Low-energy consumption dyeing method

A dyeing method and technology with low energy consumption, applied in the field of textile printing and dyeing, can solve the problems of high energy consumption, production failure, high cost, etc., and achieve the effect of easy operation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Described in this embodiment is a kind of low energy consumption dyeing method.

[0020] 80S / 2 pure cotton yarn is selected, and the dyeing formula is shown in Table 1.

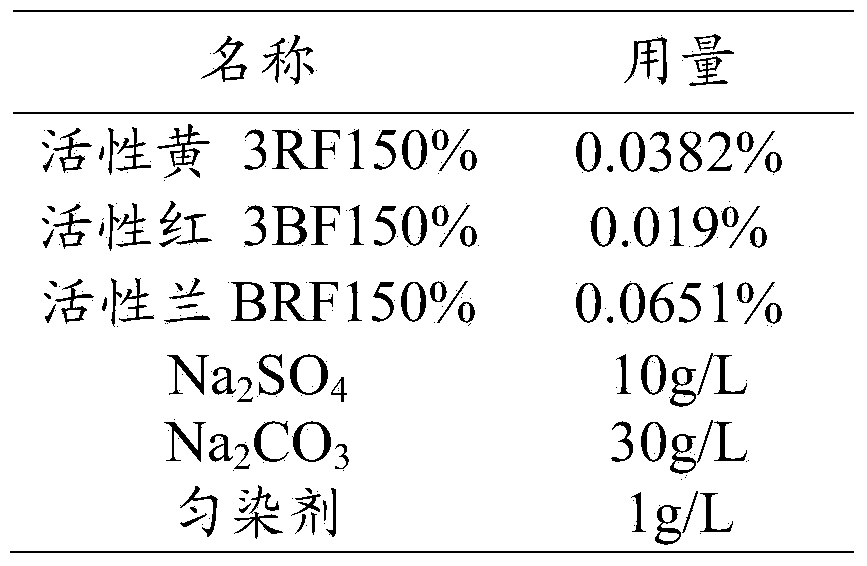

[0021] Table 1 Dyeing formula

[0022]

[0023] Proceed as follows:

[0024] (1) Input the pre-treatment, dyeing and post-processing procedures in the machine according to the dyeing process;

[0025] (2) Hang pure cotton yarn into the cylinder, lock the cylinder head and complete the pretreatment, dyeing and posttreatment processes according to the program requirements;

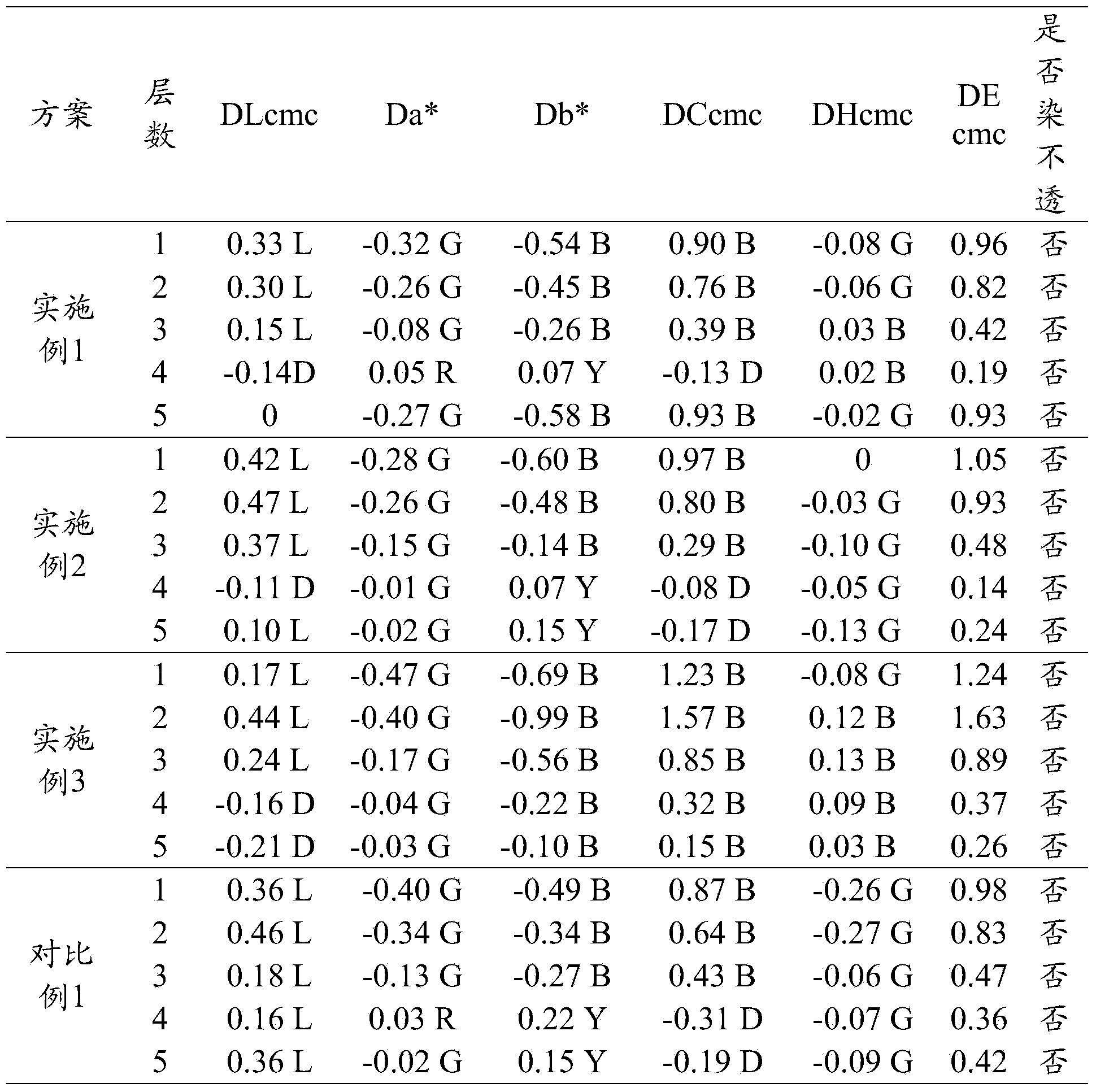

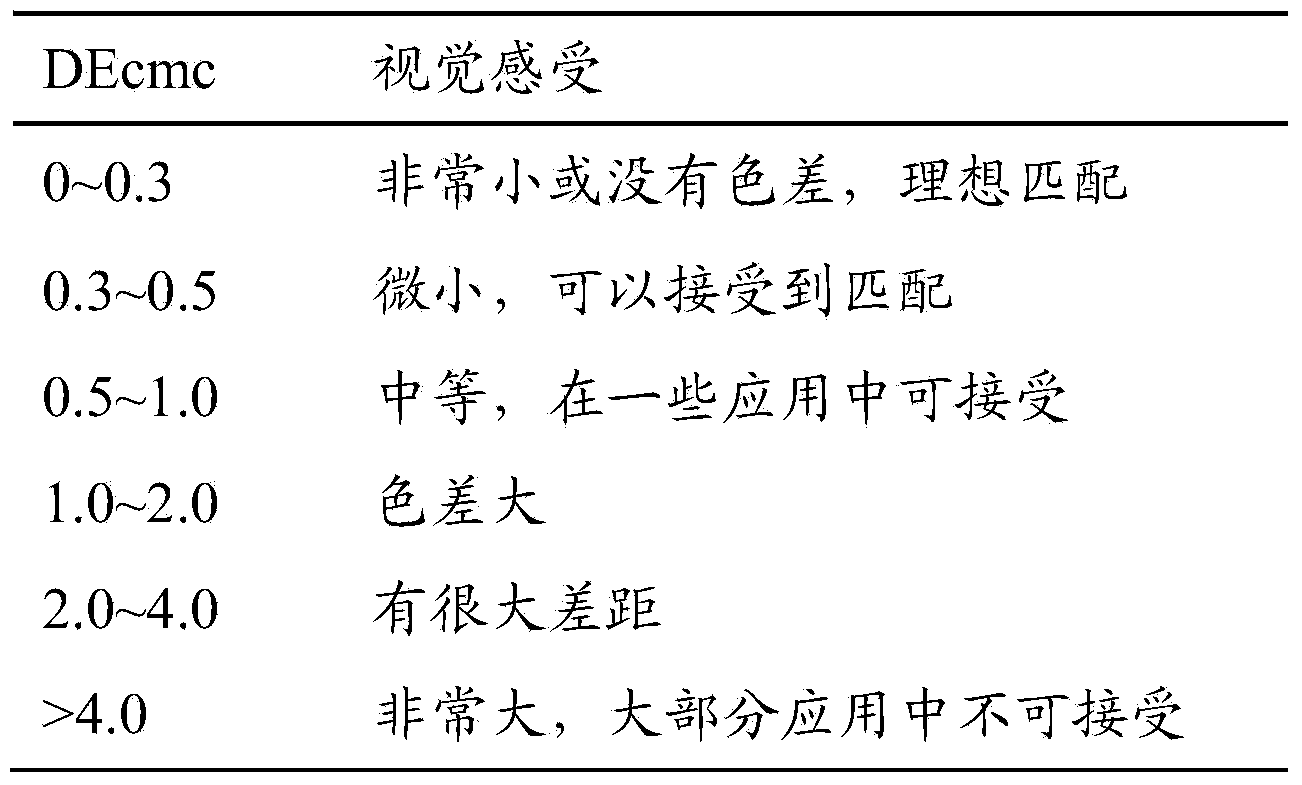

[0026] (3) Open 6 layers of pure cotton yarn and knit socks, visual inspection and computer test (take the 6th layer, that is, the innermost layer of pure cotton yarn as the standard, test the 1st to 5th layer of pure cotton yarn) dyeing quality;

[0027] In the whole dyeing process, a cycle of the main pump cycle operation is as follows: the duration of the main pump start-up speed-up period is 8s, the duration of the main pum...

Embodiment 2

[0029] Described in this embodiment is a kind of low energy consumption dyeing method.

[0030] The dyeing process parameters and steps are the same as in Example 1. In the whole dyeing process, a cycle of the main pump cycle operation is: the duration of the main pump startup speed-up period is 8s, the duration of the main pump uniform speed operation period is 15s, and the main pump stops and slows down. The duration of the period is 10s, and the duration of the main pump stop period is 20s.

Embodiment 3

[0032] Described in this embodiment is a kind of low energy consumption dyeing method.

[0033] The dyeing process parameters and steps are the same as in Example 1. In the whole dyeing process, a cycle of the main pump cycle operation is: the duration of the main pump startup speed-up period is 8s, the duration of the main pump uniform speed operation period is 15s, and the main pump stops and slows down. The duration of the period is 10s, and the duration of the main pump stop period is 10s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com