Sustained-release adhesive, preparation method and application thereof

A binder and slow-release technology, applied in the application, nitrogen fertilizer, fertilizer mixture, etc., can solve the problems of unsatisfactory product hardness and appearance, and the nutrient release of ordinary compound fertilizer is too fast, so as to achieve convenient and fast production, improve nutrient content, granule good looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] According to the reaction of urea and 37% formaldehyde molar ratio U / F=1.2, 1.3, 1.4, 1.5, 1.6, the specific operation steps are as follows:

[0027] Step 1: Add water and weighed urea to the reaction kettle, stir to dissolve, adjust pH with borax and potassium hydroxide: 9, add 37% formaldehyde solution in molar ratio, stir and react at 80°C, after 0.5 hours ;

[0028] The second step: add oxidized starch whose weight is 10% of the amount of urea, stir for 15 minutes, adjust the pH of the reaction kettle solution with phosphoric acid: 4.5, continue to stir and react at 90°C with a speed of 50r / min, and after 0.5 hours, use CaO to adjust the pH to Neutral, made slow-release binder.

Embodiment 2

[0030] According to the reaction of urea and 37% formaldehyde molar ratio U / F=1.2, 1.3, 1.4, 1.5, 1.6, the specific operation steps are as follows:

[0031] The first step: add water and weighed urea to the reaction kettle, stir and dissolve, adjust the pH to 9 with borax and potassium hydroxide, add 37% formaldehyde solution in molar ratio, stir and react at 80°C, after 1 hour;

[0032] Step 2: Add oxidized starch whose weight is 10% of the amount of urea, stir for 15 minutes, adjust the pH of the reaction kettle solution to 4 with phosphoric acid, continue to stir and react at 90°C at a speed of 45r / min, and after 1 hour, adjust the pH to neutral with CaO , to prepare slow-release binders.

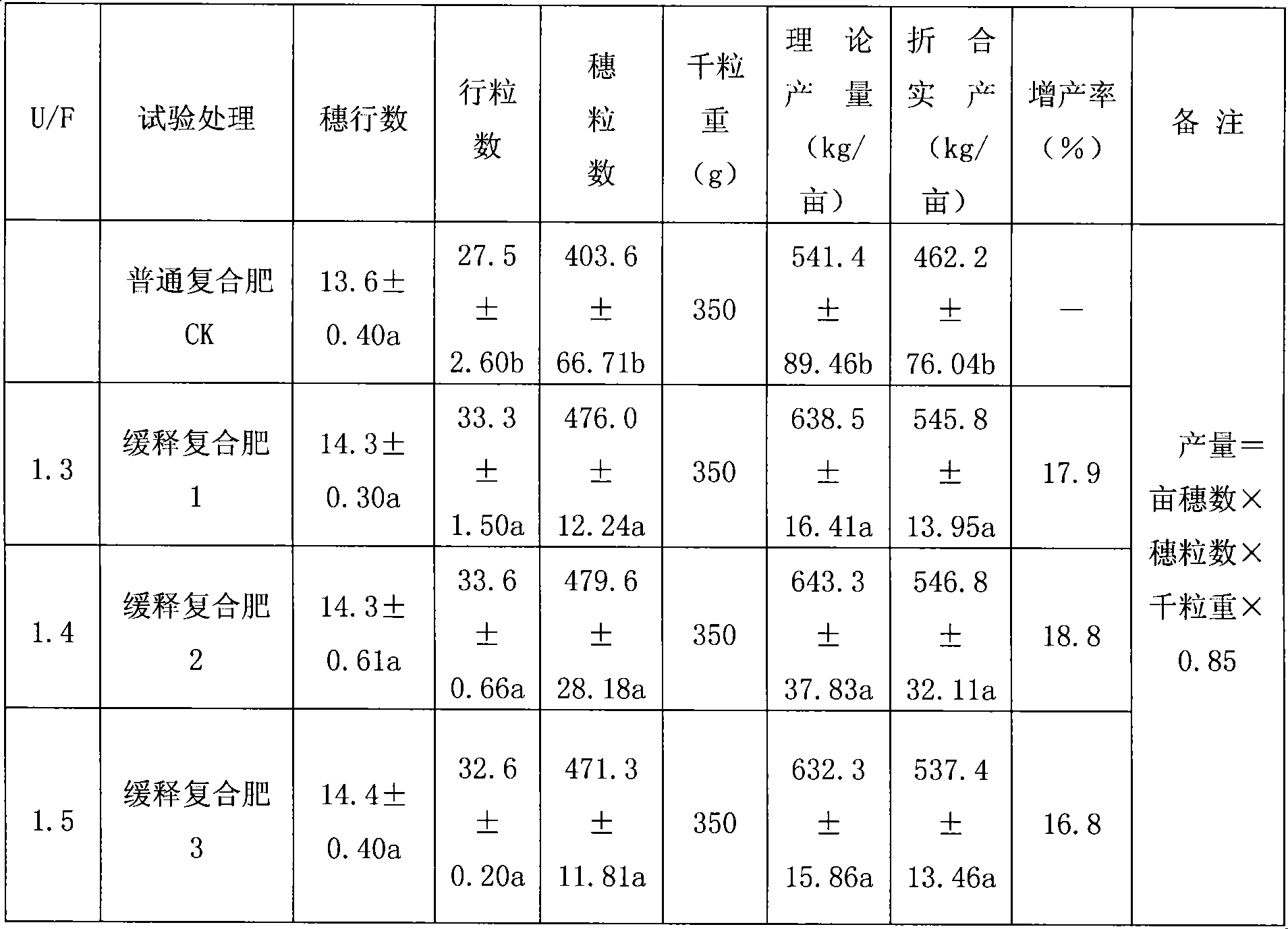

[0033] Table 1: Comparison of yield and activity of sustained-release agents with different U / F ratios

[0034] Numbering U / F Yield(%) Sustained release agent active AI(%) 1 1.2 92 56 2 1.3 90 68 3 1.4 86 72 4 1.5 78 65 5 1.6 69 53 ...

experiment example

[0036] The comparative test of the slow-release compound fertilizer made with the slow-release binder and the common compound fertilizer: the test crop is corn, and the variety T 3 -1, the fertilizer nutrient used N—P 2 o 5 —K 2 O is all 22-8-15, and the slow-release compound fertilizer is made of three kinds of slow-release agents with U / F=1.3, 1.4, 1.5; 4 treatments are set in the test, and each treatment is based on 1020kg / hm 2 Fertilization, repeated 3 times, the area of each plot is 25m 2 (Length 6m, width 5m).

[0037] Table 2: Comparative test of fertilizer efficiency of several slow-release compound fertilizers and common compound fertilizers

[0038]

[0039] The results prove that the slow-release compound fertilizer made with the slow-release binder increases the nutrient content of the slow / controlled release compound (mixed) fertilizer, and can meet the needs of crops for medium and trace elements. The method has high pelleting rate, high fertilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com