Preparation method of porous marmem damping composite material covered with metal

A technology of damping composite materials and memory alloys, which is applied in the field of damping to achieve good damping performance, improved mechanical properties, and good damping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Use industrial pure nickel powder (average particle size of 4μm) and titanium powder (average particle size of 44μm), and mix according to equiatomic ratio; after fully mixing for 24 hours, make a blank with an original porosity of (50±2)%. The size is φ25×150mm 2 ;Under the protection of an industrial pure argon atmosphere with a purity of 99.99%, put it into an industrial electric furnace for preheating; when the preheating temperature of the billet reaches 300°C, use a tungsten wire heated by electricity to ignite the billet. Spontaneously spread, the porous nickel-titanium shape memory alloy was synthesized within 30 seconds.

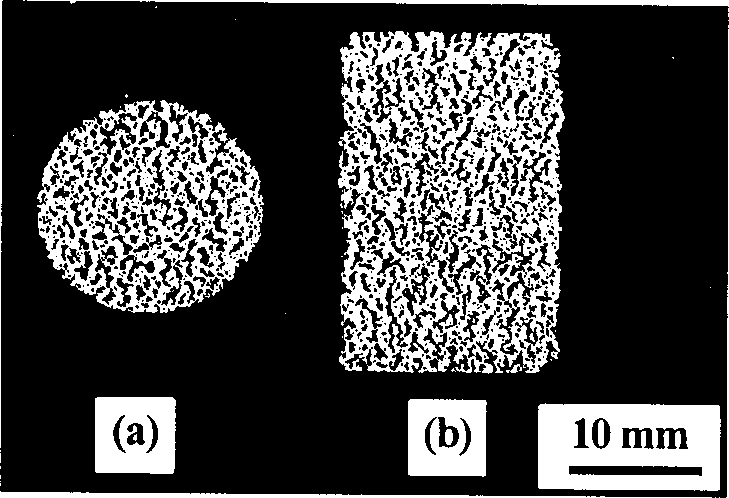

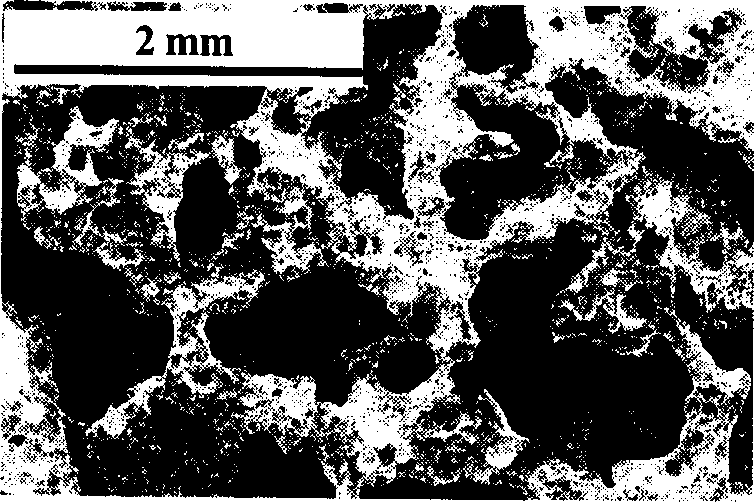

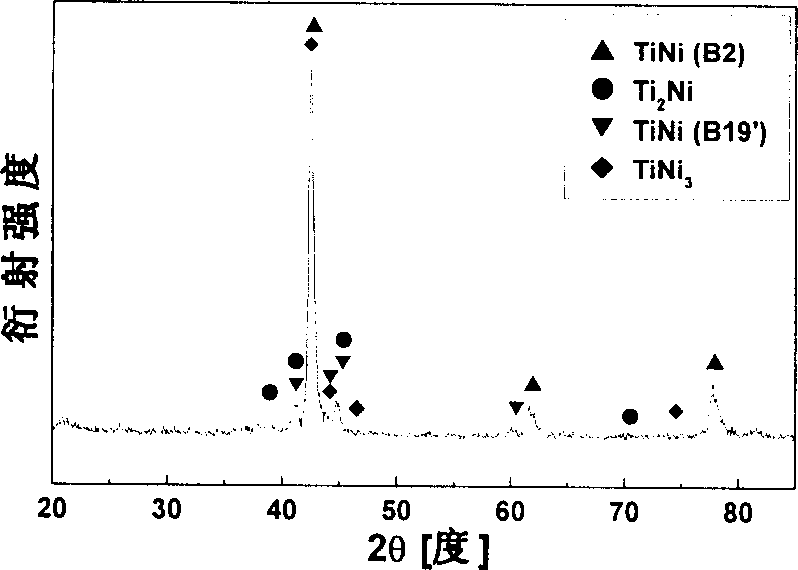

[0047] The pores of the porous nickel-titanium shape memory alloy in this embodiment are evenly distributed and have a three-dimensional connected network pore structure (such as figure 1 with figure 2 shown). In this embodiment, the porosity of the porous nickel-titanium shape memory alloy is about 58%, the average pore size is about 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com