Online detection method for dye liquor components of bundle type dye machine on basis of programmable logic controller (PLC)

A detection method and dyeing machine technology, applied in textile processing machine accessories, textile material processing, textiles and papermaking, etc., can solve the problems of large influence of dyeing component detection results, defective cloth, long time interval, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

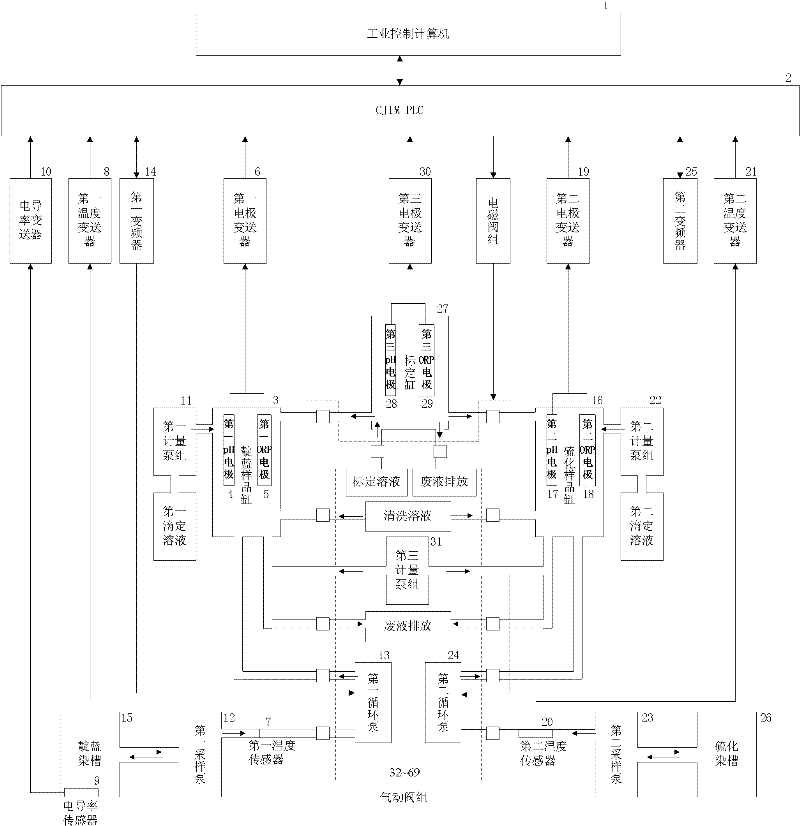

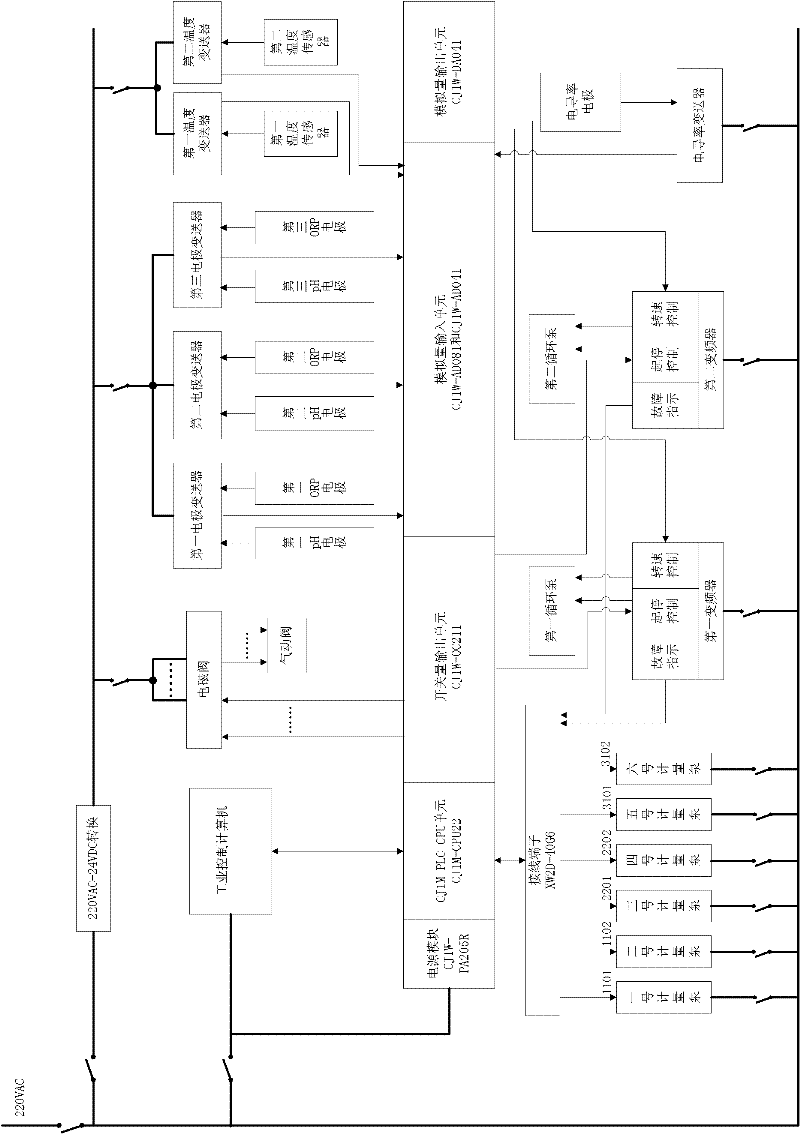

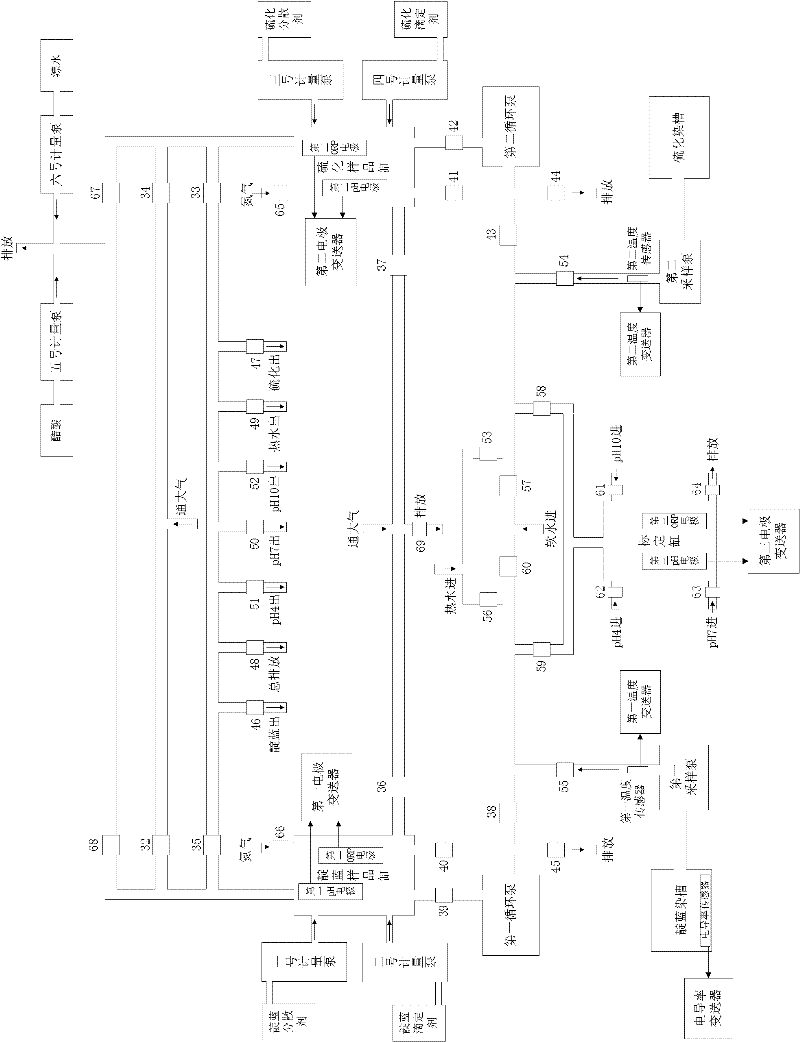

[0023] see figure 1 , a kind of online detection method of the dye liquor component of the beam dyeing machine based on PLC, comprises the steps:

[0024] ① Set up an online detection system, which includes industrial control computer 1, PLC2 controlled by the industrial control computer and detection equipment. The industrial control computer is only connected with the PLC for information exchange, and the PLC realizes the data collection and controls the operation of the online detection system, including collecting the detection data sent by the transmitter and controlling the actuator; the detection equipment includes the indigo dye online detection device pH electrode, ORP electrode and its transmitter, temperature sensor and temperature transmitter, conductivity sensor and conductivity transmitter in the on-line detection device for indigo dye solution and sulfur dye solution; the actuators include indigo dye solution on-line detection device and sulfur dye solution Met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com