Multi-layer multi-time continuous rolling ageing dyeing mechanism and method

A pressing and steaming technology, applied in continuous processing of textile materials, removal of liquid/gas/vapor with squeeze rollers, accessories of textile processing machines, etc. , reduce operating costs, improve the effect of dyeing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

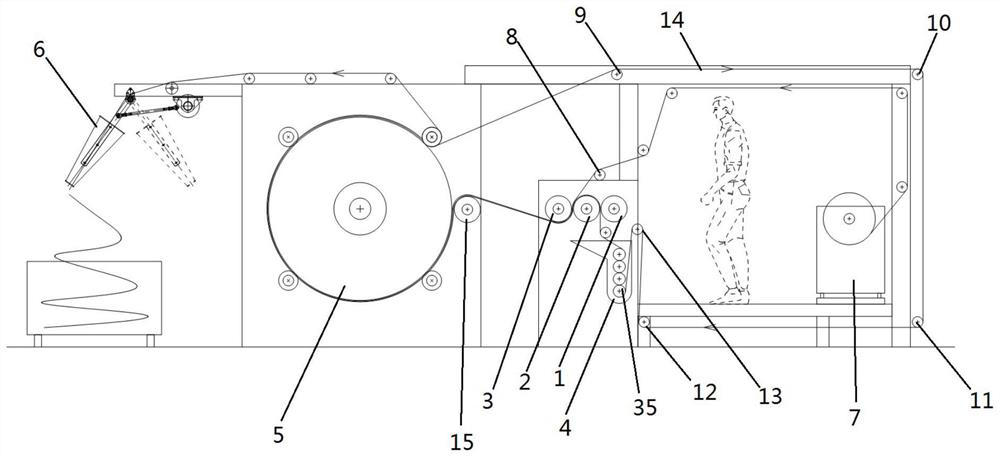

[0057] see figure 1 , a kind of multi-layer multiple continuous pressing and steaming dyeing mechanism provided in the present embodiment comprises:

[0058] Frame, cloth sending device 7 for sending cloth 14, rolling device 24, cloth guiding wheel device, first heating device 5 and finished product collecting device 6;

[0059] The bottom of the rolling device 24 is provided with a trough 4 for accommodating dye liquor or functional paint, and the first heating device 5 is arranged at the discharge end of the rolling device 24. The rolling device 24 includes at least the first roll 1, the second roll 2 and the third roll 3;

[0060] The cloth guide wheel device includes at least the first cloth guide wheel 8, the second cloth guide wheel 9, the third cloth guide wheel 10, the fourth cloth guide wheel 11, the fifth cloth guide wheel 12 and the sixth cloth guide wheel 13, the cloth 14 The moving track of the first cloth guide wheel 8, the second cloth guide wheel 9, the third...

Embodiment 2

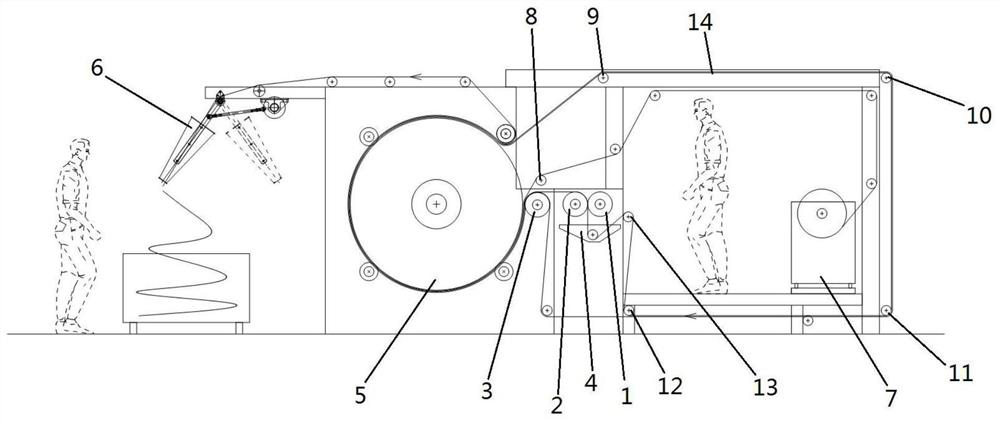

[0068] see figure 1 , the present embodiment increases the fourth roll 15 on the basis of the rolling device 24 in the first embodiment, specifically:

[0069] The rolling device 24 in this embodiment also includes a fourth roller 15;

[0070] The first roll 1, the second roll 2, and the third roll 3 are pressed against each other, and the fourth roll 15 is arranged between the third roll 3 and the first heating device 5, and is pressed against the first heating device 5;

[0071] The first cloth guide wheel 8 is arranged above the first roll 1 and the second roll 2, the first cloth guide wheel 8 guides the cloth 14 to enter between the second roll 2 and the third roll 3, and the second cloth guide Wheel 9, the third cloth guide wheel 10, the fourth cloth guide wheel 11 and the fifth cloth guide wheel 12 are sequentially arranged on the frame, and the second cloth guide wheel 9 guides the cloth coming out from the discharge end of the first heating device 5 14 is guided to t...

Embodiment 3

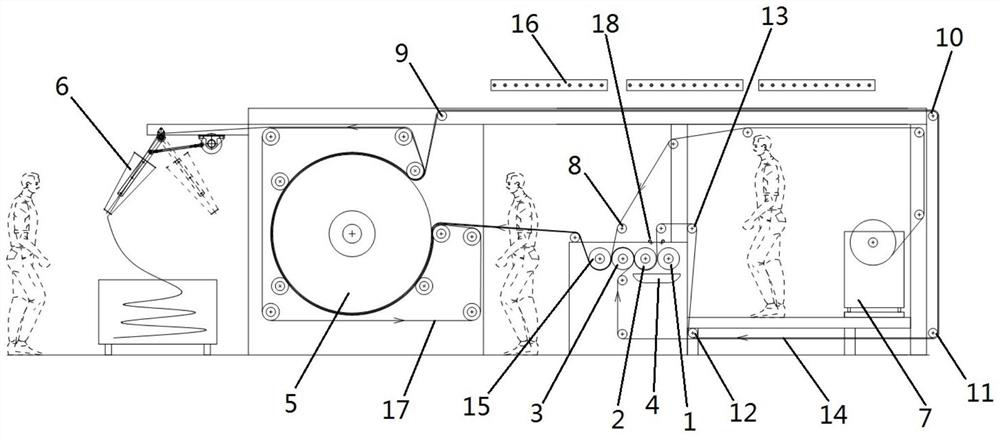

[0076] see image 3 , the present embodiment is on the basis of the trough 4 in the embodiment one, increasing the spraying device, specifically;

[0077] The spraying device in the present embodiment, the spraying device comprises spray pipe or shower head 18, pipeline, valve, pumping pump, filtering device, and spray pipe or shower head 18 is arranged on the top of rolling device 24, and toward the first roll 1 And the position between the second roll 2, nozzle or nozzle 18 is connected with hopper 4 by pipeline, filter device, valve and material pumping pump are all connected on the pipeline, nozzle or nozzle 18, hopper 4, pipeline, Valves, pumps, and filters form a cycle for liquid flow. It should be noted that, in this embodiment, the dye liquor in the trough 4 is pumped to the nozzle or nozzle 18 through the pipeline through the pumping pump, and the nozzle or nozzle installed between the first roller 1 and the second roller 2 18 can spray the dye liquor onto the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com