Dyeing method and device with anti-splashing structure for polyester chemical fiber cloth spinning

A dyeing device and a dyeing method technology are applied in the field of dyeing methods and devices with splash-proof structure for polyester chemical fiber cloth textiles, which can solve the inconvenience of polyester fabrics entangled on the surface of rollers, color patterns and stains, and insufficient cleaning of fabrics. problems, to achieve the effect of ensuring normal dyeing quality and accelerating disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

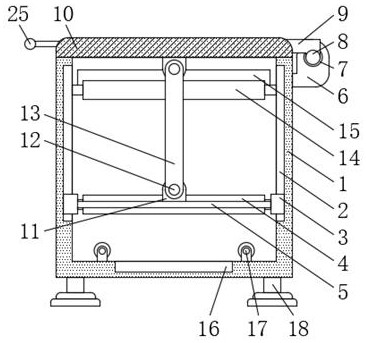

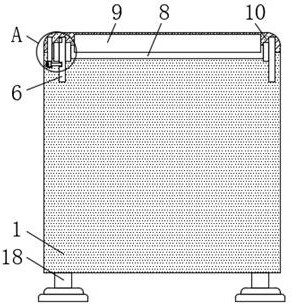

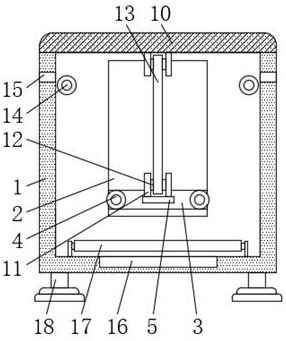

[0036] Such as Figure 1-4 As shown, the present invention provides a technical solution: a method for dyeing polyester chemical fiber cloth with splash-proof structure, comprising the following steps:

[0037] S1. Pretreatment before dyeing:

[0038]Put the polyester fabric to be dyed into the washing machine first, and when the water level reaches 13-17%, wash in the detergent and bleaching powder. By adding detergent and bleaching powder at a low water level, the detergent and bleaching powder can be made The concentration of the bleaching powder is up to the standard, so as to achieve the best washing effect, and by adding detergent and color bleaching powder, the detergent can remove the stains on the surface of the fabric, and the addition of color bleaching powder can maintain the brightness of the surface of the fabric. Cross-color occurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com