Biological slow-release fertilizer for fleece-flower root

A technology of slow-release fertilizer and Polygonum multiflorum, which is applied in the field of Polygonum multiflorum biological slow-release fertilizer, can solve the problems of no pest control formula, incomplete nutritional structure, no slow-release effect, etc., and achieve fast and long-term absorption and utilization. High, easily absorbed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

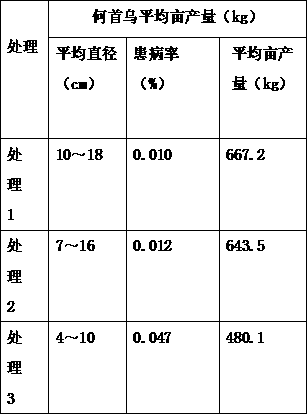

Image

Examples

Embodiment 1

[0033] The Polygonum multiflorum biological slow-release fertilizer comprises the following raw materials in parts by weight:

[0034] 20 parts of potassium polyphosphate; 10 parts of ammonium polyphosphate; 0.2 parts of magnesium sulfate; 0.2 parts of calcium chloride; 1 part of trace elements; 5 parts of manure fermented fertilizer; 1 part of tea saponin; parts; 10 parts of sustained release agent.

[0035] The preparation method of described potassium polyphosphate comprises the following steps:

[0036] ① Put yellow phosphorus in a combustion furnace and burn it at 450°C to get P 2 o 5 gas;

[0037] ②Use a blower to blow P 2 o 5 The gas is pumped into the polymerization tower, and water is continuously sprinkled to make P 2 o 5 The gas dissolves in water, to the P in the solution 2 o 5 The weight concentration of reaches 70%, obtains solution;

[0038] 3. in the solution obtained, according to hydrogen sulfide gas: solution is 1:1000 weight ratio hydrogen sulfid...

Embodiment 2

[0047] The Polygonum multiflorum biological slow-release fertilizer comprises the following raw materials in parts by weight:

[0048] 22 parts of potassium polyphosphate; 15 parts of ammonium polyphosphate; 0.3 parts of magnesium sulfate; 0.25 parts of calcium chloride; 1 part of trace elements; 8 parts of manure fermented fertilizer; 2 parts of tea saponin; parts; 12 parts of sustained-release preparations.

[0049] The preparation method of described potassium polyphosphate comprises the following steps:

[0050] ① Put yellow phosphorus in a combustion furnace and burn it at 550°C to get P 2 o 5 gas;

[0051] ②Use a blower to blow P 2 o 5 The gas is pumped into the polymerization tower, and water is continuously sprinkled to make P 2 o 5 The gas dissolves in water, to the P in the solution 2 o 5 The weight concentration of reaches 78%, obtains solution;

[0052] 3. in the solution that obtains, according to hydrogen sulfide gas: solution is 1:1550 weight ratio hy...

Embodiment 3

[0061] The Polygonum multiflorum biological slow-release fertilizer comprises the following raw materials in parts by weight:

[0062]25 parts of potassium polyphosphate; 18 parts of ammonium polyphosphate; 0.4 parts of magnesium sulfate; 0.3 parts of calcium chloride; 1.5 parts of trace elements; 12 parts of manure fermented fertilizer; 3 parts of tea saponin; parts; 15 parts of sustained-release preparations.

[0063] The preparation method of described potassium polyphosphate comprises the following steps:

[0064] ① Put yellow phosphorus in a combustion furnace and burn it at 600°C to get P 2 o 5 gas;

[0065] ②Use a blower to blow P 2 o 5 The gas is pumped into the polymerization tower, and water is continuously sprinkled to make P 2 o 5 The gas dissolves in water, to the P in the solution 2 o 5 The weight concentration of reaches 90%, obtains solution;

[0066] 3. in the solution that obtains, according to hydrogen sulfide gas: solution is 1:2000 weight ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com