Application of thermophilic Chaetomium cellulose to polishing, dyeing and one-bat technology

A technology of Chaetomium thermophilus and cellulase, applied in liquid/gas/vapor fiber/sliver/roving treatment, enzymes, enzymes, etc., can solve the problems of uneven dye adsorption, short holding time, strong damage and so on , to achieve the effect of being beneficial to dyeing, reducing dosage and reducing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 adopts the preparation of the Chaetomium thermophila cellulase expressed by Trichoderma reesei (seeing the patent application number is

[0041]

[0042]Example 1) of the specification of CN103343111A of the invention patent application publication of 201310280267.6.

Embodiment 2

[0043] Example 2 uses the preparation of Chaetomium thermophila cellulase expressed by Pichia pastoris (see Example 3 of the description of the invention patent application publication CN103343111A with the patent application number 201310280267.6).

Embodiment 3

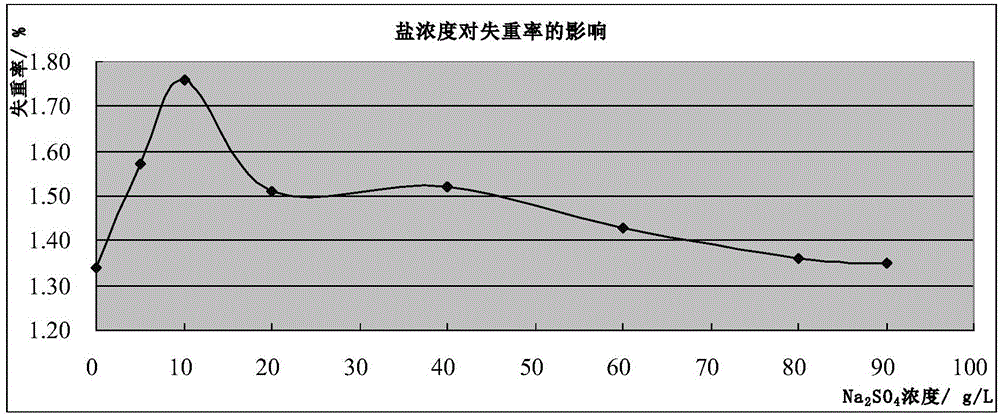

[0044] Example 3 Qualitative test of the halophilic property of Chaetomium thermophila cellulase (influence of different sodium sulfate concentrations on the polishing effect of neutral cellulase)

[0045] 1. Under the condition of 60°C and the pH value of 7.0, the fabric was polished for 60 minutes with 1.0 g / L of the Chaetomium thermophila cellulase prepared in Example 1, and the weight loss rate under different sodium sulfate concentration conditions, see Table 1 and image 3 (The higher the weight loss rate, the better the polishing effect).

[0046] Table 1

[0047]

[0048] 2. Under the condition of 60°C and the pH value of 6.0, the fabric was polished for 60 minutes with 1.0 g / L Chaetomium thermophila cellulase prepared in Example 2, and the weight loss rate under different sodium sulfate concentration conditions, see Table 2 and Figure 4 (The higher the weight loss rate, the better the polishing effect).

[0049] Table 2

[0050]

[0051] It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com