Backlight module and liquid crystal display

A liquid crystal display and backlight module technology, which is applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems affecting the display effect and reliability of liquid crystal display, so as to ensure the display effect and reliability, good display effect and reliability, and avoid leakage leaked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

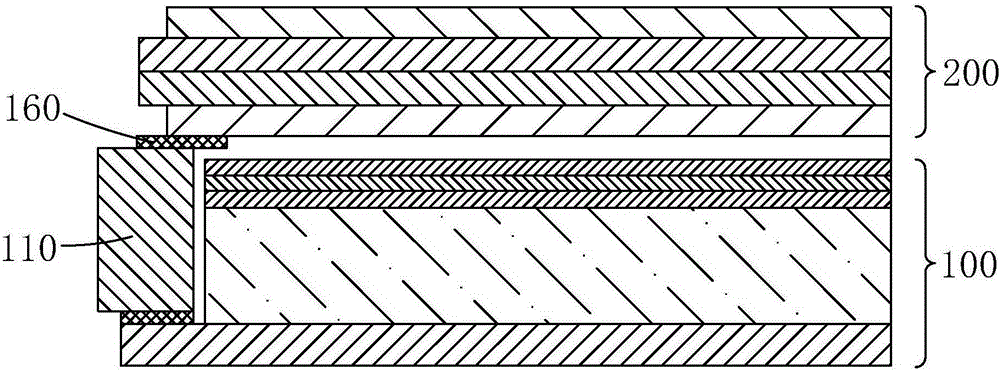

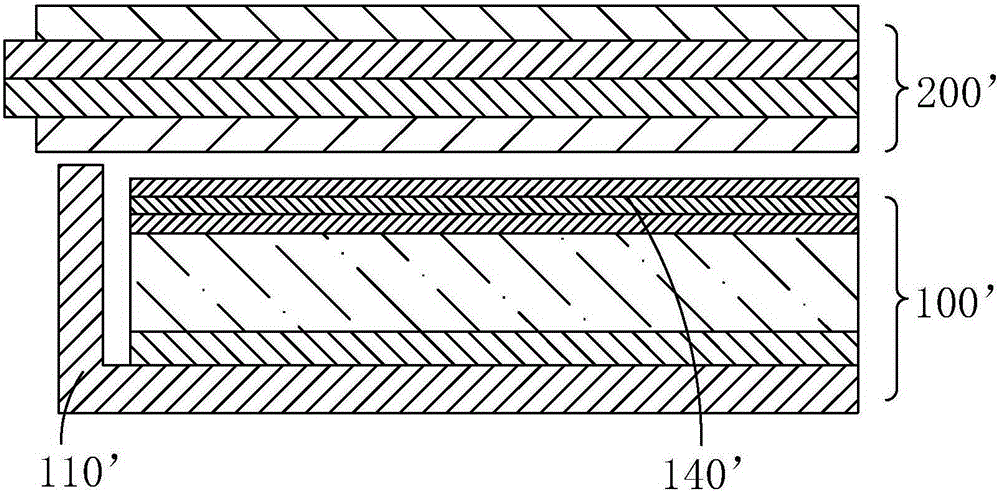

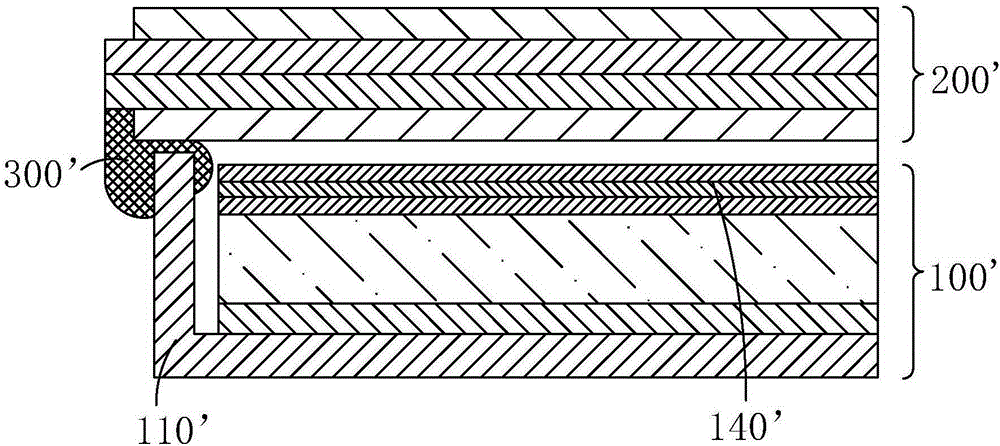

[0034] see Figure 4 to Figure 5 The present invention firstly provides a backlight module, including a backplane 11, a reflective sheet 12 disposed on the backplane 11, a light guide plate 13 disposed on the reflective sheet 12, and a light guide plate 13 disposed on the light guide plate 13. The optical film set 14 on the top.

[0035] Specifically, the optical film set 14 includes a plurality of superimposed optical films 141 , wherein the edge of the uppermost optical film 141 is provided with several outwardly extending protrusions 142 . The back plate 11 includes a bottom plate 111 and a side plate 112 vertically connected to the bottom plate 111, and several through holes are provided on the side plate 112 corresponding to the several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com