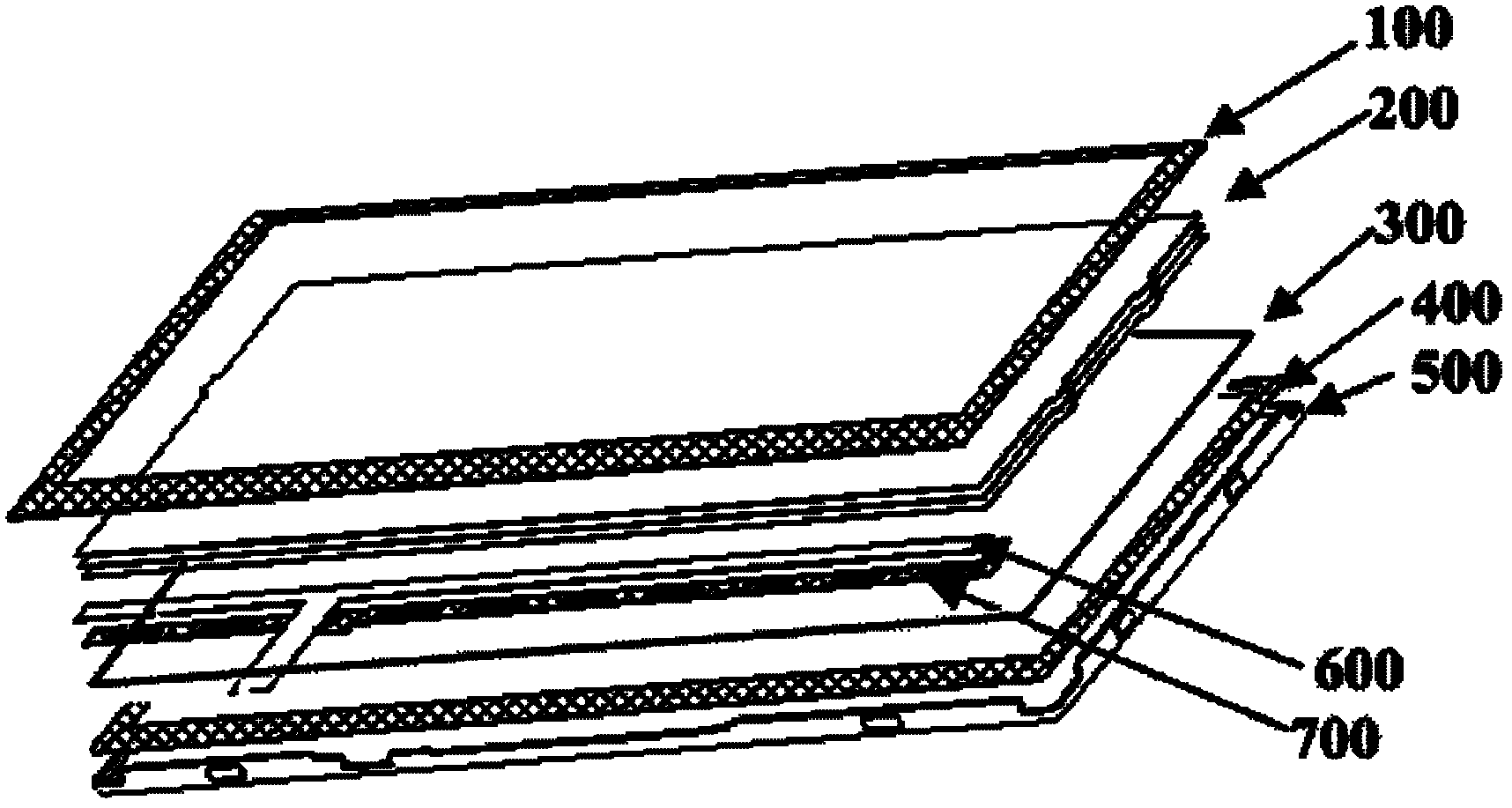

[0083] refer to image 3 As shown, this embodiment provides a backlight, including: an optical film 200, a light guide plate 300, a light source 600 and a bottom frame 500, wherein: the optical film 200 is arranged on the upper surface of the light guide plate 300, The light source 600 is arranged on the side of the light guide plate 300, and the lower surface of the light guide plate 300 is arranged on the bottom frame 500, and the bottom frame 500 includes a reflective layer (not shown in the figure) and a metal layer (not shown in the figure). shown), the reflective layer is adjacent to the light guide plate 300.

[0084] The bottom frame 500 in this embodiment includes a reflective layer and a metal layer, that is, the reflective sheet and the metal sheet in the prior art are combined into one, and the optical film 200 and the light source 600 are fixed on the light guide plate 300 , that is, the light guide plate 300 can replace the plastic frame to realize the function ...

Embodiment 2

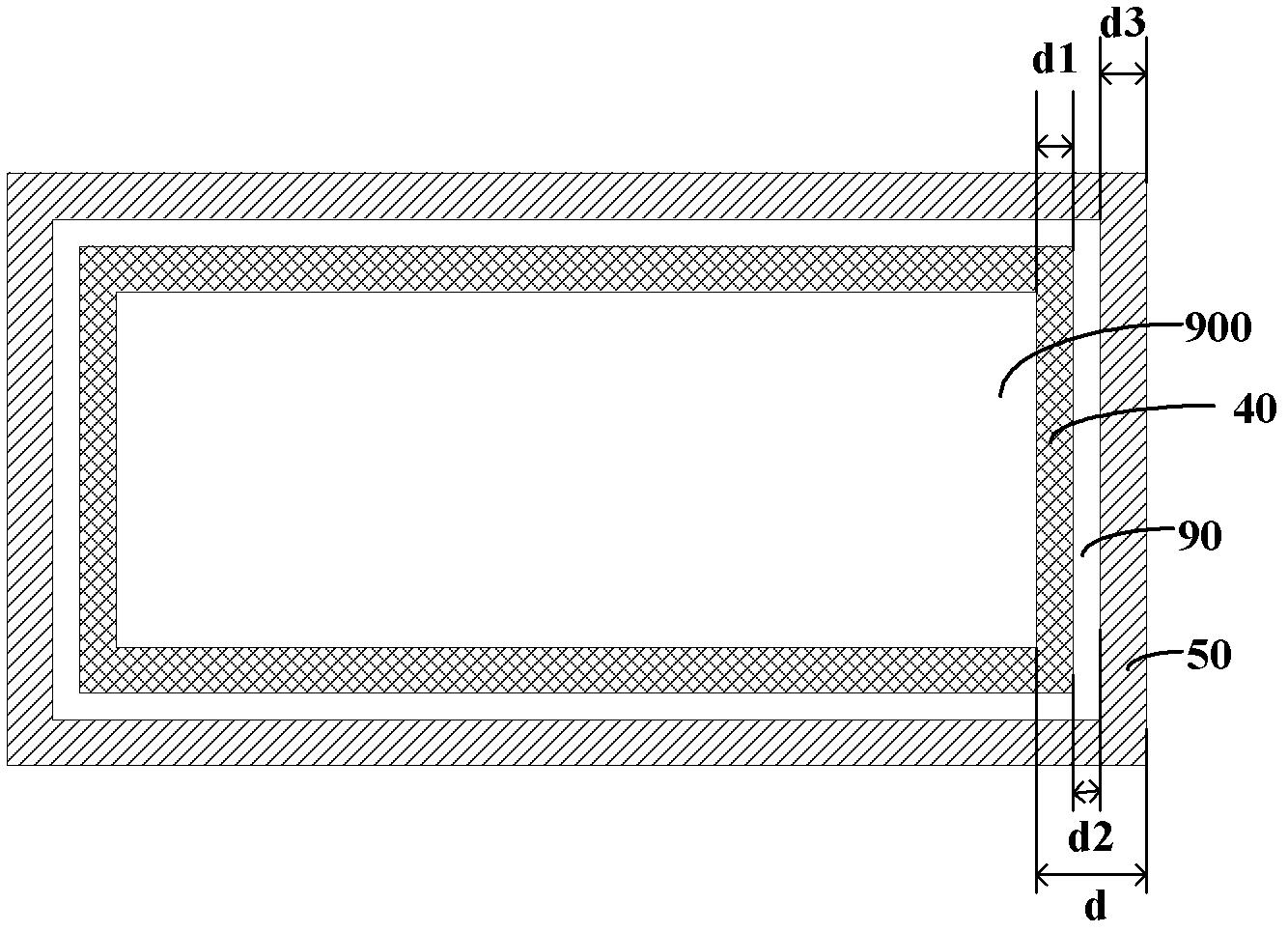

[0101] This embodiment provides a liquid crystal display, with reference to Figure 4As shown, the liquid crystal display includes: an upper polarizer 820, a liquid crystal display panel 900 located on the lower surface of the upper polarizer 820, a lower polarizer 810 located on the lower surface of the liquid crystal display panel 900, and a lower polarizer located on the lower surface of the lower polarizer 820. The backlight source 111 on the lower surface of 810, the backlight source 111 includes a bottom frame, and the lower polarizer 810, the liquid crystal display panel 900 and the upper polarizer 820 are sequentially located in the bottom frame.

[0102] Wherein, the liquid crystal display panel 900 may include a color filter substrate and an array substrate oppositely arranged, and a liquid crystal layer located between the color filter substrate and the array substrate, which are well known to those skilled in the art, so I won't repeat them here.

[0103] Wherein,...

Embodiment 3

[0109] refer to Figure 6 As shown, this embodiment provides a method for manufacturing a backlight, including:

[0110] Step S1, providing a composite material, the composite material includes a reflective material and a metallic material, and the reflective material and the metallic material are laminated together;

[0111] Step S2, forming the composite material into a bottom frame, the bottom frame including a reflective layer formed of the reflective material and a metal layer formed of the metal material;

[0112] Step S3, providing a light guide plate, and disposing the lower surface of the light guide plate on the reflective layer;

[0113] Step S4, providing an optical film, and disposing the optical film on the upper surface of the light guide plate;

[0114] Step S5, providing a light source, and disposing the light source on the side or bottom of the light guide plate.

[0115] First, execute step S1, refer to Figure 7 As shown, a composite material is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com