Color purity improving sheet, optical apparatus, image display, and liquid crystal display

A technology of color purity and light-emitting devices, applied in optics, optical components, lighting devices, etc., can solve problems such as insufficient filtering of color filters, lack of practicability, and unstable wavelength distribution and spectrum of emitted light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

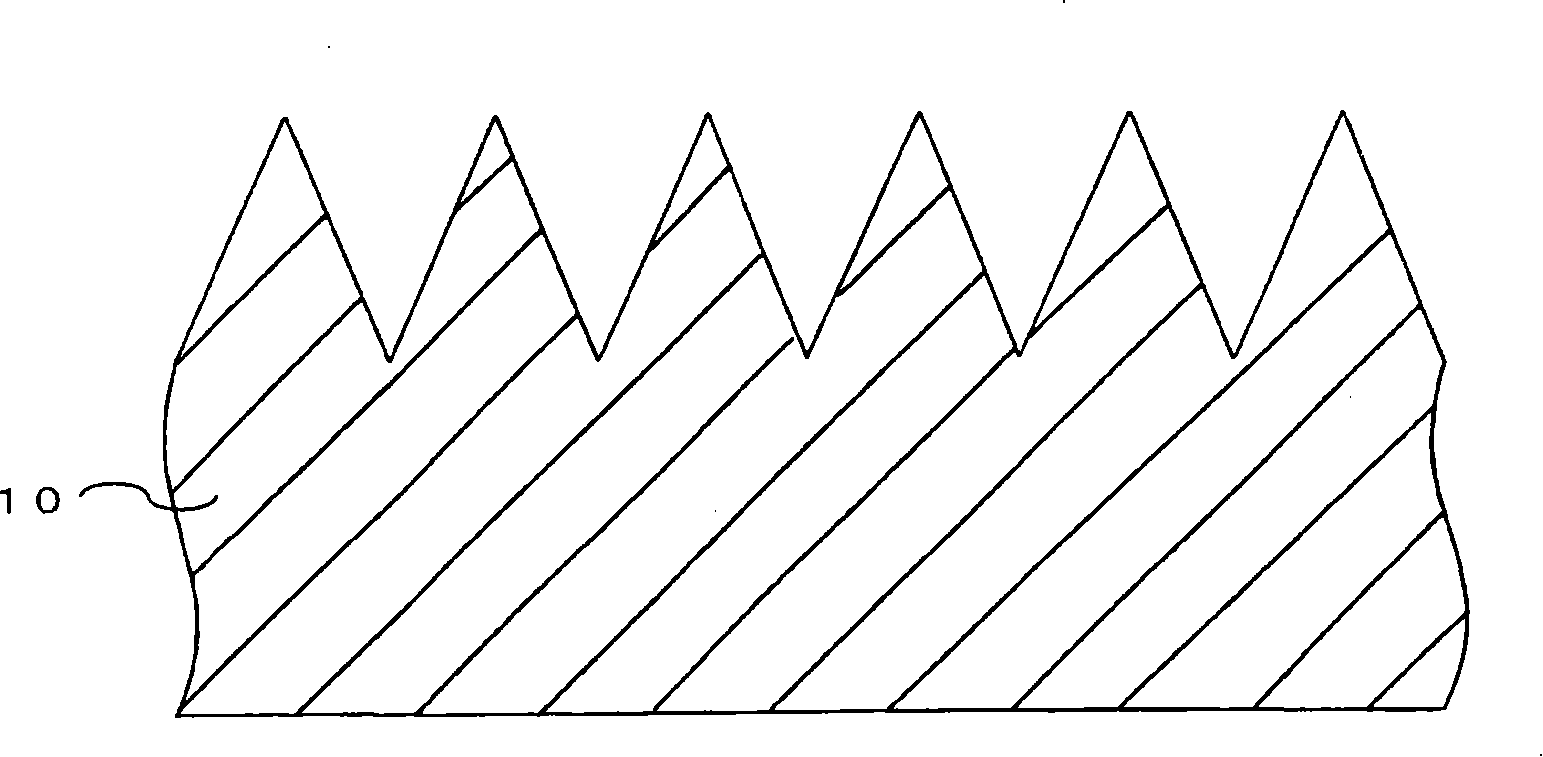

[0075] Manufacture of Color Purity Improved Sheets

[0076] A fluorescent substance having a structure represented by the above formula (1) (produced by BASF A.G., "LumogenF Red 305" (trade name)) was added and dissolved in a toluene solution of 30% by weight of polymethyl methacrylate to make it It is 0.19 weight% with respect to polymethylmethacrylate. This solution was applied on a polyethylene terephthalate (PET) film substrate with an applicator to form a coating film, and then dried at 80° C. for 30 minutes. Thus a thin film is obtained. After drying, the film was separated from the PET film substrate to obtain a 30 μm thick polymethyl methacrylate film. One surface (light output side surface) of the resulting film was subjected to surface grinding treatment with sandpaper (#100), thus obtaining the color purity improving sheet of this example. The surface on the light output side of the color purity improving sheet had an arithmetic mean surface roughness Ra of 0.8 μ...

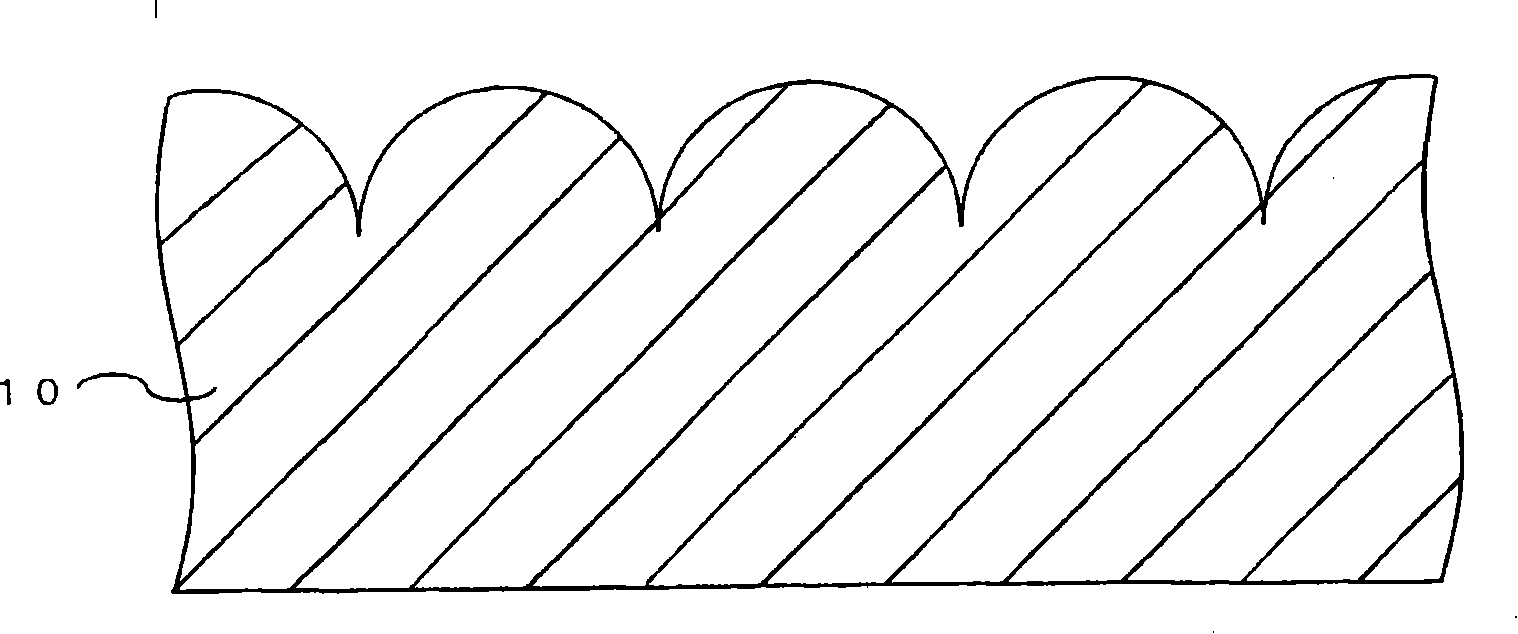

Embodiment 2

[0078] The color purity improving sheet of this example was obtained in the same manner as in Example 1, except that the surface was ground with sandpaper (#700). The surface on the light output side of the color purity improving sheet had an arithmetic mean surface roughness Ra of 0.13 μm.

Embodiment 3

[0080] The color purity improving sheet of this example was obtained in the same manner as in Example 1, except that the surface was ground with sandpaper (#800). The surface on the light output side of the color purity improving sheet had an arithmetic mean surface roughness Ra of 0.15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com