Patents

Literature

121results about How to "Guarantee the quality of dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

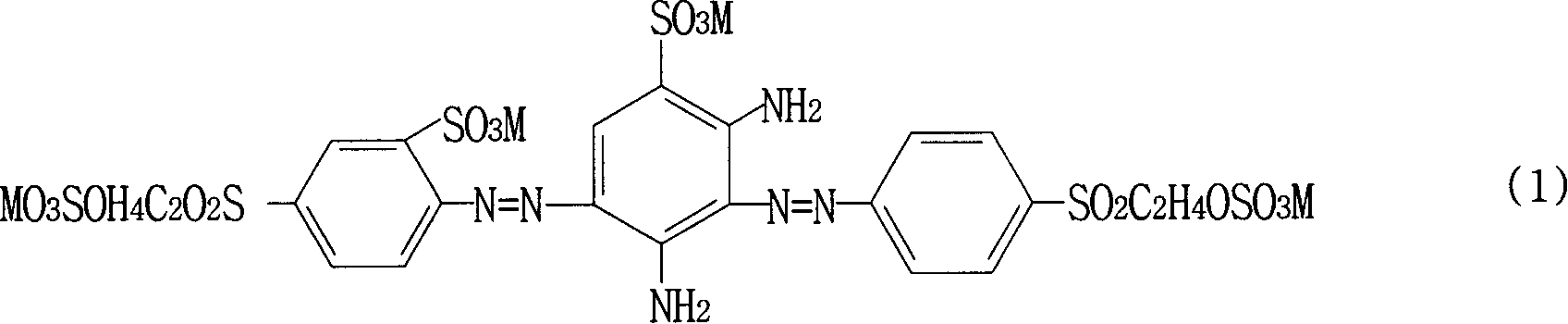

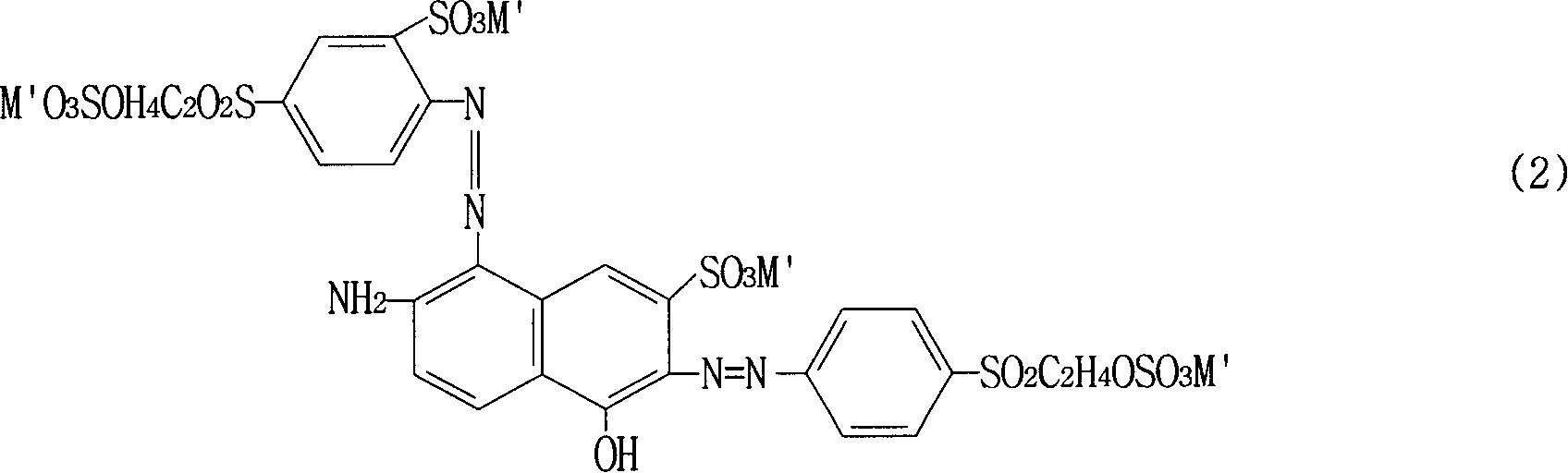

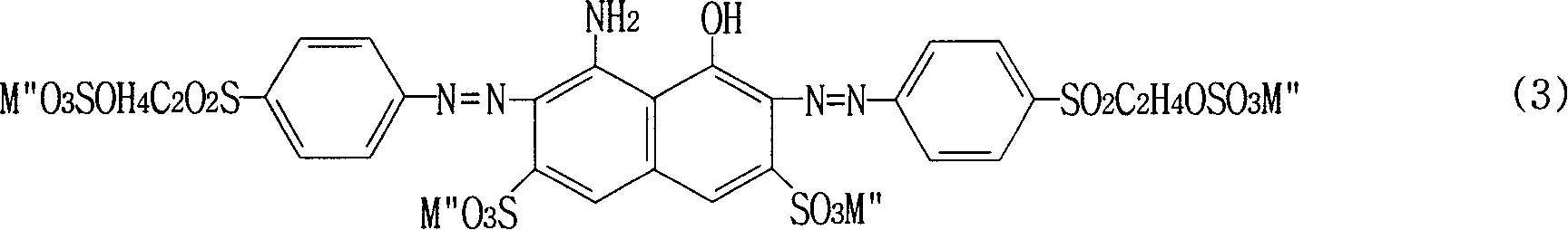

Active composite dye

ActiveCN1858118AGood synchronization of dyeingGood level dyeingOrganic dyesDyeing processCelluloseCompound c

The active composite dye includes at least one of compound A, at least one of compound B and at least one of compound C, with the compounds A, B and C being shown. The active composite dye is suitable for dyeing cellulose or protein fiber, and has the composition meeting the environmental and ecological requirement of Oeko-Tex Standard 100. The active composite dye has high build-up, good level dyeing property, good color reproduction, high dye uptake and other excellent performance.

Owner:ZHEJIANG RUIHUA CHEM

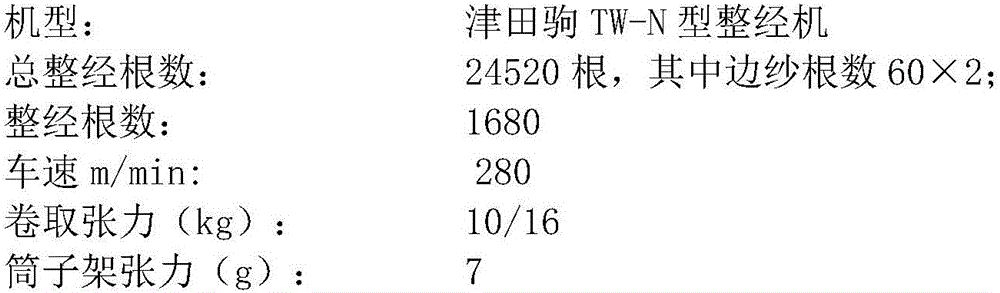

Jacquard acetic acid filament home textile fabric and production method thereof

ActiveCN106012214AGood coloring effectSoft touchHeating/cooling textile fabricsDry-cleaning apparatus for textilesSocial benefitsAcetic acid

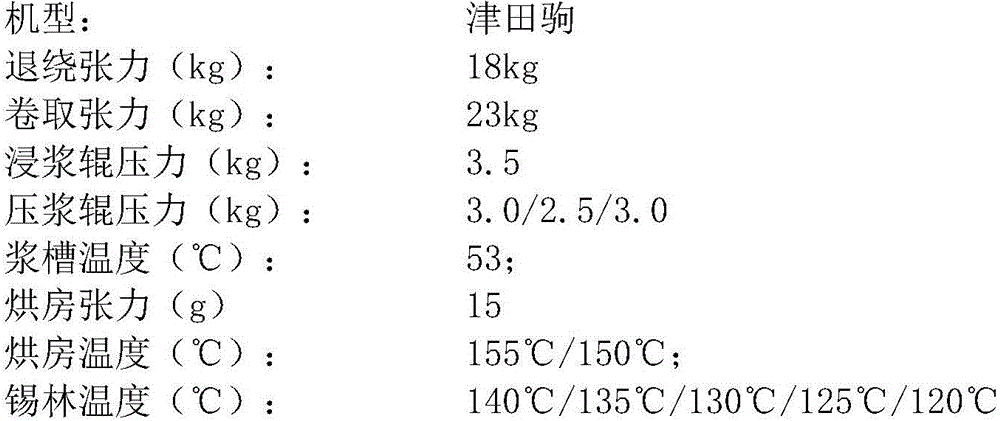

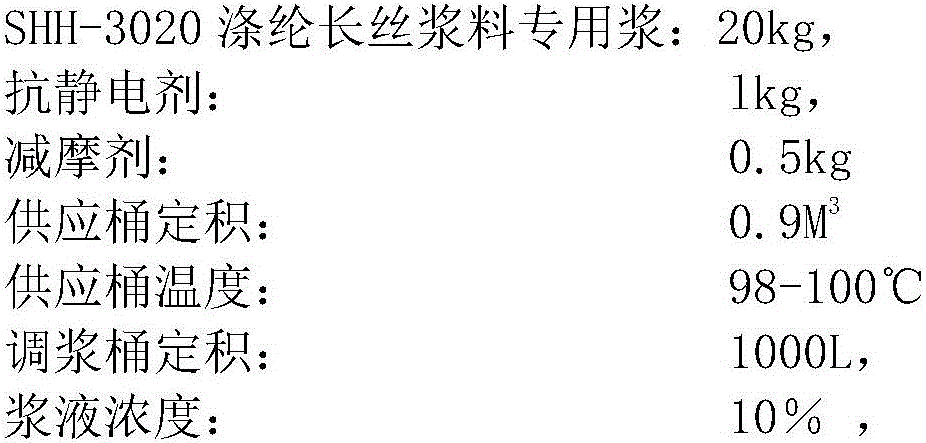

The invention provides a jacquard acetic acid filament home textile fabric. Warp is semi-dull polyester filaments with the specification of 50D / 72F, and warp density is 200 pieces per inch. Weft is 75 D acetic acid filaments, and weft density is 96.5 pieces per inch. The structure is a large jacquard fabric. The breadth of the finished product is 160 cm. A production method of the fabric includes the steps that firstly, weaving is conducted, wherein weaving is conducted through warping by means of a warping machine, sizing by means of a filament sizing machine, re-beaming by means of a combining machine, leasing by means of a leasing machine, drafting and weaving by means of a rapier jacquard loom; secondly, dyeing is conducted, wherein dyeing is conducted through unwinding, desizing, dyeing, dewatering, scotching and setting. The fabric is flat, fine, smooth in cloth surface, soft in hand feeling, light, thin, cool, easy to wash, quick to dry, high in color fastness, good in air permeability, gentle and elegant. Reagents of the fabric successfully meet the requirement for comfort and cool of home textile summer quilt fabric of people, and the fabric has high addition value and wide market prospects and is remarkable in economic and social benefit.

Owner:JIANGSU YUEDA HOME TEXTILE

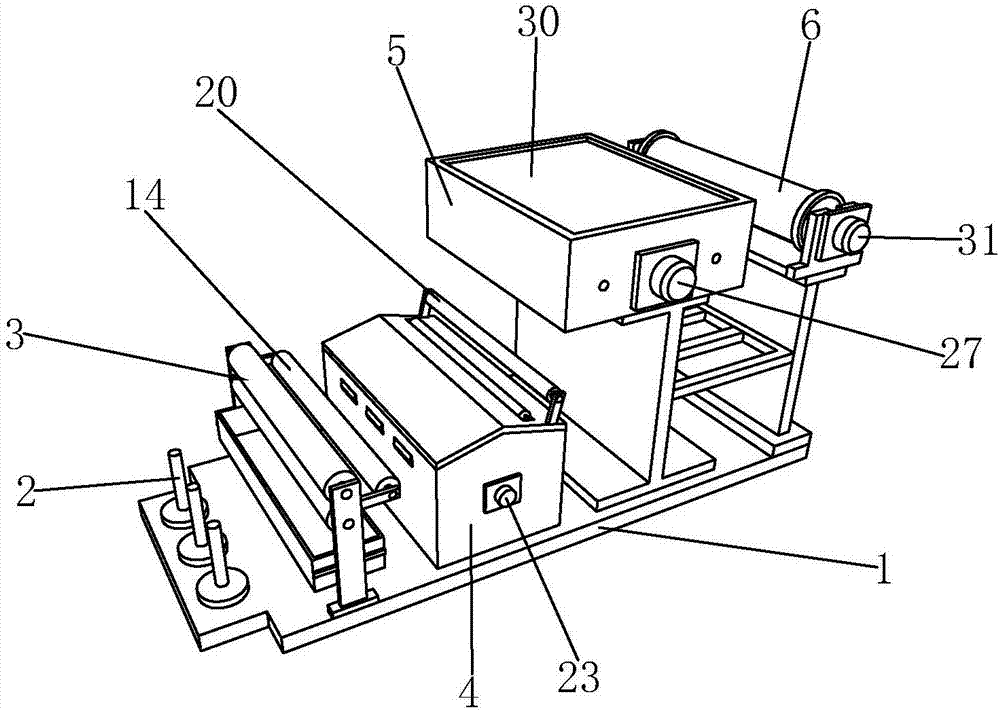

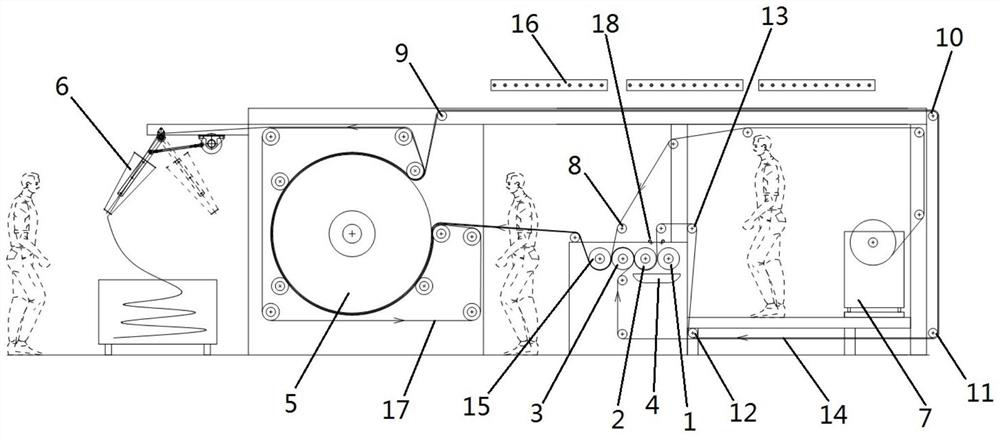

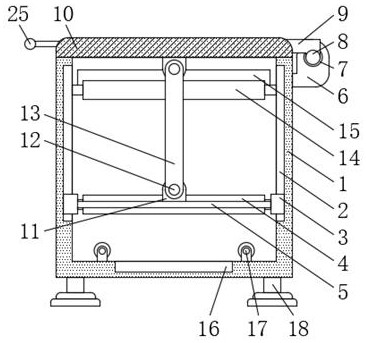

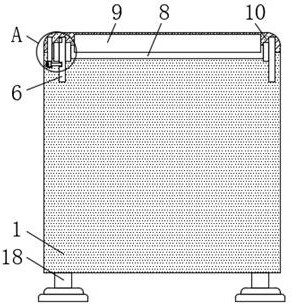

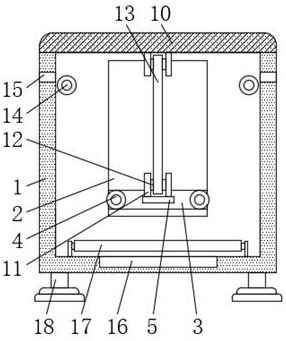

Cloth dyeing and drying integrated machine

InactiveCN107419464ADyeing completion time shortenedEase of mass productionTextile treatment containersLiquid/gas/vapor removalElectric machineryEngineering

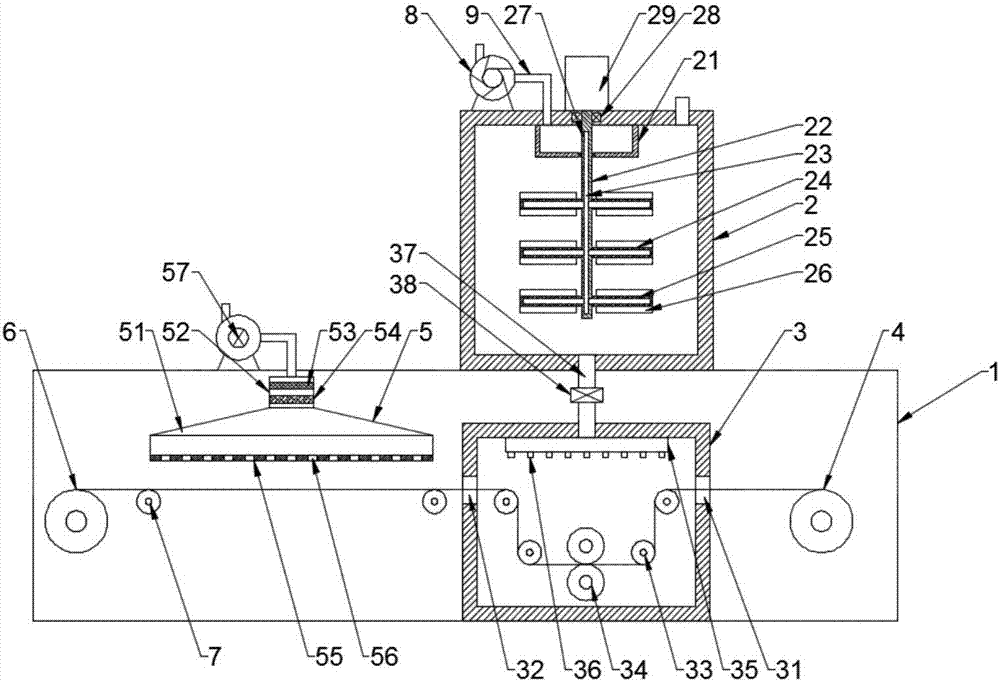

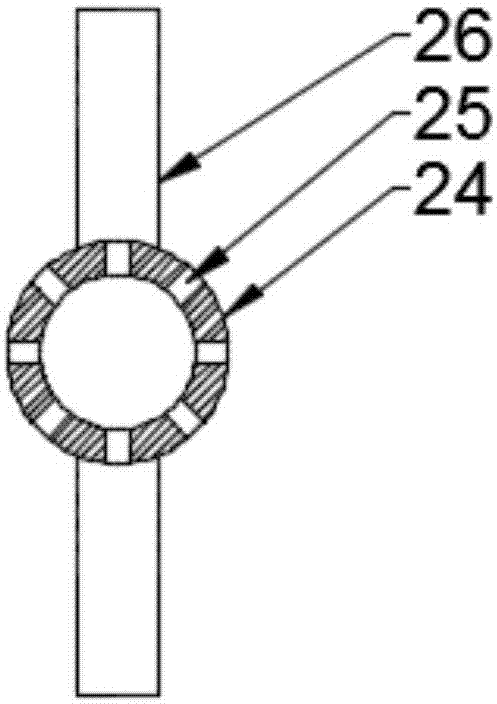

The invention discloses a cloth dyeing and drying integrated machine, which comprises a machine body, a stirring box, a cloth dyeing box and a drying device. The top of the machine body is provided with a stirring box and a blower. The top wall of the inner cavity is provided with a revolving air box, a rotating shaft is provided in the mixing box, an air passage is provided in the rotating shaft, a number of stirring tubes are uniformly arranged on the rotating shaft, and a finished product roller and a drying device are arranged in sequence from left to right in the body. , dyeing box and raw material roller, the left and right side walls of the dyeing box are respectively provided with discharge holes and feeding holes, the inner cavity of the dyeing box is provided with a guide roller group and a dyeing roller group, and the inner cavity of the dyeing box is topped. The wall is equipped with a spraying device, and the drying device includes an air outlet hood, a heating box and a blower; the present invention realizes all processing procedures from rendering to drying of white cloth by setting a dyeing box and a drying device on the body, so that the dyeing of the cloth The time is greatly shortened, which is convenient for large-scale production; the setting of the mixing box can homogenize the dyes for dyeing cloth, which is convenient for later coloring of the cloth.

Owner:冯飞燕

Dyeing method of mulberry silk cheese

InactiveCN101838941AAvoid deformationDegumming evenly and fullyDyeing processLiquid/gas/vapor textile treatmentFiberEngineering

The invention provides a dyeing method of a mulberry silk cheese, comprising the following procedures: slack-spooling, pre-processing, dehydrating, drying, dyeing, postprocessing, dehydrating and drying. The dyeing method is characterized in that the constant weight of the cheese for slack-spooling is 0.55-0.6kg / pcs, the density is 0.35-0.4g / cu.cm., and the cheese is wrapped by an elastic fiber sleeve and then is subjected to the pre-processing procedure; and secondary slack-spooling is carried out on the cheese after the procedures of pre-processing, dehydrating and drying, the constant weight of the cheese is still 0.55-0.6kg / pcs, the density is 0.35-0.4g / cu.cm., and the cheese performed with secondary slack-spooling is wrapped by the elastic fiber sleeve and then is subjected tp the dyeing procedure. In the invention, slack-spooling and secondary slack-spooling can effectively overcome various adverse factors affecting the density and the shape of the cheese in the procedures; and situations of uneven dyeing and great inner-outer color difference owing to overlarge density do not occur, and cheese collapse owing to too small density does not occur, thus ensuring the dyeing quality of the cheese. The dyeing method has the outstanding advantage of effectively solving unstable dyeing quality of the mulberry silk cheese.

Owner:TIANJIN TIANGE TEXTILE

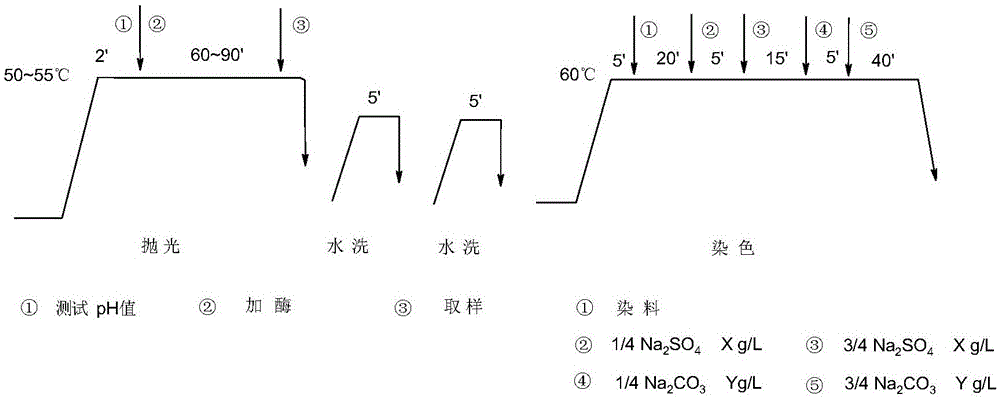

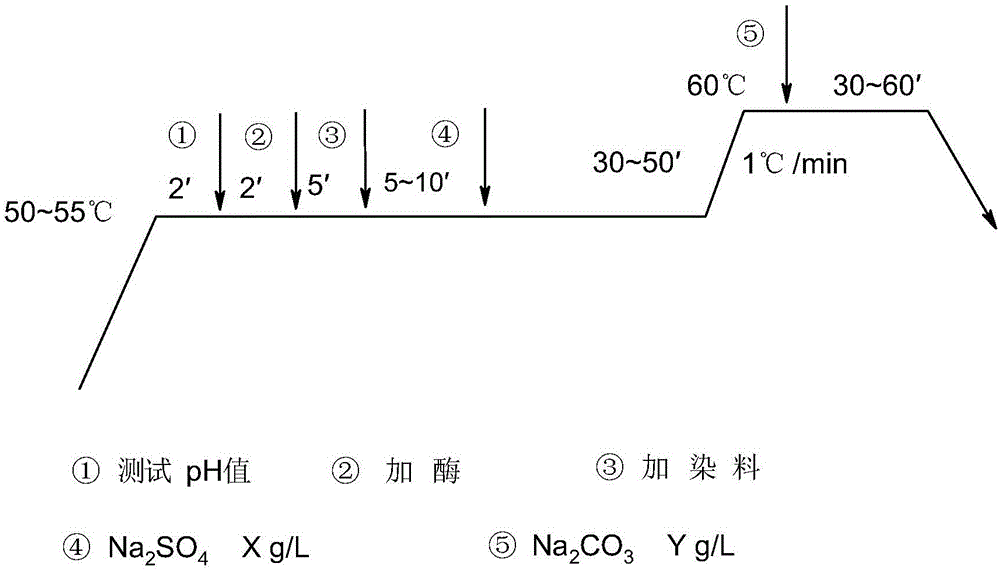

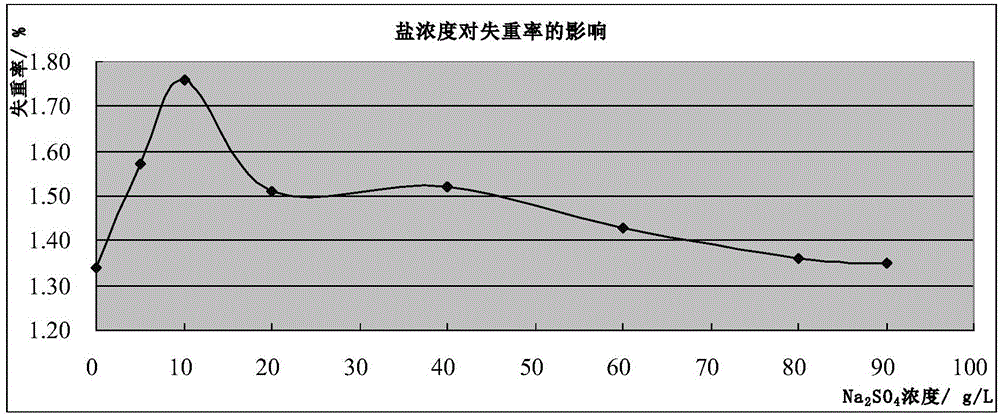

Application of thermophilic Chaetomium cellulose to polishing, dyeing and one-bat technology

ActiveCN105155167AImprove polishing effectReduce dosageTextile treatment machine arrangementsEnzymesHigh concentrationChaetomium

The invention discloses an application of thermophilic Chaetomium cellulose to polishing, dyeing and one-bat technology. The thermophilic Chaetomium cellulose is expressed via Trichoderma reesei or pichia pastoris; the thermophilic Chaetomium cellulose is neutral cellulose having a halophilic function; salt with high concentration has obvious lifting action on activity of neutral cellulose; the optimal action temperature of the neutral cellulose is 57 to 63 DEG C, so polishing temperature and dyeing temperature are the same; during the polishing, even dyeing can be achieved and guaranteed.

Owner:希杰尤特尔(湖南)生物科技有限公司 +1

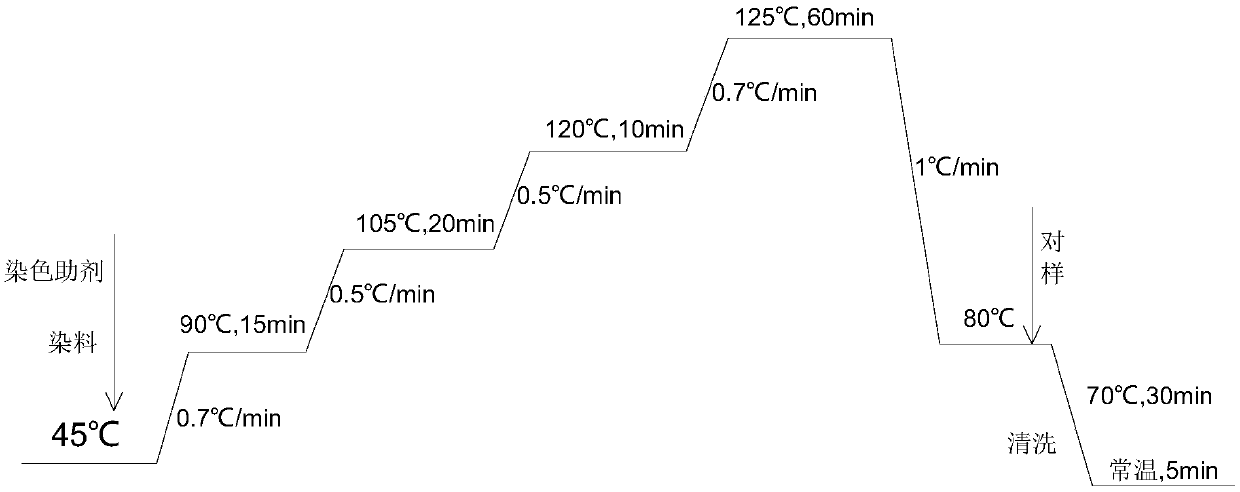

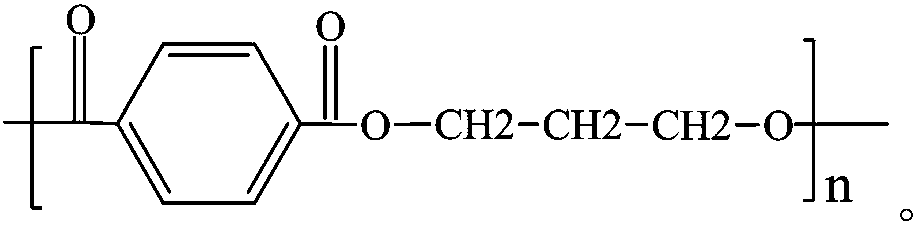

Dyeing and finishing processing technique of memory T400 fabric based on biological based material

InactiveCN109554911AImprove color reproducibilityRealize large-scale productionFibre treatmentDry-cleaning apparatus for textilesDisperse dyeEngineering

The invention discloses a dyeing and finishing processing technique of memory T400 fabric based on a biological based material. The technique sequentially includes: pretreating, dyeing and shaping; the pretreating process sequentially includes: first-time open-width desizing, cold pad-batching and second-time open-width desizing, and a dyeing agent adopted in the dyeing process is composed of a dyeing aid and dye which is disperse dye; the dyeing process utilizes a high-temperature high-pressure liquid flow dyeing machine for dyeing, and the dyeing aid and the disperse dye are started to be injected respectively when temperature of a dyeing vat of the dyeing machine reaches 45 DEG C; the shaping process utilizes shaping treatment liquid to shape fabric greige cloth after being dyed througha shaping machine. By formulating proper pretreating, dyeing and shaping processes, processed fabric is enabled to be free of defects like crepe mark and scratch while dyeing quality is ensured, andthe fabric is endowed with high elasticity, memorability and additional functional function.

Owner:SHENGHONG GRP CO LTD

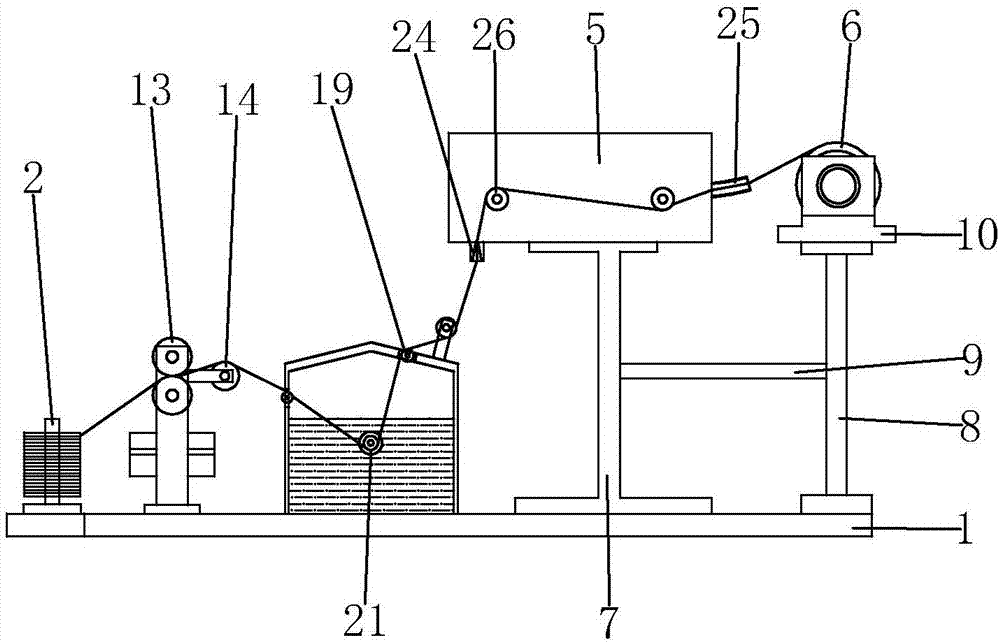

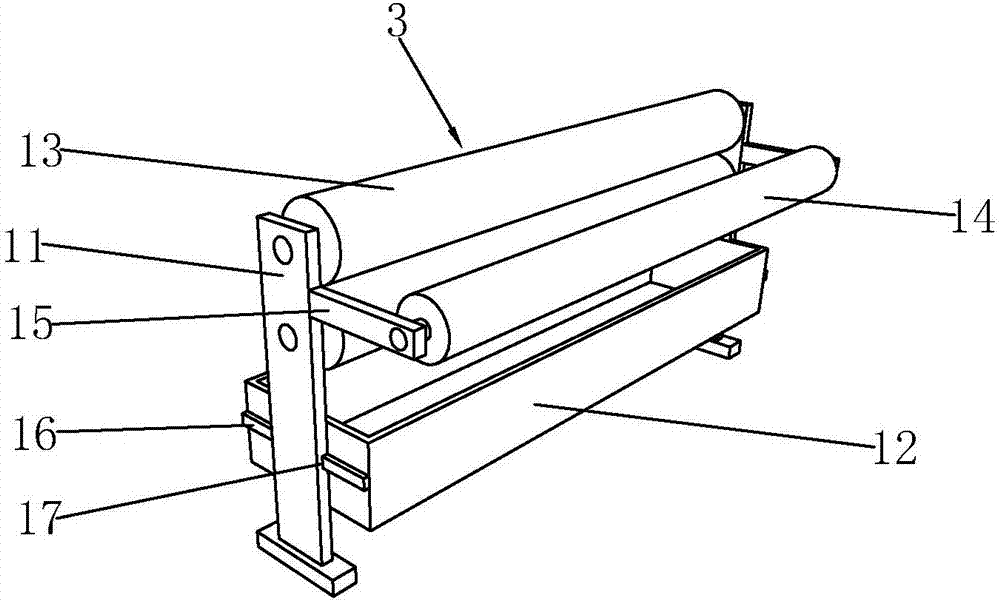

Yarn dyeing device for textile production

InactiveCN106930024AFlexible connectionEasy to cleanTextile treatment containersSucessive textile treatmentsYarnEngineering

The invention discloses a yarn dyeing device for textile production, which comprises a supporting platform, on which a bobbin holder, a yarn feeding mechanism, a dye box, an air-drying box and a take-up roller are respectively arranged, and on the yarn feeding mechanism, there are Waste box, one side of the dye box is provided with a feeding trough, the top surface of the dye box is provided with an outlet slot, the inside of the dye box is provided with a dyeing roller, the dyeing roller is evenly distributed with wire grooves, and the outside of the dye box is provided with a drive motor. The driving motor is connected to the dyeing roller. There is an inlet hose at the bottom of the air-drying box. The lead roller is connected with a take-up motor on one side of the take-up roller. The invention has the advantages of simple structure, flexible connection, multi-strand yarn dyeing at one time, and winding together, high working efficiency, good dyeing effect, and high quality and good performance of the obtained yarn product.

Owner:嵊州市靖洁纺织机械有限公司

Textile dyeing device capable of saving dyes

InactiveCN107488959ARealize deliveryAvoid damageLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringDrying time

The invention discloses a textile dyeing device capable of saving dyes. The textile dyeing device comprises a box body, a dye box is fixedly connected between two opposite sides of the inner wall of the box body through a supporting plate, the two opposite sides of the inner wall of the box body are fixedly connected with a fixing device through fixing blocks, one side of the top of the supporting plate is fixedly connected with a pressing device, a leaky bucket is fixedly connected between two opposite sides of the inner wall of the box body, the bottom of the leaky bucket communicates with a first dye tube, one end of the first dye tube communicates with a water pump, the outlet end of the water pump is connected with a spray dyeing tube through a second dye tube, the two opposite sides of the inner wall of the box boy are fixedly connected with a pair of cushioning devices, the centers of the cushioning devices are rotatably connected with pressed roller wheels, and a drying device is fixedly connected between the two opposite sides of the inner wall of the box body through a fixing plate. The invention relates to the technical field of textile processing. The textile dyeing device capable of saving the dyes improves the dyeing efficiency, shortens the drying time, saves the dyes, reduces the labor intensity and improves the work efficiency.

Owner:李文艳

Unidirectional circulation dyeing process for cheese

ActiveCN103726244ALess power consumptionAvoid layer differenceTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentDyeingEngineering

The invention provides an unidirectional circulation dyeing process for cheese. The unidirectional circulation dyeing process for the cheese is characterized in that a single circulation mode is adopted by dyeing liquor, and the dyeing liquor is driven to circulate from the interior of the cheese to the exterior of the cheese through the changing of the rotating speed of a main pump in a dyeing vat. According to the unidirectional circulation dyeing process for the cheese, a dyeing pulse technique and a spray technique are adopted to change a circulation mode of the dyeing process as single outflow dyeing, only half or even lower water level of raw materials are soaked by the dyeing liquor, dyeing can be carried out, the bath ratio can be lowered to 1:3, and production water consumption can be reduced greatly.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

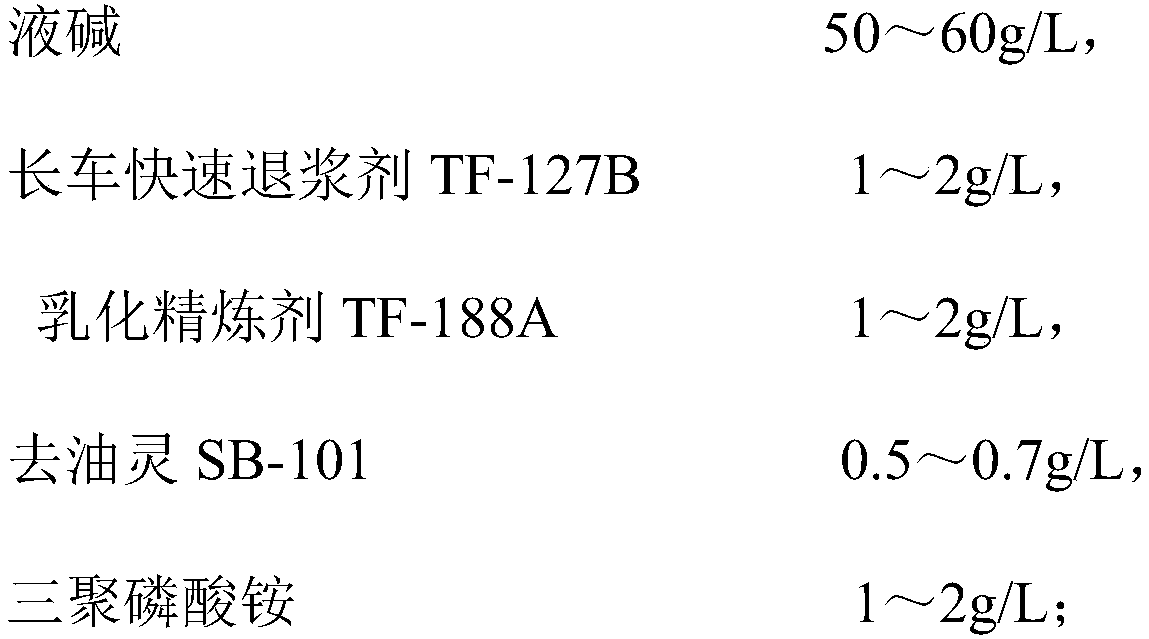

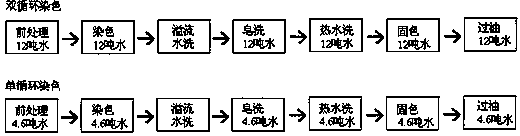

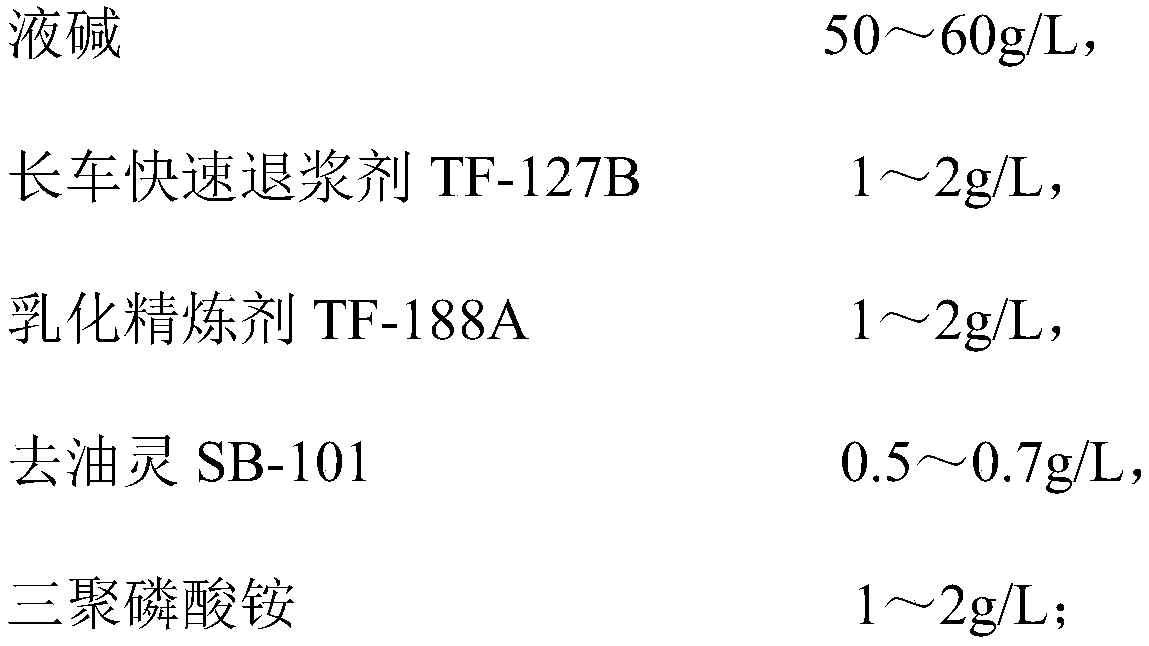

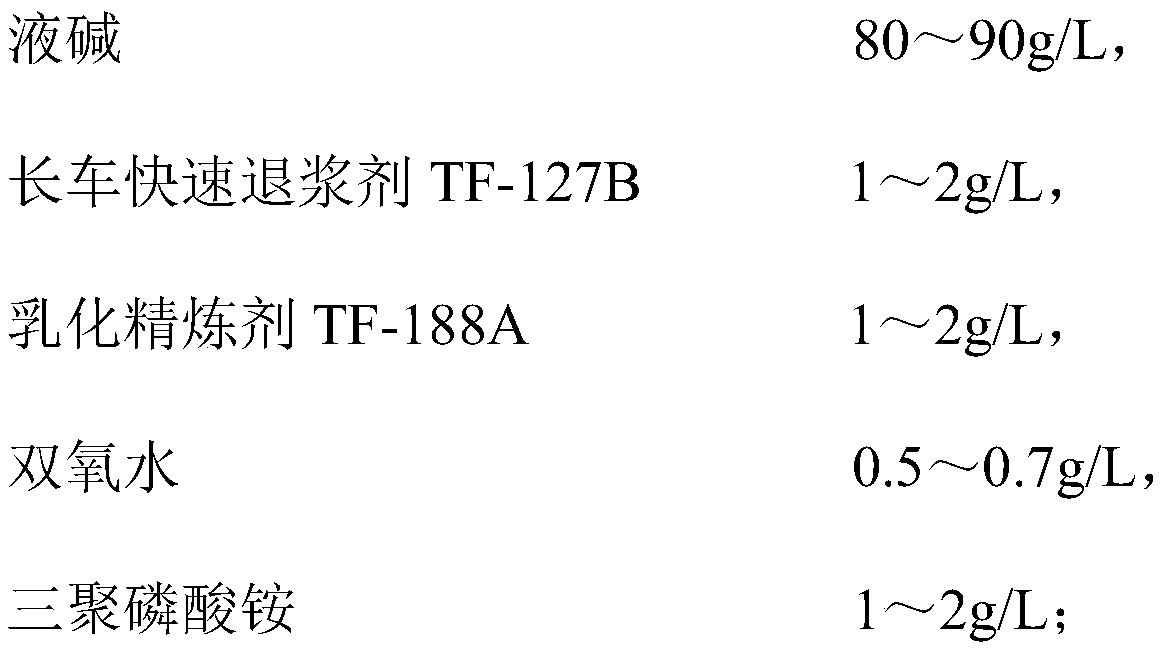

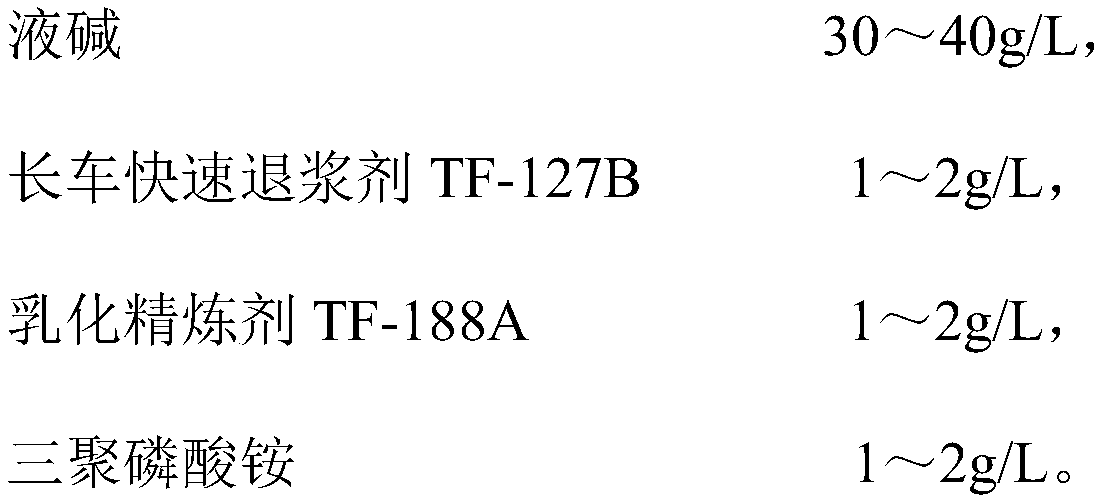

Pretreatment process for memory T400 fabric based on biological based material

InactiveCN109594323ASoft and plumpGuarantee the quality of dyeingFibre treatmentDry-cleaning apparatus for textilesMelamine phosphateProcess engineering

The invention discloses a pretreatment process for a memory T400 fabric based on a biological based material. The pretreatment process comprises a first open width desizing process, a cold rolling process and a second open width desizing process which are carried out in sequence, wherein a desizing aid used in the first open width desizing process has a formula of a 50-60g / L liquid caustic soda, a1-2g / L long-vehicle rapid desizing agent TF-127B, a 1-2g / L emulsification refining agent, a 0.5-0.7g / L oil remover SB-101 and 1-2g / L melamine phosphate; a rolling treatment liquid used in the cold rolling process has a formula of a 80-90g / L liquid caustic soda, a 1-2g / L long-vehicle rapid desizing agent TF-127B, a 1-2g / L emulsification refining agent, a 0.5-0.7g / L hydrogen peroxide and 1-2g / L melamine phosphate; a desizing aid used in the second open width desizing process has a formula of a 30-40g / L liquid caustic soda, a 1-2g / L long-vehicle rapid desizing agent TF-127B, a 1-2g / L emulsification refining agent and 1-2g / L ammonium triphosphate. By adopting the pretreatment process, an appropriate pretreatment process is made, various impurities on a fabric can be removed, smooth later dyeing procedures can be ensured, and the softness of the fabric can be also ensured.

Owner:SHENGHONG GRP CO LTD

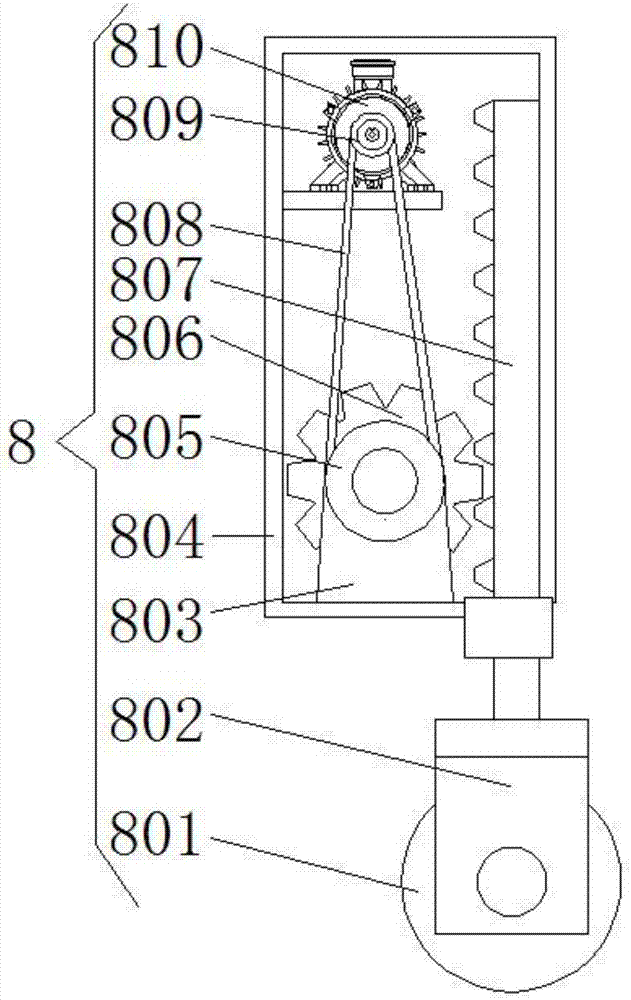

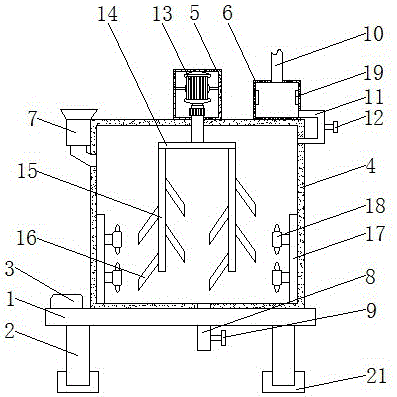

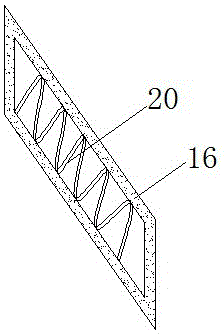

High-efficiency fabric dye mixer

InactiveCN106040038AQuality improvementGuarantee the quality of dyeingTransportation and packagingRotary stirring mixersBiochemical engineeringElectric wire

The invention discloses a high-efficiency fabric dye mixer. The mixer comprises a base. Support legs are symmetrically fixed to the bottom of the base. The top of the base is orderly provided with a controller and a tank from left to right. The top of the tank is orderly provided with a motor case and a heating water tank from left to right. A feeding hopper is fixed to one side of the tank. The bottom of the feeding hopper is communicated with one side of the tank through a pipe. The bottom of the tank is communicated with a discharge pipe. One end of the discharge pipe far away from the tank goes through the base and extends to the lower part of the base. The high-efficiency fabric dye mixer utilizes the heating water tank to preheat water to be stirred, guarantees good mixing of water and dye raw materials and is convenient for dye raw material stirring. Through use of a heating electric wire in the stirring rod, in stirring, the stirring solution is heated so that the dye raw materials and water are fully mixed and dye quality is improved.

Owner:锡山区方隆五金厂

Dyeing cylinder in dyeing assembly line of non-woven fabric

The invention discloses a dyeing cylinder in a dyeing assembly line of non-woven fabric. The dyeing cylinder comprises a cylinder body, a plurality of fixing buckles, an aeration pipe, an adjusting valve, a plurality of air outlets, a plurality of guide rollers, a protection cover, heat insulation layers, a plurality of connecting bodies, a handle, a discharge outlet and a thermometer, wherein the internal side surface and the internal bottom surface of the cylinder body are both provided with the fixing buckles, the fixing buckles are provided with the aeration pipe, the aeration pipe is provided with the adjusting valve and the air outlets, the cylinder body is internally provided with the guide rollers, the cylinder body is provided with the protection cover which can be opened and closed in a matching way, the internal top surface and the internal side surface of the protection cover are both provided with the heat insulation layers, the side surface of the protection cover is provided with an inlet and an outlet of the non-woven fabric, the bottom part of the cylinder body is provided with the discharge outlet, and the cylinder body is provided with the thermometer. The dyeing cylinder disclosed by the invention has the advantages that manpower is not needed for stirring, the labor can be saved, the stirring is uniform, the heat loss in the dye cylinder can be also reduced, impurities such as dust and particles can be prevented from entering the dyeing cylinder, the dyeing quality of a product is ensured, and the structure is simple.

Owner:HANGZHOU JINMUZHI GARMENT ACCESSORIES

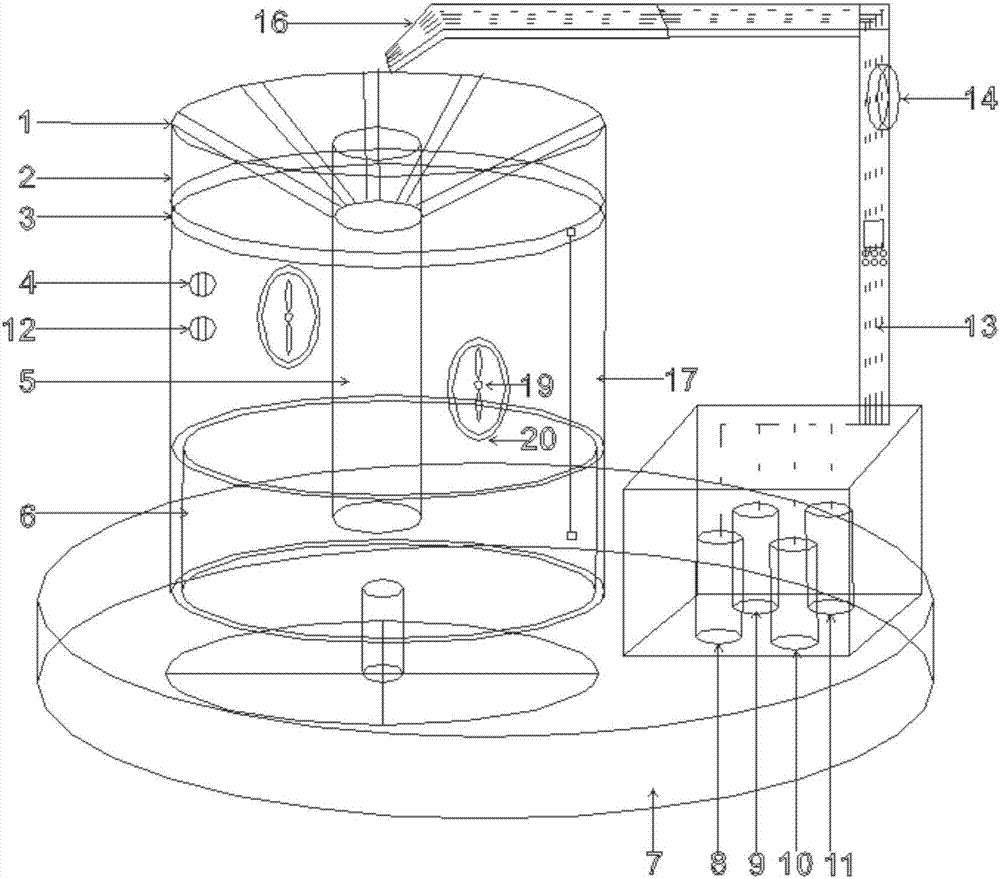

High-temperature high-pressure dyejigger

InactiveCN102493139AReasonable designSimple structureLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsFrequency conversionEngineering

The invention belongs to the technical field of printing and dyeing equipment, in particular to a high-temperature high-pressure dyejigger which solves the technical problems that the prior art is not reasonable enough in design, and the like. The high-temperature and high-pressure dyejigger comprises a pressure container, wherein the side part of the pressure container is provided with a window, and a side cover is arranged at the window; a first roller and a second roller are arranged in the pressure container, wherein a dye vat is arranged below the first roller and the second roller; a steam input mechanism is connected to the pressure container; the first roller and the second roller are respectively connected with a first frequency-conversion drive device and a second frequency-conversion drive device; a vertical tensioning mechanism is arranged between the first roller and the dye vat; and another vertical tensioning mechanism is arranged between the second roller and the dye vat. The high-temperature high-pressure dyejigger disclosed by the invention has the advantages of reasonable design, simple structure, difficulty in generating chromatic aberration, easiness in operation and use, time and labor saving, high working efficiency and capability of effectively ensuring the evenness of fabrics. According to the high-temperature high-pressure dyejigger, pressure balance and temperature evenness in the pressure container can be realized, the dyeing quality is effectively ensured, and the product quality is good.

Owner:骆玛丽

Production technique for copper ammonia fiber looped fabrics

InactiveCN103014996AHigh degree of automationEasy to operateBiochemical fibre treatmentDry-cleaning apparatus for textilesCotton fibreFiber loop

A production technique for copper ammonia fiber looped fabrics is characterized in that blended yarns blended by copper ammonia fibers and cotton fibers and / or 100% of copper ammonia yarns are used as weaving yarns, and are woven to obtain grey fabrics, wherein the weaving yarns are refined before the weaving, or the grey fabrics are refined after the weaving; and then the grey fabrics are softened to prepare the copper ammonia fiber looped fabrics. The technique is simple, reliable and convenient to implement; and prepared copper ammonia looped products have the characteristics of freshness, amenity, health, comfort, humidity absorption, breathability, natural color, soft texture, good skin friendliness and the like.

Owner:SUNVIM GROUP

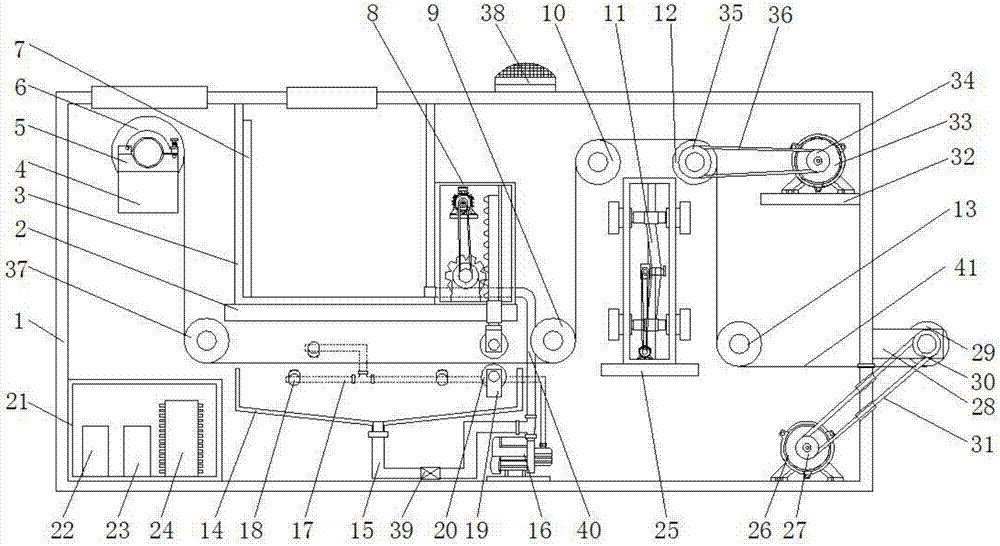

Convenient and sanitary full-automatic slide dyeing device

InactiveCN107367418AEasy loading and unloadingEasy accessPreparing sample for investigationProcess engineeringFully automated

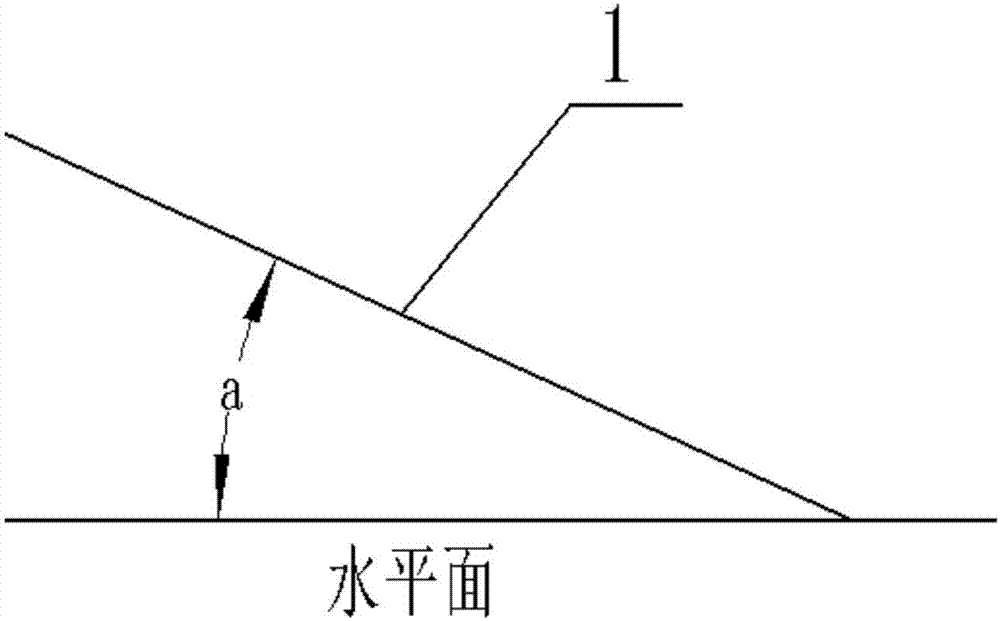

The invention relates to the technical field of medical inspection, in particular to a convenient and sanitary full-automatic slide dyeing device. By a cantilever spraying structure and an inclination angle adjustable rotating dyeing platform, a dyeing reagent is in non-adhesion mobile contact with cells, and time consumed for dye liquor changing and dye liquor drying in a cell dyeing operation process is shortened, the production efficiency and the convenience for experimental operation are greatly improved, waste and pollution of the reagent are reduced, and the reagent and the labor cost are saved. Cross contamination caused when cells are soaked in different dyeing reagents is avoided. The convenient and sanitary full-automatic slide dyeing device has the characteristics of relatively independent operation, sealing, convenience in moving and the like.

Owner:付亚平

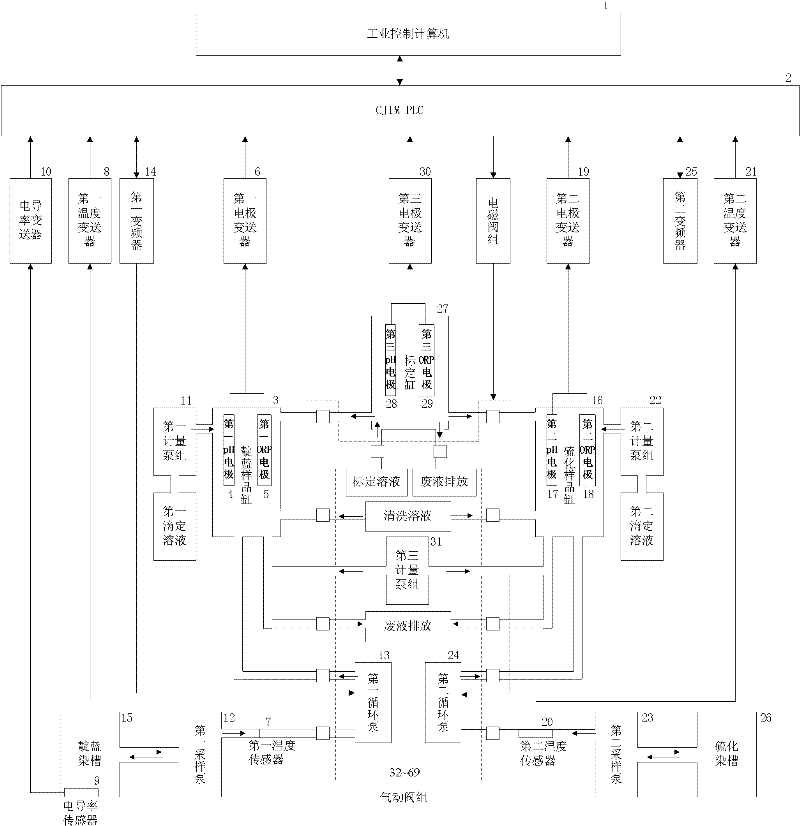

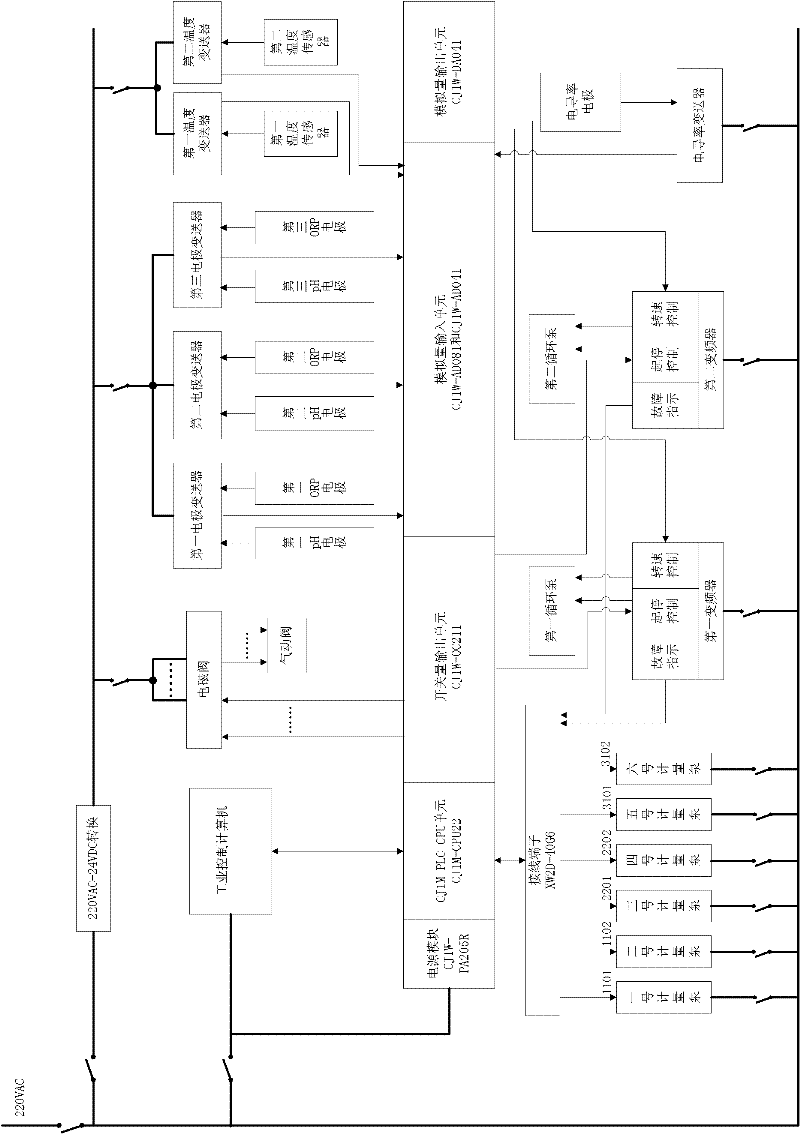

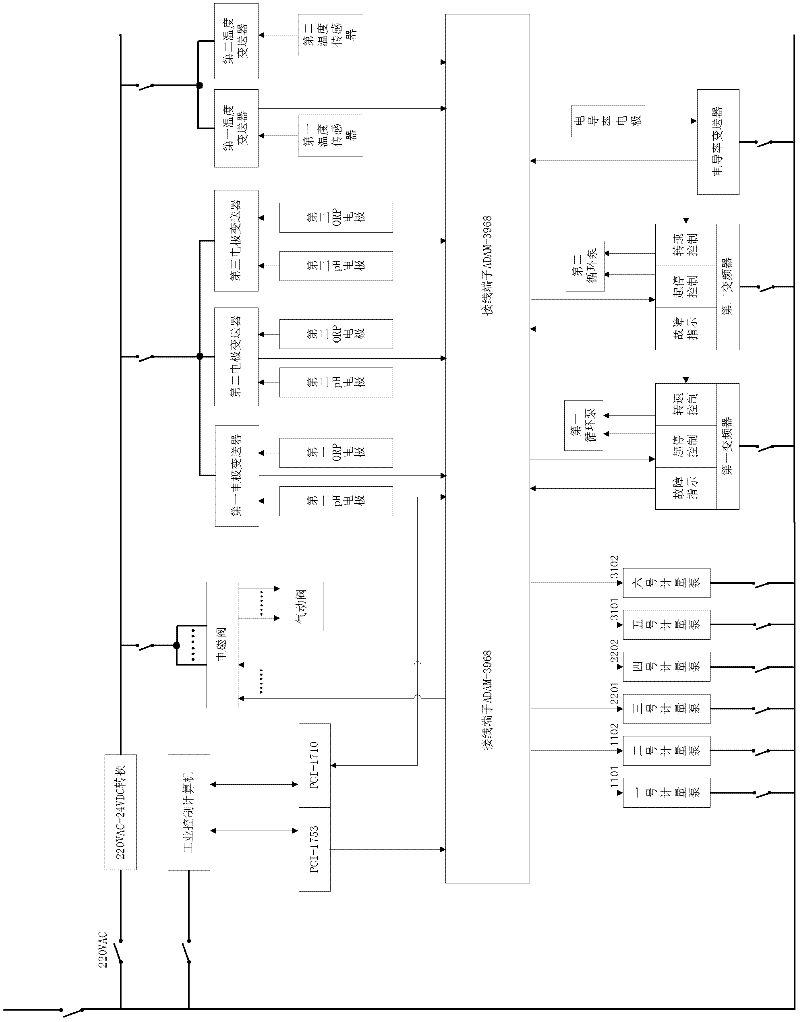

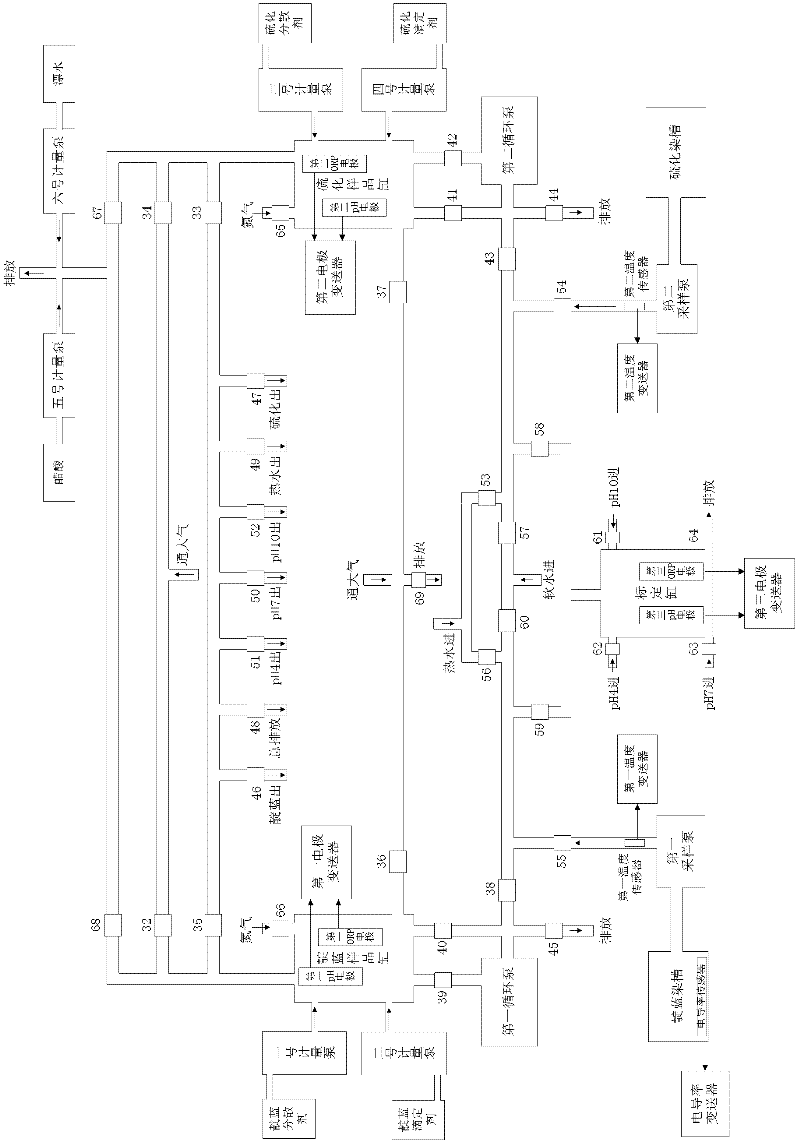

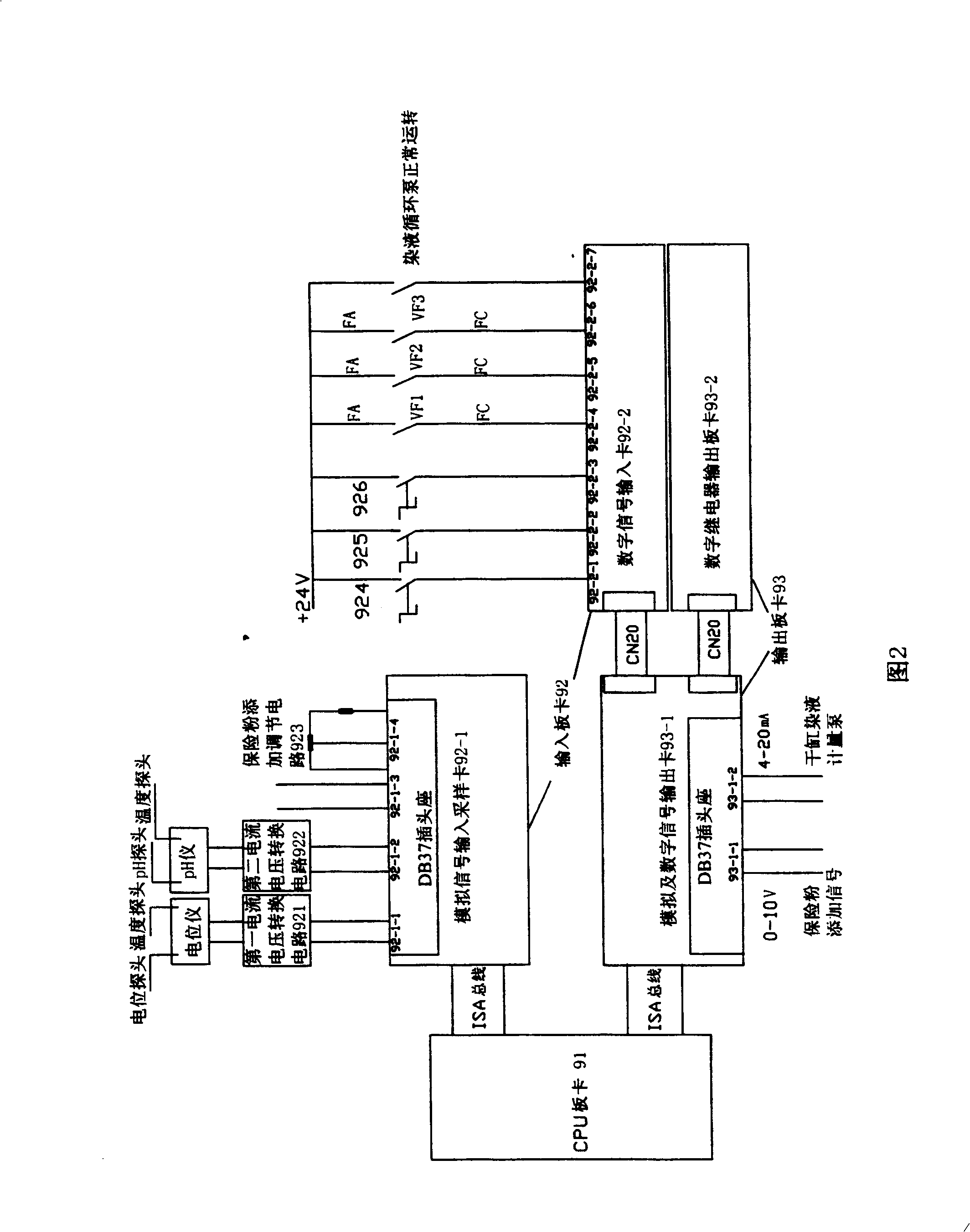

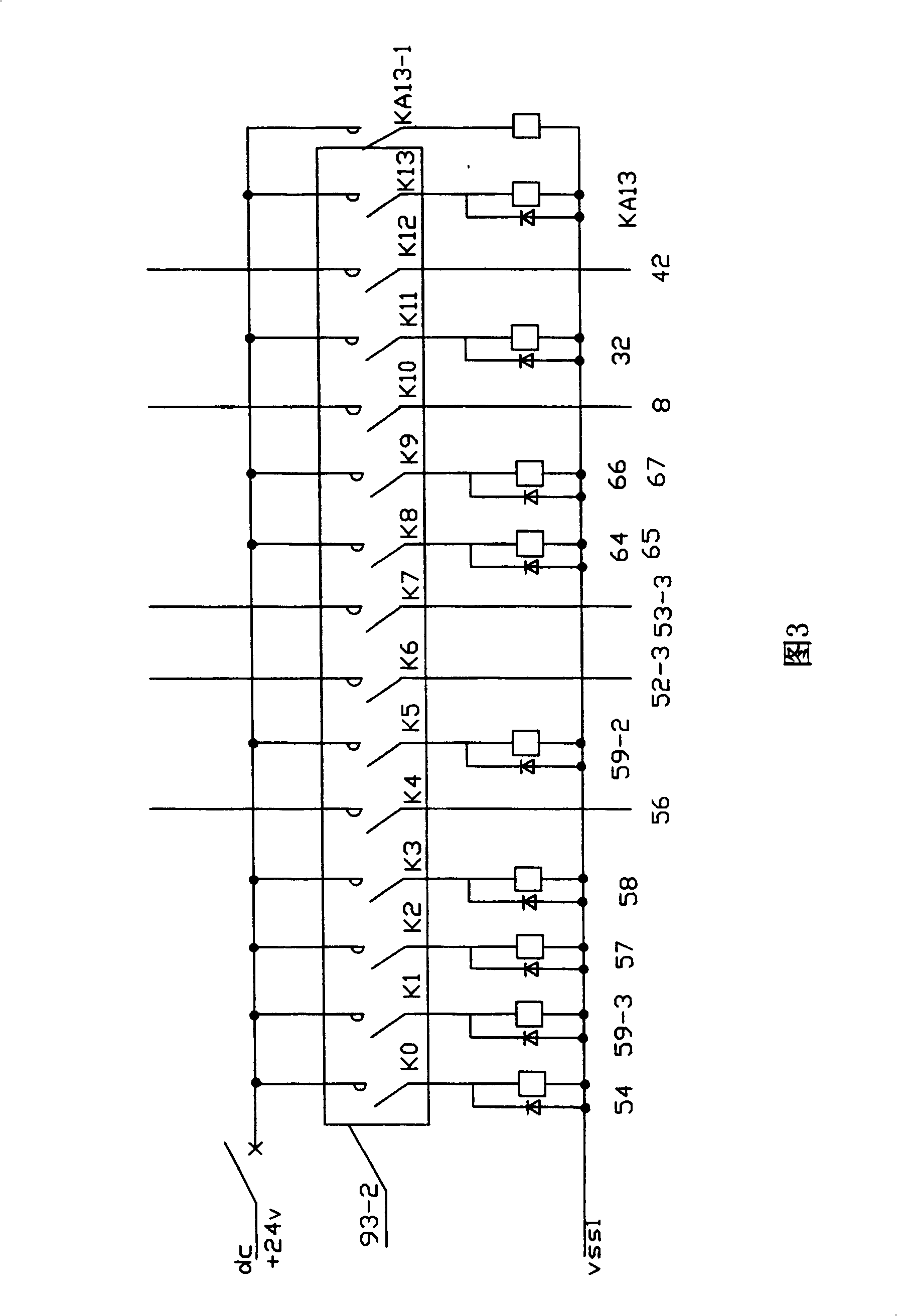

Online detection method for dye liquor components of bundle type dye machine on basis of programmable logic controller (PLC)

InactiveCN102535071AGuaranteed accuracyGuarantee the quality of dyeingTextile treatment machine partsProgrammable logic controllerPotentiometric titration

The invention discloses an online detection method for dye liquor components (sodium hydrosulfite, indigo and sodium hydroxide) of a bundle type dye machine on the basis of an Omron programmable logic controller (PLC). An online detection system comprises an indigo dye liquor online detection device, a vulcanizing dye liquor online detection device, a calibration device, the PLC and an industrialcontrol computer. The online detection method collects dye liquor samples in a dye tank of the dye machine in a real-time online mode, utilizes the industrial control computer and the PLC to serve ascores, detects concentration of corresponding components of the dye liquor in an online timing mode by means of a potentiometric titration method, and detects the pH value and the temperature of the dye liquor in an online real-time mode. The system can clean pipelines after completion of every test. The online detection method can calibrate the indigo dye liquor online detection device or the vulcanizing dye liquor online detection device according to requirements to ensure accuracy of detection results. The online detection method can ensure detection accuracy of the dye liquor components to improve dye quality of dyed fabrics and enable production cost and labor strength of skilled workers to be reduced.

Owner:QINGDAO UNIV +1

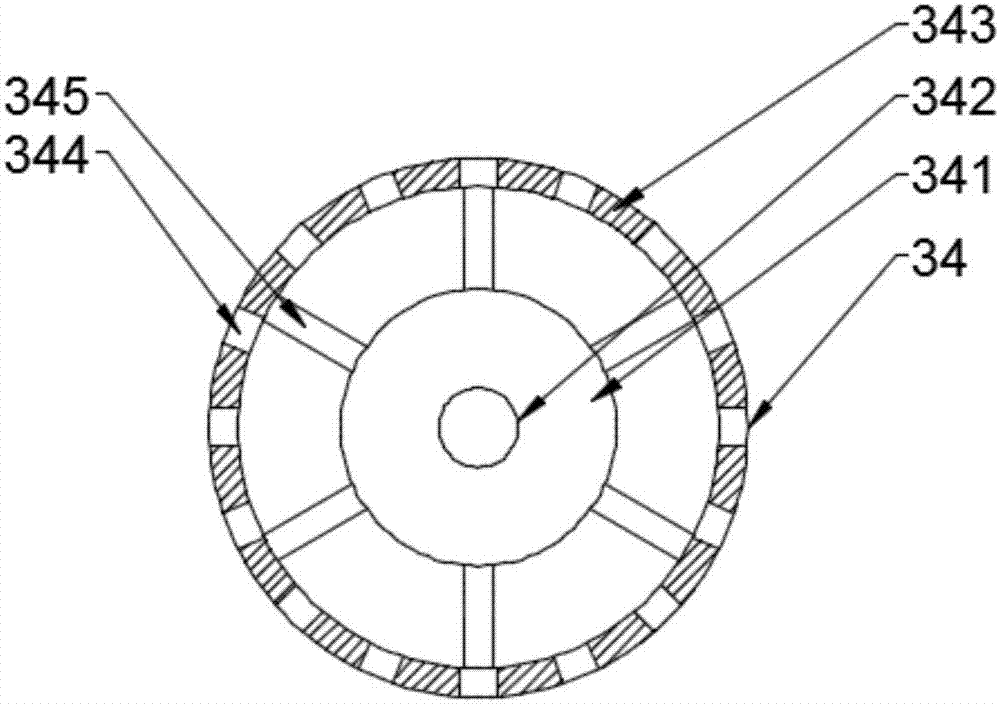

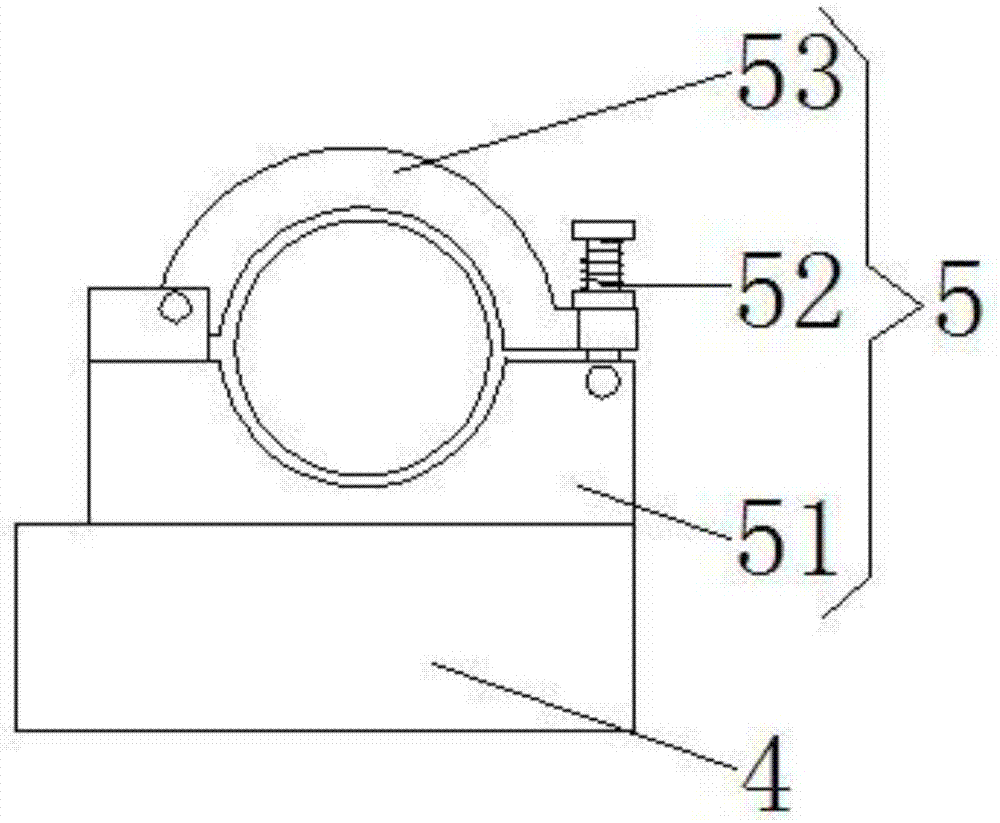

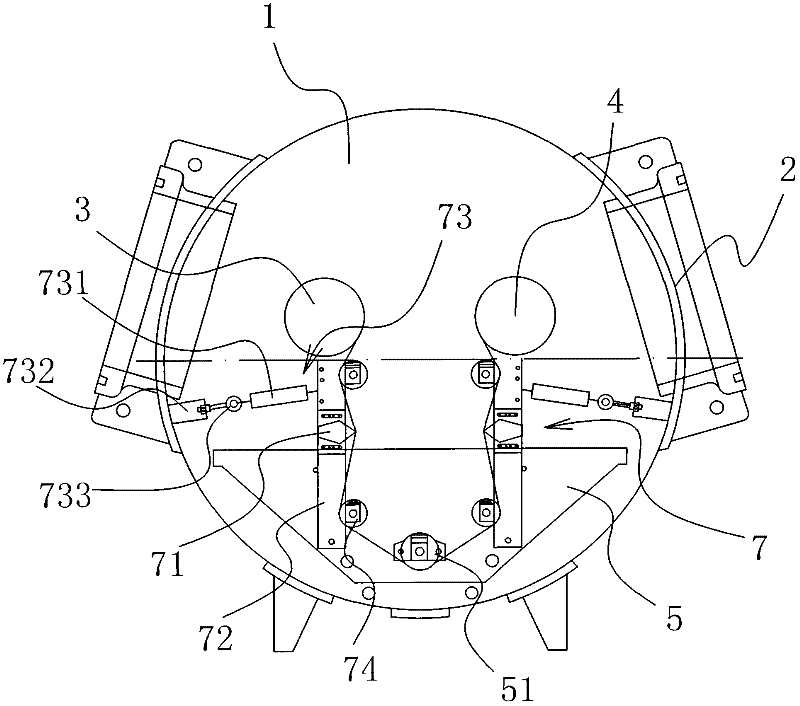

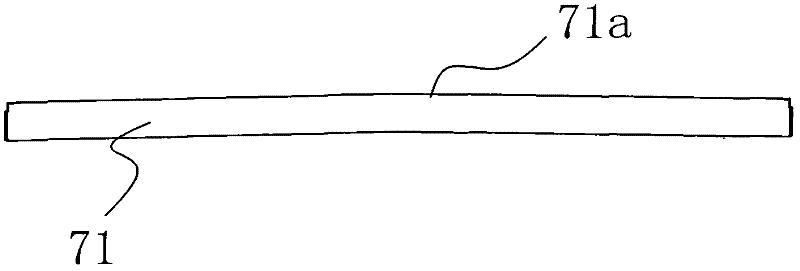

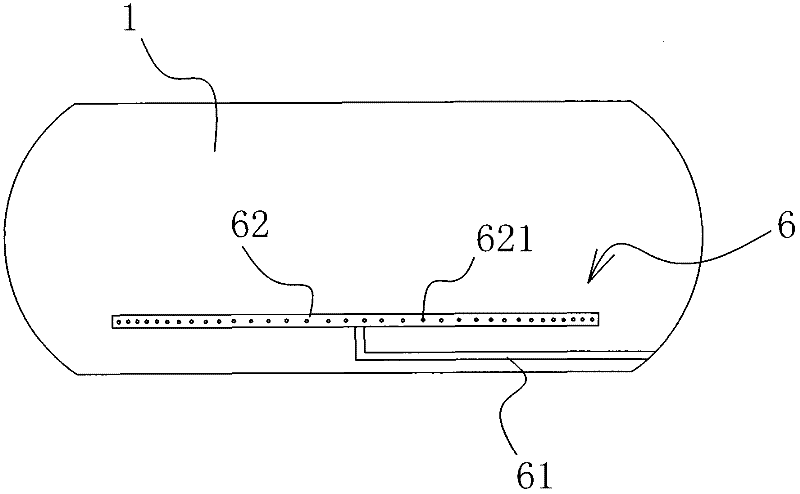

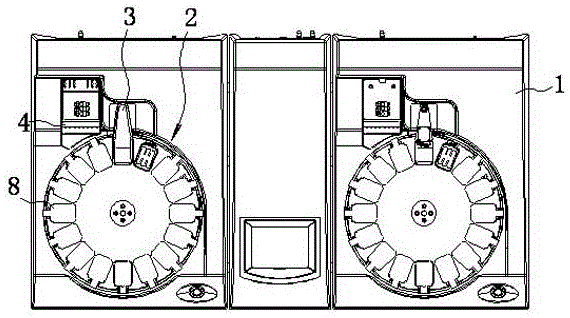

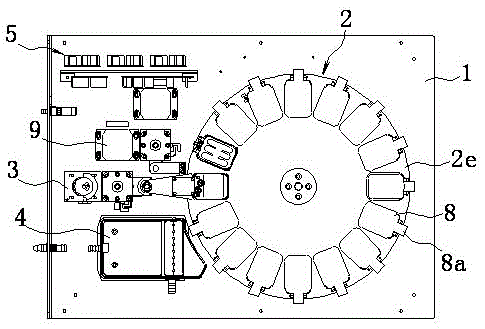

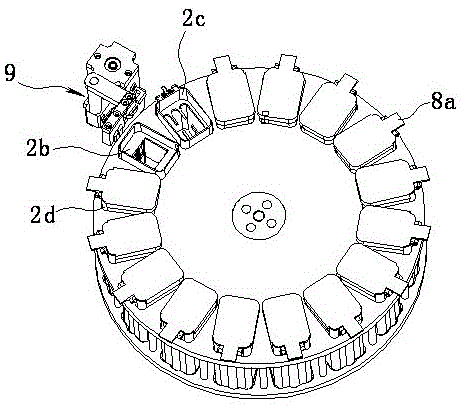

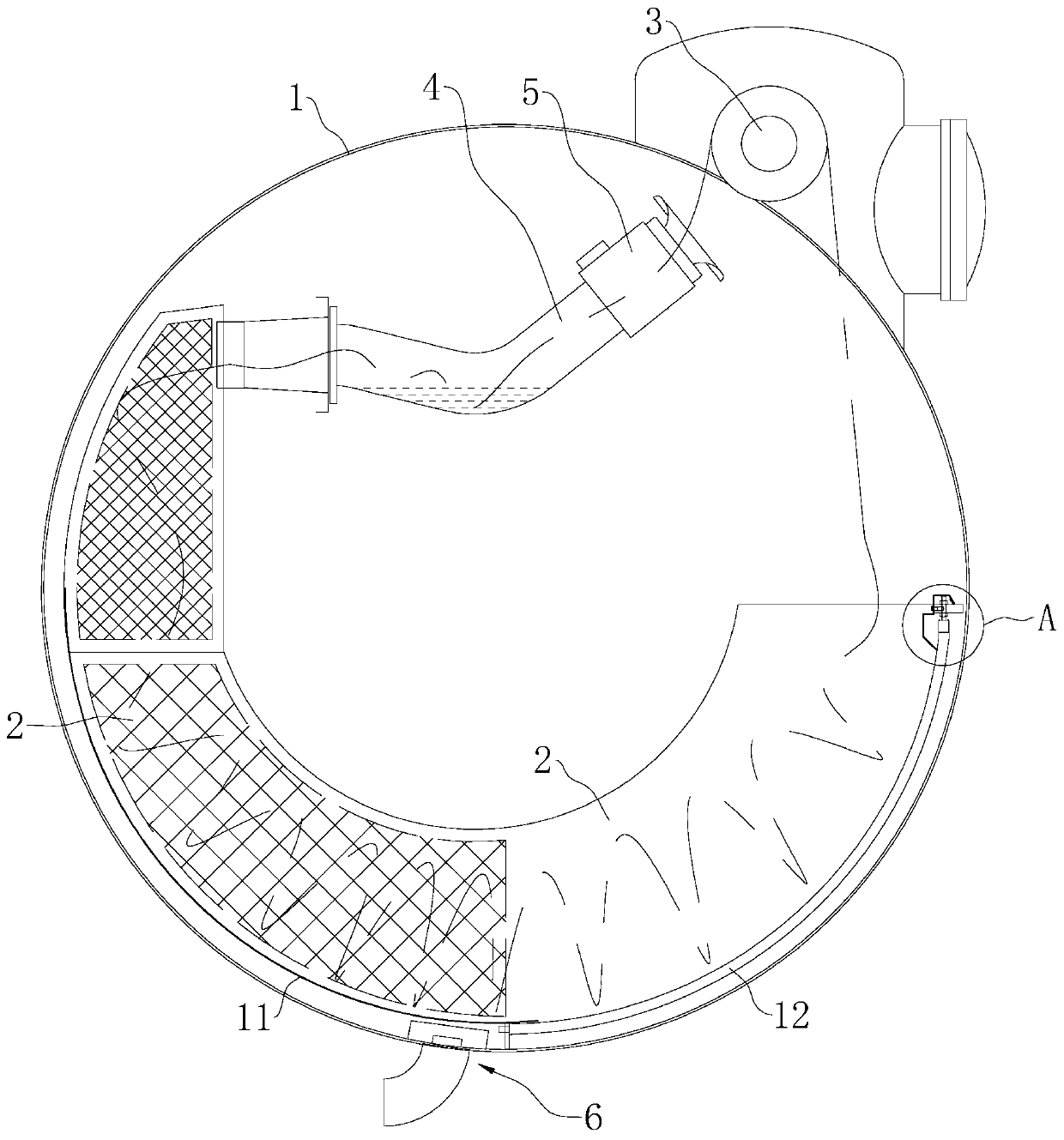

Turntable type frozen section staining device

ActiveCN105021443AImprove work efficiencyGuarantee the quality of dyeingPreparing sample for investigationEngineeringMechanical engineering

The invention discloses a turntable type frozen section staining device and belongs to the technical field of staining devices. The turntable type frozen section staining device is technically characterized by comprising a machine body, wherein at least one set of staining unit is arranged on the upper end face of the machine body; each staining unit mainly comprises a turntable module, a lifting clamping mechanism arranged on the side edge of the turntable module and a flushing tank arranged on the side edge of the lifting clamping mechanism; each turntable module mainly comprises a turntable, and a sample injection cylinder, a sample discharging cylinder and a plurality of staining cylinders which are uniformly distributed on the turntable along the circumferential direction; each lifting clamping mechanism mainly comprises a lifting support arranged on the machine body, a first lifting sliding block arranged on the lifting support, a lifting driving mechanism connected with the first lifting sliding block, a rotating mechanism arranged on the first sliding block, a cylinder arranged on the rotating mechanism and a clamp which is connected with the cylinder and is used for clamping a slide. The invention aims at providing the turntable type frozen section staining device which is compact in structure, low in manufacturing cost and high in working efficiency and is used for staining a frozen section.

Owner:广州耐确医疗器械有限责任公司

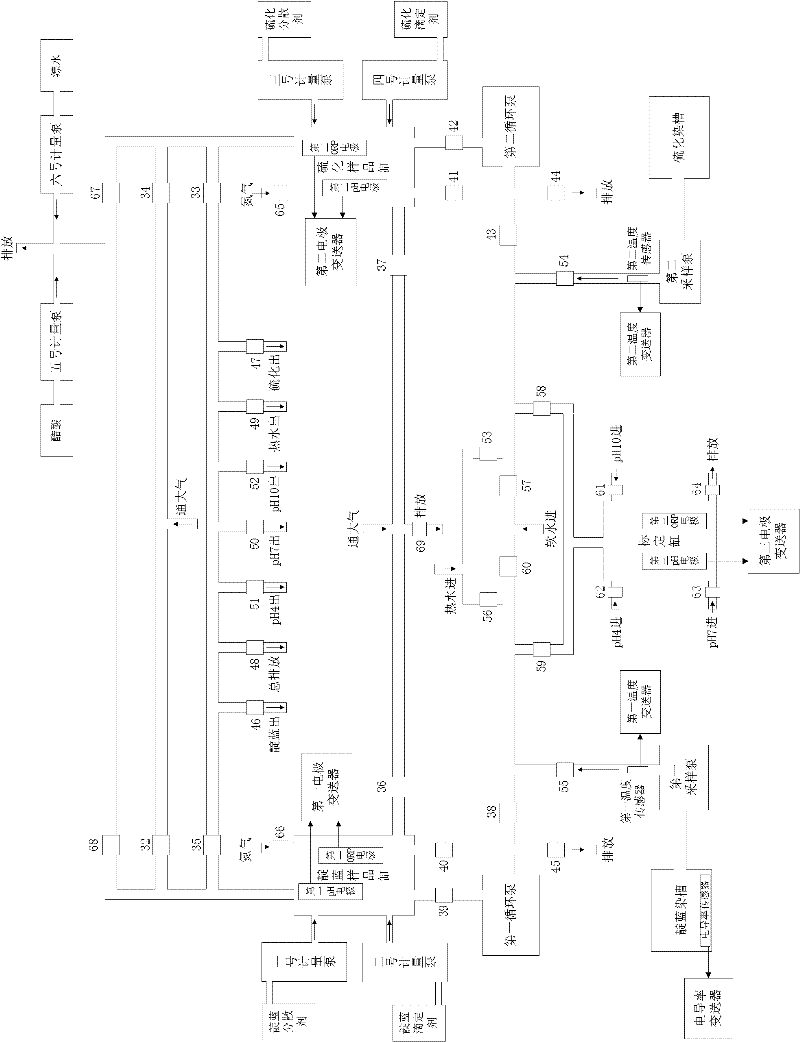

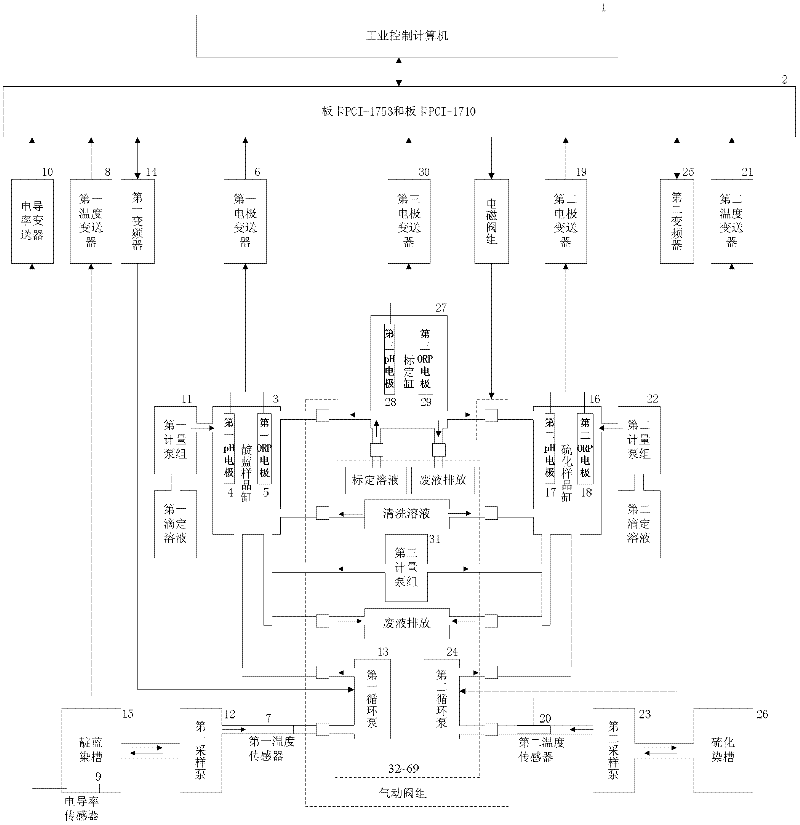

On-line detection method of dye liquor components of bundle dyeing machine based on boards

InactiveCN102520199AGuaranteed accuracyGuarantee the quality of dyeingMaterial analysisSystems designOn board

The invention discloses an on-line detection method of dye liquor components (rongalite, indigo and sodium hydroxide) of a bundle dyeing machine based on YanHua boards. An on-line detection system designed by the method comprises an indigo dye liquor on-line detection unit, a sulfuration dye liquor on-line detection unit, a calibration unit, boards, and an industrial control computer. According to the invention, a dye liquor sample in a dye vat of the dyeing machine is on-line detected in real time, the industrial control computer and the boards are used as a core are used, the concentration of the corresponding components of the dye liquor is on-line detected in real time by using potentiometric titration method, and the pH value and temperature of the dye liquor are on-line detected in real time, and pipelines are cleaned by the system after every detection completes. The method further can calibrate the indigo or sulfuration dye liquor on-line detection unit according to requirements to guarantee the accuracy of the detection results. The method can guarantee the detection precision of the dye liquor components, so as to raise the dyeing quality of dyed fabrics, thus the production cost is reduced, and the labor intensity of technical workers is reduced.

Owner:QINGDAO UNIV +1

Cloth dyeing machine

ActiveCN109736040AImprove dyeing effectReduce the number of cycles required for dyeingLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine arrangementsEngineeringDyeing

The invention relates to a cloth dyeing machine comprising a cylinder body, a cloth storage trough arranged in the cylinder body, a cloth lifting device, a nozzle, a cloth layout pipe and a water collecting device; one end of the cloth layout pipe is in communication with one end of the cloth storage trough; the cloth layout pipe is bent and is arranged in a V shape with an upward opening, the bent part of the cloth layout pipe is arranged to be a circular arc, and the section of the cloth layout pipe is arranged to be polygonal; and the nozzle comprises a seat body and a nozzle core, the seatbody is coaxially fixed with the cloth layout pipe, a placing channel for placing the nozzle core is formed inside the seat body, the side wall of the seat body is in communication with a liquid inlet pipe, an annular groove in communication with the liquid inlet pipe and the placing channel is formed along the circumference in the seat body, and a plurality of rotation preventing plates I are uniformly arranged along the circumference in the annular groove. The cloth dyeing machine has the effects of reducing cloth damage and guaranteeing the quality of the cloth by reducing overturning andtwisting probability in a cloth conveying process.

Owner:HANGZHOU DONGLIN DYEING & FINISHING MACHINERY

Dyeing machine with squeezing device

InactiveCN104109955AWith water squeeze functionReduce chemical residueLiquid/gas/vapor textile treatmentLiquid/gas/vapor treatment of propelled fabricsElectric machinerySewage

The invention relates to a dyeing machine, in particular to a dyeing machine with a squeezing device. The dyeing machine comprises a dyeing machine body, a circulation pump and a sewage drainage outlet and further comprises the squeezing device installed on the dyeing machine body. The squeezing device comprises a driving motor, a pushing-out mechanism, a driving roller and a driven roller. The driving motor is connected with the driving roller through a belt. The driven roller is connected with the pushing-out mechanism. The pushing-out mechanism is fixed to the dyeing machine body. Compared with a traditional dyeing machine, the dyeing machine has a squeezing function, the water consumption can be reduced by 50%, water resources are saved, cleaning efficiency is improved, and dyeing cost is reduced.

Owner:WUXI YANGJIA MACHINERY

Pretreatment method for dyeing of nylon skein

InactiveCN102587061AEmission reductionReduce intermediate circulation linksLiquid/gas/vapor textile treatmentPretreatment methodRoom temperature

The invention relates to a pretreatment method for dyeing of nylon skein. According to the technical problem, the provided method has the characteristics of safety, reliability, good effect, simpleness in operation, energy saving and environment protection and comprises the following steps of: (1) spreading the nylon skein out on a working platform in a skein balancing chamber with a constant-temperature and constant-humidity system, wherein the spread thickness is less than 5cm; (2) closing a door of the skein balancing chamber to seal the skein balancing chamber, heating and humidifying till the temperature is 18-45 DEG C and the relative humidity is 60-90% wherein the heating rate is less than 1.0 DEG C / min; then keeping the temperature and the humidity constant for 20-50min; (3) cooling to room temperature and keeping for 15-25min, wherein the cooling rate is controlled to be less than 1.0 DEG C / min; and (4) opening the door of the skein balancing chamber, circulating indoor and outdoor air for at least 10min to ensure that the surface of the nylon skein is contracted and dried, and finally packaging and delivering the finished products.

Owner:宿迁市华一科技有限公司

Dyeing and finishing technology of grey cloth

InactiveCN107558041AEasy to operateReduce manufacturing costHeating/cooling textile fabricsDyeing processAfter treatmentEngineering

The invention discloses a dyeing and finishing technology of grey cloth. The technology comprises the following steps that 1, the flat grey cloth is selected to be pretreated; 2, the grey cloth obtained after pretreatment is subjected to steaming; 3, ingredients are added into a dye vat to be fully stirred and mixed; 4, the grey cloth obtained after treatment is put into the dye vat, low temperature heating is conducted, and the PH is adjusted; 5, dye liquor is heated to keep constant temperature; 6, the grey cloth obtained after dyeing is subjected to setting. The adopted dyeing and finishingtechnology is easy to implement, low in production cost, high in dyeing rate and good in dyeing effect, and the production efficiency is improved.

Owner:江苏欣捷纺织科技有限责任公司

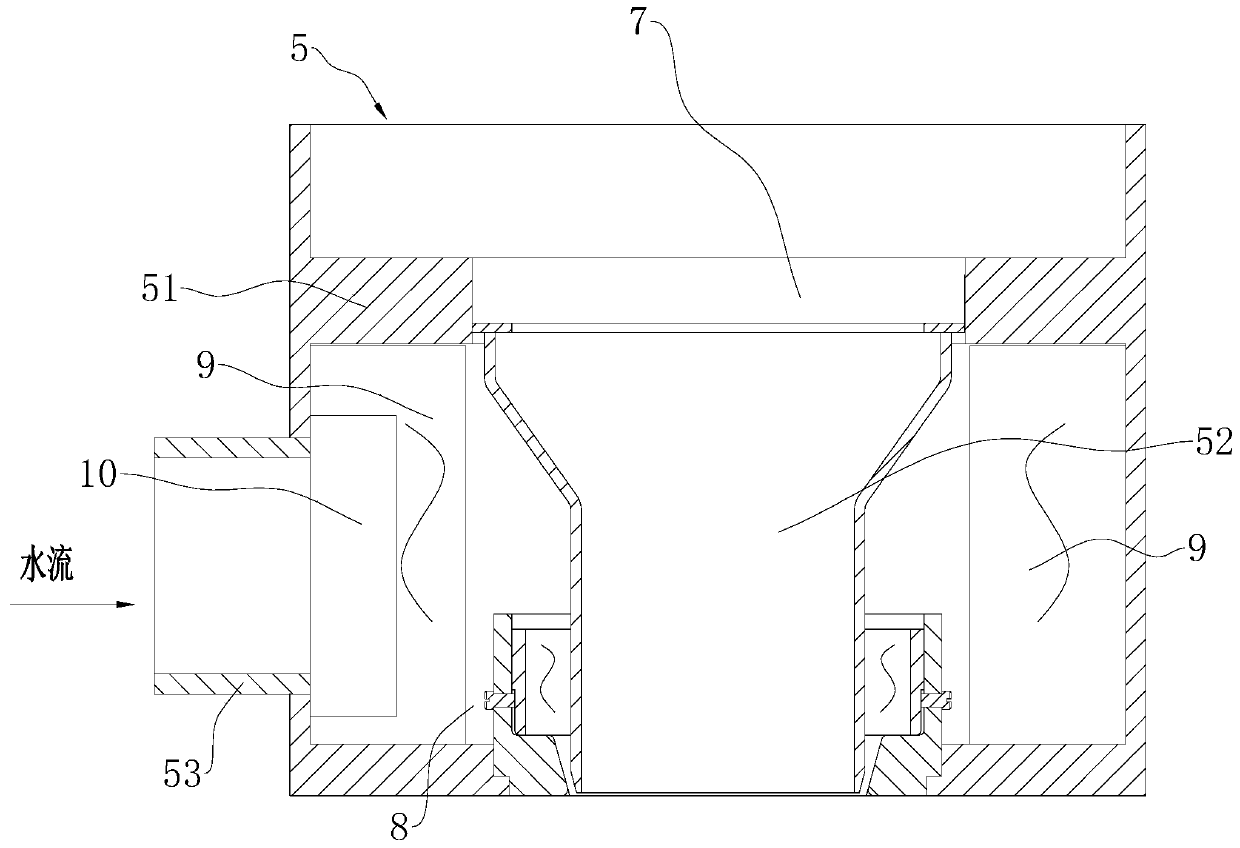

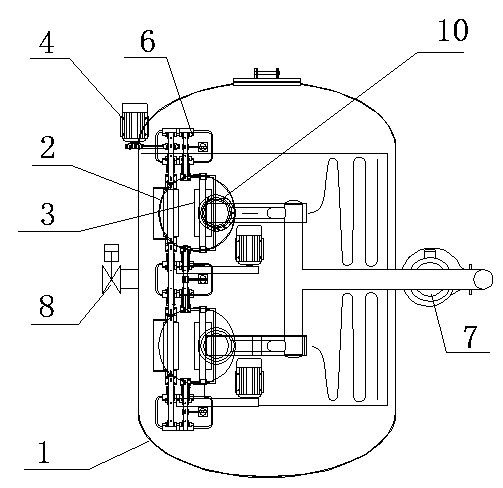

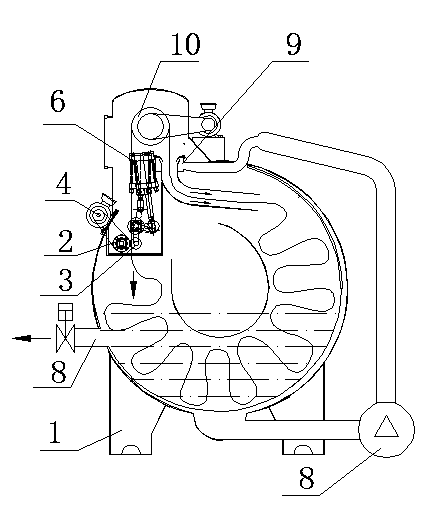

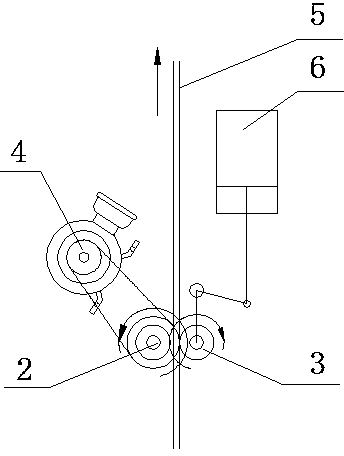

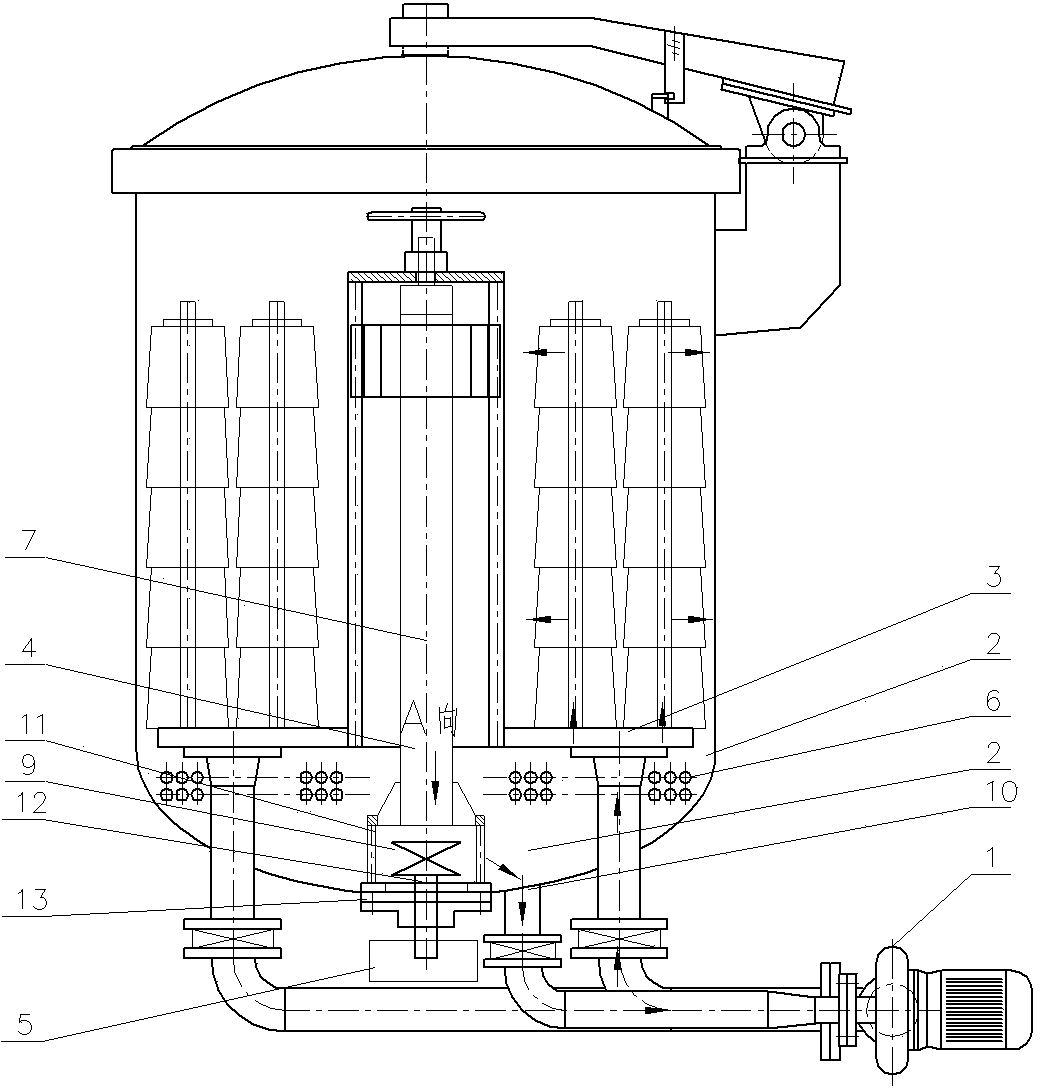

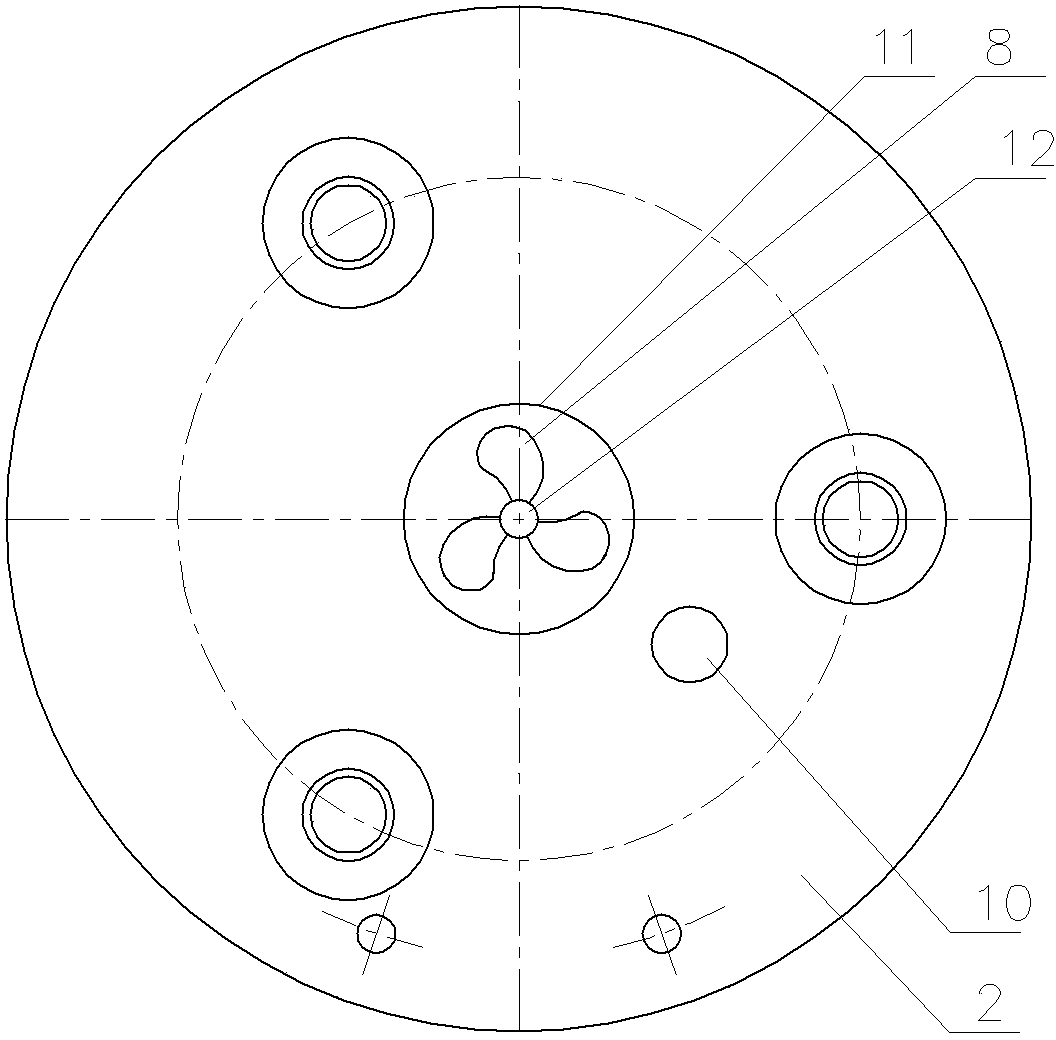

Main cylinder dyeing liquor evenly-distributing device of high-temperature and high-pressure cone dyeing machine

ActiveCN103882641AGuaranteed uniformityGuarantee the quality of dyeingTextile treatment machine arrangementsTextile treatment carriersDyeingHigh pressure

The invention provides a main cylinder dyeing liquor evenly-distributing device of a high-temperature and high-pressure cone dyeing machine. According to the main cylinder dyeing liquor evenly-distributing device, the evenness of dyeing liquor in a main cylinder below a dyeing liquor evenly-distributing type dyeing structure can be guaranteed, then the dyeing evenness is guaranteed, and the dyeing quality is guaranteed. The main cylinder dyeing liquor evenly-distributing device comprises the main cylinder at the bottom of a cheese cage, the cheese cage and a cheese cage center pipe, and the cheese cage is located above the main cylinder located at the bottom of the cheese cage. The main cylinder dyeing liquor evenly-distributing device is characterized in that a stirring device is installed in the center of the bottom of the main cylinder at the bottom of the cheese cage, a center shaft of the stirring device is parallel to the center line of the cheese cage center pipe, blades of the stirring device perform the circumference rotation movement along the center shaft of the stirring device, and a motor is externally connected with the center shaft of the stirring device.

Owner:WUXI DONGBAO MACHINERY MFG

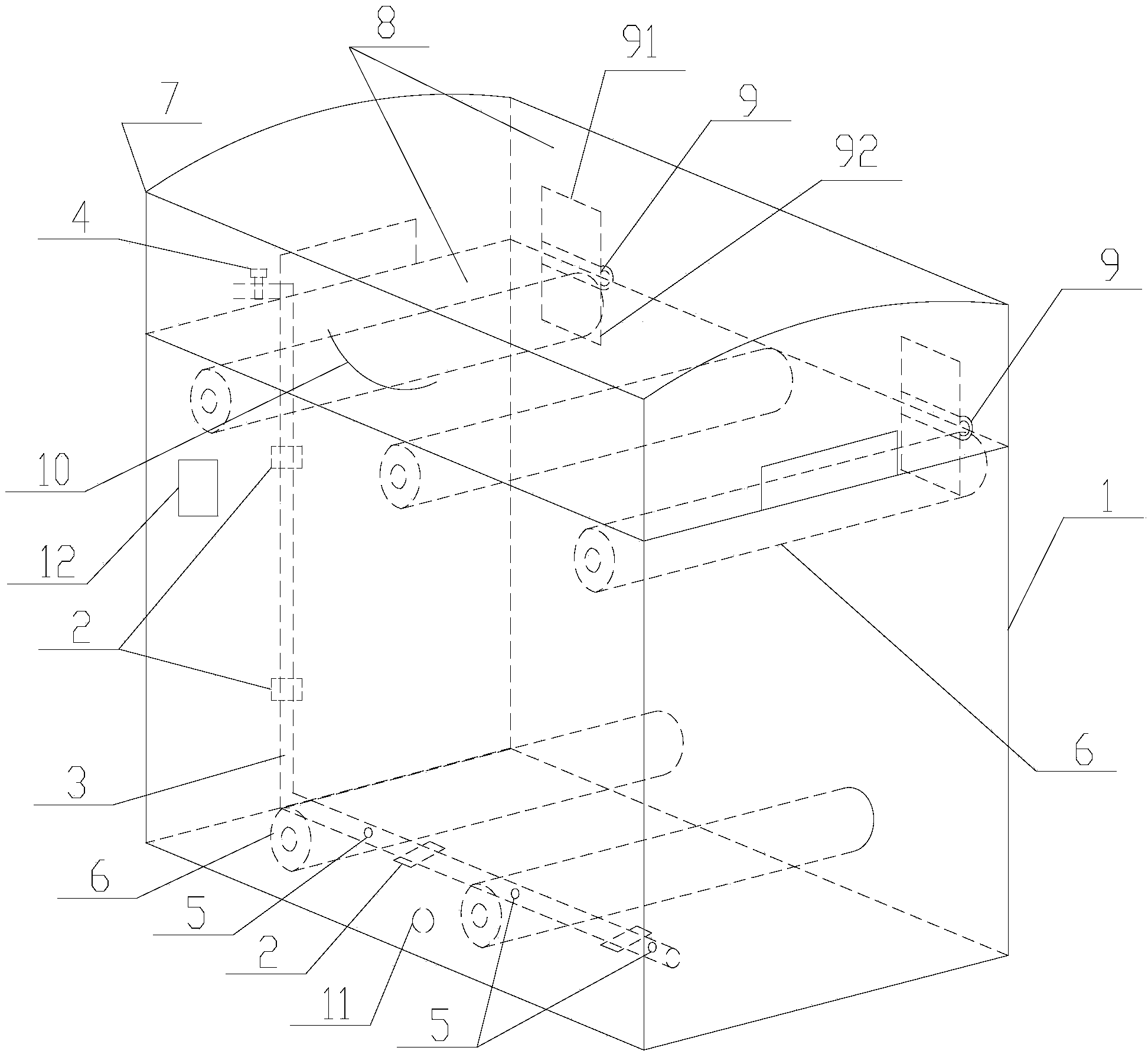

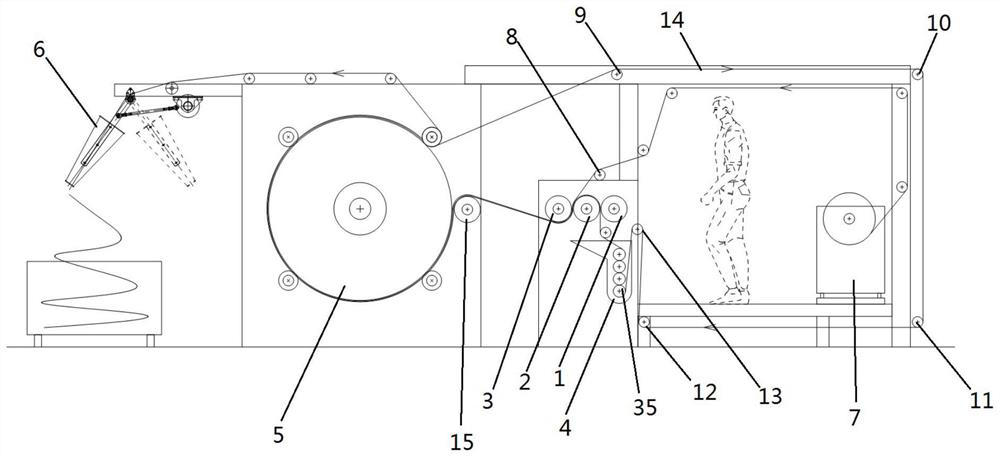

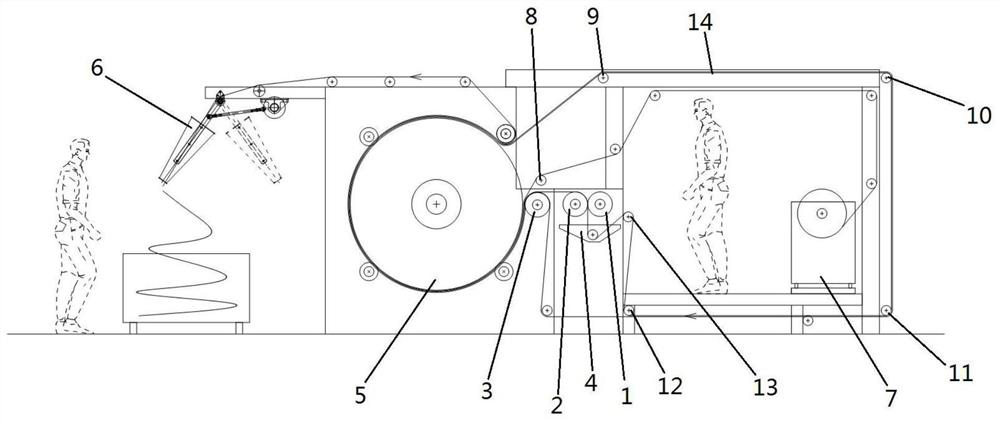

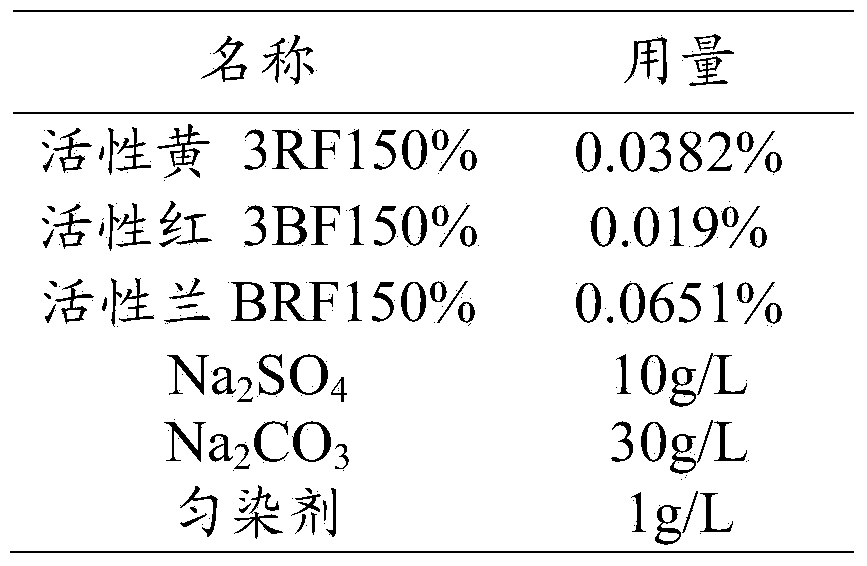

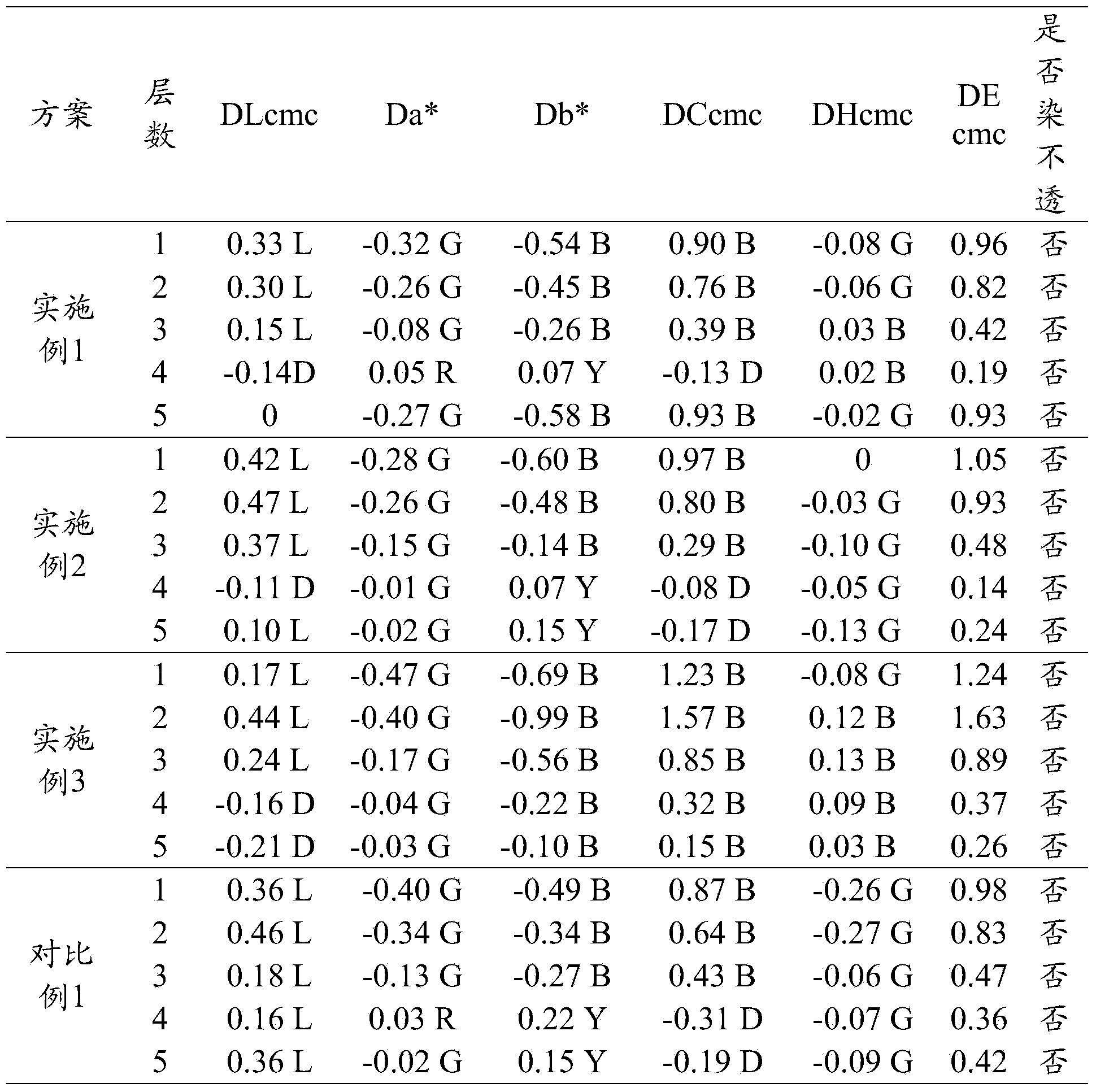

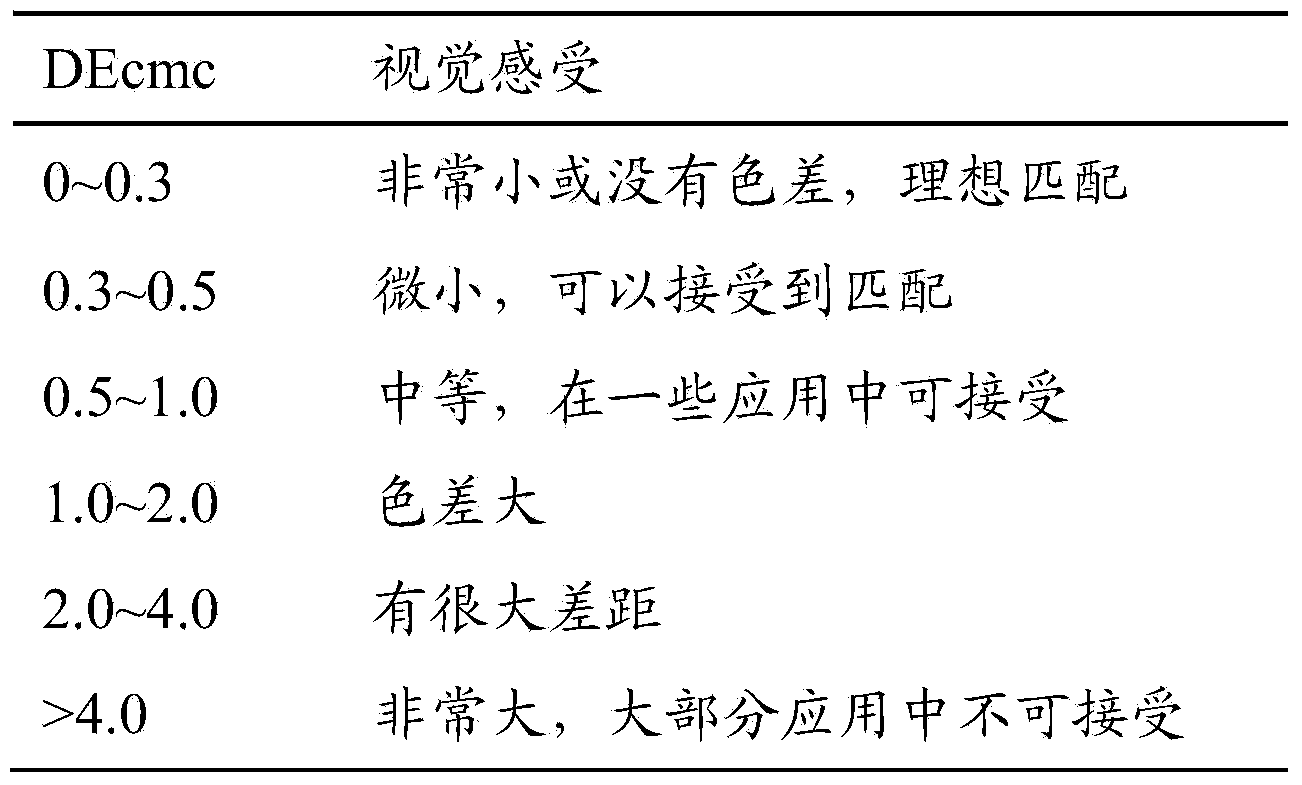

Multi-layer multi-time continuous rolling ageing dyeing mechanism and method

PendingCN111778666APromote migrationReduce liquid volumeSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersMechanical engineeringContinuous rolling

The embodiment of the invention discloses a multi-layer multi-time continuous rolling ageing dyeing mechanism and a multi-layer multi-time continuous rolling ageing dyeing method, which are used for solving the technical problem that the liquid carrying amount of rolled cloth is too high in the existing rolling mode for cloth dyeing. The dyeing mechanism comprises a rolling device and a cloth guide wheel device. The rolling device at least comprises a first roller, a second roller and a third roller; the cloth guide wheel device at least comprises a first cloth guide wheel, a second cloth guide wheel, a third cloth guide wheel, a fourth cloth guide wheel, a fifth cloth guide wheel and a sixth cloth guide wheel; the moving track of the cloth is an irregular involute-shaped track; a cloth feeding device is located at the starting end of the involute-shaped track. A finished product collecting device is arranged at the tail end of the involute-shaped track, rolling points between the rollers are distributed on the involute-shaped track at intervals, the cloth guide wheels are distributed on the involute-shaped track at intervals, and the moving tracks of the cloth passing through a first heating device multiple times are arranged at intervals and are in a stacked shape.

Owner:李雅

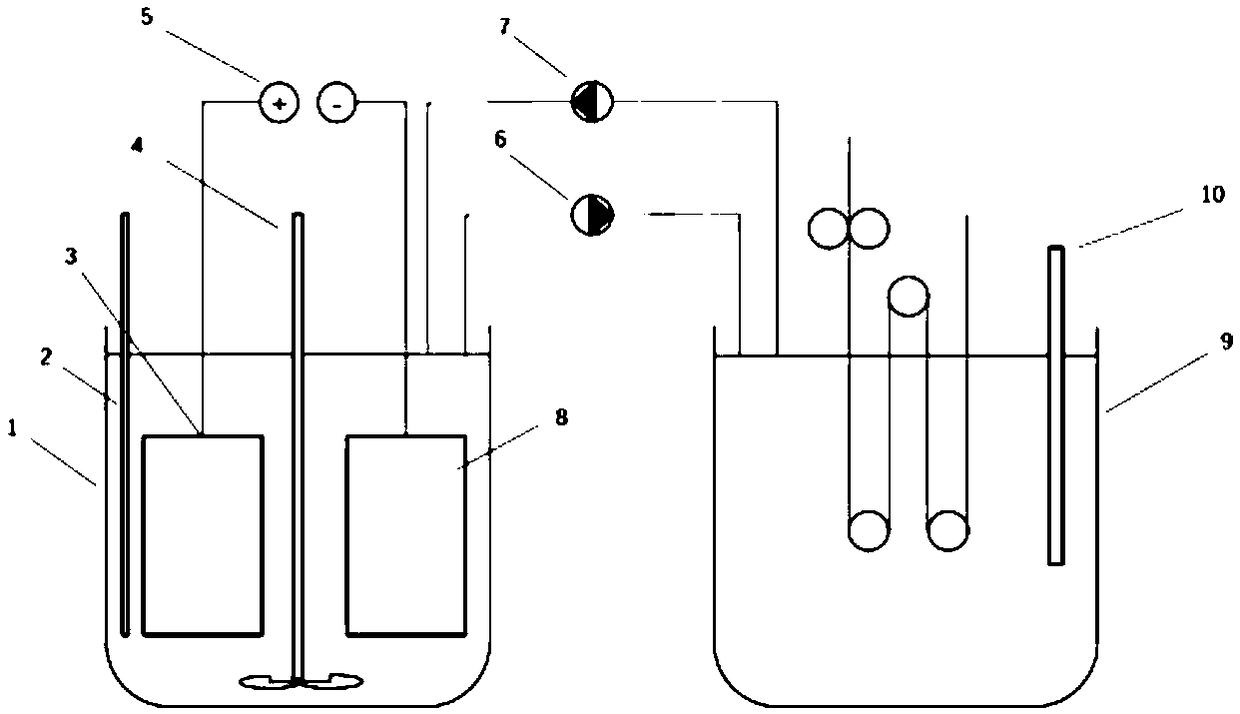

Dyeing liquor and dyeing method for reducing indigo blue through indirect electrochemistry of single solute

The invention relates to dyeing liquor and a dyeing method for reducing indigo blue through indirect electrochemistry of a single solute. The dyeing liquor takes water as a solvent and is prepared from the following raw materials at concentrations: strong base at 0.01 to 0.1 mol / L, an electron transfer promoter at 0.001 to 0.1 mol / L and an indigo blue dye at 0.01 to 0.1 mol / L. The dyeing method comprises the following steps: firstly, completely reducing the dyeing liquor in an electrolytic tank, then transferring the dyeing liquor into a dyeing tank, dyeing yarn, pumping part of oxidized dyeing liquor back into the electrolytic tank in the dyeing process, then reducing the dyeing liquor, pumping the reduced dyeing liquor into the dyeing tank to dye the yarn, continuously performing the dyeing, and pumping back the oxidized part of the dyeing liquor for reducing and reuse. The dyeing liquor has the beneficial effects that dioxyanthraquinone is used as the electron transfer promoter, sothat the electrochemical reducing rate is effectively increased, and the current efficiency is improved; after the electron transfer promoter is added, the indigo blue can be reduced in the alkaline solution at a relatively low concentration, so that the chemical consumption is reduced, and the production cost is greatly reduced.

Owner:WUHAN TEXTILE UNIV

Staining method of diacetate fiber deep colors

The invention relates to a staining method of diacetate fiber deep colors. The staining method comprises the following staining steps of entering a cylinder of diacetate fiber or fabric, adding water to adjust a bath ratio, heating (1), adding staining assistants and dyes, heating (2), insulating (1), overflowing and cooling, cleaning, adding water to adjust the bath ratio, heating (1), adding post-processing assistants, heating (3), insulating (2), overflowing and cooling, cleaning, emptying the water and letting out of the cylinder. Two dyes of disperse dyes and cationic dyes with different properties are adopted to stain, and the staining method of simultaneous staining in the same cylinder by using a one-bath process is adopted, so that the technical problems of non-deep colors by adopting the disperse dyes or only light colors by adopting the cationic dyes are solved, the diacetate fiber can be stained to deep colors such as navy blue, black and the like, and additionally, the production quality requirements of color fastness, spinning and the like are satisfied.

Owner:JIANGSU DANMAO TEXTILE

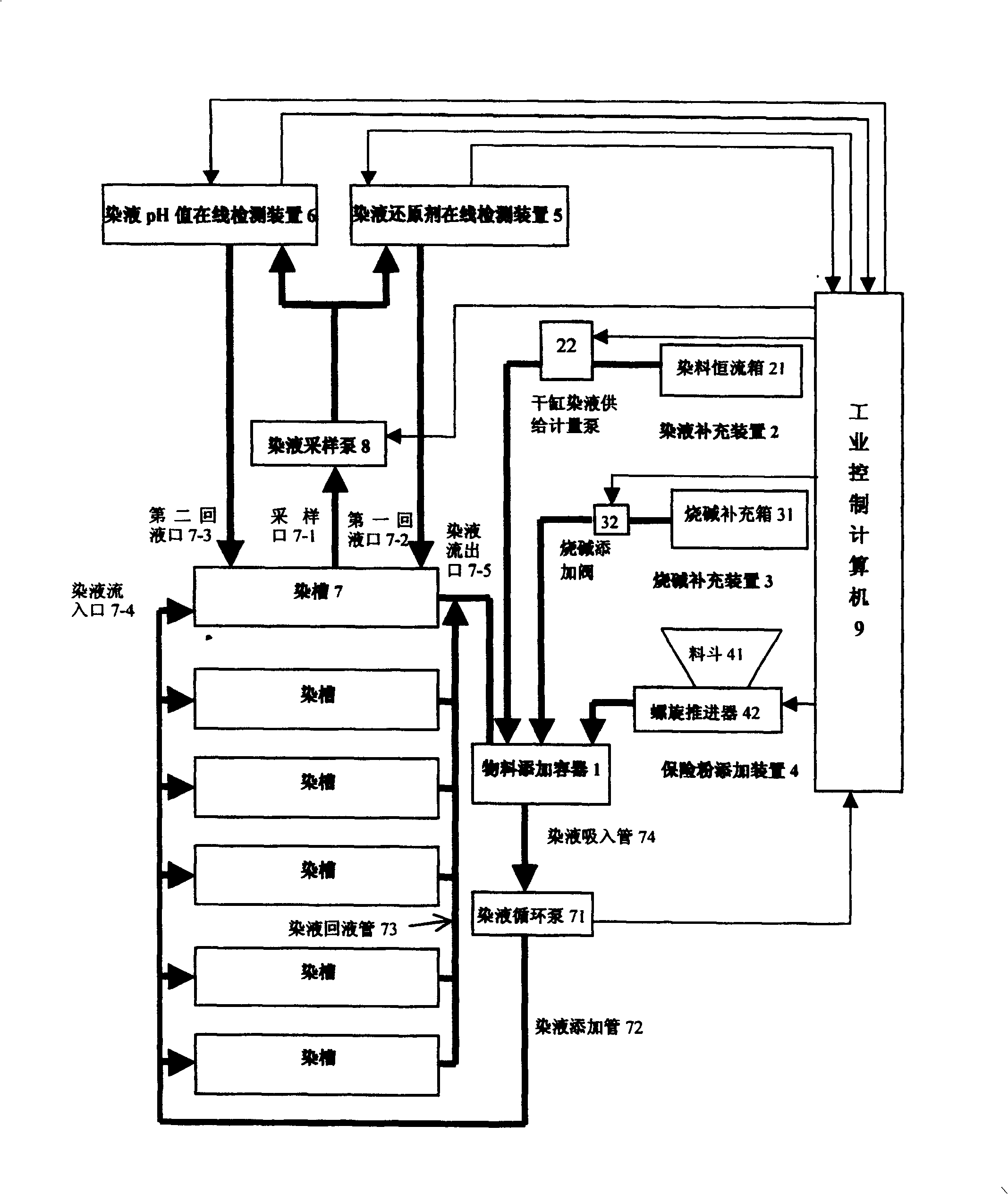

System for inspecting and controlling dyeing liquid component of dyeing machine on-line

ActiveCN100429597CGuarantee the quality of dyeingRealize online automatic detectionControlling ratio of multiple fluid flowsChemical variable controlControl systemEngineering

A detection and control system of dyeing liquid composition used on dyeing machine comprises addition unit of dyeing liquid composition, on - line detection unit of reducing agent and pH value for dyeing liquid, sampling pump and computer. It is featured as using potentiometric titration to detect reducing agent concentration in dyeing liquid and pH value of dyeing liquid on - line with set time, comparing obtained value with set value and controlling addition unit to add dyeing liquid according to compared result to keep dyeing liquid composition to be the same as set value for ensuring quality of dyeing.

Owner:BLACK PEONY TEXTILE CO LTD

Low-energy consumption dyeing method

ActiveCN104047136AReduce energy consumptionSimple and fast operationTextile treatment machine partsLiquid/gas/vapor yarns/filaments treatmentEngineeringOperation mode

The invention discloses a low-energy consumption dyeing method. A circulation operation mode is adopted in a main pump in a dyeing vat, a period in cycle operation comprises a main pump operation period and a main pump stopping period, and the duration of the main pump operation period is 1.5-3.5 times that of the main pump stopping period. According to the low-energy consumption dyeing method, a main pump is adjusted so that the main pump can be in cycle operation, a continuous high-speed operation mode of a main pump of a traditional dyeing technology is broken through, compared with the traditional dyeing technology, 40 percent to 65 percent of energy of the main pump can be saved, operation is simple and convenient, and the low-energy consumption dyeing method meets the technology and production requirements.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Dyeing method and device with anti-splashing structure for polyester chemical fiber cloth spinning

ActiveCN111749035AWon't breakAvoid sexTextile treatment machine arrangementsDyeing processPolyesterPolymer science

The invention discloses a dyeing method and device with an anti-splashing structure for polyester chemical fiber cloth spinning, and belongs to the technical field of spinning dyeing. The method comprises the following steps that pretreatment before dyeing is conducted, wherein polyester fabric needing to be dyed is put into a cleaning machine; when the water level reaches 13-17%, a laundry detergent and color bleaching powder are added; when the water level reaches 15-20%, heating is conducted to make the water temperature rise to 30-45 DEG C, the washing rotating speed of the cleaning machine is 30-40 r / min at the moment; and after cleaning is completed, the polyester fabric is dehydrated, the operation is repeated, and cleaning is conducted three times. According to the dyeing method with the anti-splashing structure for polyester chemical fiber cloth spinning, by arranging the pretreatment process before dyeing, oil dirt, dust and pigment generated on the surface of the polyester fabric in the production process can be treated thoroughly, therefore, the problem that when the polyester fabric is dyed, due to the fact that the polyester fabric is not cleaned thoroughly, dyeing defects such as various dyeing defects and color spots are generated in the dyeing process is avoided, and the normal dyeing quality of the polyester fabric is guaranteed.

Owner:江苏申久纺织科技有限公司

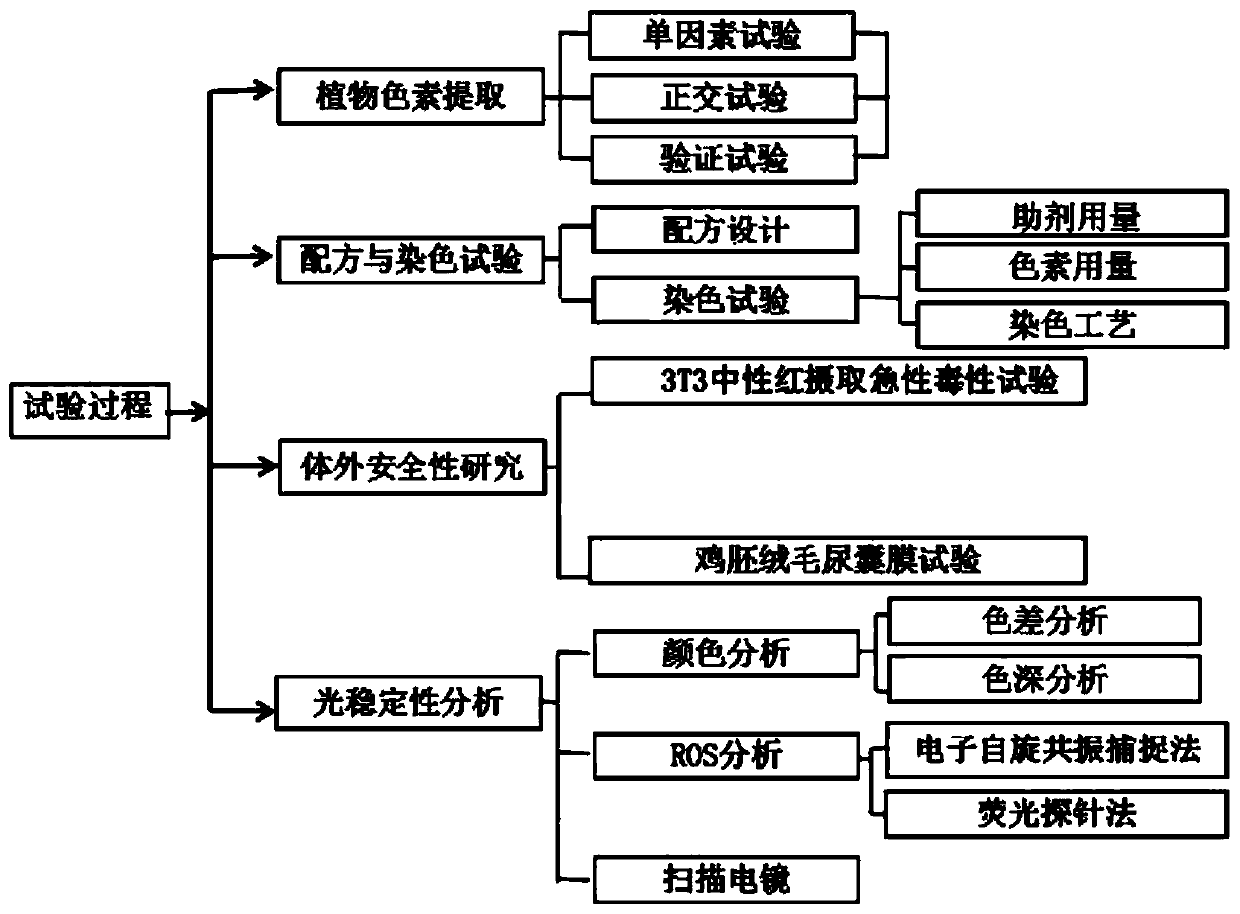

Environmentally-friendly textile dye and method for preparing textile fabric by using textile dye

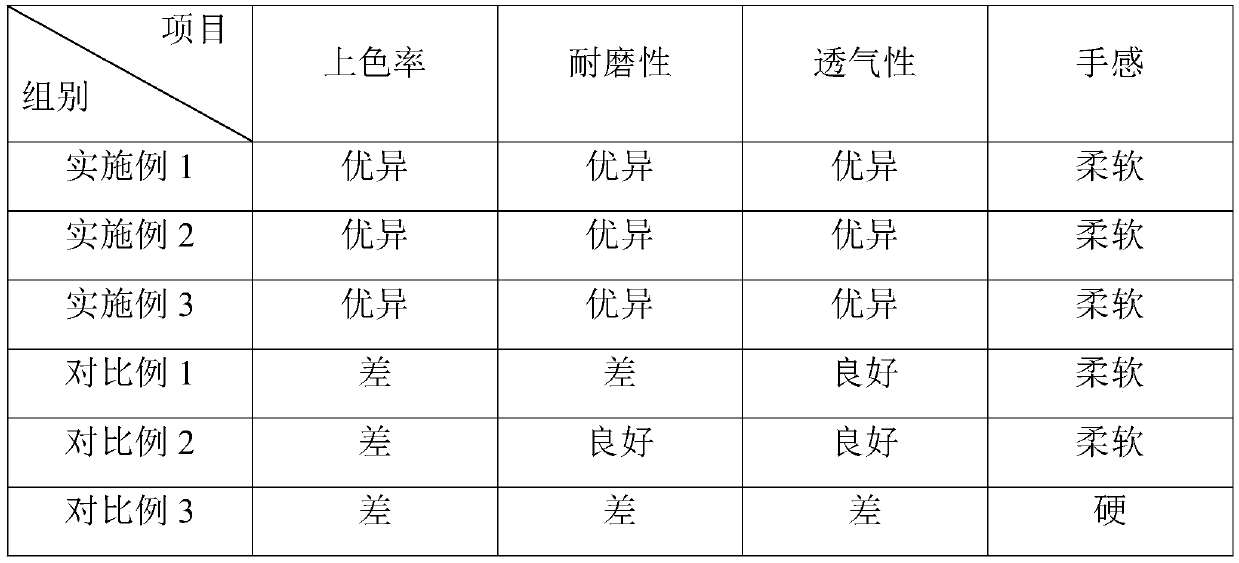

InactiveCN111118923AHigh extraction rateGood quality pigmentNatural dyesDyeing processAcetic acidPolymer science

The present invention discloses environmentally-friendly textile dye and a method for preparing textile fabric by using the textile dye. The environmentally-friendly textile dye contains a natural pigment prepared from discarded dragon peels through condensation and reflux extraction, and the natural pigment is compounded with acrylic emulsion and additives containing cationic polymers to form theenvironmentally-friendly textile dye that can be applied to the textile fabric; by extracting the pigment from discarded dragon peels, not only waste resources can be reused, but also a pigment of good quality can be obtained; the pigment is compounded with acrylic emulsion, acetic acid and cationic polymers to achieve high compound stability, and the negative charge on the textile fabric synergistically forms a stable combination; and through the Coulomb gravitational effect, the adhesion strength and wear resistance of natural pigments on the textile fabric can be effectively enhanced, thecoloring rate of dyeing can be improved, and then high-quality uniform coloring effect can be obtained to ensure production quality.

Owner:BIEM L FDLKK GARMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com