Patents

Literature

284results about How to "Easy to achieve mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

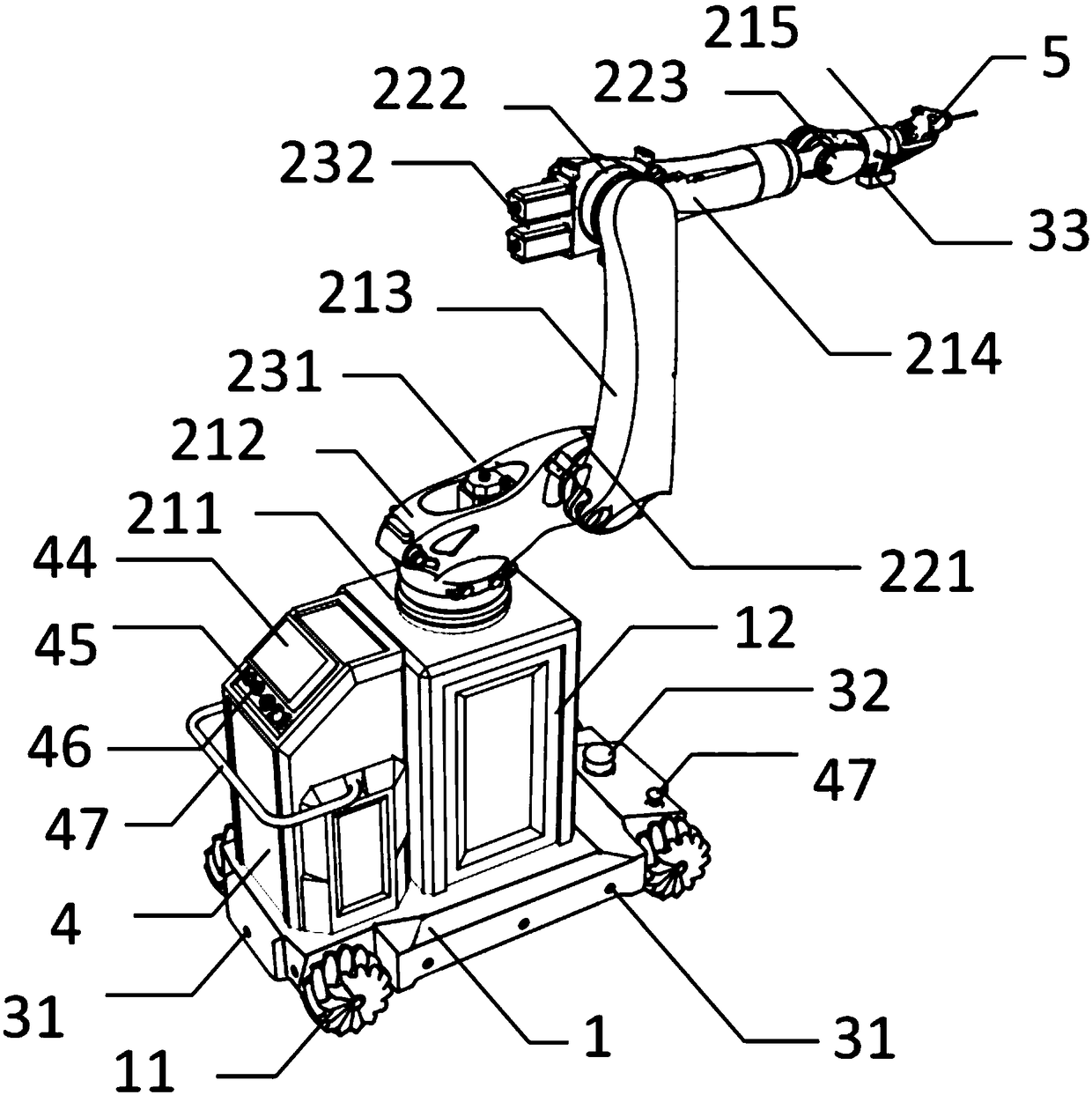

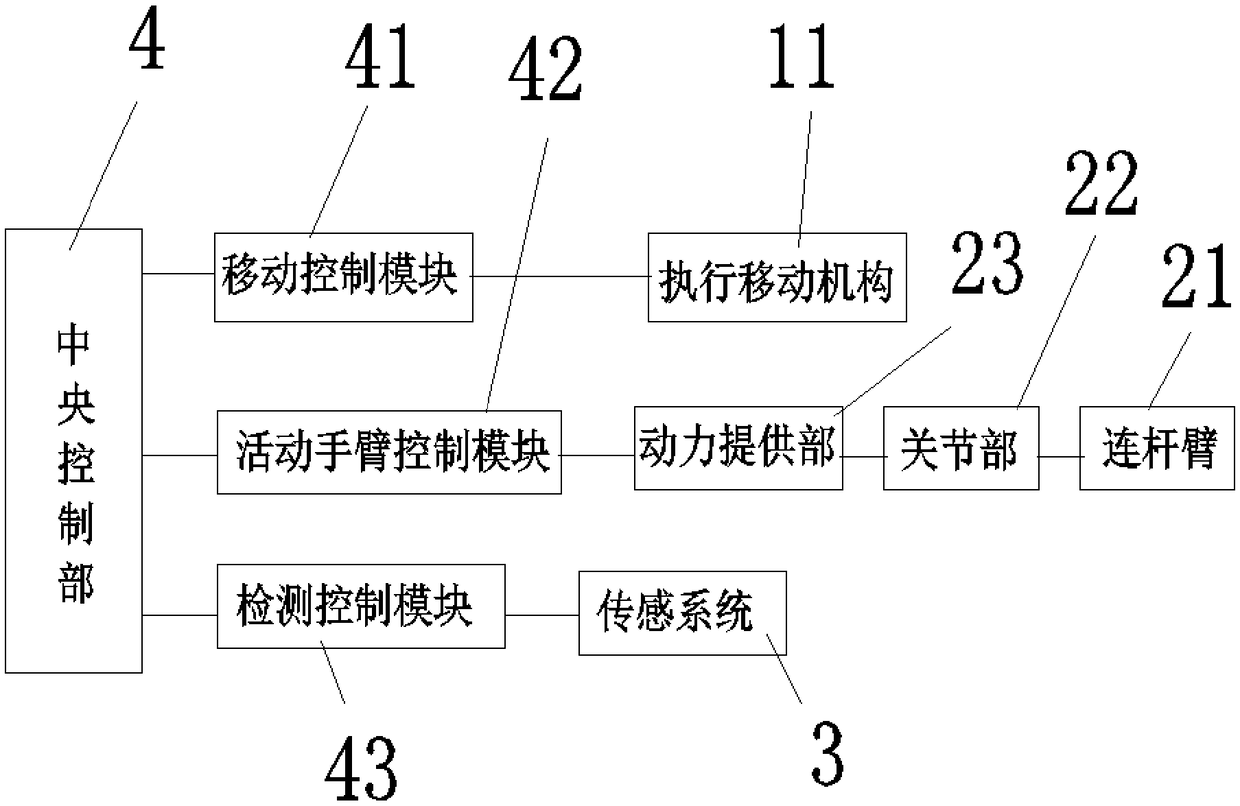

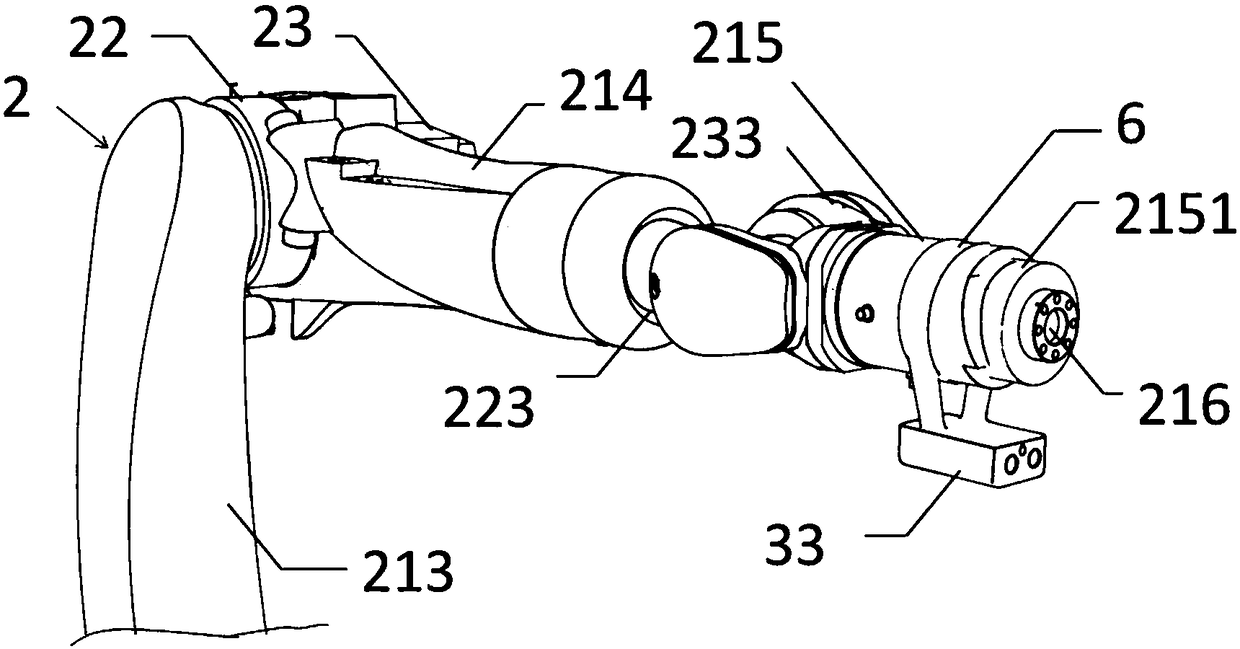

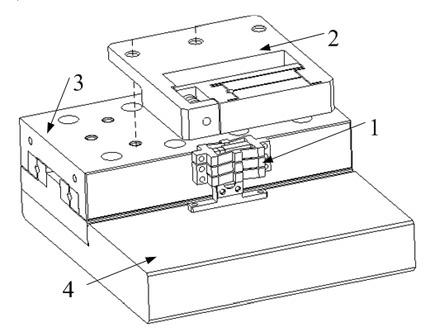

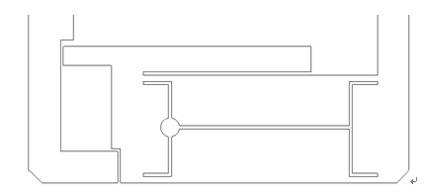

General building indoor engineering intelligent robot

PendingCN108942873AImprove health and hygieneReduce labor intensityManipulatorControl engineeringEngineering

The invention discloses a general building indoor engineering intelligent robot. The general building indoor engineering intelligent robot is characterized by comprising a movable base part, a robot movable arm, sensing systems, and a central control part, wherein the robot movable arm is provided with at least two connecting rod arms and power supply parts for driving all joint parts; the adjacent connecting rod arms move by dint of the joint parts; the sensing systems are arranged on the movable base part and the robot movable arm; the sensing systems comprise detecting modules for realizingobstacle avoidance and distances and detecting relative coordinates of space of the movable base part; the central control part is connected with the movable base part, the robot movable arm and thesensing systems; and the central control part comprises a movable control module, a movable arm control module and a detecting control module. The general building indoor engineering intelligent robotis simple in structure and easy to realize large-scale production, and effectively improves the construction quality and the working efficiency through automatic work of the movable base part, the control part, a power distribution management system and multi-axis mechanical arms.

Owner:珠海心怡科技有限公司

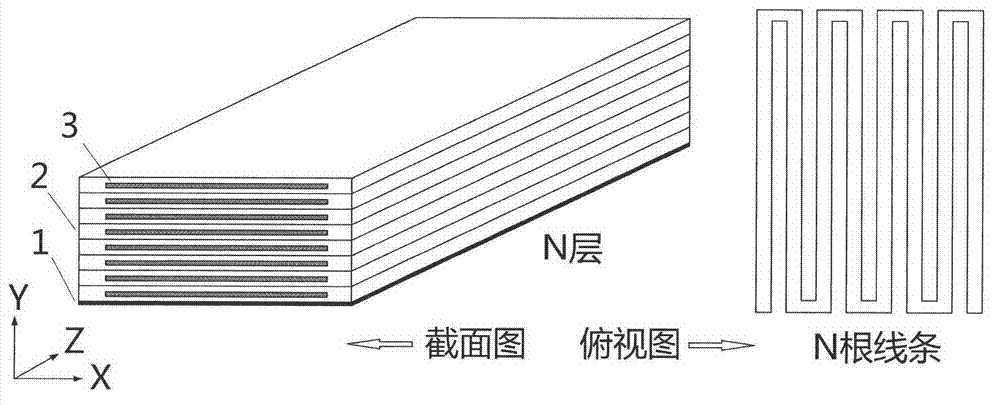

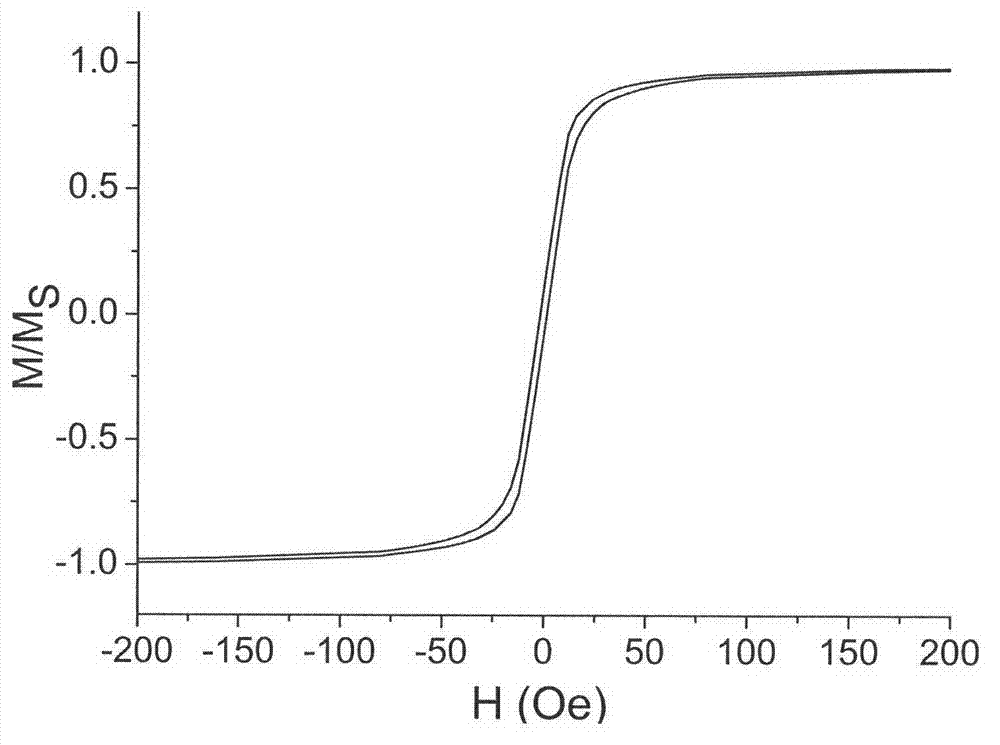

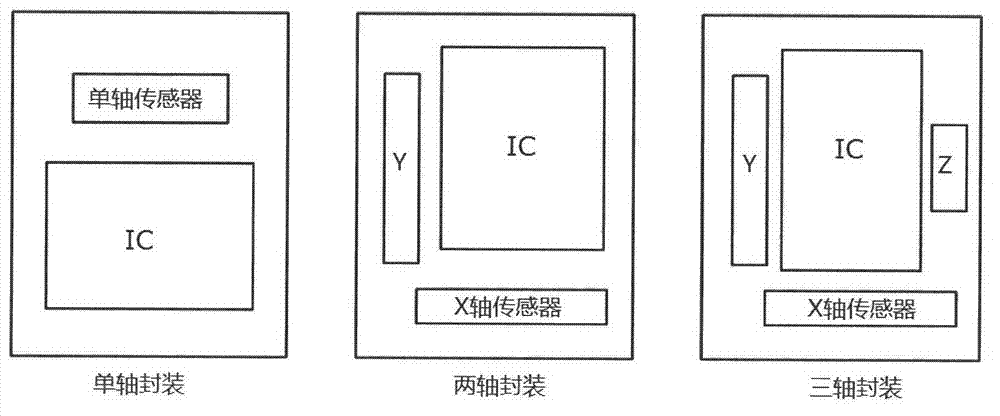

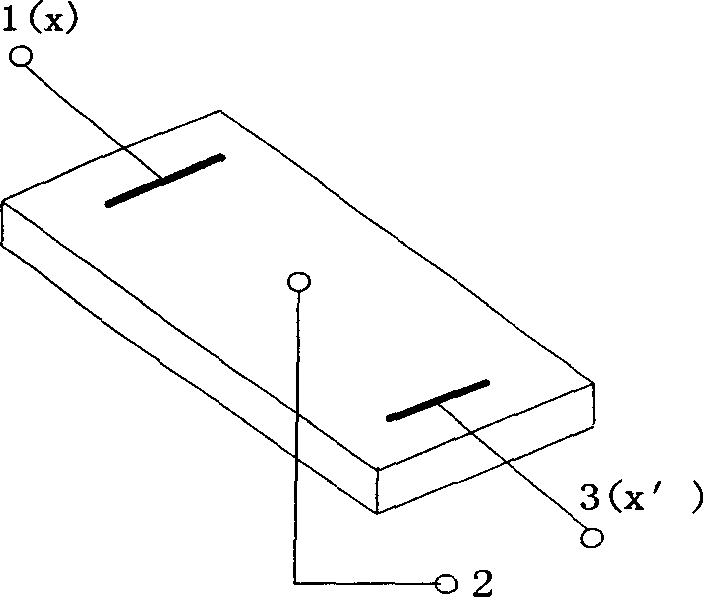

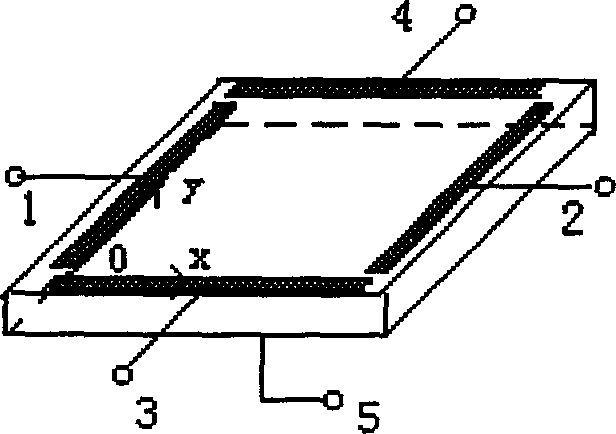

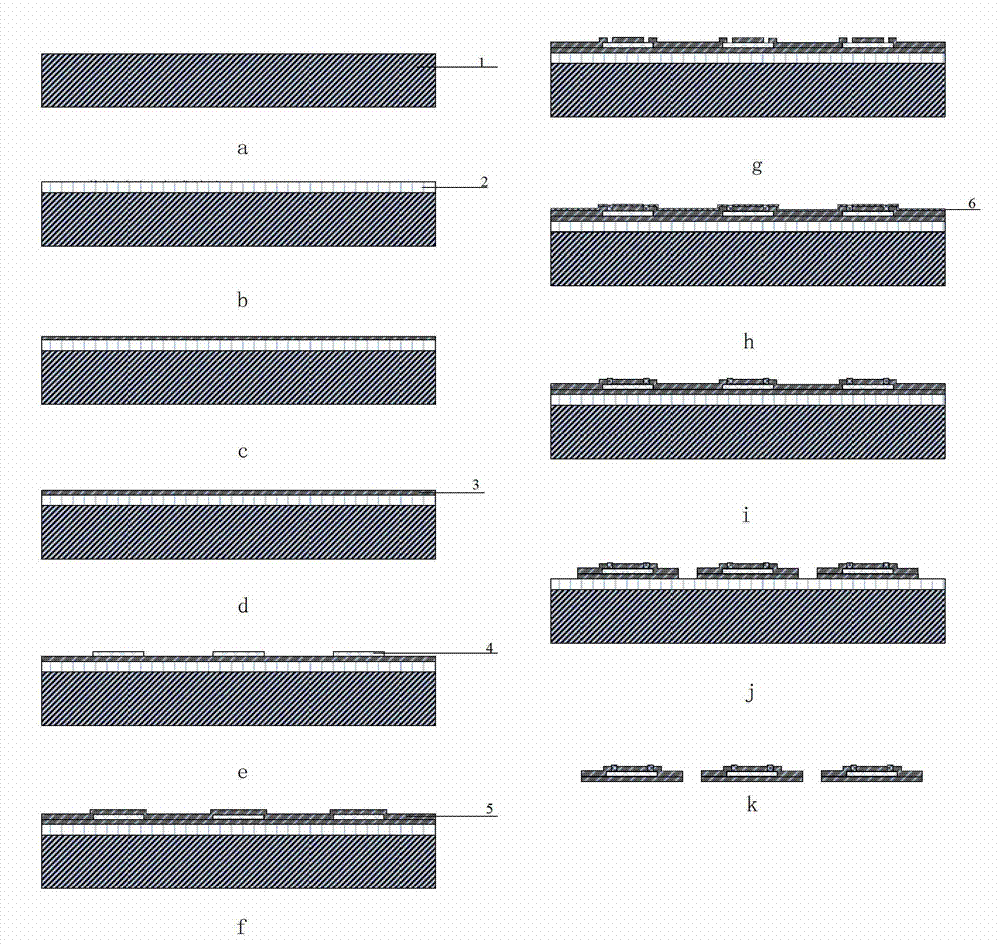

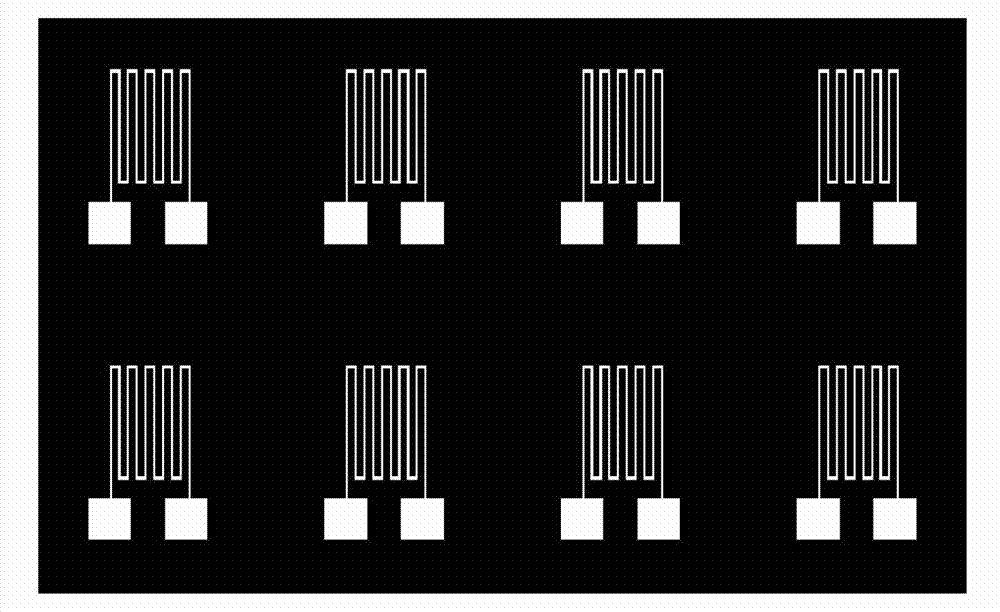

Design and manufacture technology of sensor chip for detecting magnetic field and acceleration

InactiveCN103076577ASimple processHigh sensitivityAcceleration measurement using interia forcesMagnetic measurementsManufacturing technologyEngineering

The invention discloses a design and manufacture technology of a sensing unit of a sensor and one or more types of sensor chips consisting of the sensing unit, in particular to one or more types of sensor chips capable of detecting the magnetic field parallel and vertical to the surface of the chip and the acceleration of an object. The invention has the advantages that the process is simple and easy, the sensitivity is high, and batched production is easily realized; the sensing unit of the sensor comprises a wafer substrate, a seed layer, a soft magnetic material layer, a conducting layer and a N-layer structure; the conducting layer is wrapped by the soft magnetic material layer; the N-layer structure is formed by combination of the soft magnetic material layer and the conducting layer; and simultaneously a bent structure is formed by N long lines in the plane (the sensing unit is a single-strip-shaped structure when N is equal to 1). The sensing unit of the sensor realizes single-axis, double-axis and three-axis magnetic field detection by different packaging forms. Simultaneously, due to the combination of the sensing unit of the sensor and a cantilever structure with magnetic mass blocks, the single-axis, double-axis and three-axis acceleration detection can be realized.

Owner:陈磊

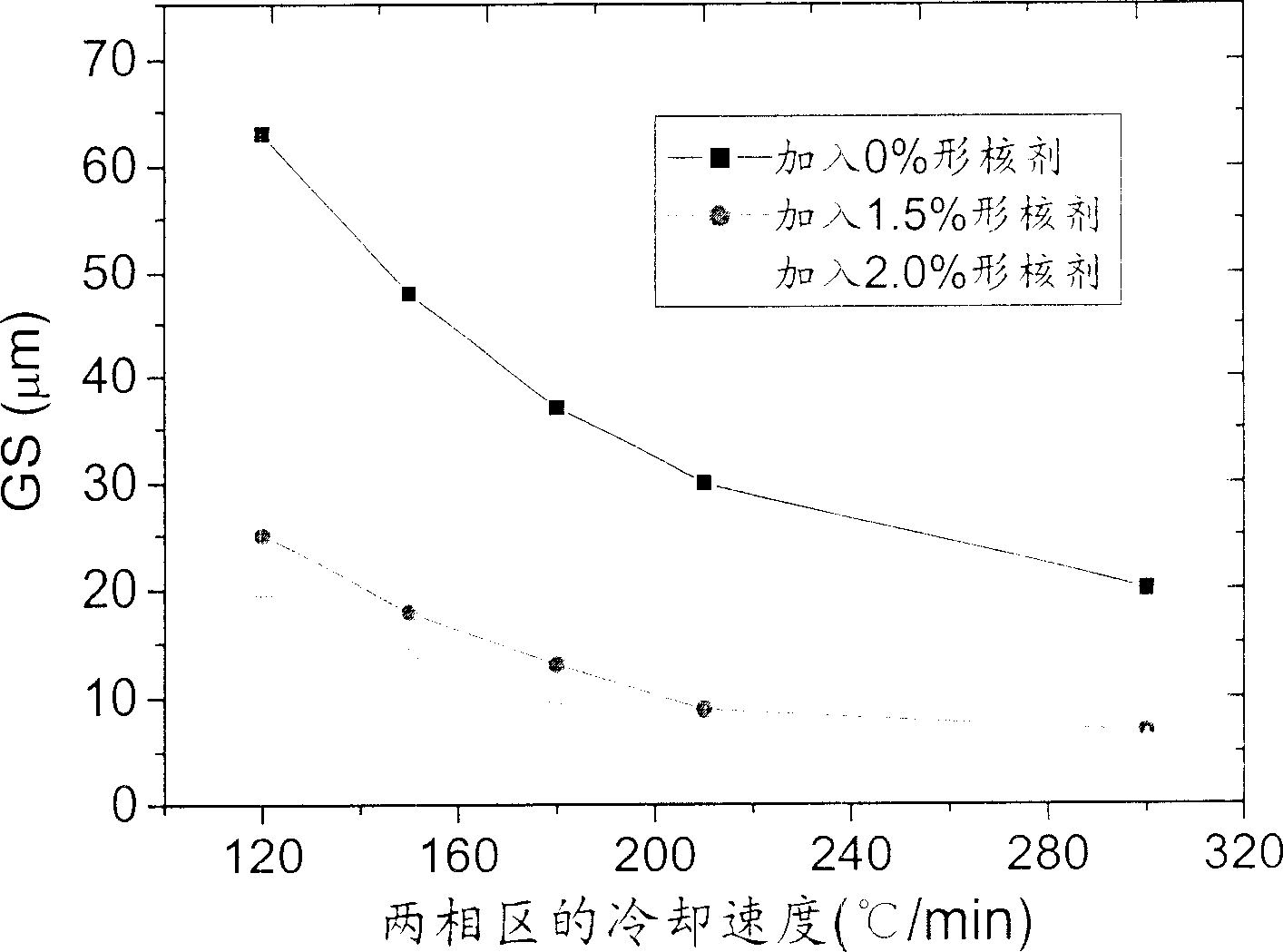

Manufacture method for obtaining superfine crystal grain steel

A manufacturing method for super fine crystal grain steel including the following steps: smelting in terms of the following composition and weight percentage: C0.02~0.20%, Nb 0.01~0.10%, Si 0.80%, Mn1.0~2.0%, Ti0.08~0.025%, Als is not greater than 0.20%, casting: the temperature for pouring is lower than or equal to +20deg.c nucleation agent is added when pouring, the cooling speed of the steel melt is greater than or equal to 180deg.c / min, the strand crystal grain is smaller than 15mum, rolling: heating it to over AC3 then to cool it to about Ar3 to continuously un-re crystallization to control the rolling, the accumulated step-down rate is greater than 80%, cooling: cooling it to below 450deg.C then cooling it naturally to the room temperature to get ferrite crystal grains smaller than 3.0mum.

Owner:BAOSHAN IRON & STEEL CO LTD

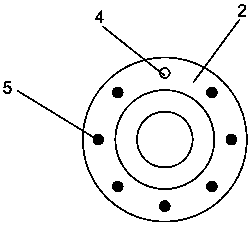

MEMS (Micro-Electro-Mechanical Systems) processing technique-based cylindrical capacitive sensor

InactiveCN102607394AReduce edge effectsHigh measurement accuracyDecorative surface effectsUsing electrical meansCapacitanceCopper electrode

The invention discloses an MEMS processing technique-based cylindrical capacitive sensor. The MEMS processing technique-based cylindrical capacitive sensor comprises a rotary spindle electrode and a cylindrical fixed electrode coaxially mounted on the outside of the rotary spindle electrode; in the rotary spindle electrode, a first insulating layer, a copper spindle electrode and a second insulating layer outwardly and sequentially wrap the outer cylindrical surface of a spindle; and in the cylindrical fixed electrode, a third insulating layer, an equipotential protective ring, a fourth insulating layer and four arc-shaped electrodes equidistantly embedded in the inner circle of the fourth insulating layer are inwardly and sequentially wrapped in the cylindrical hole of an electrode base. The MEMS processing technique can be adopted to process the electrodes to be ultrathin, the complex processing and assembly process of the main conventional method in producing the cylindrical capacitive sensor can be overcome, the size of the sensor is reduced, moreover, the edge effect of the sensor can be inhibited as well, and the cylindrical capacitive sensor is suitable for monitoring the rotation error of the spindle. Due to the technique, the miniaturized cylindrical capacitive sensor can be easily produced, and the sensor can also be easily produced in batches.

Owner:ZHEJIANG UNIV

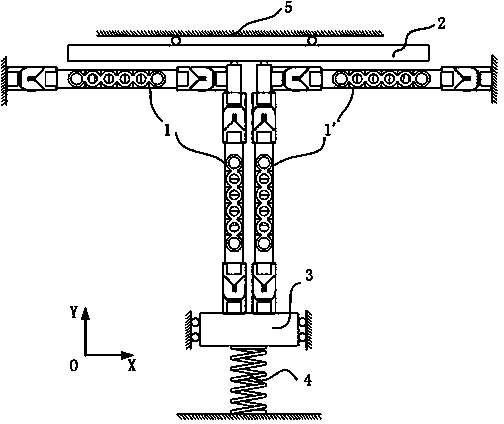

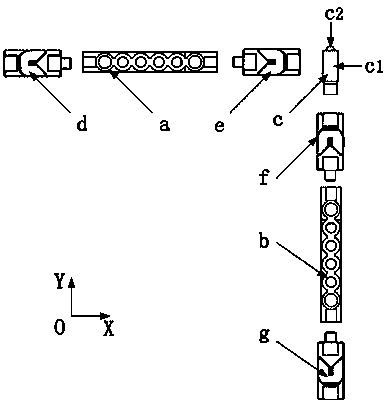

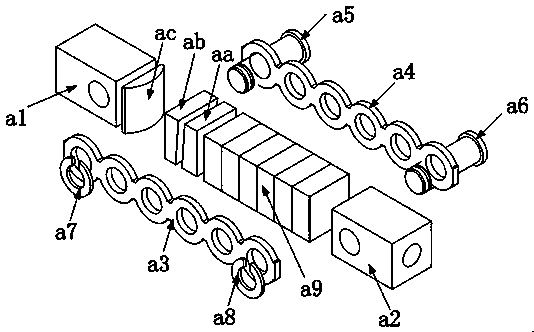

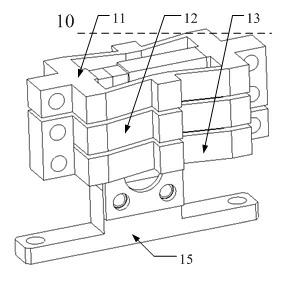

Double-foot driving piezoelectric linear motor and electric excitation mode

InactiveCN103427704AImprove efficiencyIncrease thrustPiezoelectric/electrostriction/magnetostriction machinesElectricitySignal on

The invention discloses a double-foot driving piezoelectric linear motor and an electric excitation mode. The motor is composed of two stator sets, a rotor / linear guide rail, a pre-pressing guide rail, a pre-pressing spring and a base. The two stator sets are distributed symmetrically along axes, and the ends of the two stator sets are fixedly connected with the pre-pressing guide rail. Under the action of elastic restoring force generated by elastic deformation of the pre-pressing spring, the two stator sets keep in contact with the rotor / linear guide rail, so that an outage self-locking function is provided for the piezoelectric linear motor. Each of the two stator sets is composed of piezoelectric actuation units, flexible connectors and a driving foot, wherein two ends of the piezoelectric actuation units are connected with the driving feet and the base through the flexible connectors. The piezoelectric actuation units serve as modular structures, so that the whole motor structure is simple, the motor assembly efficiency is improved, and batch production is facilitated. According to the double-foot driving piezoelectric linear motor and the electric excitation mode, the rotor / linear guide rail can be driven by the two stator sets alternately to perform rectilinear motion by imposing specific excitation voltage signals on laminated piezoelectric ceramic sets in the piezoelectric actuation units.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

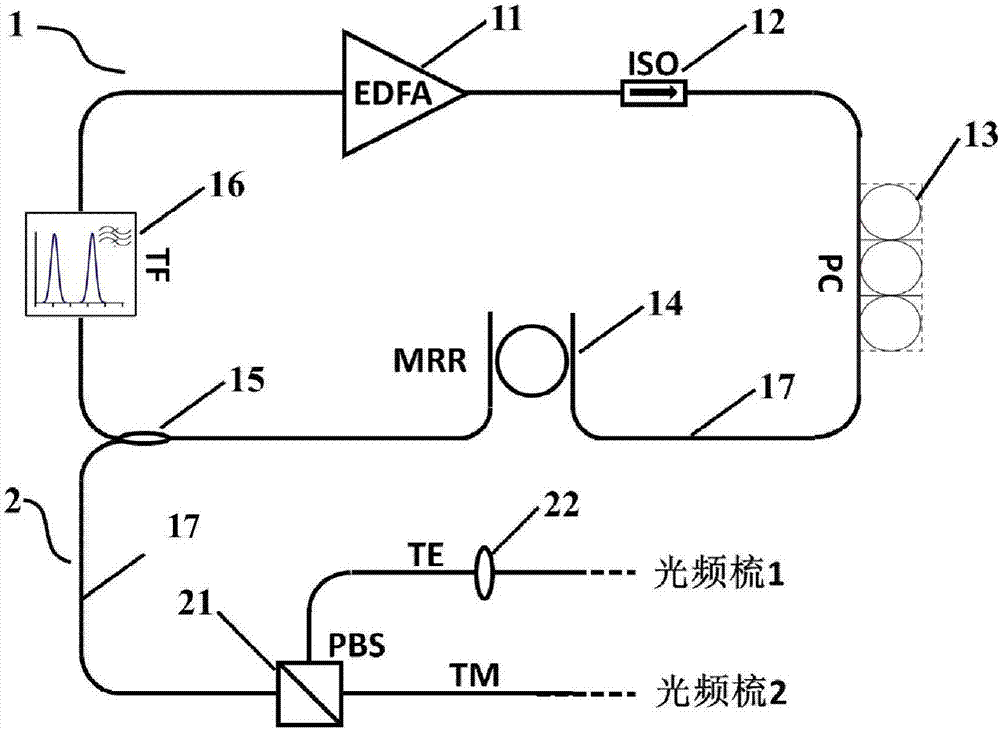

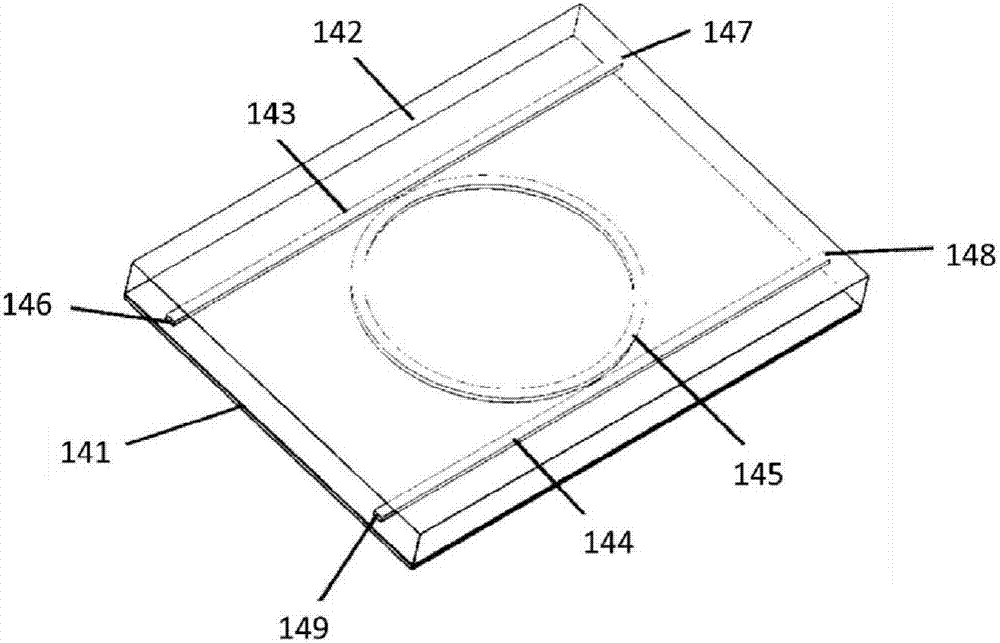

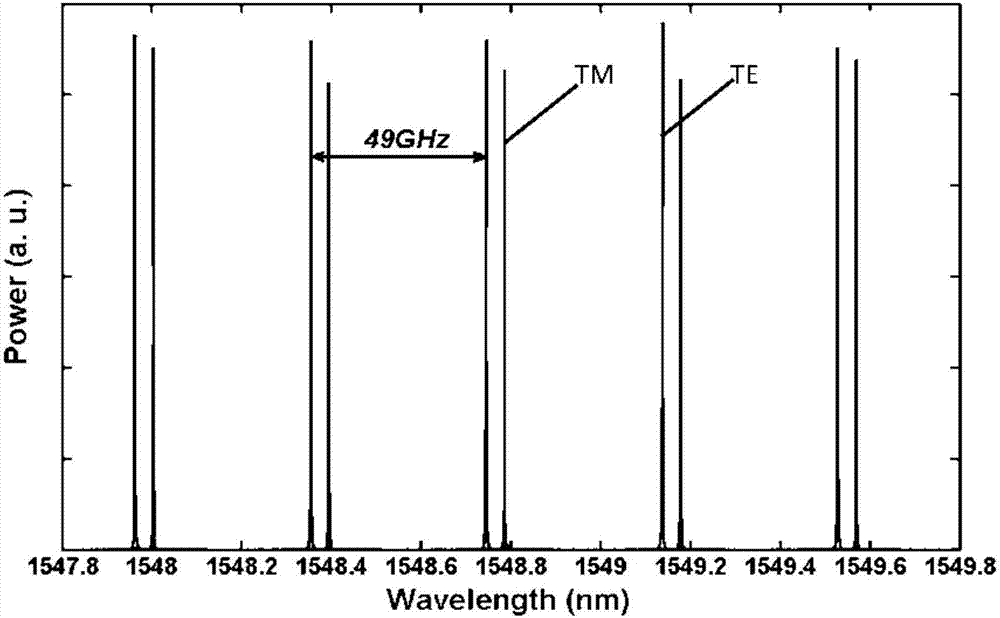

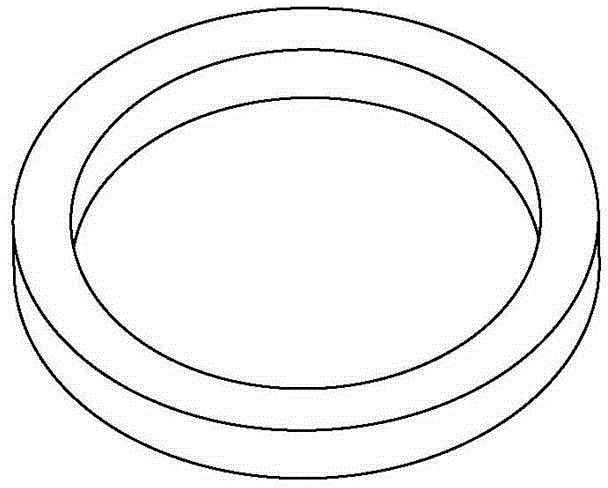

Micro annular resonant cavity-based self-locking dual-optical-frequency comb generation system and method

PendingCN107104353ASimple structureEasy to controlActive medium shape and constructionBroadbandOptical amplifier

The invention discloses a micro annular resonant cavity-based self-locking dual-optical-frequency comb generation system and method, belongs to the field of an optical frequency comb generation system, and specifically relates to the micro annular resonant cavity-based dual-optical-frequency comb generation system and method. The system comprises an annular resonant cavity and a dual-optical-frequency comb separation system connected with the annular resonant cavity through polarization maintaining optical fibers; the annular resonant cavity comprises an optical amplifier, an optical isolator, a first polarization controller, a micro annular resonant cavity and an optical filter which are connected through the polarization maintaining optical fibers in the cavity; the dual-optical-frequency comb separation system comprises a polarization light beam splitter and a second polarization controller which are connected through the polarization maintaining optical fibers; and the micro annular resonant cavity is a nonlinear micro annular resonant cavity with four ports. By virtue of the asymmetry of the waveguide structure, the TE mode and the TM mode of the waveguide have different indexes of refraction; two modes can be excited at the same time to generate two sets of broadband optical frequency combs with different polarization directions and multiple frequencies; and by virtue of separation and polarization rotation of the cross-polarization dual-frequency comb, the homoclitic super-high multi-frequency broadband optical frequency comb can be obtained.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

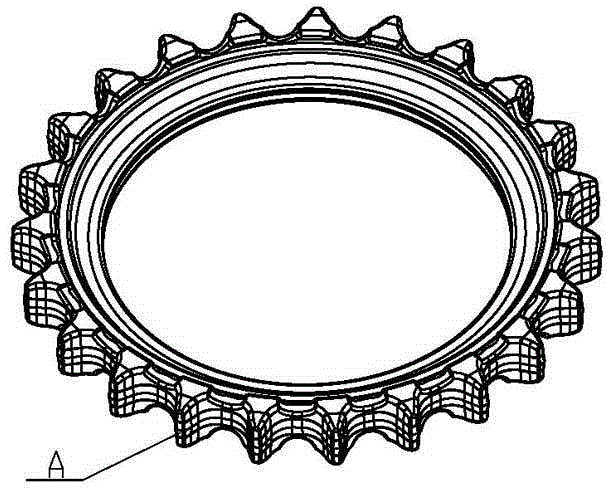

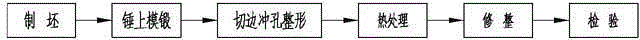

Manufacturing method for large driving wheel forged pieces

ActiveCN104858344AExtended service lifeImprove consistencyMetal-working apparatusWheelsMetallographyPunching

A manufacturing method for large driving wheel forged pieces includes the first step of blank forming including blanking, heating and blank forming, the second step of hammer forging including heating and hammer forging, the third step of trimming, punching and shaping, the fourth step of thermal treatment including suspended hardening and tempering, hardness detection and metallography detection, the fifth step of finishing including cleaning and grinding, and the sixth step of inspection including fluorescent magnetic particle flaw detection, dimension inspection and appearance inspection. The large driving wheels are forced integrally in a hammer forging mode, so that the driving wheels are good in strength; an annular intermediate billet is used, and the utilization rate of materials is high; all teeth of the driving wheels are cut at a time in the step of trimming, punching and shaping, and are of good consistency; the driving wheels are subjected to suspended hardening and tempering and thermal treatment, so that deformation caused in the thermal treatment process is effectively reduced; by adoption of integral forging, the production process is simple, the production cycle is short, the production cost is low relatively, reliability is good, and quality is stable.

Owner:FIRST TRACTOR

Piezoelectric drive type electric spindle chip mingling detection device used for numerical control machine tool

ActiveCN110695765AImprove detection accuracyAlarm Threshold StabilityMeasurement/indication equipmentsMaintainance and safety accessoriesNumerical controlEngineering

The invention relates to the technical field of machine tool parts, in particular to a piezoelectric drive type electric spindle chip mingling detection device used for a numerical control machine tool. The piezoelectric drive type electric spindle chip mingling detection device comprises a conical clamp body used for clamping a tool handle and is characterized in that piezoelectric ceramic blockswhich can stretch out of the clamp body after being electrified are evenly distributed in the end, making contact with the tool handle, of the clamp body; the ends, being capable of stretching out ofthe clamp body, of the piezoelectric ceramic blocks are provided with electric conduction touch terminals; and the piezoelectric ceramic blocks include one movable piezoelectric ceramic block and multiple fixed piezoelectric ceramic blocks, and different electric properties are applied to the electric conduction touch terminals at the end portions of the fixed piezoelectric ceramic block and themovable piezoelectric ceramic blocks. During tool feeding of the numerical control machine tool, whether iron chips are mingled between the faces, making contact with the two end faces and two positions of a conical face of the tool handle clamp installed on the electric spindle of the numerical control machine tool, of the tool handle or not is detected, the detected alarming critical value can be preset, the numerical value is stable, and the detection accuracy, stability and reliability are improved.

Owner:YANTAI UNIV

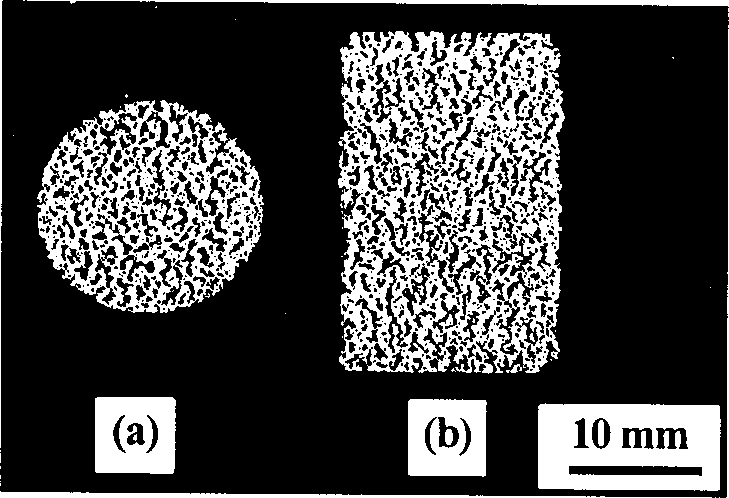

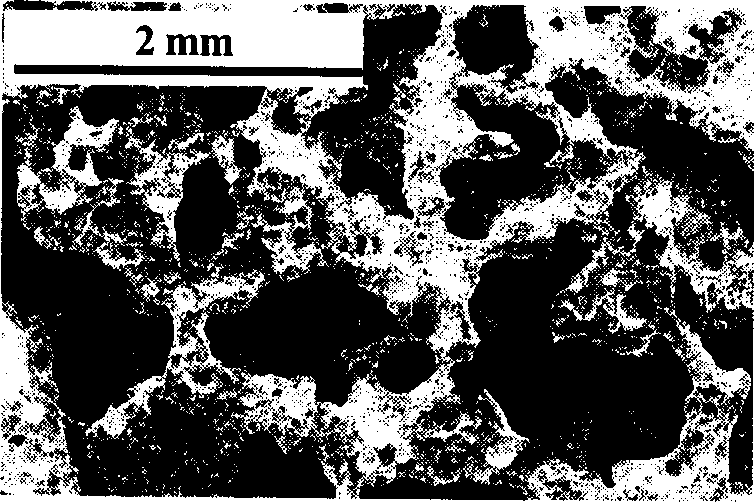

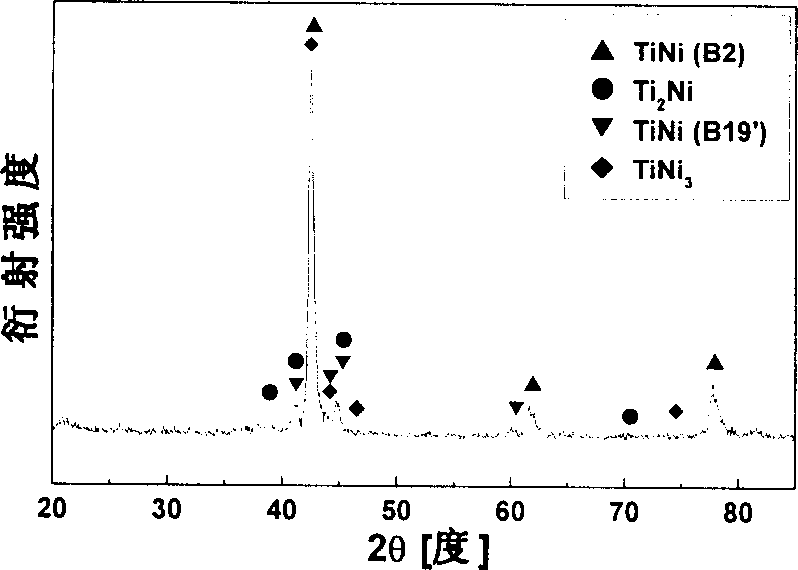

Preparation method of porous marmem damping composite material covered with metal

InactiveCN1428239AIncrease dampingThe problem of not being able to make a large shielding material is solvedSolid based dampersMetal layered productsMetal alloyShape-memory alloy

The present invention relates to the field of damping technology, in particular, it relates to a method for preparing porous marmen damping composite material covered with metal, and its preparation method includes the following steps: (1) preparing porous marmen: mixing original marmen powders, making blank material, prehaeting in heating furnace, lighting blank to synthesizing the porous marmen.; (2) treating porous marmen; machining to obtain the required form and size and cleaning; and (3). covering with metal; melting metal alloy for covering the marmen, cleaning die mould, placing the treated porous marmen into mould, closing die mould, pouring covering metal alloy into die mould, press-casting so as to obtain the invented product with excellent damping and mechanical properties andsmall density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

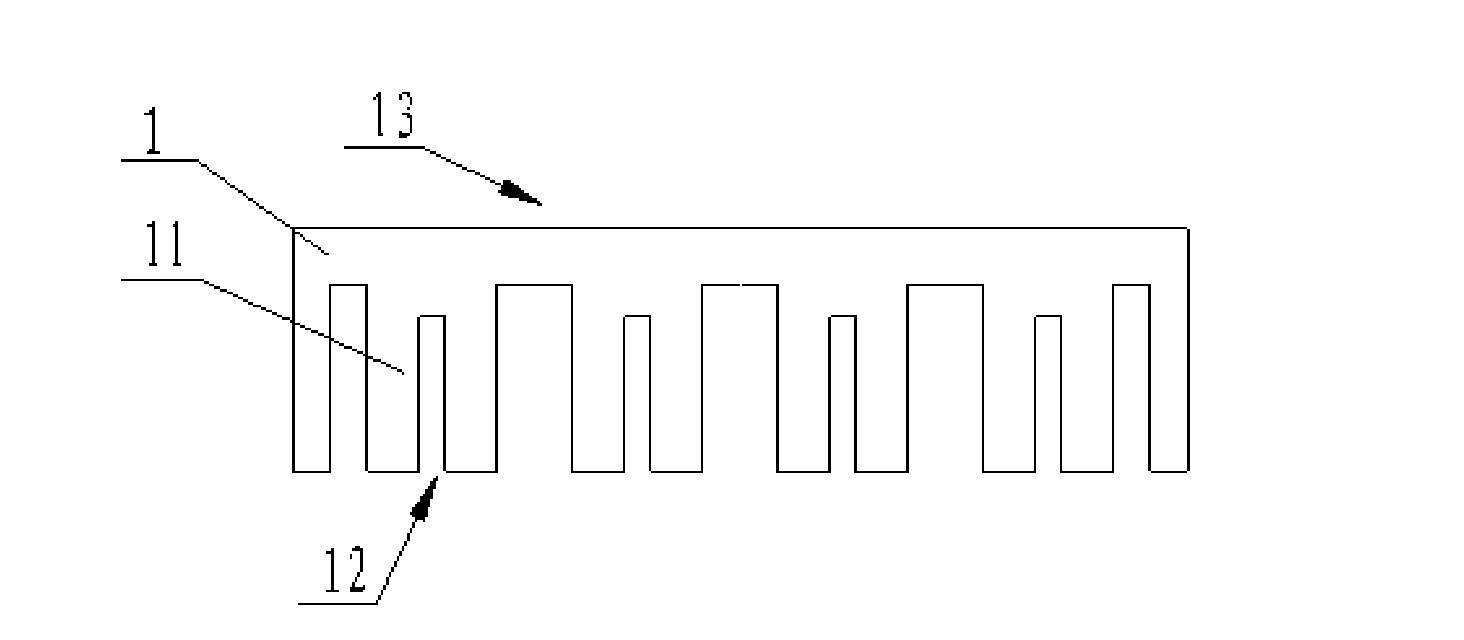

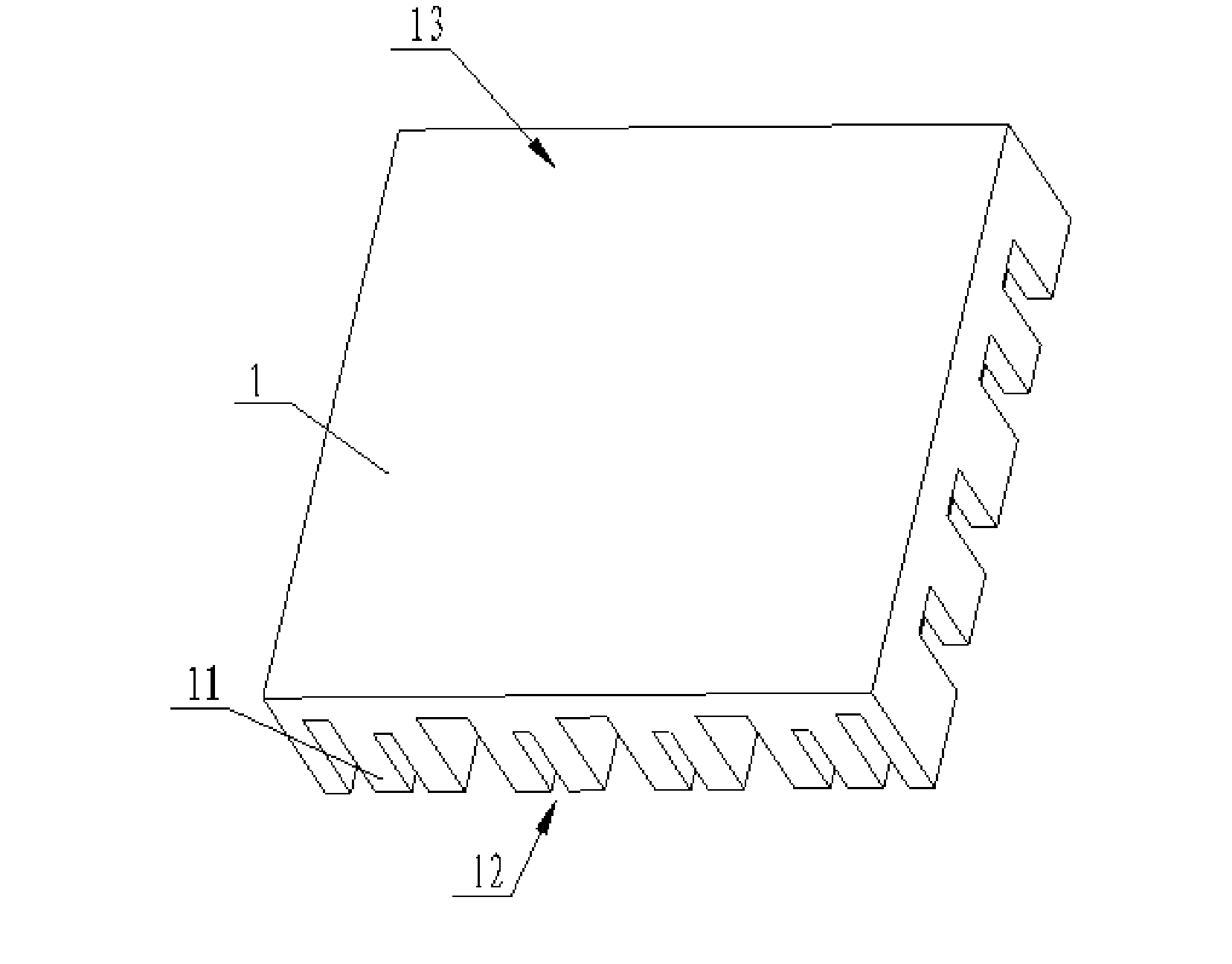

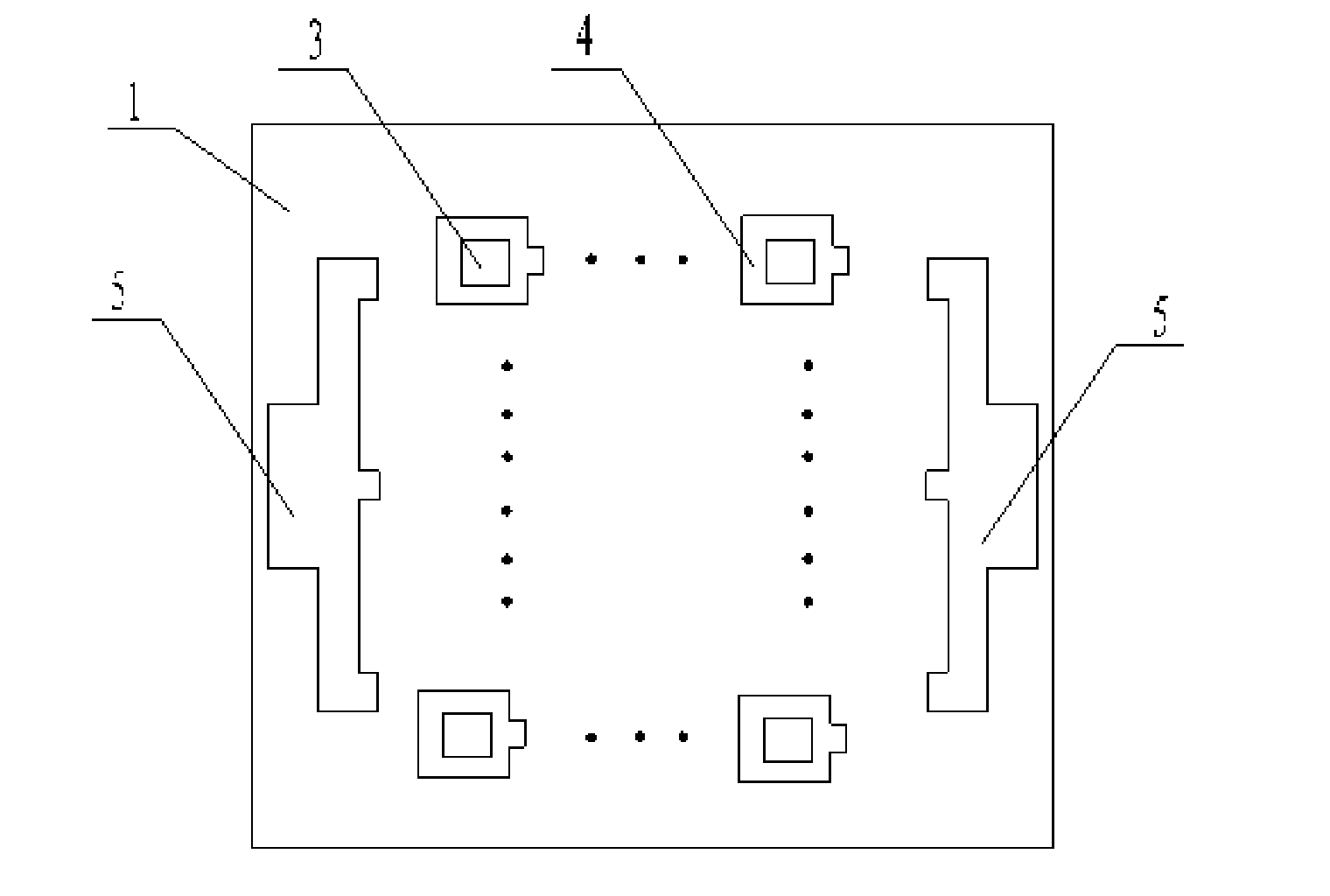

LED light source with heat dissipation device and processing method thereof

InactiveCN101839414AGuaranteed lifeSimple processPoint-like light sourceElectric circuit arrangementsHeat resistanceEngineering

The invention discloses an LED light source with a heat dissipation device and a processing method thereof, relating to an LED light source. The conventional LED light source has low heat dissipation efficiency, large size, heavy weight and more production procedures. The LED light source comprises a base, a plurality of LED chips arranged on the upper surface of the base and an electrode lead-out region which is convenient to connect a driving power supply. The LED light source is characterized in that a convex rib is arranged at the lower part of the base in an extension way, a heat radiation tank is arranged in the middle of the convex rib, an LED chip supporting body is arranged at the upper part of the base, and the heat dissipation device is arranged at the lower part of the base. Differing from an LED light source and heat dissipation device split structure in the prior art, the invention prevents the thermal resistance between the LED light source and the heat dissipation device from generating, greatly improves the heat dissipation efficiency because heat generated during the working process of the LED chips is directly transferred to heat dissipation fins through the base and heat resistance layers, such as an adhesion layer, and the like is not arranged between the LED light source and the heat dissipation device, improves the heat dissipation and the quality of an LED lamp, reduces the size of a lamp body for accommodating LEDs, and can ensure that the product is standardized and serialized, and has less working procedures and high processing efficiency.

Owner:ZHEJIANG MANELUX LIGHTING

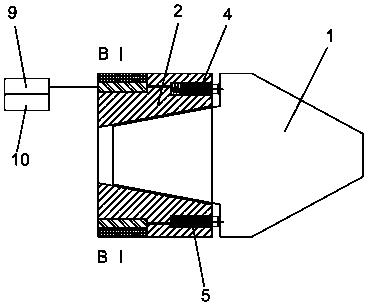

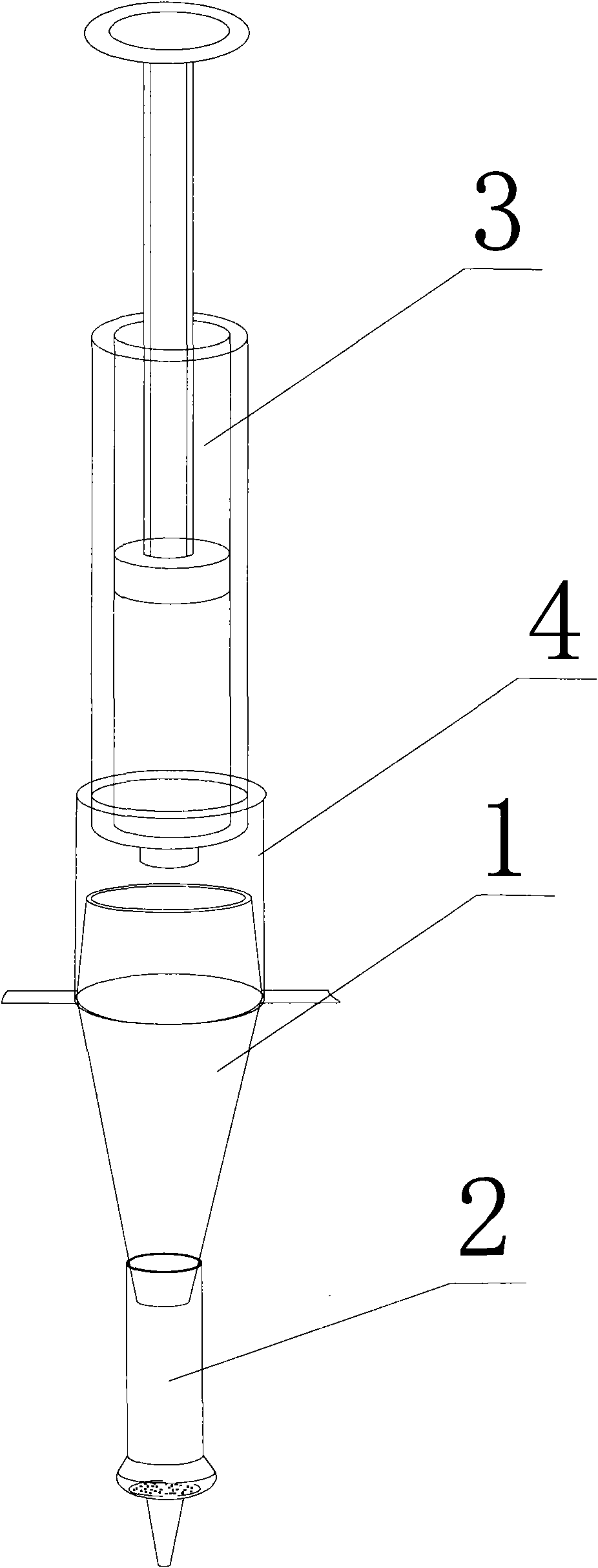

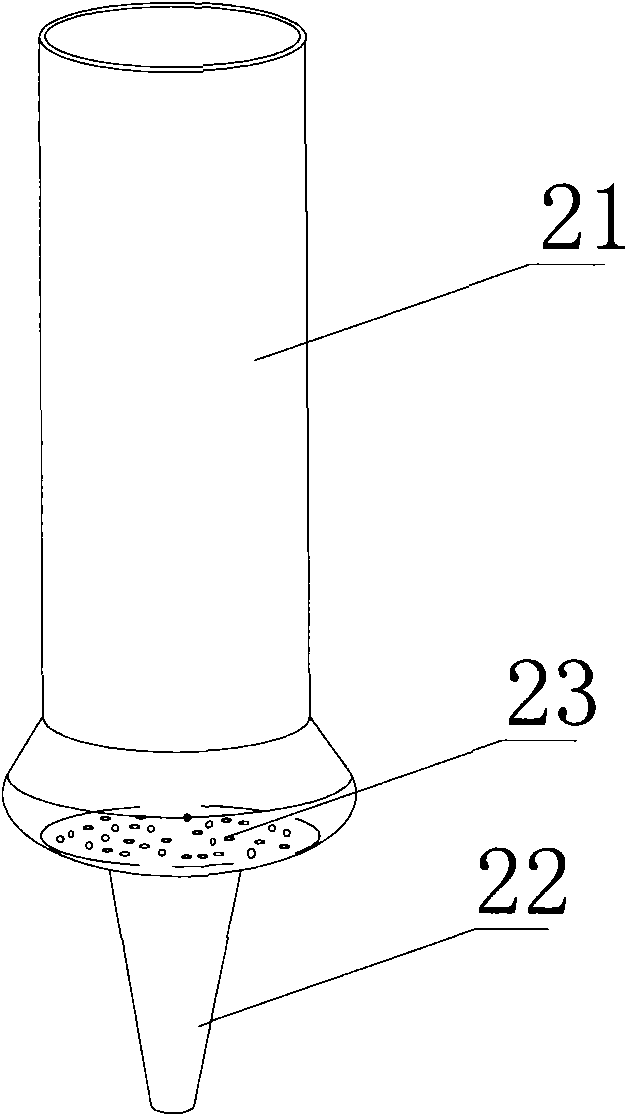

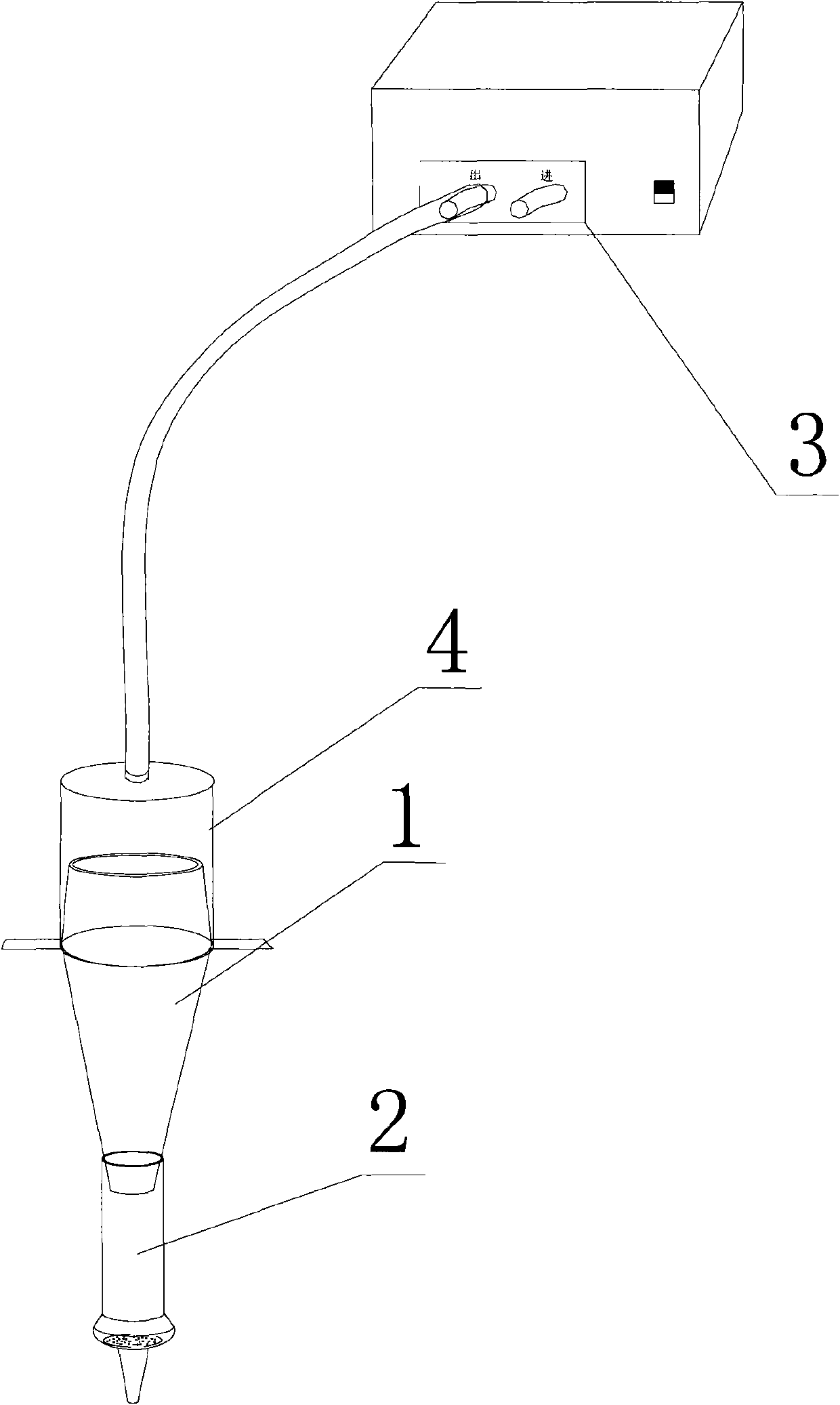

Split-type nanometer fibre solid-phase extraction column and application thereof

InactiveCN101947393ASimple filling methodEasy to mass produceSolid sorbent liquid separationChemistrySolid phase extraction

The invention discloses a split-type nanometer fibre solid-phase extraction column and an application thereof, comprising a sample storage tube (1), wherein a fibre filling tube (2) is sleeved at the lower end of the sample storage tube (1) and nanometer fibre used as a column filler is filled inside the fibre filling tube (2). The extraction column has the advantages that the operation flow is simplified, the enriching efficiency is improved, the operation time is shortened, and the like. Compared with the traditional solid-phase extraction column, the utility model ensures that the use amount of adsorbent is greatly reduced and is convenient and rapid to manufacture and use.

Owner:SOUTHEAST UNIV

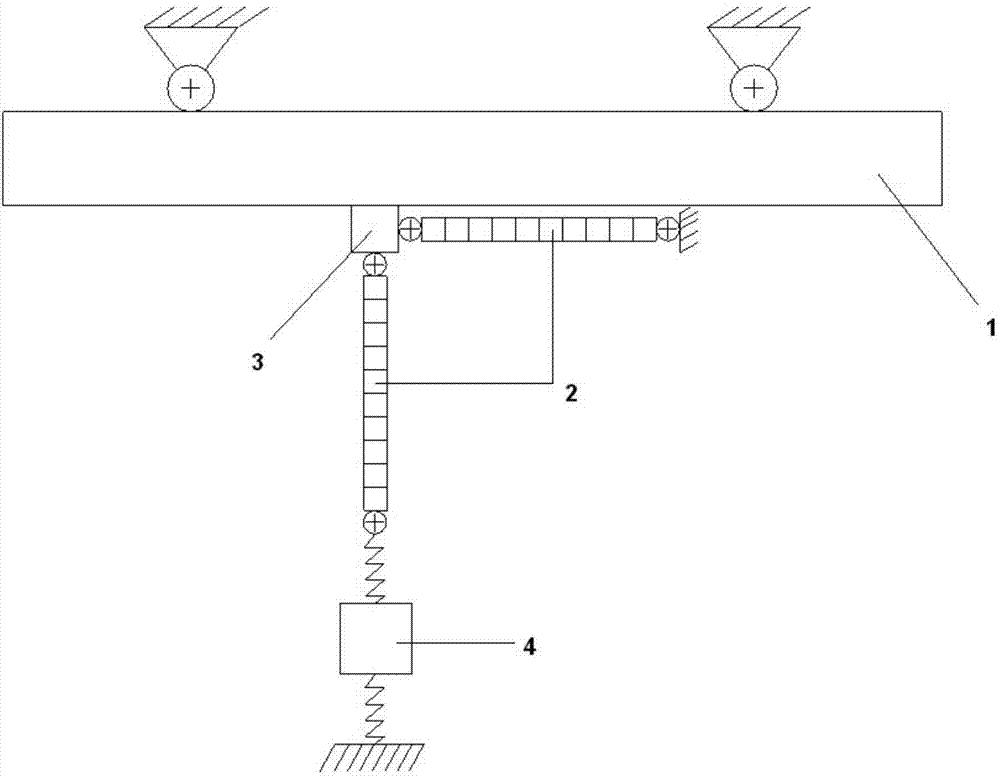

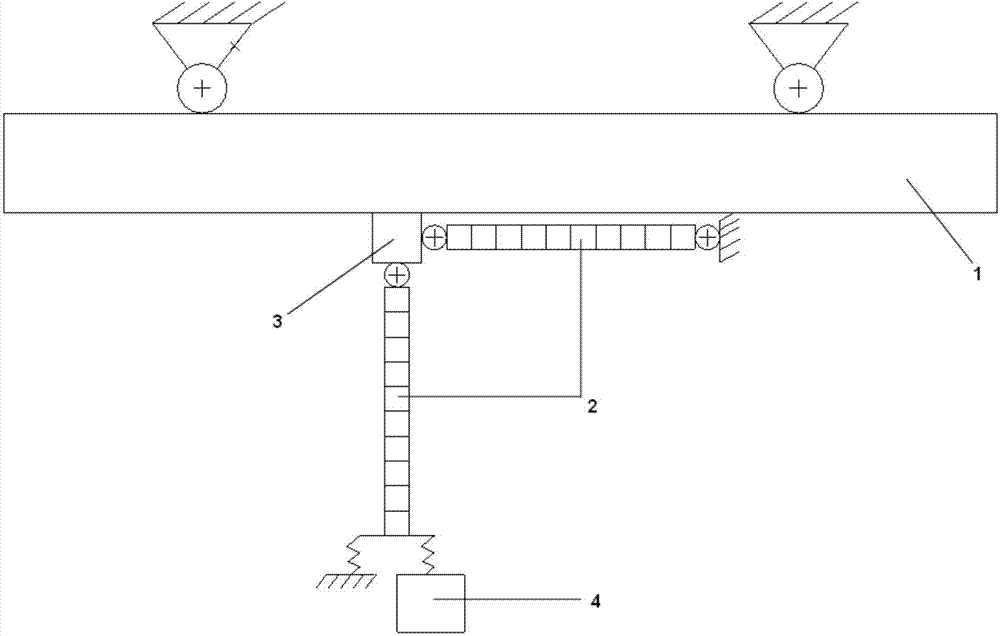

Balance weight type variable contact force piezoelectric motor

InactiveCN103701358AWith power-off self-locking functionExtended service lifePiezoelectric/electrostriction/magnetostriction machinesElectric machineMoving parts

The invention discloses a balance weight type variable contact force piezoelectric motor. The piezoelectric motor comprises a piezoelectric body and a moving part, wherein the piezoelectric body is contact with the moving part through elastic restoring force produced by an elastic prepressing element; the elastic extension direction of the elastic prepressing element is perpendicular to the actuating direction of the piezoelectric motor; in addition, the piezoelectric body is hinged to a transverse base; a connecting line between the piezoelectric body and the transverse base is parallel to the actuating direction of the piezoelectric motor. The piezoelectric motor has high thrust and large stroke, can bilaterally move, has a long service life, and simultaneously has a self-locking function during power off.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Inorganic colorful electrolysis coloring technology for aluminium profile anodic oxide film

ActiveCN102330137ASimple processEasy to achieve mass productionSurface reaction electrolytic coatingElectricityElectrolysis

The invention discloses an inorganic colorful electrolysis coloring technology for an aluminium profile anodic oxide film, which is characterized by comprising the following working procedures of: removing oil, etching by alkaline, oxidizing an anode, carrying out intermediate treatment and electrolysis coloring, and sealing holes, wherein the intermediate treatment working procedure is set between the working procedures of oxidizing an anode and electrolysis coloring and comprises three steps: a. DC (Direct Current) section: setting a supply voltage into a direct-current output mode, cleaning the micropores of the anodic oxide film, and reducing the thickness of a barrier layer, wherein a voltage value is 8-14V, and time is 20-50 seconds; b. AC (Alternating Current) section: setting the supply voltage into an alternating-current output mode, and generating a second layer of oxide film in the anodic oxide film; c. DC section: switching the supply voltage to the direct-current output mode, generating a third layer of film on the basis of the second layer of oxide film, wherein the voltage value is 10-20V, and operation time is controlled to 60-500s. According to the inorganic colorful electrolysis coloring technology, the existing electrolysis coloring equipment can be utilized to finish the full-color colorful electrolysis coloring aluminium or aluminium alloy in short time, and the inorganic colorful electrolysis coloring technology has the advantages of low production cost and good coloring quality.

Owner:GUANGYA ALUMINUM +1

Food health product for improving sleep and preparation method thereof

The invention provides a food health product for improving sleep and a preparation method thereof. The food health product is prepared from the following components in parts by weight: 30-50 parts of spine date seed extract, 10-20 parts of broken spore ganoderma lucidum powder, 5-15 parts of gamma-aminobutyric acid powder, 5-10 parts of Indian buead extract, 5-10 parts of thinleaf milkwort root extract, 12-16 parts of lily bulb extract, 1-4 parts of fructus shisandrae extract, 3-6 parts of pearl powder extract, 4-8 parts of oyster shell power, 10-15 parts of magnesium stearate and 0.1-0.5 part of vitamin B6. The invention overcomes the defects in the prior art and provides a health product for improving sleep, and the food health product is simple in formula and reasonable in compatibility of medicines and accords with the principle of syndrome differentiation of traditional Chinese medicine, and the medicines in the formula supplement each other and have obvious effects of improving the sleep.

Owner:GUANGZHOU WANKANG HEALTH CARE PROD CO LTD

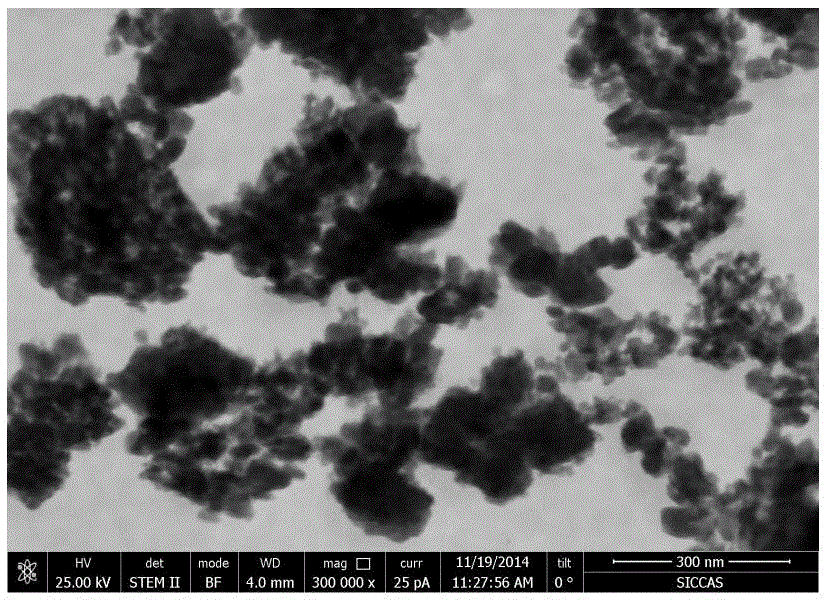

Method for preparing nano nickel powder by precipitation-hydrogen reduction process

The invention provides a method for preparing nanometer nickel powder by deposition-hydrogen-reduced process, belonging to the metal powder preparing technique. The method comprises: dissolving the salt with nickel ion into water to be reacted with prepared (NH4)2CO3 solution to generate a deposit of NI2(OH)2CO3; stably laying said solution and extracting the clean blue solution of upper layer while the nanometer deposited paste of lower layer is separated by centrifugal machine; drying the centrifugally separated powder in the oven to be clean and filtered; reverting the dried powder in the strong-exhaust hydrogen reducing furnace to attain the nanometer nickel powder in the temperature of 200-500 Deg. C. The invention has the advantages of simple device, short process, lower cost and fast-continuous large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

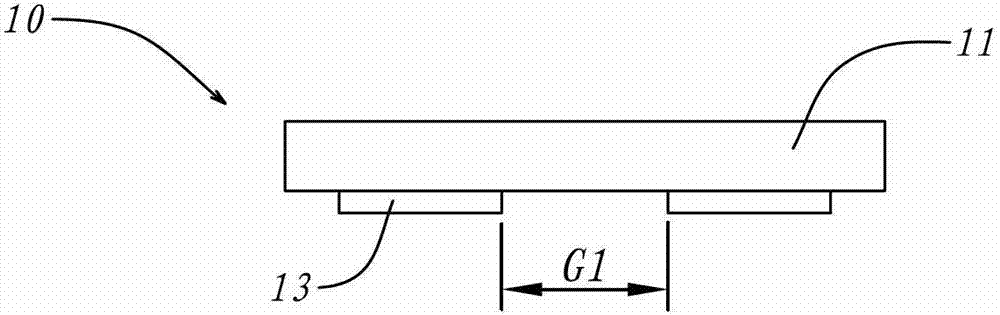

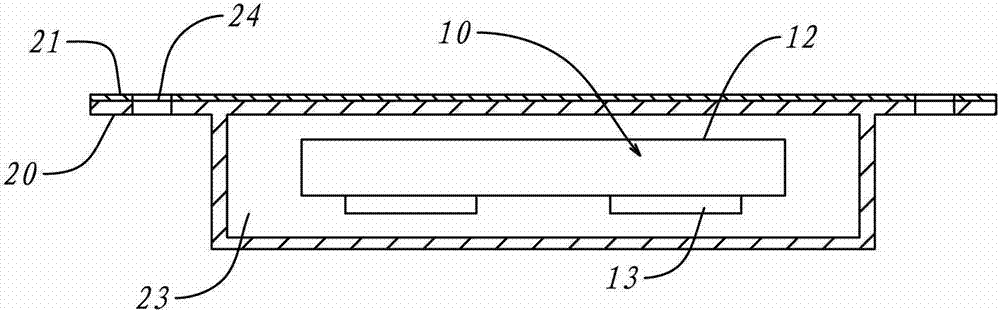

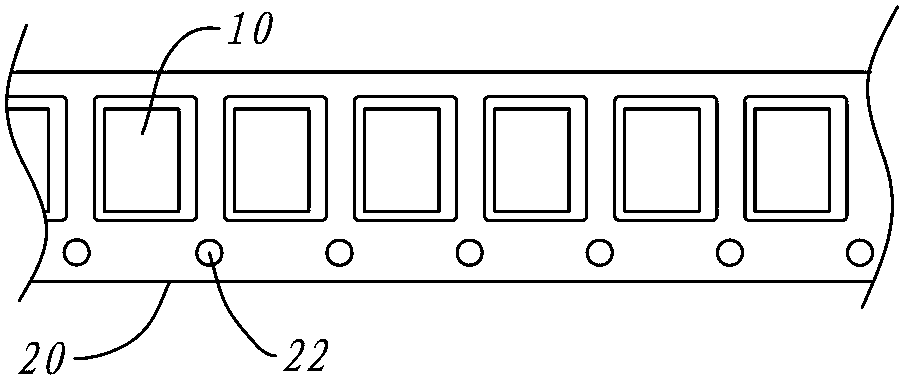

Manufacturing method of patch type LED (Light-Emitting Diode) module

InactiveCN102779923ASave packaging material and packaging process timeGood consistency of geometric featuresFinal product manufacturePrinted circuit aspectsPatch typeManufacturing line

The invention discloses a manufacturing method of a patch type LED (Light-Emitting Diode) module. The manufacturing method is characterized by comprising the following steps of: preparing materials; providing LED chips with flip chip structures, wherein one face of each LED chip is provided with a metal electrode, and the surface intervals of the metal electrodes are not smaller than 80 mum; arranging: putting the plurality of chips into a braid, wherein the metal electrodes of the LED chips are positioned at the bottom of a braid accommodating space, and the light emitting surfaces of the LED chips are positioned on the opening of the accommodating space; patching: sucking the LED chips out of the braid by using a vacuum suction nozzle, and placing onto a bonding pad of a substrate, wherein the metal electrodes are opposite to the bonding pad, and the light emitting surfaces of the LED chips face upwards; and fixing: correspondingly fixing and communicating the bonding pad and the metal electrodes. A braid loading way is directly adopted for flip chip LED chips, so that encapsulation of a single LED light source is avoided, and the encapsulating materials, encapsulating process time and production line of a single LED light source are saved.

Owner:XIAMEN G WATT LIGHTING TECHNOLOGY INC

Preparation method of porous medium composite phase change energy storage particles

ActiveCN103666380AOvercome the disadvantage of easy agglomeration and agglomerationEasy to operateHeat-exchange elementsPorous mediumForced convection

The invention discloses a preparation method of porous medium composite phase change energy storage particles. The preparation method is characterized in that: a porous mineral medium is taken as a carrier, a liquid phase change material is subjected to mixed adsorption, and is injected into a fluidized bed; cold air with a certain flowing speed in the fluidized bed is used for forced convection cooling of uncooled phase change particles, and particle dispersing is realized via impact effect between the air flow and the phase change particles. Internal phase change material holding capacity of the porous medium composite phase change energy storage particles prepared via the preparation method is relatively high; leakage is difficult to be caused under high temperatures; adsorption stability of the porous medium composite phase change energy storage particles is high; particle dispersibility is high; the surfaces of the porous medium composite phase change energy storage particles are dry; and caking is difficult to be caused. The preparation method is simple; technological processes are few; cost is low; batch production of the porous medium composite phase change energy storage particles can be realized; and the preparation method possesses engineering application value on a certain degree.

Owner:NANJING UNIV OF TECH

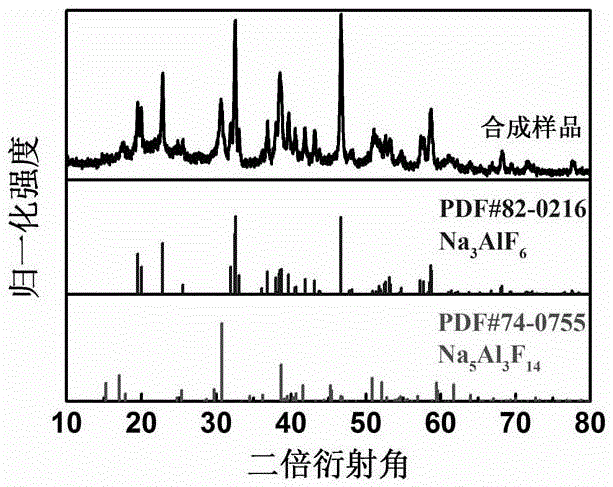

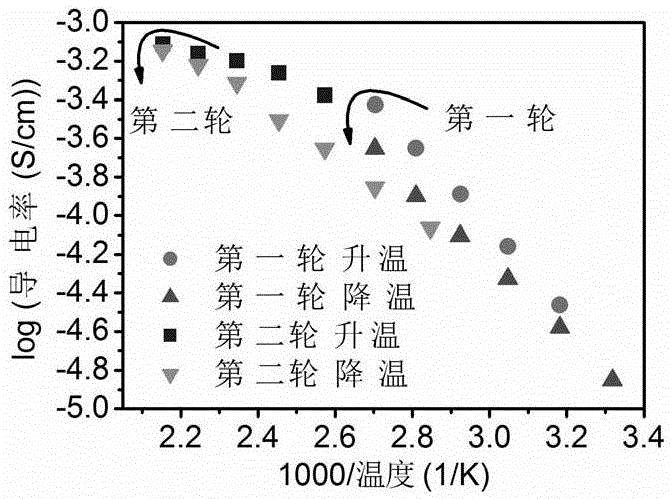

Open framework fluorine-based solid-state electrolyte material and preparation method of open framework fluorine-based solid-state electrolyte material

ActiveCN106887639AImprove conductivityReduce performanceFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteOpen framework

The invention relates to an open framework fluorine-based solid-state electrolyte material and a preparation method of the open framework fluorine-based solid-state electrolyte material. A chemical formula of the electrolyte material is as follows: AxMyFx+3y, wherein x is more than 0 and less than or equal to 6, y is more than 0 and less than or equal to 3, A is Na and / or Li and M is Al and / or Ga. The open framework fluorine-based solid-state electrolyte material AxMyFx+3y provided by the invention is lithium-enriched or sodium-enriched phase aluminum-based or gallium-based fluoride; the invention provides application of a novel open framework structural prototype to fluoride solid-state electrolyte for the first time; meanwhile, lithium enriching or sodium enriching is realized; the concentration of transferable alkali metal ions is increased so that the intrinsic ionic conductivity is easy to improve; the electrical conductivity of a bulk phase and a particle boundary can be improved through means of nanocrystallization, disordering, surface modification and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Surface mounting welding process for wafer-level chip

InactiveCN102915933ASave back sealLow costPrinted circuit assemblingSolid-state devicesSurface mountingMetal electrodes

The invention discloses a surface mounting welding process for a wafer-level chip, which is characterized by comprising the following steps of: firstly, providing the wafer-level chip with a flip chip structure and placing the wafer-level chip into a temporary storage container, wherein one surface of the chip is provided with a metal electrode and the metal electrode also can comprise a part extending to the lateral surface of the chip; then providing a substrate, wherein the substrate is provided with a matchable pad and solder paste is arranged on the pad in advance in a steel mesh printing manner; sucking the chip from the temporary storage container by adopting a vacuum suction nozzle and placing the chip on the pad of the substrate; temporarily fixing the metal electrode of the chip on the substrate by utilizing the surface tension of the solder paste; and finally, communicating the pad and the metal electrode which are temporarily fixed together in a reflow soldering manner. According to the technical scheme, the post packaging process step and the cost of the wafer-level chip are saved, the competitiveness of a product is promoted, existing SMT (Surface Mounting Technology) equipment can be basically continuously used, additional hardware do not need to be greatly invested, the cost of a packaging line and the process time are avoided, and the mass production of the wafer-level chip is easy to implement.

Owner:XIAMEN RXD ELECTRONICS

Method for manufacturing flexible-substrate metal microneedle array

ActiveCN104307097AAvoid complicated processEasy to prepareDecorative surface effectsMicroneedlesSputteringMetal

The invention relates to the technical field of biomedical engineering methods, in particular to a method for manufacturing a flexible-substrate metal microneedle array. The method includes a, preparing solidifiable iron magnetic fluid; b, manufacturing a flexible substrate; c, arranging liquid drops of the solidifiable iron magnetic fluid on the flexible substrate in an array manner to form a combination of a solidifiable iron magnetic fluid liquid drop array and the flexible substrate; d, disposing the combination obtained in the step c in a magnetic field to enable each liquid drop to become needle-shaped, and solidifying each liquid drop to form a stable and solidified microneedle array structure; e, forming a layer of metal uniform in texture on the surface of the microneedle array structure obtained in the step d through vacuum sputtering to form a metal microneedle array. The microneedle array structure is formed by through mutual action between the magnetic field and the iron magnetic fluid liquid drops containing magnetic nanoscale iron magnetic particles.

Owner:SUN YAT SEN UNIV

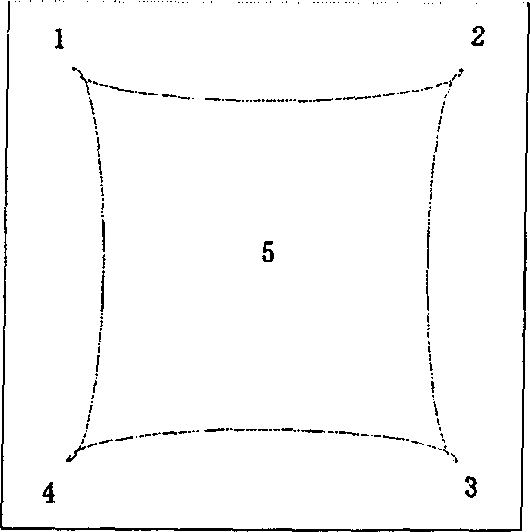

PSD type Hartmann-Sheck wave front sensor based on microprism array

InactiveCN1796949AOvercoming the problem of inconsistency of unit focal lengthImproving Wavefront Detection AccuracyOptical measurementsPhotometryPupilData collecting

The invention is a PSD Hartmann-Shack wavefront sensor based on microprism array, characterized in comprising microprism array, focusing lens, position sensitive detector (PSD) array, and data collecting and wavefront reconstructing unit, where the microprism array and the focusing lens clinging to the microprism array combinedly divide the system pupil, the PSD array is arranged on the focal plane of the focusing lens and the output of the PSD array is connected to the data collecting and wavefront reconstructing unit. The invention can overcome the problem of inconsistent focuses of all cells of the microlens array. The invention largely raises the sampling speed and omits the software-based calculating course, simple and largely reducing the follow-up processing burden. And the system is simple in structure and easy to manufacture and implement and batch production.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

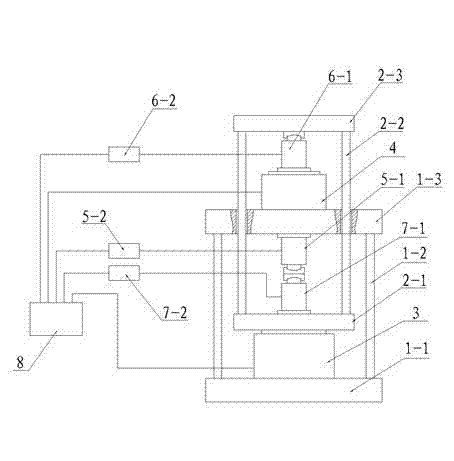

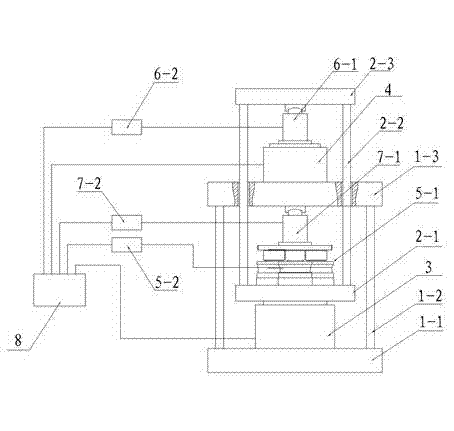

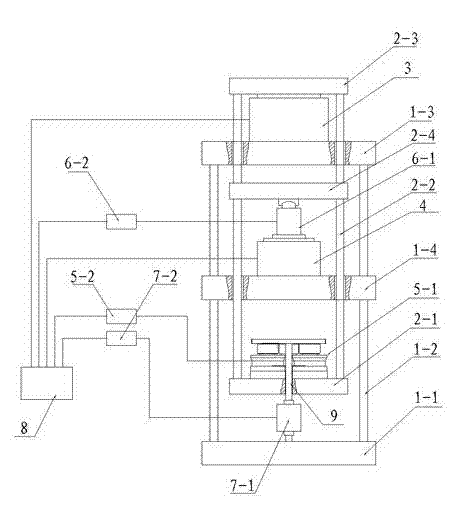

Build-up force standard machine with wide range,

ActiveCN102564557AReduce manufacturing costSimple structureWeighing apparatus testing/calibrationForce/torque/work measurement apparatus calibration/testingLower limitEngineering

The invention discloses a build-up force standard machine with a wide range, belongs to the technical field of force standard machinery, and is characterized in that the build-up force standard machine comprises a first detecting unit and a second detecting unit, wherein the upper limit of the range of the first detecting unit is in accordance with that of the build-up force standard machine; the lower limit of the range of the first detecting unit is in accordance with the upper limit of the range of the second detecting unit; the lower limit of the second detecting unit is in accordance with that of the build-up force standard machine; the force output directions of the first and the second detecting units are in accordance with each other; and the stress axis of a to-be-detected sensor is overlapped with those of the first and the second detection units. The build-up force standard machine has the advantages of large range, low manufacturing cost and the like.

Owner:绍兴市肯特机械电子有限公司

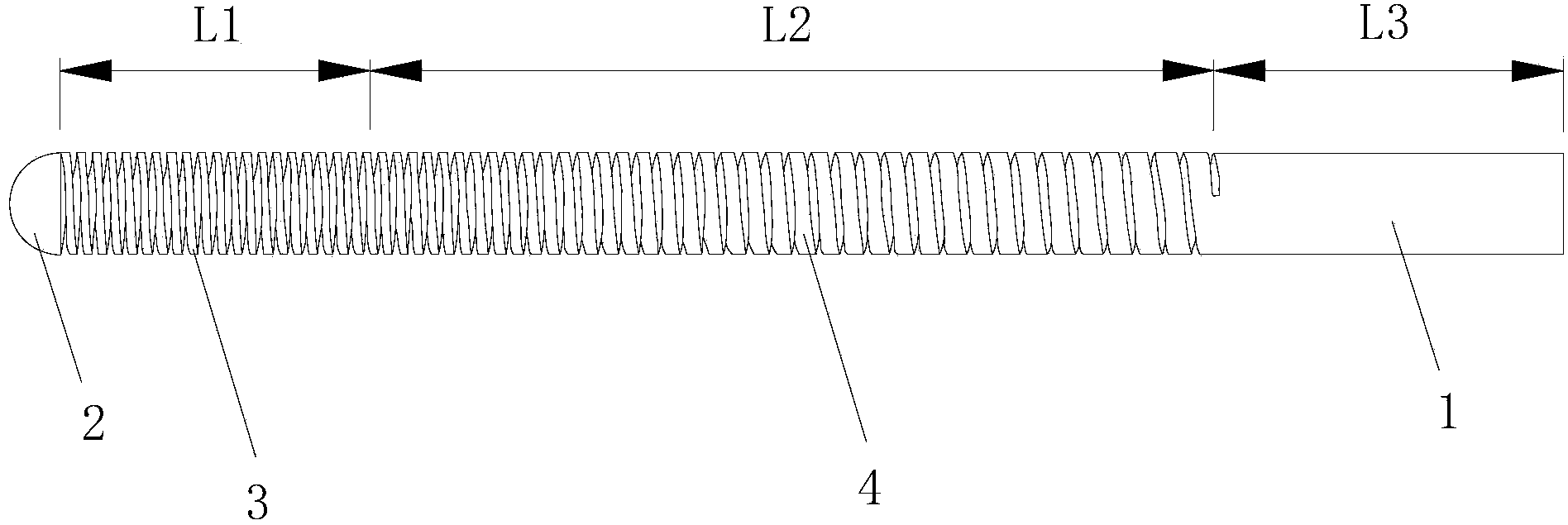

Titanium alloy guide wire for surgical interventional therapy

ActiveCN103623494ALarge range of performance adjustmentsSimple structureGuide wiresGroove widthInterventional therapy

The invention discloses a titanium alloy guide wire for interventional therapy. The titanium alloy guide wire comprises a titanium alloy small-diameter thin-wall tube and a noble metal end head which is distributed at the far end of the titanium alloy small-diameter thin-wall tube; the titanium alloy small-diameter thin-wall tube is divided into a guide wire far section, a guide wire middle section and a guide wire near section from far to near; a single spiral groove I is formed in the tube wall of the guide wire far section; a single spiral groove II is formed in the tube wall of the guide wire middle section; the single spiral slot I is an uniform-pitch spiral groove; the single spiral groove II is a variable-pitch spiral groove; the groove widths of the single spiral groove I and the single spiral groove II are same; the pitch of the single spiral groove II is gradually increased from far to near, and the pitch at the far end of the single spiral groove II is equal to that of the single spiral groove I; the groove depth of the single spiral groove I and the single spiral groove II is the same as the wall thickness of the titanium alloy small-diameter thin-wall tube. The titanium alloy guide wire disclosed by the invention is simple in structure, reasonable in design, simple and convenient to machine and manufacture, good in using effect, and capable of effectively solving the problems such as a complex machining process, high cost and poor adaptability of the existing titanium alloy guide wire.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

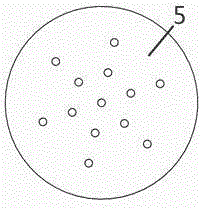

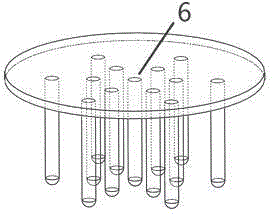

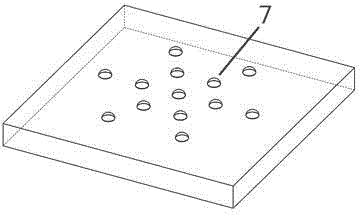

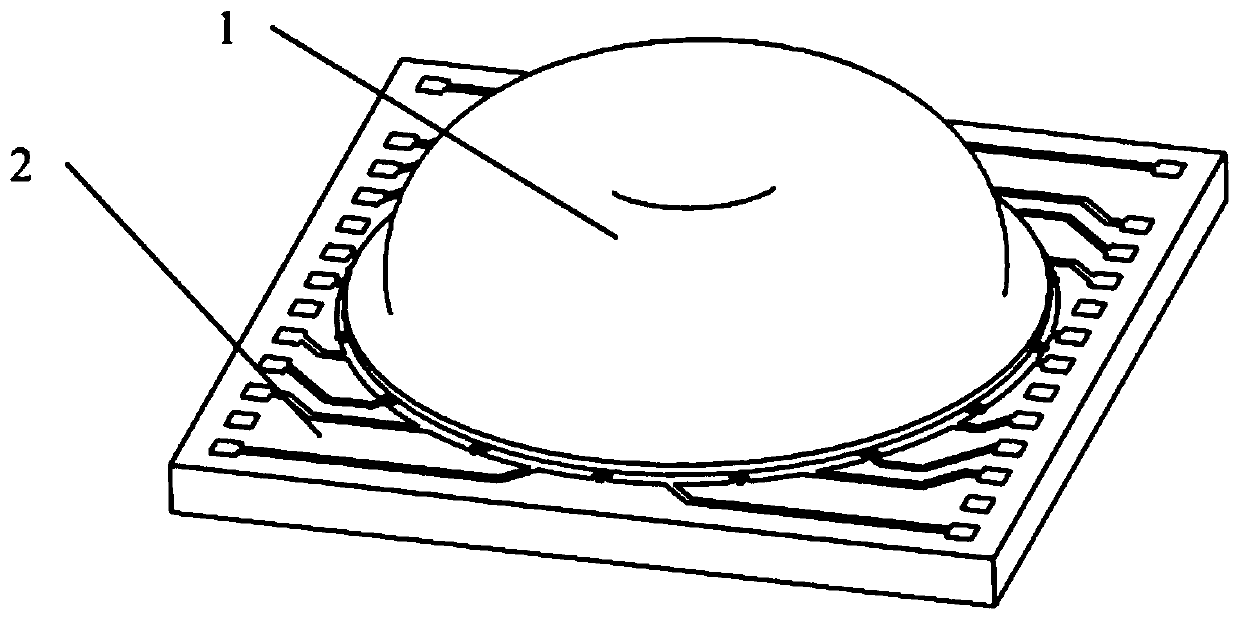

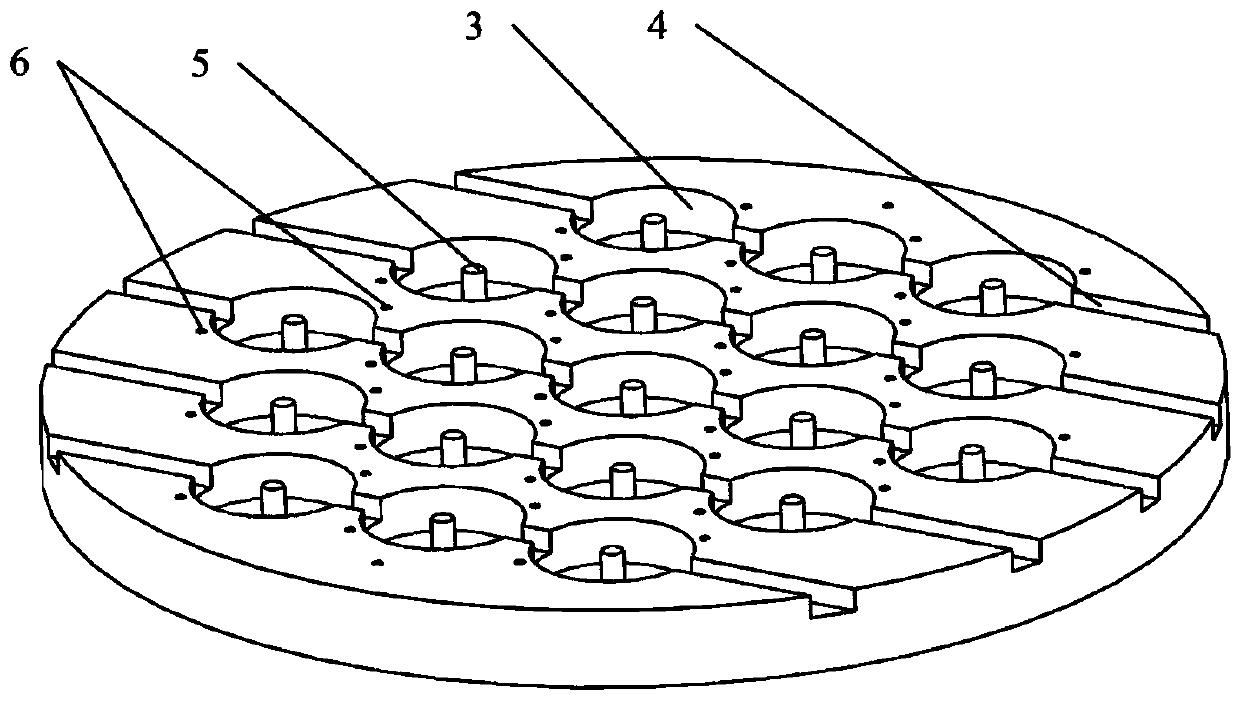

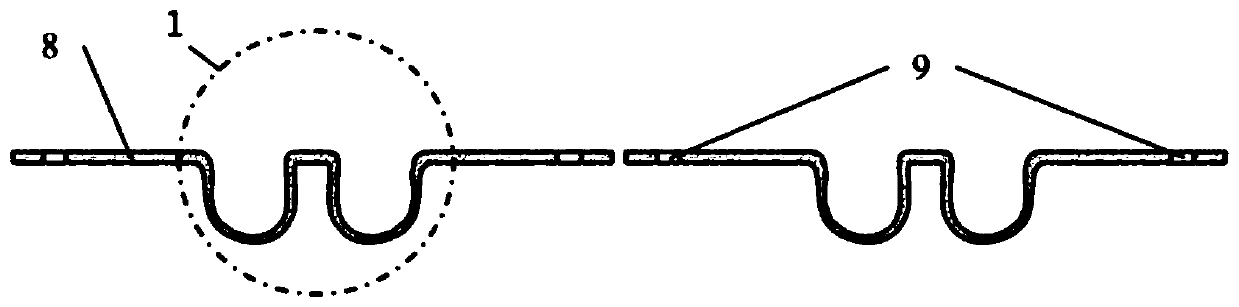

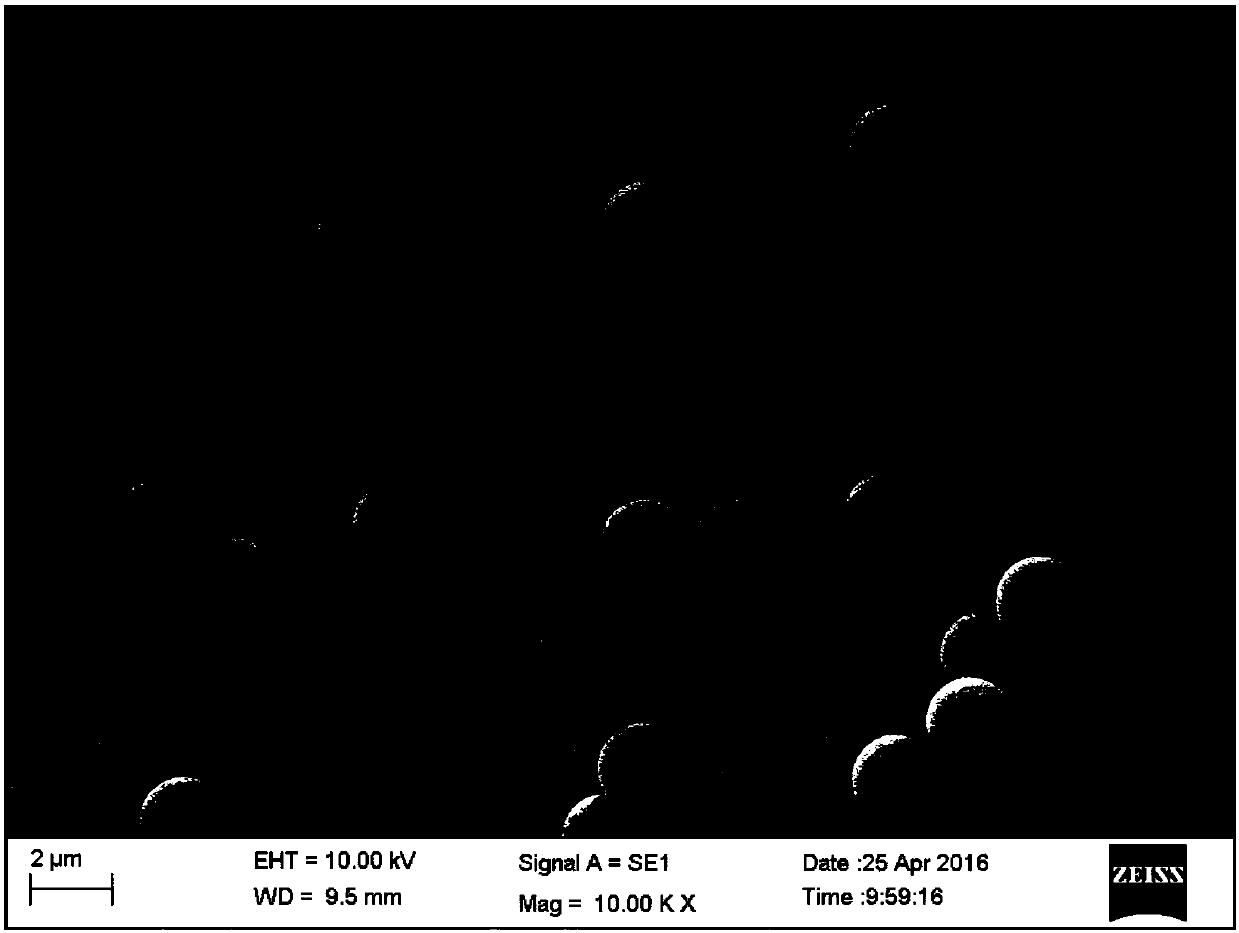

Micro-hemispherical resonator gyro structure, assembly method and wafer fixture

InactiveCN110749315AReduce assembly errorsImprove stabilitySpeed measurement using gyroscopic effectsMicrostructural device assemblyPhysicsResonator

The invention relates to a micro-hemispherical resonator gyro structure, an assembly method and a wafer fixture. The invention discloses a micro-hemispherical resonator gyro structure wafer level assembly method, comprising the following steps: performing high temperature softening deformation machining and forming on independently manufactured glass sheets, then forming a micro-hemispherical resonant structures in the middle of each glass sheet, cutting glass sheet locating holes at the two ends of each glass sheet by adopting laser cutting, and by taking the locating holes as a benchmark, aligning multiple micro-hemispherical resonant structures which are the same and fixing the same micro-hemispherical resonant structures on the wafer fixture; and then performing operations by taking the wafer fixture as a unit, and completing subsequent processes, namely micro-hemispherical resonant structure releasing, surface metallization, fixation with a planar electrode, separation from the wafer fixture as well as cleaning, thus the micro-hemispherical resonator gyro structure driven by the planar electrode at the bottom is obtained. The micro-hemispherical resonator gyro structure waferlevel assembly method disclosed by the invention fixes and mounts multiple independently manufactured micro-hemispherical resonant structures on the same wafer fixture, a wafer level mounting operation is realized, an assembly error of the micro-hemispherical resonator gyro structure can be obviously reduced, stability and consistency of the processes as well as assembly efficiency are improved.

Owner:NAT UNIV OF DEFENSE TECH

Method capable of realizing volume production and used for preparing micron order single-dispersibility polysiloxane microspheres

ActiveCN105949464AReduce typesThe reaction steps are simpleMicroballoon preparationMicrocapsule preparationPolymer scienceOrganic solvent

The invention discloses a method capable of realizing volume production and used for preparing micron order single-dispersibility polysiloxane microspheres. The method comprises the following steps of (1) preparing a basic catalyst solution; (2) adding trialkoxysilane monomers into the basic catalyst solution (1) to prepare a seed solution; (3) then adding trialkoxysilane monomers into the seed solution obtained in the step (2) to perform a polycondensation reaction; performing filtering, washing and drying to obtain a finished product. The operation can be performed under the conditions of normal temperature, normal pressure and no atmosphere protection; the synthesis steps are simple; the operation is easy; synthesis equipment does not have special requirements; the volume production can be easily realized. No organic solvents polluting the environment are used in the reaction process; no dispersing agents, swellers, stabilizing agents, emulgators or the like are used; the types of reaction polymerization raw materials are few; the product purity is high; the yield is high; the cost is low; the size of the particle diameter of the microspheres can be effectively regulated through controlling the concentration of an initial seed solution; the distribution of the particle diameter of the obtained microspheres is uniform; the high-degree monodispersity is shown; the surface is regular; the degree of sphericity is high.

Owner:贵州正业龙腾新材料开发有限公司

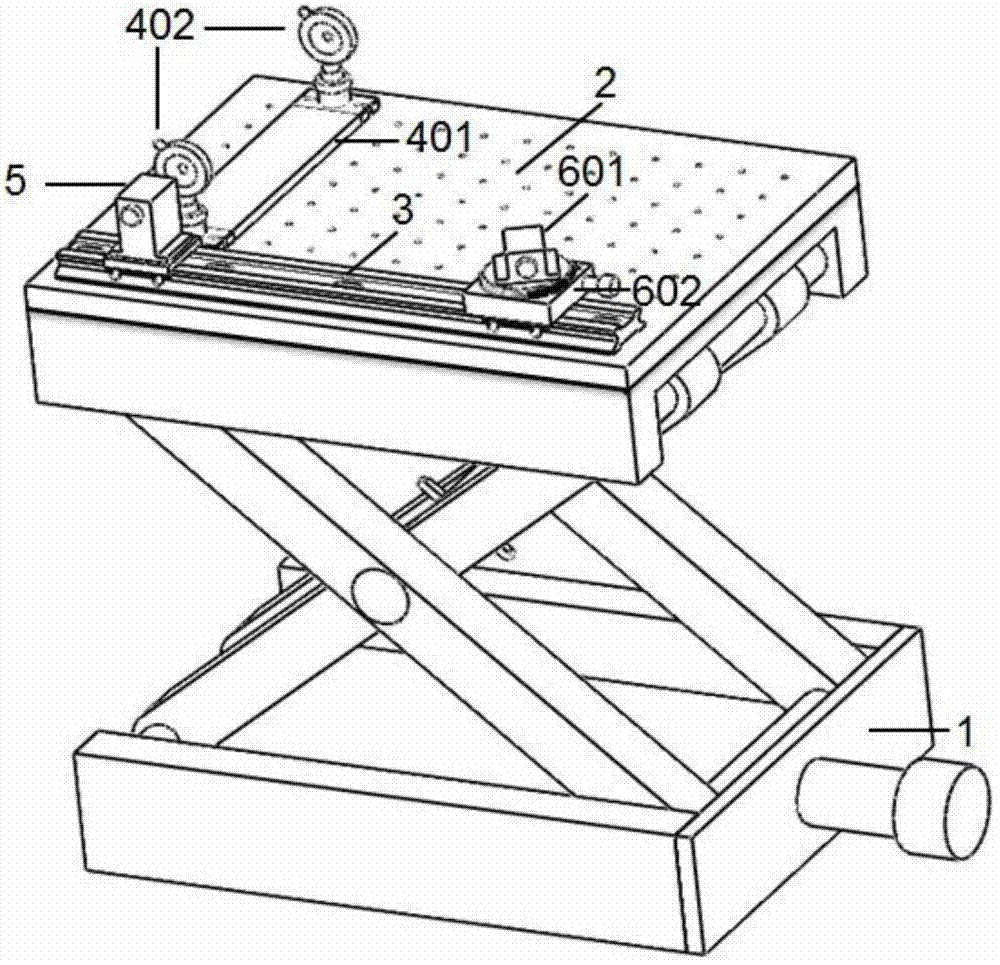

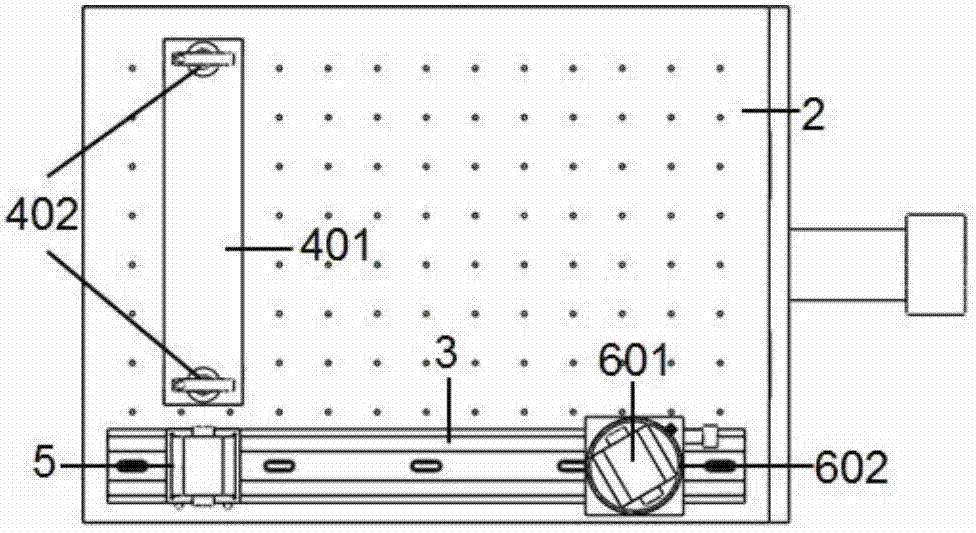

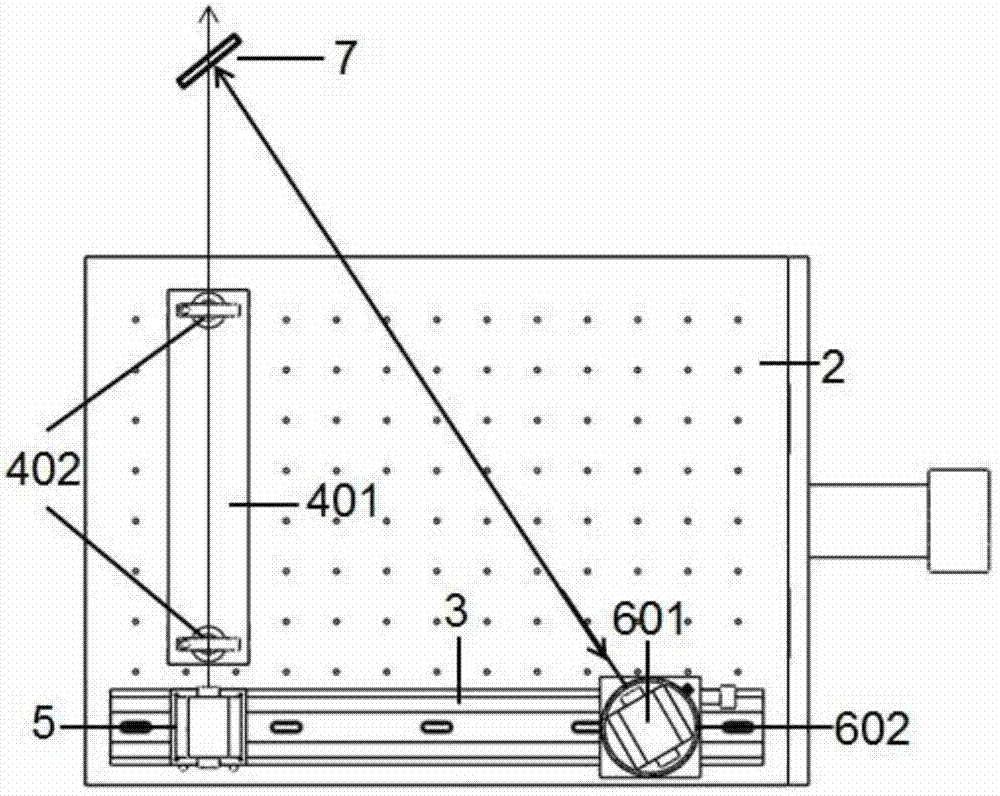

Auxiliary device for light path standard and angular adjustment and use method thereof

ActiveCN103094815AMeet the adjustment needsEasy to useLaser constructional detailsAudio power amplifierLaser light

Disclosed are an auxiliary device for a light path standard and angular adjustment and a use method of the auxiliary device. The auxiliary device for the light path standard and the angular adjustment comprises a lifting pedestal, a standard platform, a sliding rail, a double-light-hole light path standard module, a standard light source and a high-accuracy rotation angle gauge. The standard platform is placed on the lifting pedestal and capable of achieving adjustment of lifting and pitching. A series of regular locating holes are formed in the standard platform and respectively used for fixation of the sliding rail and the double-light-hole light path standard module. The standard light source and the high-accuracy rotation angle gauge are placed on the sliding rail. The auxiliary device for the light path standard and the angular adjustment has the advantages of being simple in structure, convenient to operate and high in accurate. Position locating and the angle adjustment in a laser light path of an optical lens can be rapidly and conveniently achieved. Therefore, complex light path debugging of a laser, particularly a laser amplifier, is achieved, and output performance of the laser is improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

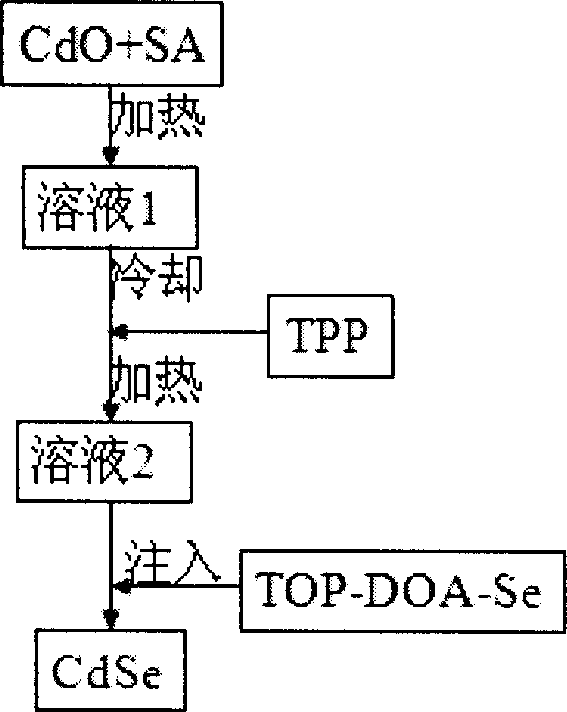

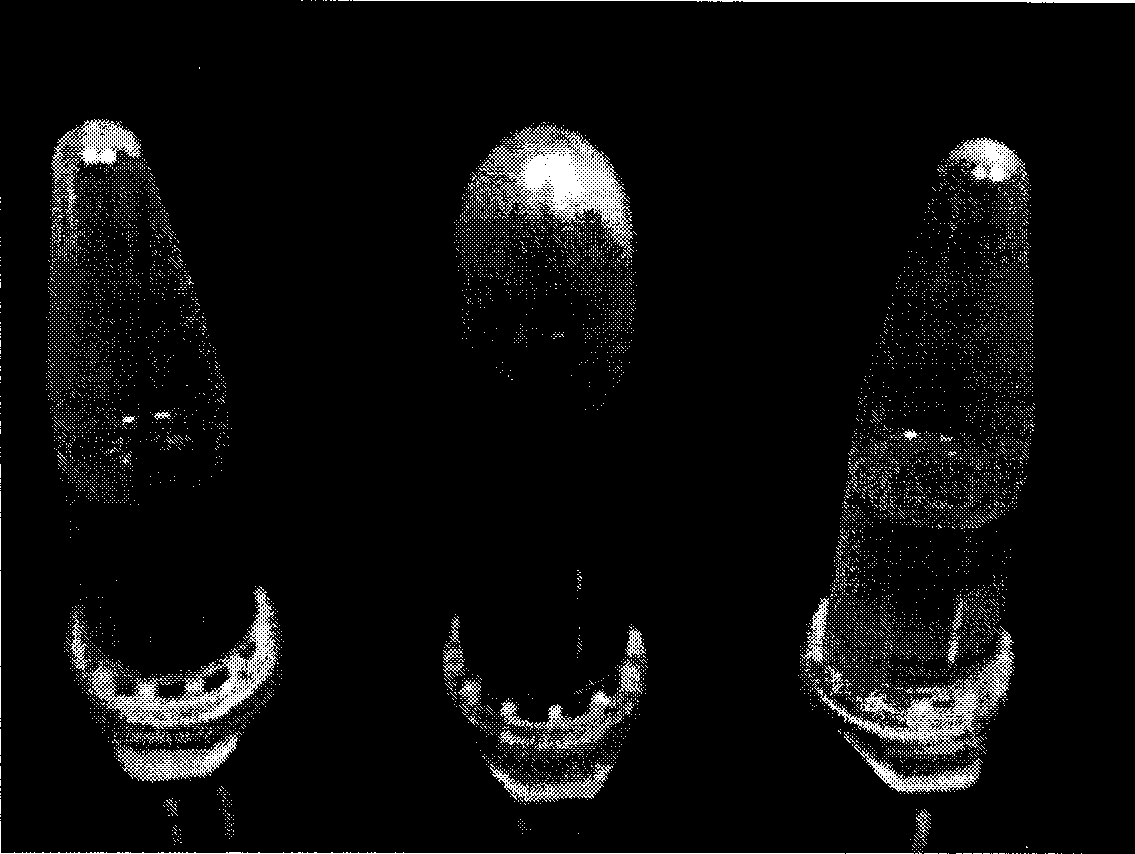

Method for preparing CdSe quantum

InactiveCN1789372ASimple and efficient operationSimple and fast operationLuminescent compositionsQuantum yieldQuantum dot

The invention discloses the method for preparation of CdSe quantum point. The method uses selenium powder and Cd compound, such as cadmium oxide and cadmium acetate, as raw material, to prepare CdSe quantum point of different grain diameter at the temperate condition. The method avoids using the inflammable, explosive, expensive and poisonous compounds, such as TOPO, HAD and TBP. The method has the advantages of handling safety, simplicity, low cost and good repeatability. The products are equal and the monodispersity of the product is good, and the grain diameter can be controlled. The products have the advantages of good fluorescence and stability, long fluorescence life time, high quantum productivity, and good light stability and light resistance. The CdSe quantum point can be used in fluorescence labeling substance, light emission device, laser ray and other fields, and also used in biology and medical detecting and analysis after surface finish.

Owner:WUHAN UNIV +1

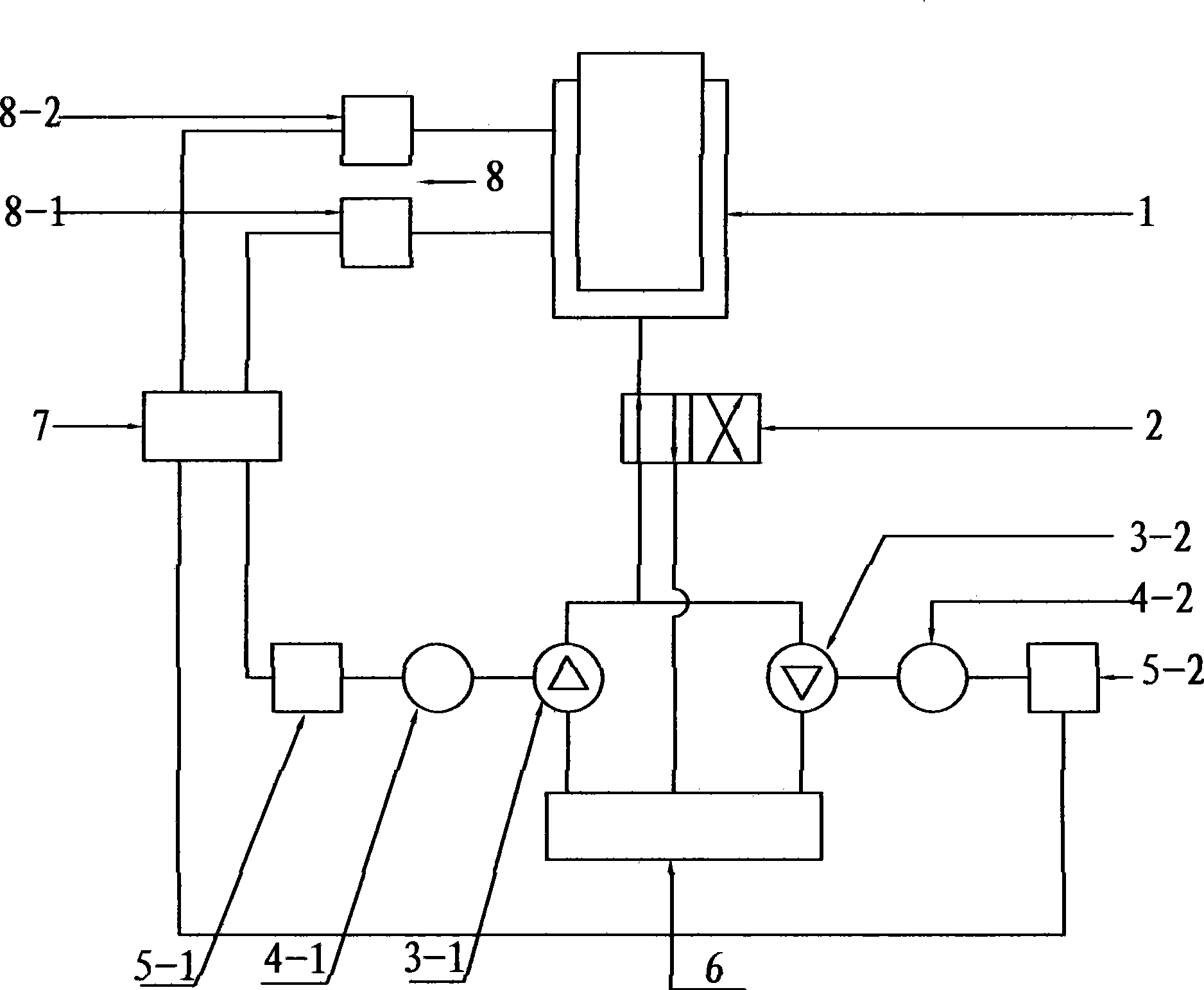

High precision hydraulic power source for directly driving oil pump by speed governing generator

ActiveCN101392769AGood energy saving effectSimple structureServomotorsFluid-pressure actuator componentsMotive powerControl system

The invention discloses a high-precision hydraulic power source which uses a speed regulating motor to drive an oil pump directly, and belongs to the technical field of hydraulic power installation. The high-precision hydraulic power source comprises an actuating mechanism, a reversing valve, an oil tank, servo drive units, a data acquisition and control system, and a feedback unit, wherein the reversing valve is connected with the actuating mechanism, the servo drive units are connected with the reversing valve, the data acquisition and control system is connected with the servo drive units, the feedback unit is connected with the data acquisition and control system, and the actuating mechanism is connected with the feedback unit; and the servo drive units have two groups which are parallelly connected with the reversing valve, one group of the servo drive units is in charge of controlling the oil feed for the actuating mechanism, while the other group is in charge of controlling the oil discharge for the actuating mechanism. The high-precision hydraulic power source has the advantages of energy conservation and high control precision.

Owner:绍兴市肯特机械电子有限公司

S-shaped multi-pin clamped piezoelectric motor and operating mode thereof

InactiveCN102195516AExtended service lifeAmplified output displacementPiezoelectric/electrostriction/magnetostriction machinesElectricityPiezoelectric actuators

The invention discloses an S-shaped multi-pin clamped piezoelectric motor and an operating mode thereof and belongs to the technical field of piezoelectric precision actuation. The motor consists of a stator assembly (1), a rotor assembly (2), a motion output assembly (3) and a base (4), wherein a core element of the stator assembly has an S-shaped structure formed by connecting three displacement transformation frames end to end and combining the three displacement transformation frames in a laminated way; in the three displacement transformation frames, a laminated piezoelectric stack serves as an actuated element, and each frame can output displacement in two spatially orthogonal directions; and a middle displacement transformation frame has the function of clamping and driving simultaneously during operation, and the other two displacement transformation frames only serve as clamping units. The motor can operate in two modes, namely a direct drive mode and a stepping mode, whereindeformation of the laminated piezoelectric stack can be directly controlled in the direct drive mode so as to realize accurate positioning; and quick positioning can be realized in the stepping mode.In addition, the motor has a compact and simple structure and a simple process, and is self-locked during power failure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for processing metal film strainometer based on MEMS (Micro-electromechanical Systems)

InactiveCN102730632AImprove performanceHigh sensitivityDecorative surface effectsElectrical/magnetic solid deformation measurementAdhesiveMicroelectromechanical systems

The invention discloses a method for processing a metal film strainometer based on an MEMS (Micro-electromechanical Systems). According to the method, repeated polyimide spinning and processing are adopted so that a substrate and a covering layer of the strainometer are respectively formed, a sensitive grid part and an anchoring point of the strainometer are respectively formed by adopting metal stripping, wet-method corrosion and the like, and self release of the strainometer is realized by using alcohol soaking. Compared to the prior art, in the method, the sensitive grid layer material of the strainometer is directly sputtered on the substrate of the strainometer by adopting a magnetron sputtering process without using adhesives so that the performance of the strainometer is improved; by adopting the new process, the problem of lower flatness caused by air bubbles generated by manually sticking a polyimide film can be solved, thus saving time and labor; by adopting an MEMS processing process, the sensitivity, the resolution ratio and the measuring range of the strainometer are improved, and the power consumption of the strainometer is reduced; the method realizes tiny strain measurement and point strain and torsion measurement, reduces influences on tested pieces in the measuring process and improves the measurement precision; and the method is easy to realize mass production and reduces the cost of individual device.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com