Humic acid membrane wrapping control-releasing fertilizer

A technology of coated controlled-release fertilizer and humic acid, which is applied in the direction of fertilization equipment, fertilizer mixture, application, etc., can solve the problems of high production cost, low impact resistance, low wear resistance, and low effective nutrient content of controlled-release fertilizer. Achieve the effects of increasing microbial flora, strong abrasion resistance, and improving crop quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

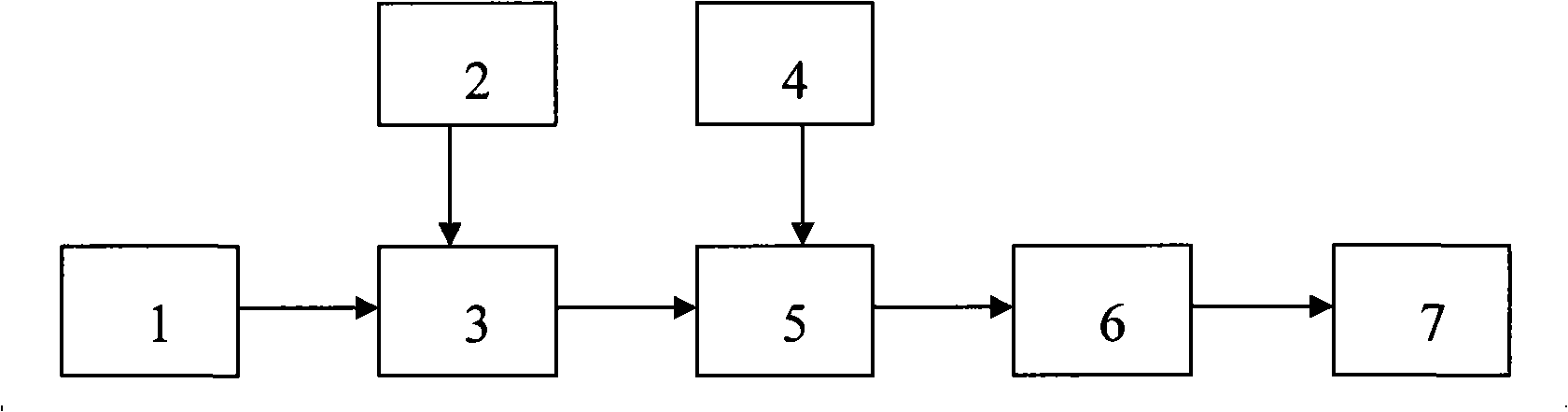

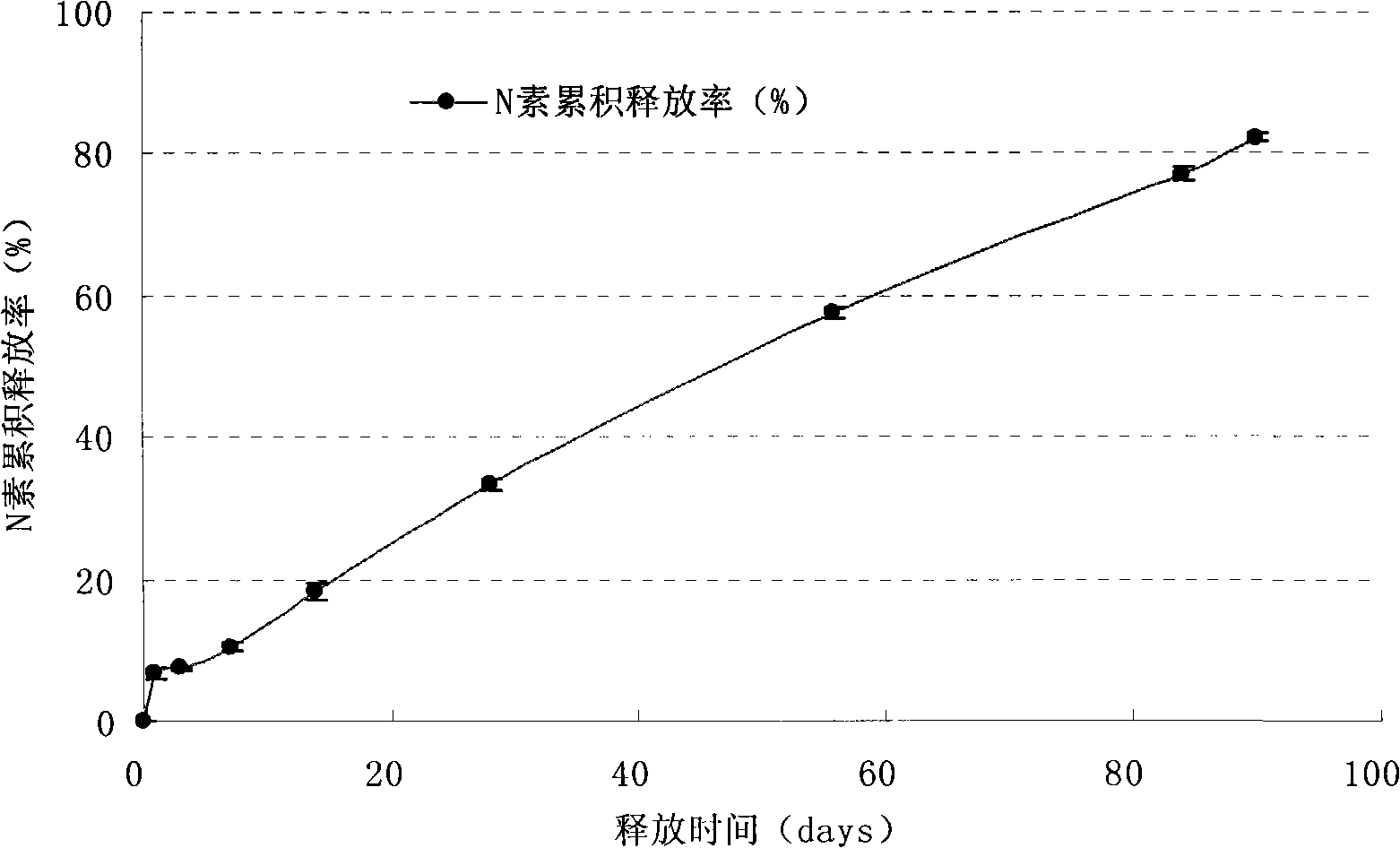

[0032] Example 1, preparing humic acid-coated controlled-release fertilizer with controlled release for 2 months.

[0033] Weigh 500kg of diammonium phosphate (18-46-0) granular fertilizer, preheat to 60°C in a disc granulator (1), mix 1.12kg of 4,4'-diphenylmethane diisocyanate and 1.38kg of tung oil Evenly (2) added to the moving fertilizer particles, with the continuous movement of the fertilizer particles, a cohesive liquid layer (3) is formed on the surface, and 5 kg of air-dried and crushed weathered coal (4) weighed is scattered on the disc On the fertilizer in the granulator, continue to heat and keep the temperature at 60-70°C. With the continuous rotation of the granulator, the weathered coal powder is evenly wrapped on the surface of the fertilizer, and it can be solidified into a film after about 6 minutes (5); The amount of coating material weighed above is repeatedly wrapped 2 times on the 500kg diammonium phosphate fertilizer, and the about 4%wt of total coating...

Embodiment 2

[0034] Example 2, preparing humic acid controlled release fertilizer with controlled release for 9 months.

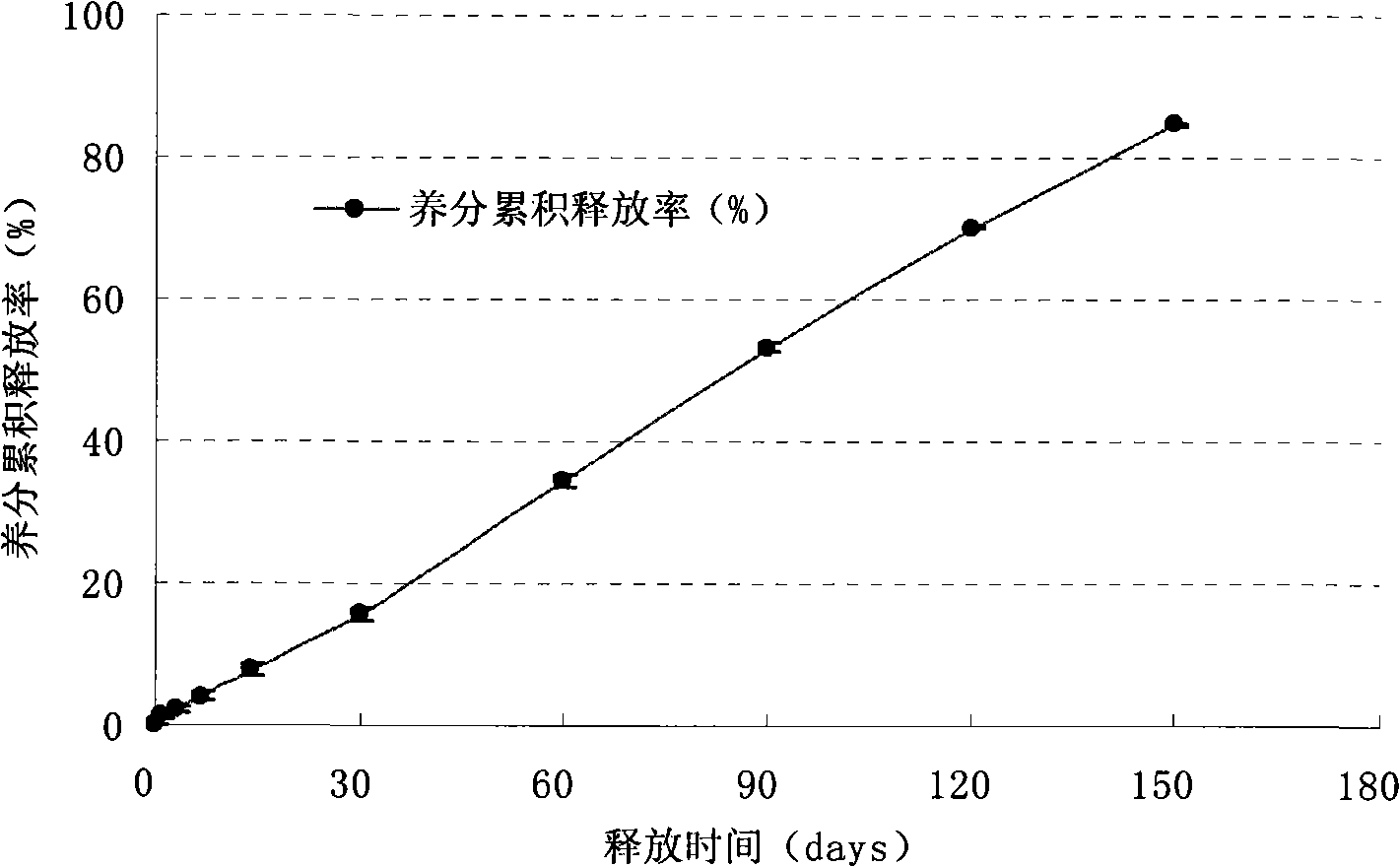

[0035] Weigh 500kg of Shima brand (15-15-15) granular fertilizer from BASF, Germany, preheat to 65°C in a disc granulator (1), mix 2.6kg polymethylene polyphenylisocyanate and 2.4kg soybean oil Mix evenly (2) and add to the moving fertilizer particles, as the fertilizer particles continue to move, a cohesive liquid layer (3) is formed on the surface, weigh 25 kg of lignite with a particle size of 0.08-0.25mm, air-dried and pulverized Sprinkle lignite (4) on the fertilizer in the disc granulator, continue heating to keep the temperature at 65°C, and with the continuous rotation of the granulator, the weathered coal powder is evenly wrapped on the surface of the fertilizer, and it can be solidified after about 5 minutes. Film (5); according to the amount of coating material weighed above, wrapping is repeated once, and a humic acid controlled-release fertilizer with a tot...

Embodiment 3

[0036] Example 3, preparing humic acid controlled release fertilizer with controlled release for 6 months.

[0037]Weigh 500kg of Shima brand (15-15-15) granular fertilizer from BASF, Germany, preheat it to 65°C in a disc granulator (1), mix 1.2kg polymethylene polyphenylisocyanate and 1.8kg soybean oil Mix evenly (2) and add to the moving fertilizer particles, with the continuous movement of the fertilizer particles, a cohesive liquid layer (3) is formed on the surface, and 10kg weighed air-dried and pulverized lignite (4) is sprinkled on the disc On the fertilizer in the granulator, continue to heat and keep the temperature at 60-70°C. With the continuous rotation of the granulator, the weathered coal powder is evenly wrapped on the surface of the fertilizer, and it can be solidified into a film after about 5 minutes (5); The amount of coating material weighed above is wrapped twice on 500kg Shima brand 15-15-15 fertilizer, and a humic acid controlled-release fertilizer with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com