Pretreatment process for memory T400 fabric based on biological based material

A bio-based, process technology, applied in fiber processing, textile and papermaking, dry cleaning fiber products, etc., can solve the problems affecting dyeing quality, cannot guarantee fabric softness, etc., and achieve the effect of guaranteeing dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Fabric fabric: width 175cm, density 155g / m 2 .

[0021] The pretreatment process of the bio-based material-based memory T400 fabric of the present invention includes the first open-width desizing process, the cold pad-batch process and the second open-width desizing process in sequence.

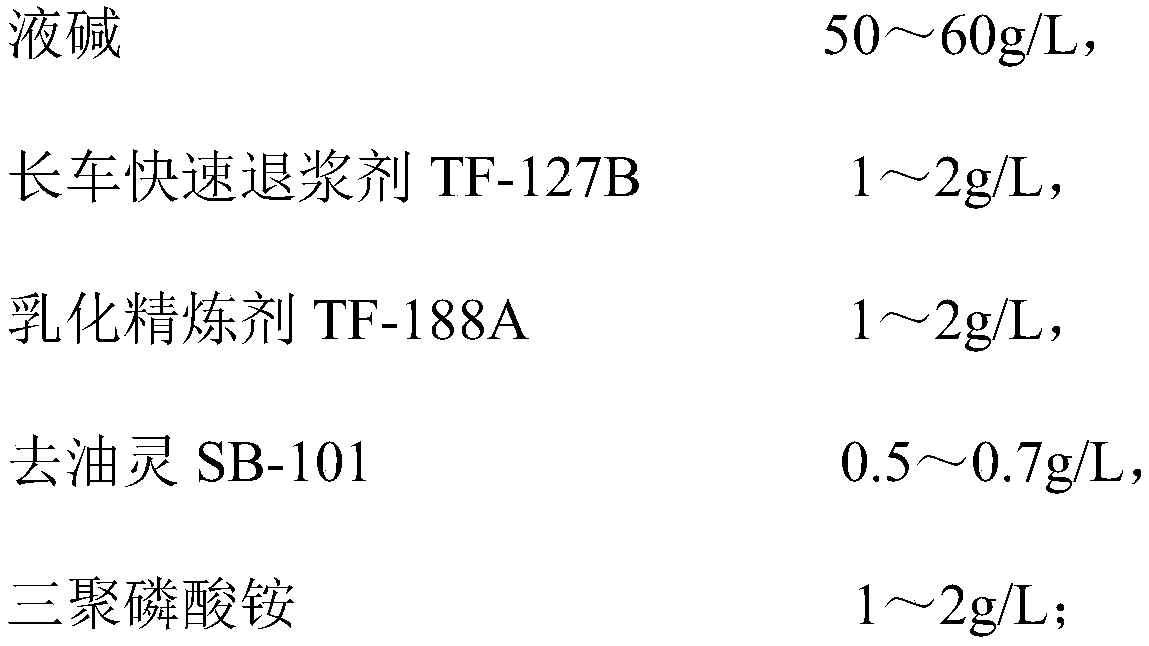

[0022] In the first step, an open-width desizing machine is used to carry out the first open-width desizing treatment on the gray fabric. The formula of the desizing aid used in the first open-width desizing process is as follows:

[0023]

[0024] The temperature condition of the first open-width desizing process is 98° C., and the vehicle speed is 55 m / min.

[0025] In the first open-width desizing process, TF-127B oxidative desizing agent has good alkali resistance and stability under hot alkali conditions at 98°C, and can weave chemical fiber fabrics into commonly used polyacrylate pulp The ester bond in the macromolecule of the material is oxidized and decomposed to become a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com