Dyeing machine with squeezing device

A dyeing machine and padding technology, applied in the field of dyeing, can solve the problems of difficulty in meeting customer requirements, decreased cleaning efficiency, and increased dyeing costs, and achieve the effects of reducing dyeing costs, water consumption, and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

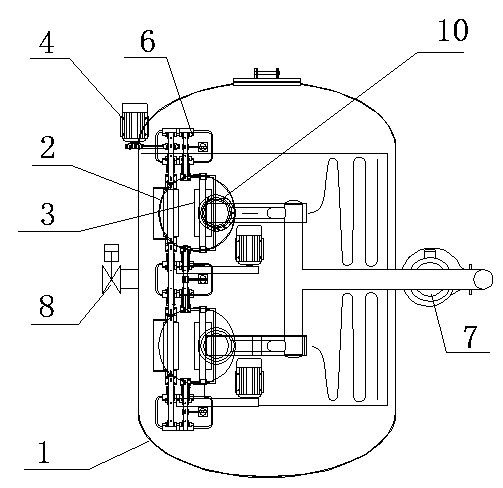

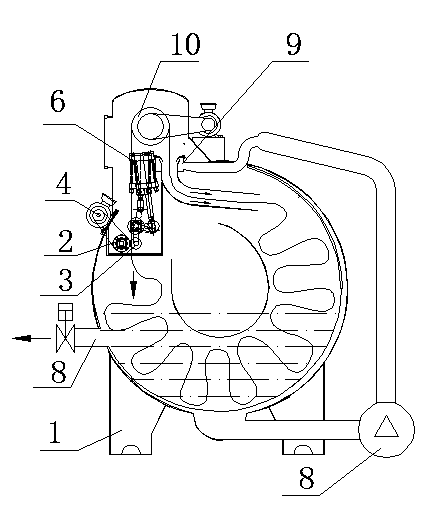

[0020] Embodiment: The main body 1 of the dyeing machine described in this embodiment is also provided with a cloth lifting wheel 10 with a dyeing nozzle 9 .

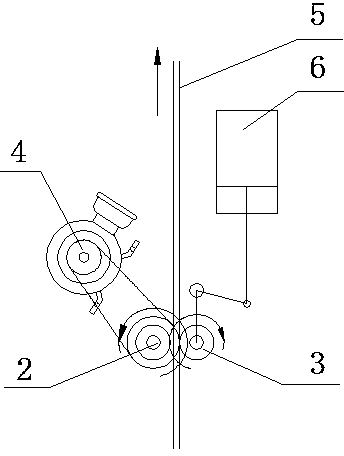

[0021] Working principle: first start the drive motor 4, the driving roll 2 and the driven roll 3 rotate counterclockwise under the drive of the drive motor 4, and at the same time the cloth 5 passes between the two rolls; Moving roll 3 is rolled out, as image 3 As shown, it is the state diagram of the water rolling device, the drive motor 4 drives the driving roll 2 to rotate, the driven roll 3 is pressed tightly, and the cloth 5 is squeezed between the driving roll 2 and the driven roll 3, under the action of friction Down, the cloth 5 is driven to move upward, the driven roller 3 rotates clockwise, the residual chemicals contained in the cloth 5 are squeezed out together with the water under the extrusion of the two rollers, the sewage valve is opened, and the discharged sewage It is discharged through the sewage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com