Intermittent sizing device for dyed yarns and sizing technology thereof

A dyed yarn and process technology, applied in the field of dyed yarn interval sizing device and its sizing process, can solve the problems of transformation, unfavorable existing equipment, high cost, etc., and achieve the goal of improving the quality of dyed yarn, large promotion and use value, and low transformation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

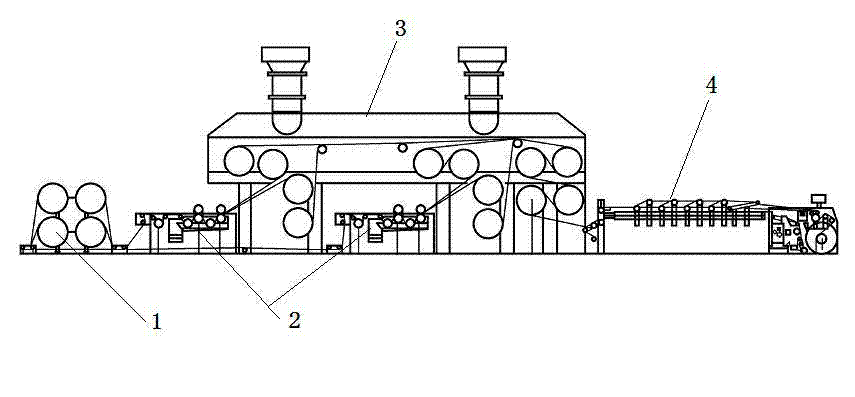

[0022] Specific implementation methods: such as figure 1 As shown, a colored yarn interval sizing device, the colored yarn sizing device includes from front to back according to the sizing process: a warp creel part 1, a size tank part 2, a drying room part 3, and a dry splitting part 4.

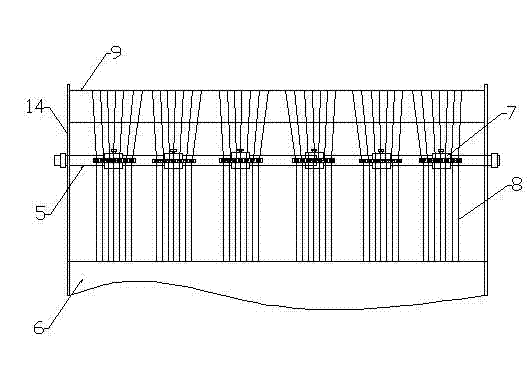

[0023] Such as figure 2 As shown, a splitting roller 5 is arranged between the warp beam 9 in the creel part 1 and the yarn delivery roller 6, and a plurality of yarns 8 for respectively guiding dark and light-colored yarns are installed on the splitting roller 5. The yarn dividing comb tooth 7. Splitting roller 5 is the polished rod that is fixed on the warp beam frame 14, and splitting roller 5 is arranged in parallel with warp beam 9.

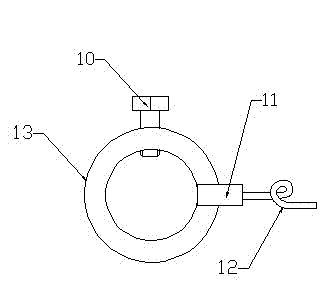

[0024] Such as image 3 , 4 As shown, the splitting comb 7 includes a sleeve 13 which is socketed with the splitting roller 5, and the outer wall of the sleeve 13 is fixed with a comb plate 11 parallel to the splitting roller 5, and a number of paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com