Dyeing and finishing processing technique of memory T400 fabric based on biological based material

A processing technology, bio-based technology, applied in the field of dyeing and finishing of memory T400 fabrics, can solve the problems of scratching and polishing, crepe feel, hard and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

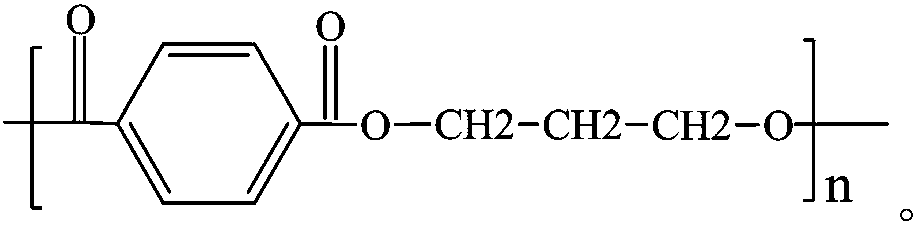

[0039] Fabric fabric: width 175cm, density 155g / m 2 .

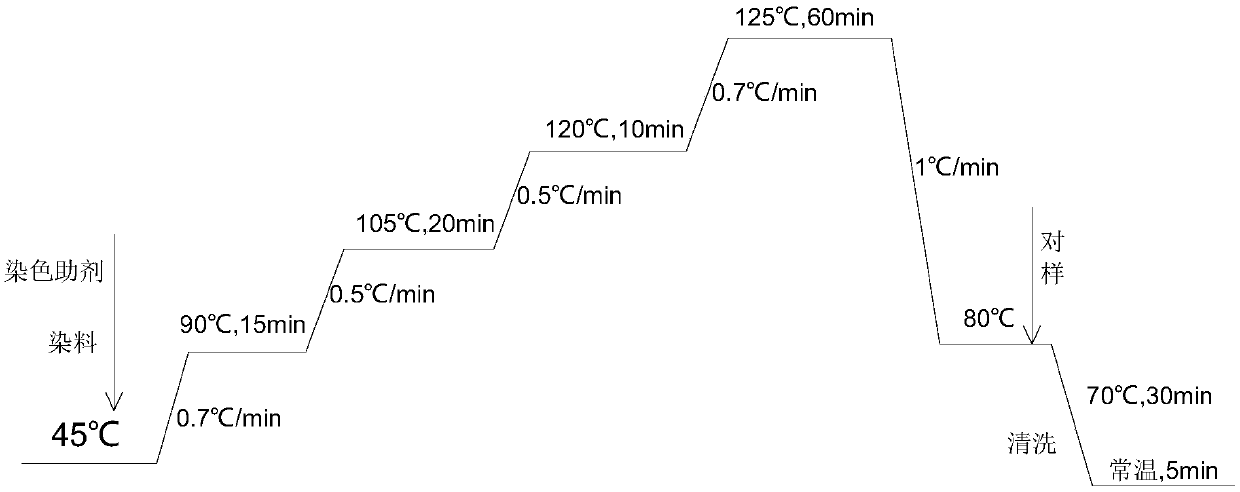

[0040] The dyeing and finishing process of the memory T400 fabric based on the bio-based material of the present invention includes a pretreatment process, a dyeing process and a setting process carried out in sequence.

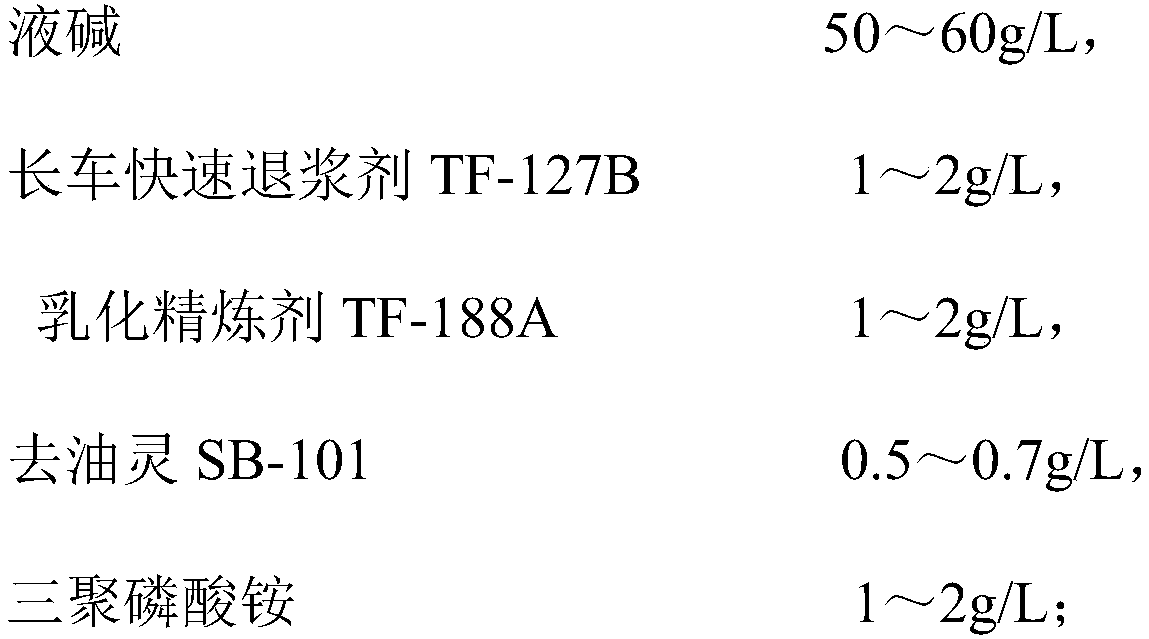

[0041] During the weaving process, the memory T400 fabric is subjected to high tension and friction in the warp direction, and is prone to breakage. In order to reduce breakage, improve weaving efficiency and gray fabric quality, warp yarns need to be sized. However, the size is beneficial to weaving but not conducive to dyeing and finishing. The size film covered on the surface will hinder the diffusion of dyestuffs into the fiber during the dyeing process. If impurities and dirt are not removed, it will not only affect the feel and color of the fabric, but also affect the hygroscopicity of the fabric, making the fabric color uneven, the color not bright, and affect the color fastness. Therefore, befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com