S-shaped multi-pin clamped piezoelectric motor and operating mode thereof

A technology of piezoelectric motor and working mode, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., which can solve the problem that clamping units cannot achieve clamping and guide rail parallelism Difficulties, reducing the efficiency of movers, etc., to achieve the effects of easy mass production, improving workability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical scheme of the present invention is described in further detail below in conjunction with accompanying drawing;

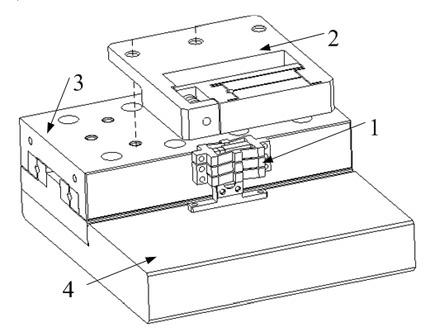

[0045]As shown in Figure 1(a), the stator 1 and the slide table 3 are fixed on the base 4 by screws, the mover 3 is fixedly connected with the upper slide table of the cross roller slide table by screws, and the three pairs of clamping feet of the stator The front frame and the rear frame of the mover are clamped by the action of the pre-tightening mechanism of the mover.

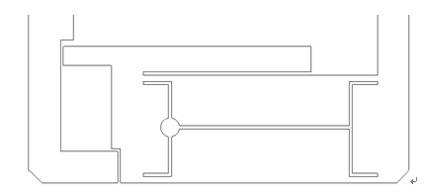

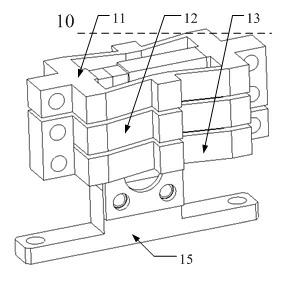

[0046] As shown in Figure 2(a), the core element of the stator assembly is an S-shaped structure composed of three displacement conversion frames connected end to end. The shape of the displacement conversion frame is shown in Figure 2(b), and the laminated piezoelectric stack is enclosed by a The structure is preloaded, and the structure can amplify the deformation 2dx in the x-axis direction of the laminated piezoelectric stack to 2dy in the y-axis direction, so the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com