Patents

Literature

30 results about "Stress axis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Principal axis of stress. [′prin·sə·pəl ′ak·səs əv ′stres] (mechanics) One of the three mutually perpendicular axes of a body that are perpendicular to the principal planes of stress. Also known as stress axis.

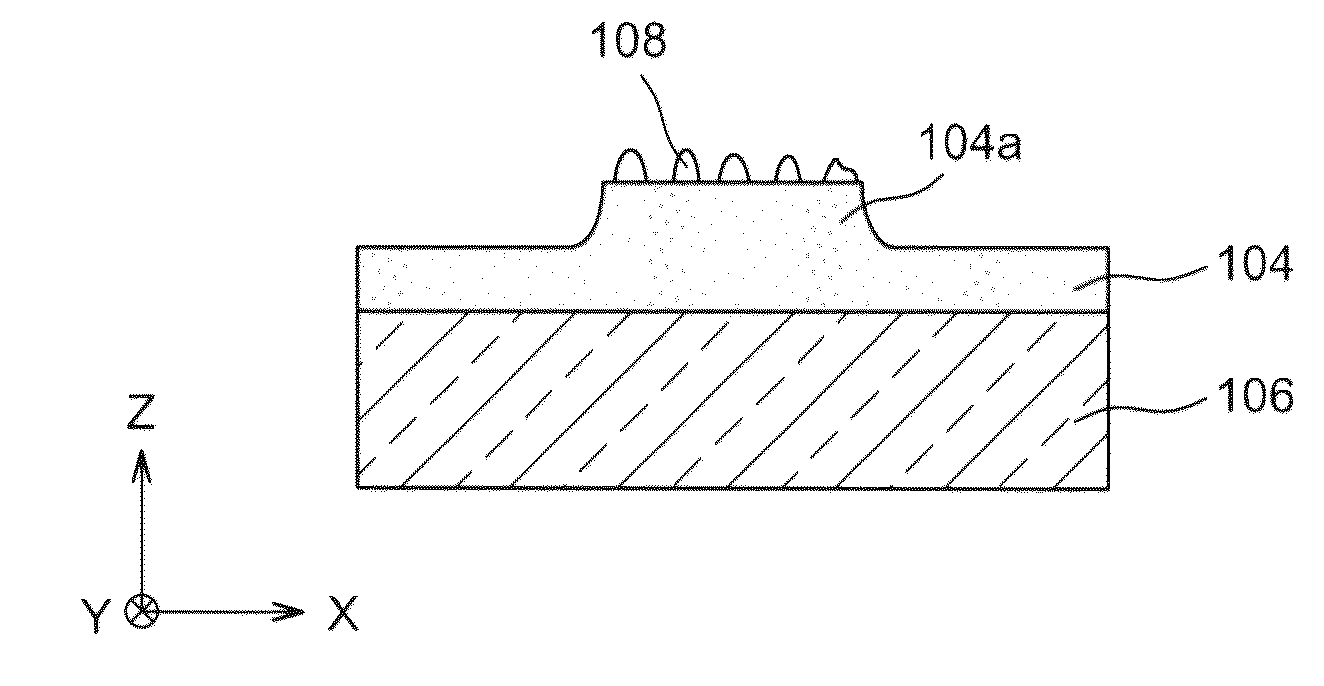

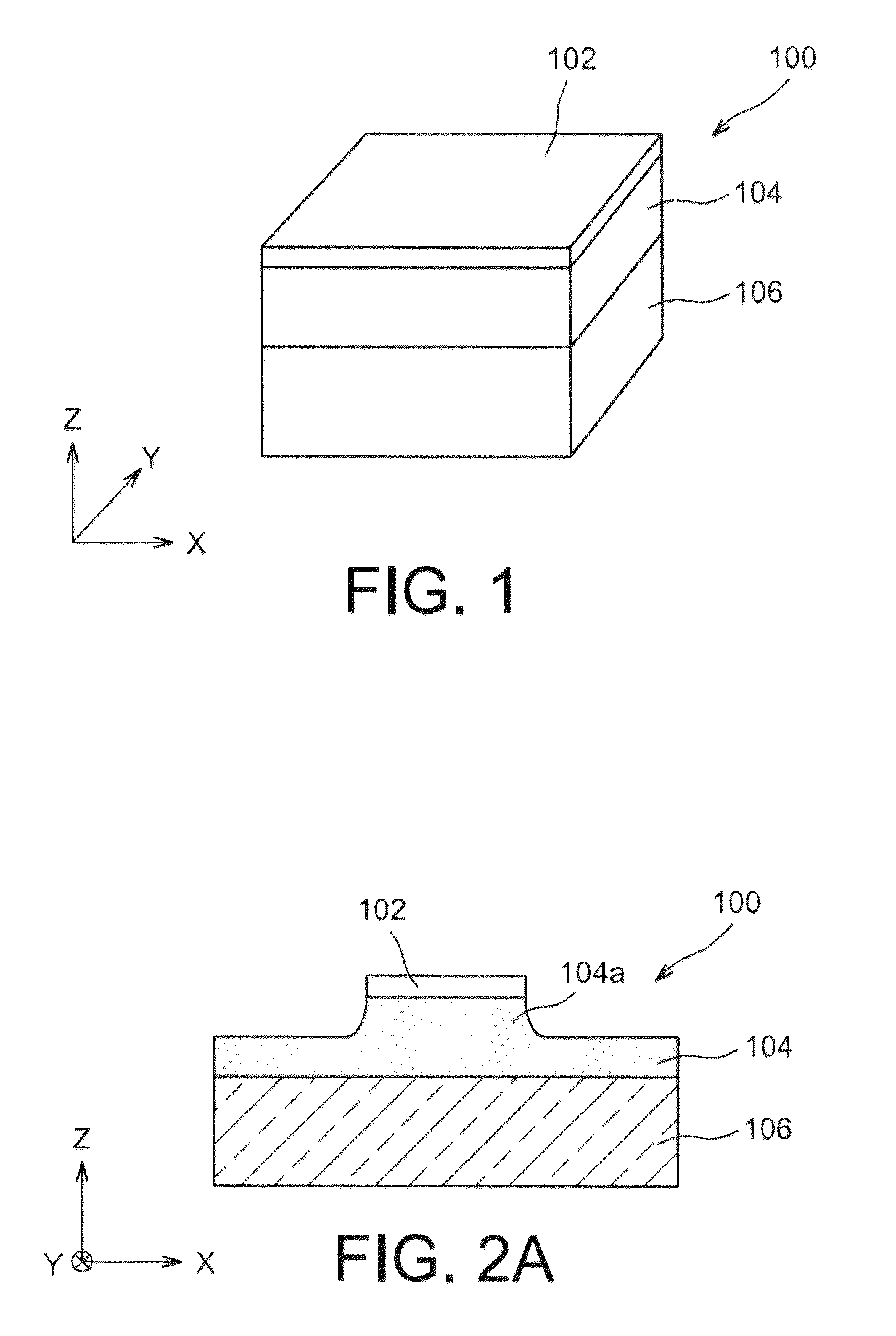

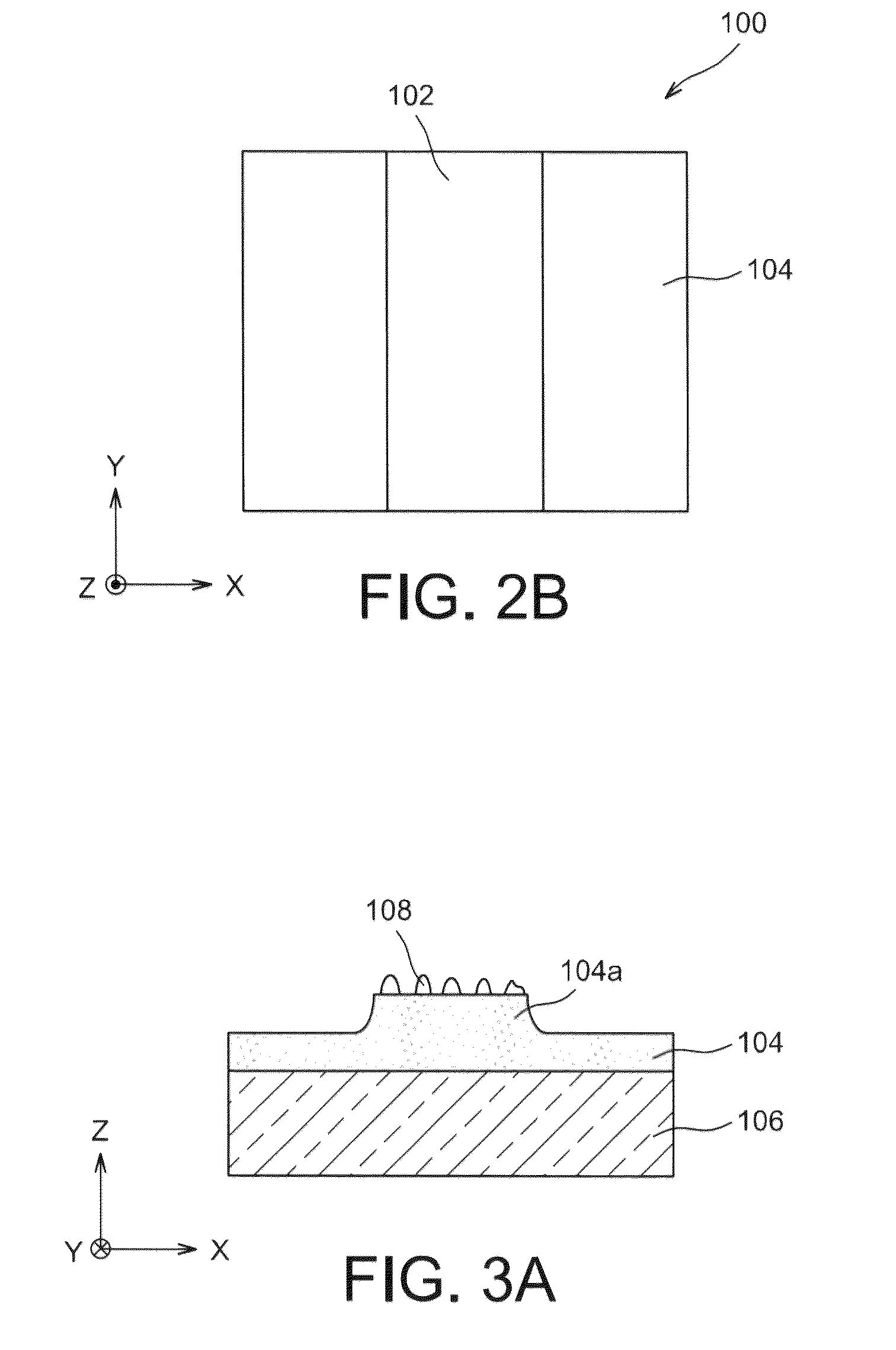

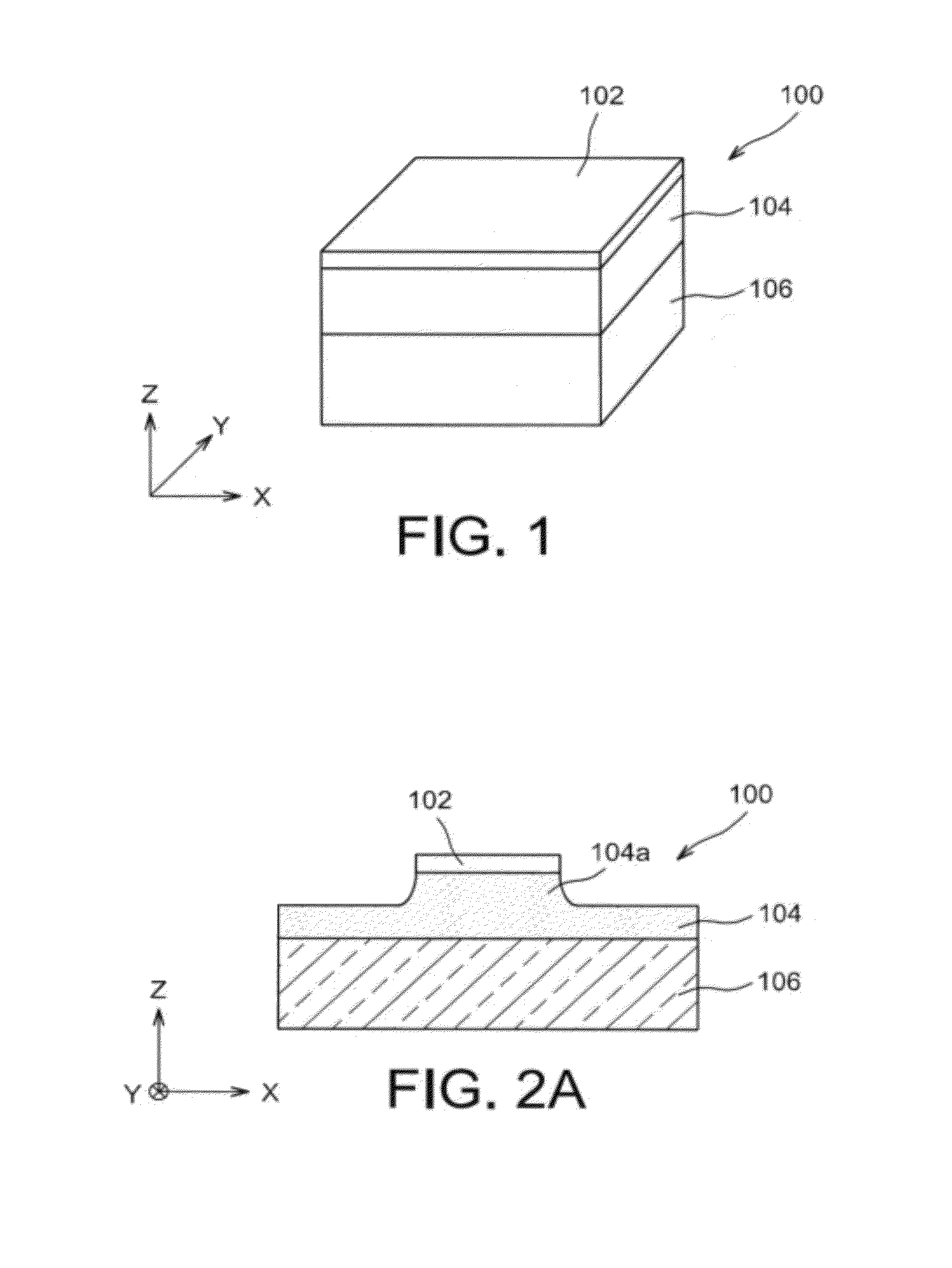

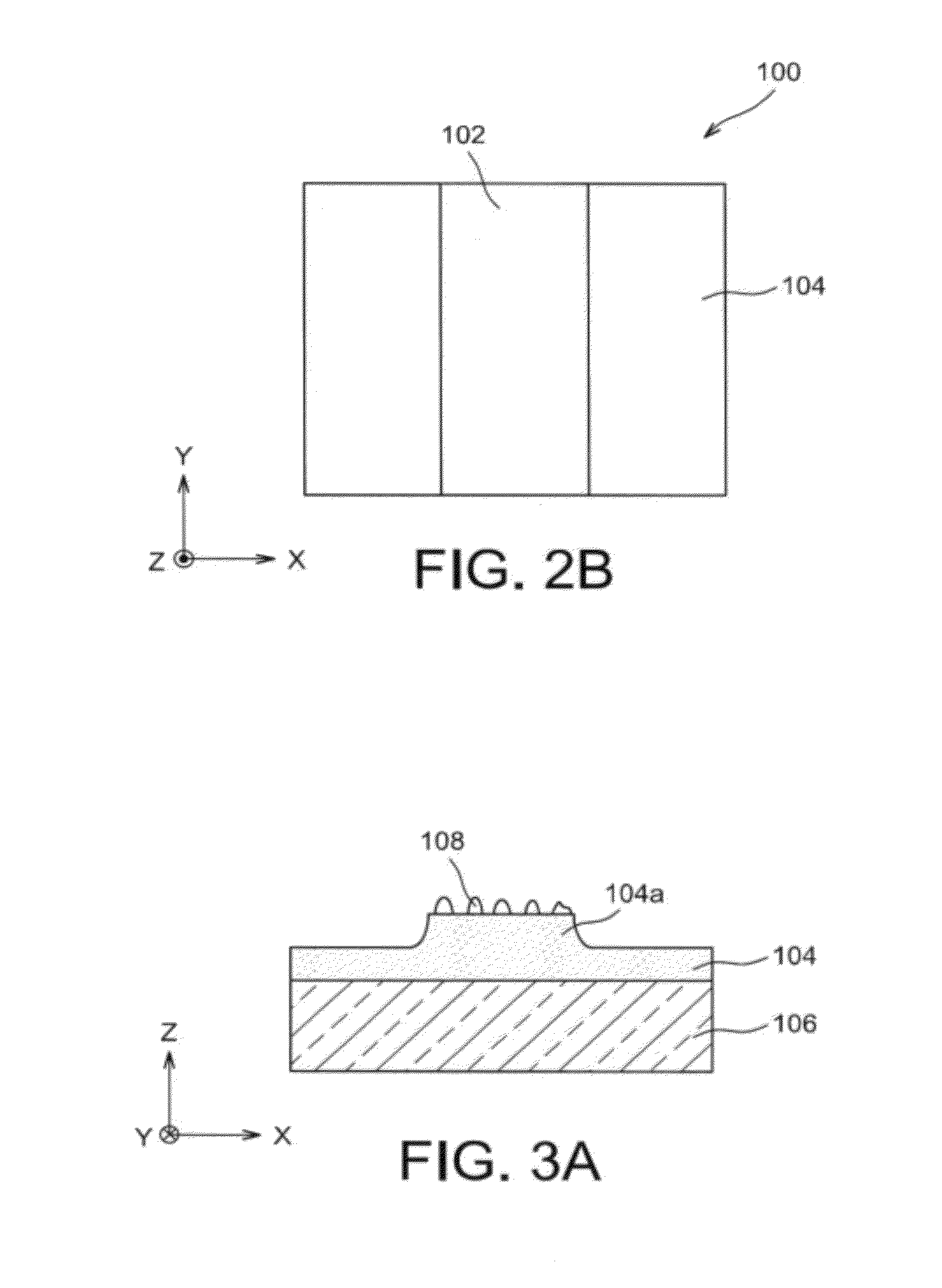

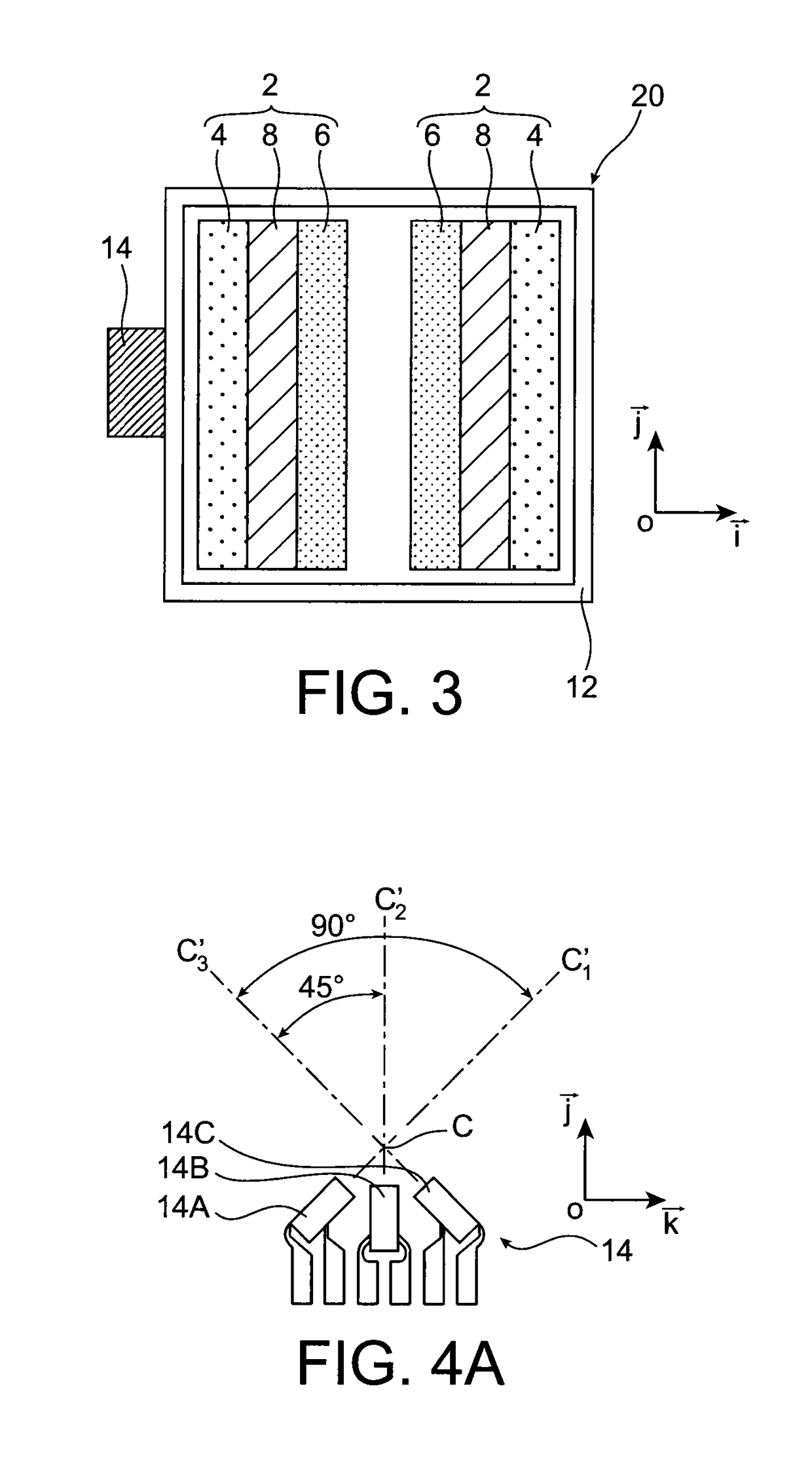

Method for making semi-conductor nanocrystals oriented along a predefined direction

A method for making a semi-conductor nanocrystals, including at least the steps of:making a stack of at least one uniaxially stressed semi-conductor thin layer and a dielectric layer,annealing the semi-conductor thin layer such that a dewetting of the semi-conductor forms, on the dielectric layer, elongated shaped semi-conductor nanocrystals oriented perpendicularly to the stress axis.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

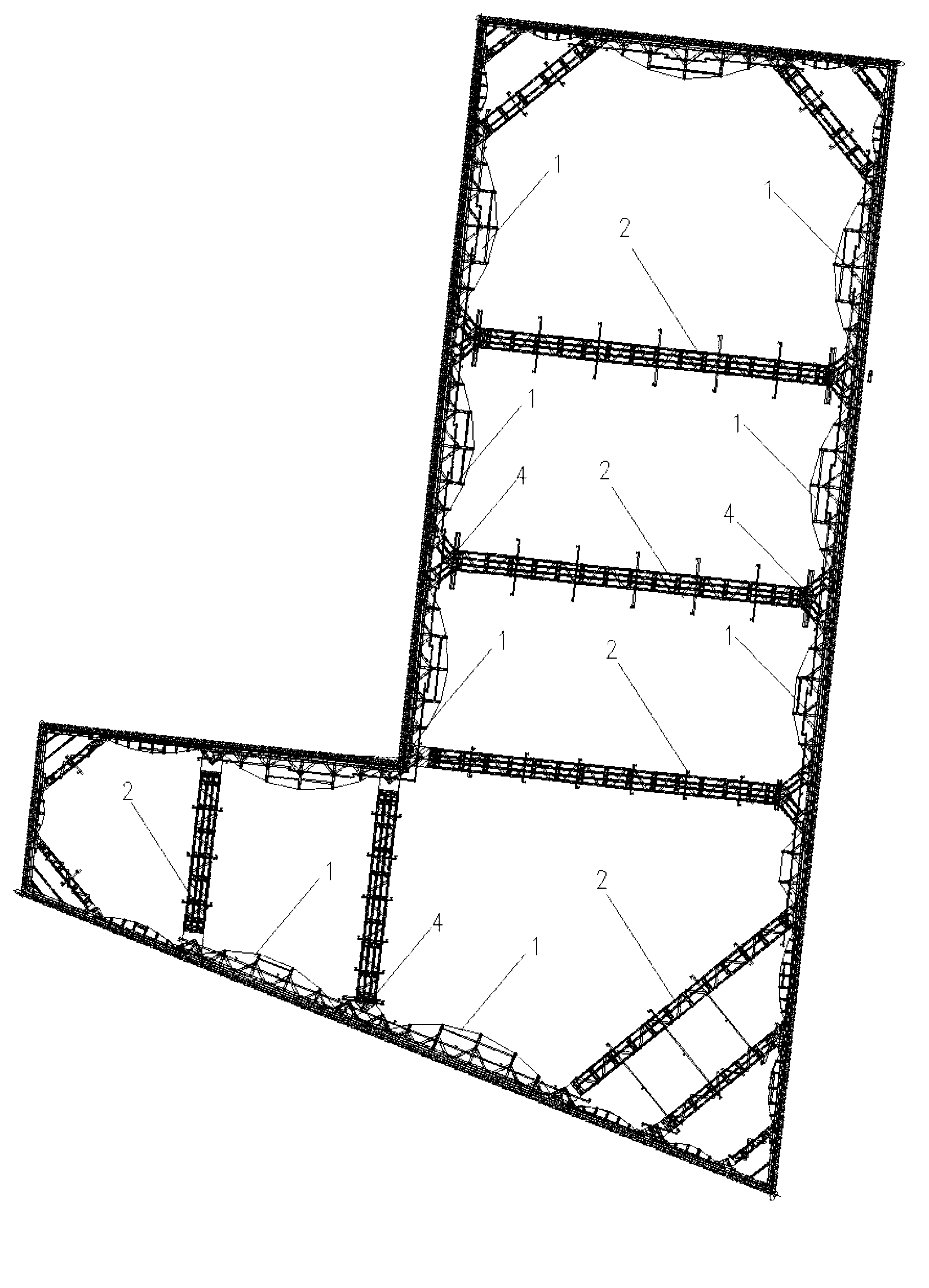

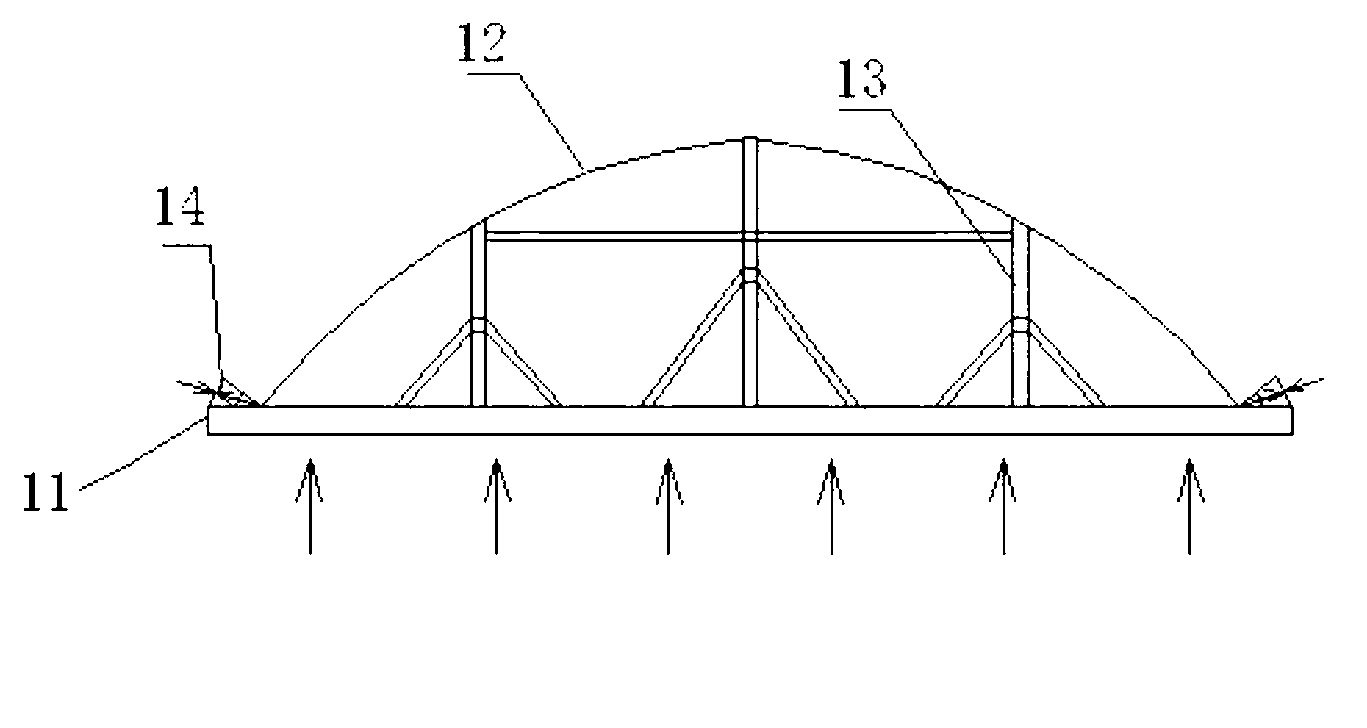

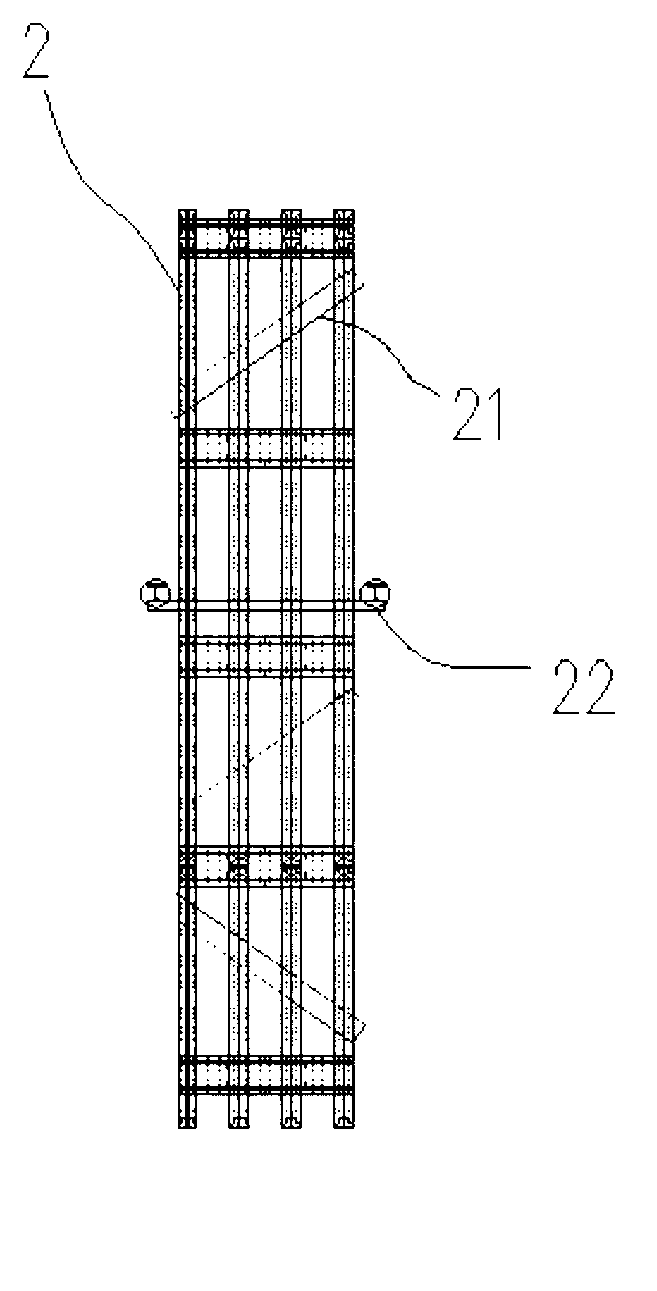

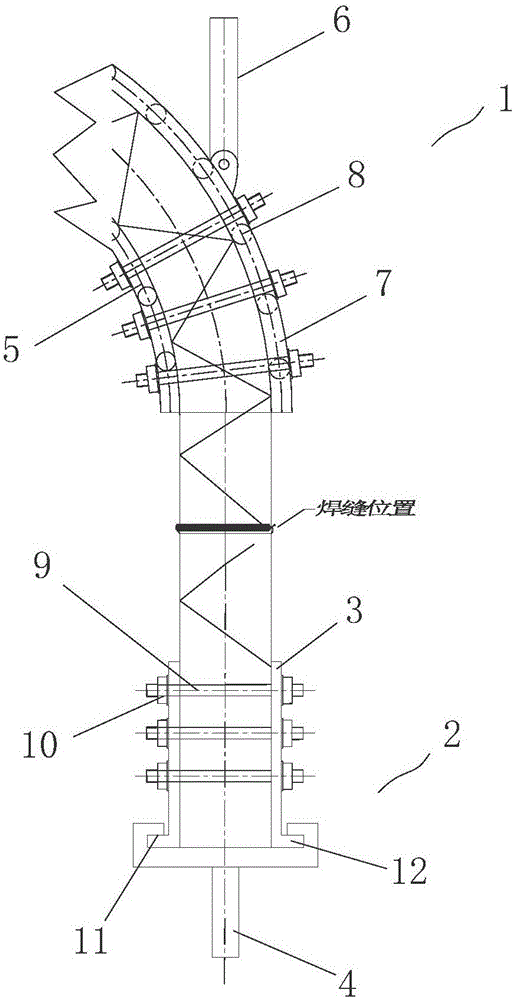

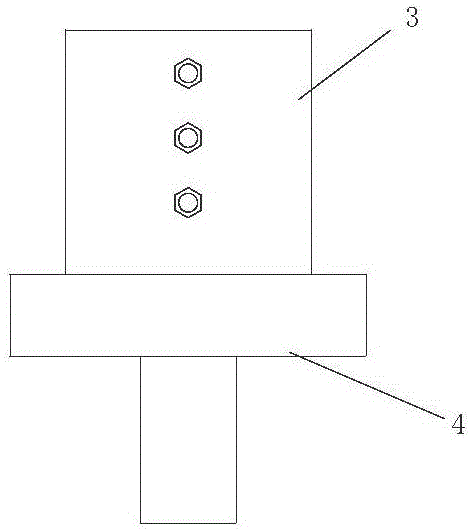

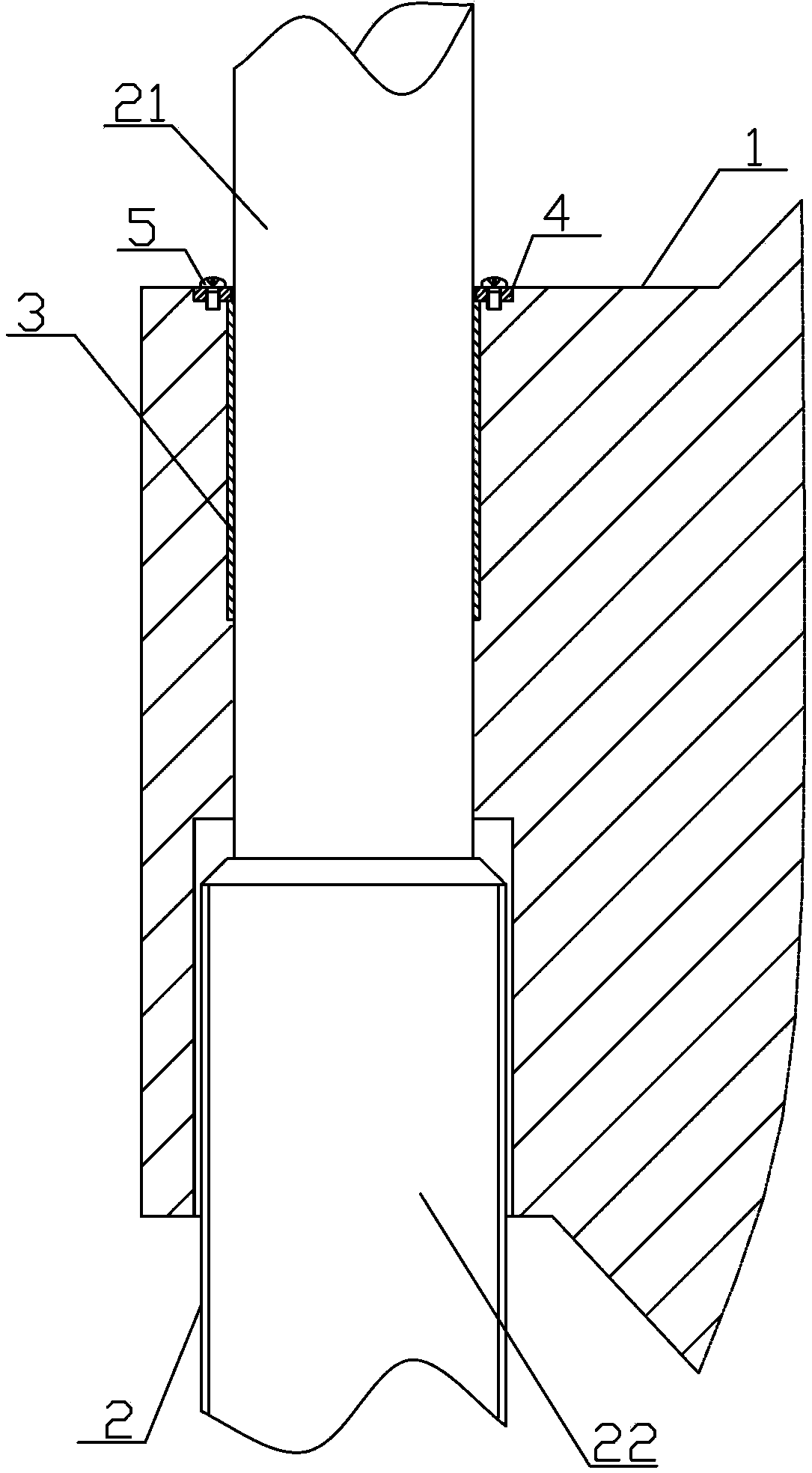

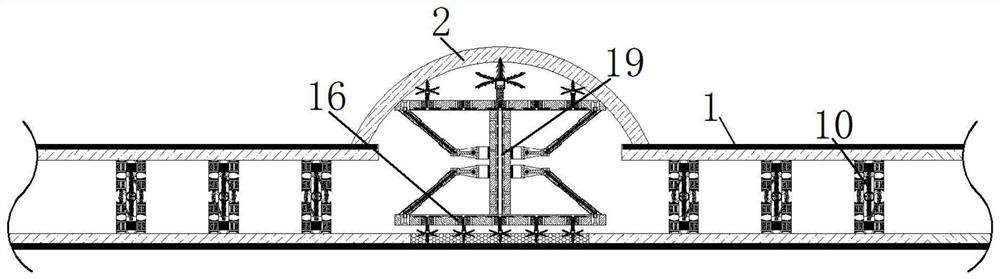

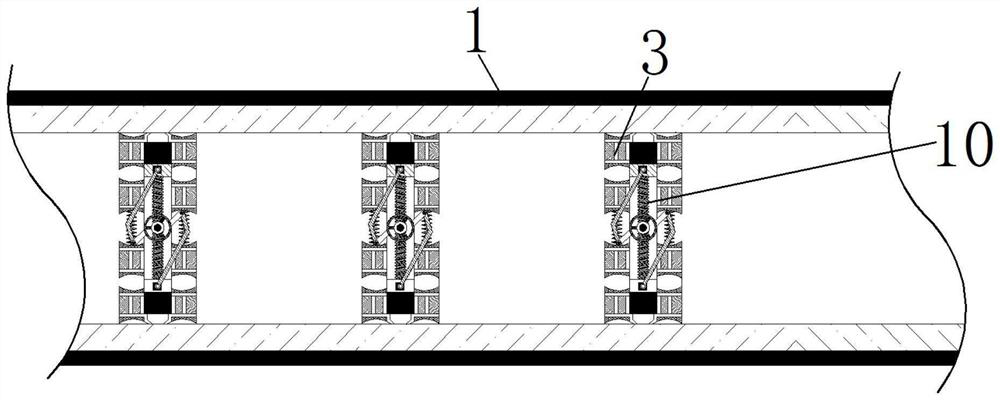

High-stiffness monolithic prestress assembly type foundation pit bracing inner-supporting system

InactiveCN103015434AOvercoming large deformationOvercoming adjustmentExcavationsPurlinSupporting system

The invention provides a high-stiffness monolithic prestress assembly type foundation pit bracing inner-supporting system, which comprises an opposite brace, an angle brace and a prestress enclosing purlin, wherein the opposite brace can apply prestress to the outer side of a foundation pit along an axis of the foundation pit; the prestress enclosing purlin is connected with the angle brace and the opposite brace into a whole, and the stressing axes are on the same plane; and finally, the high-stiffness monolithic prestress assembly type foundation pit bracing inner-supporting system is formed. The system has the advantages of high stiffness, large span, controllable deformation, convenience in construction and the like, and materials can be recycled.

Owner:SHANGHAI STRONG FOUND ENG

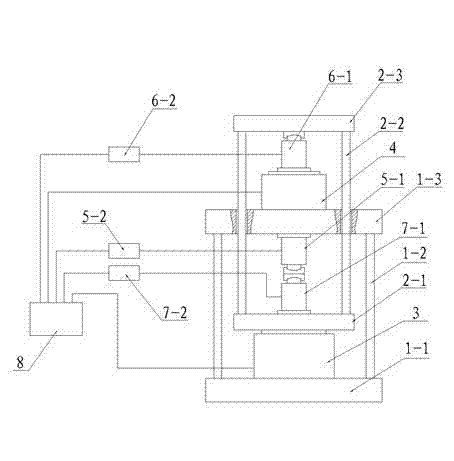

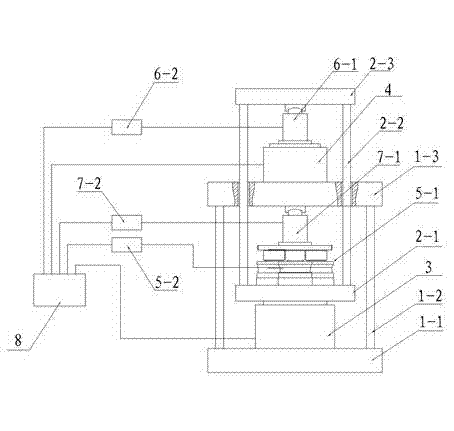

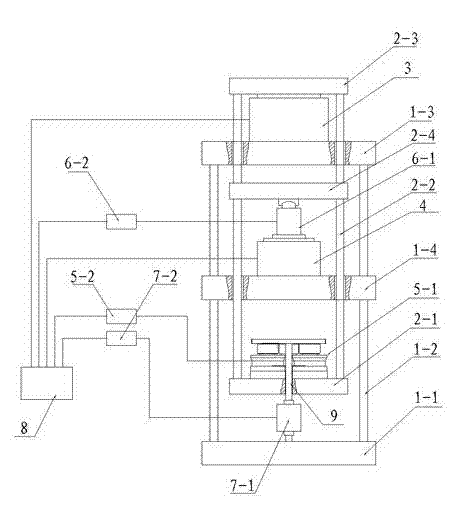

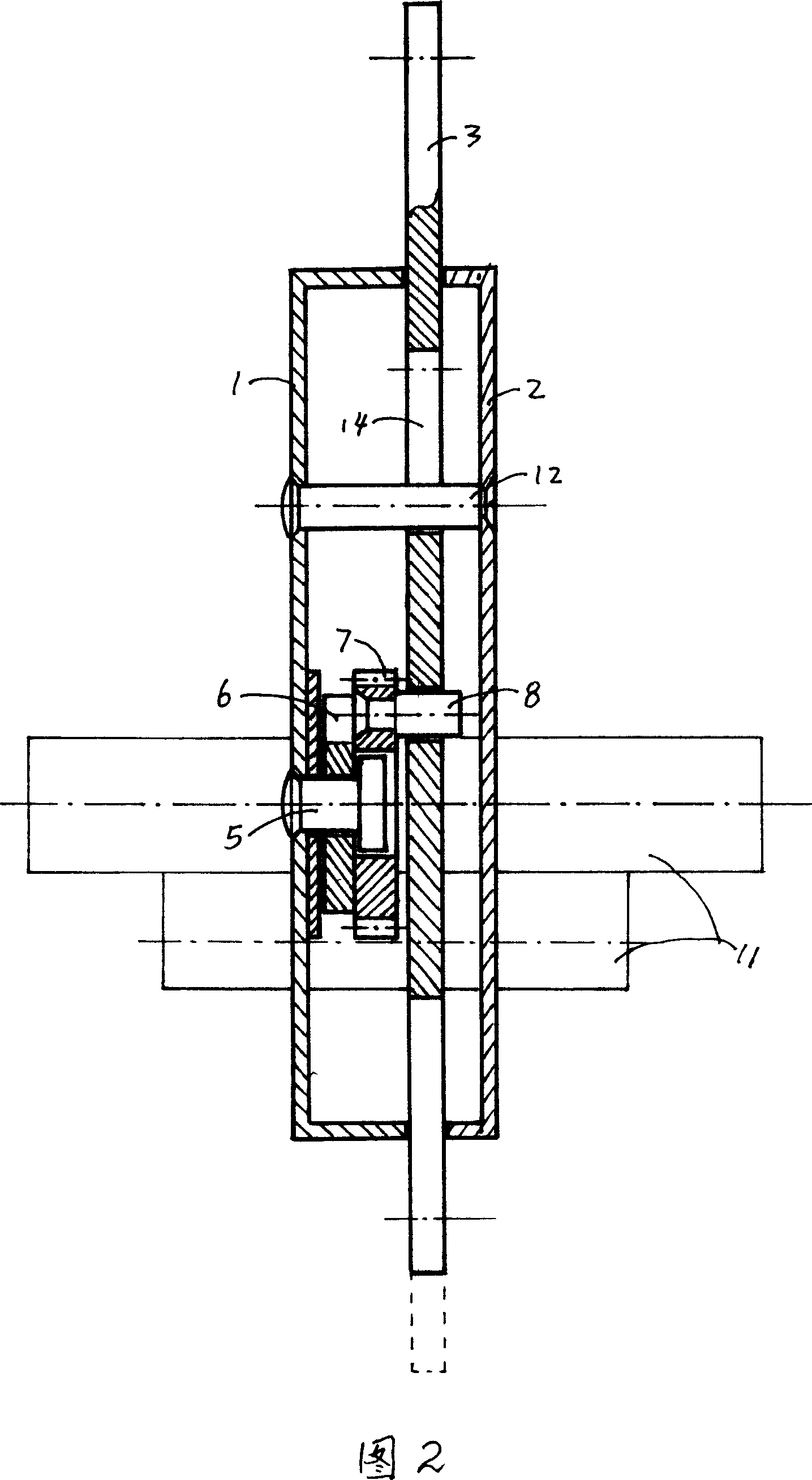

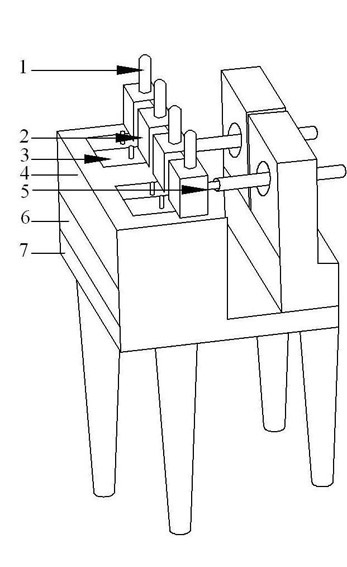

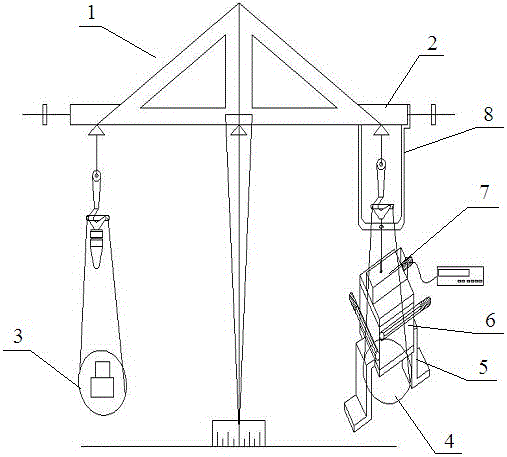

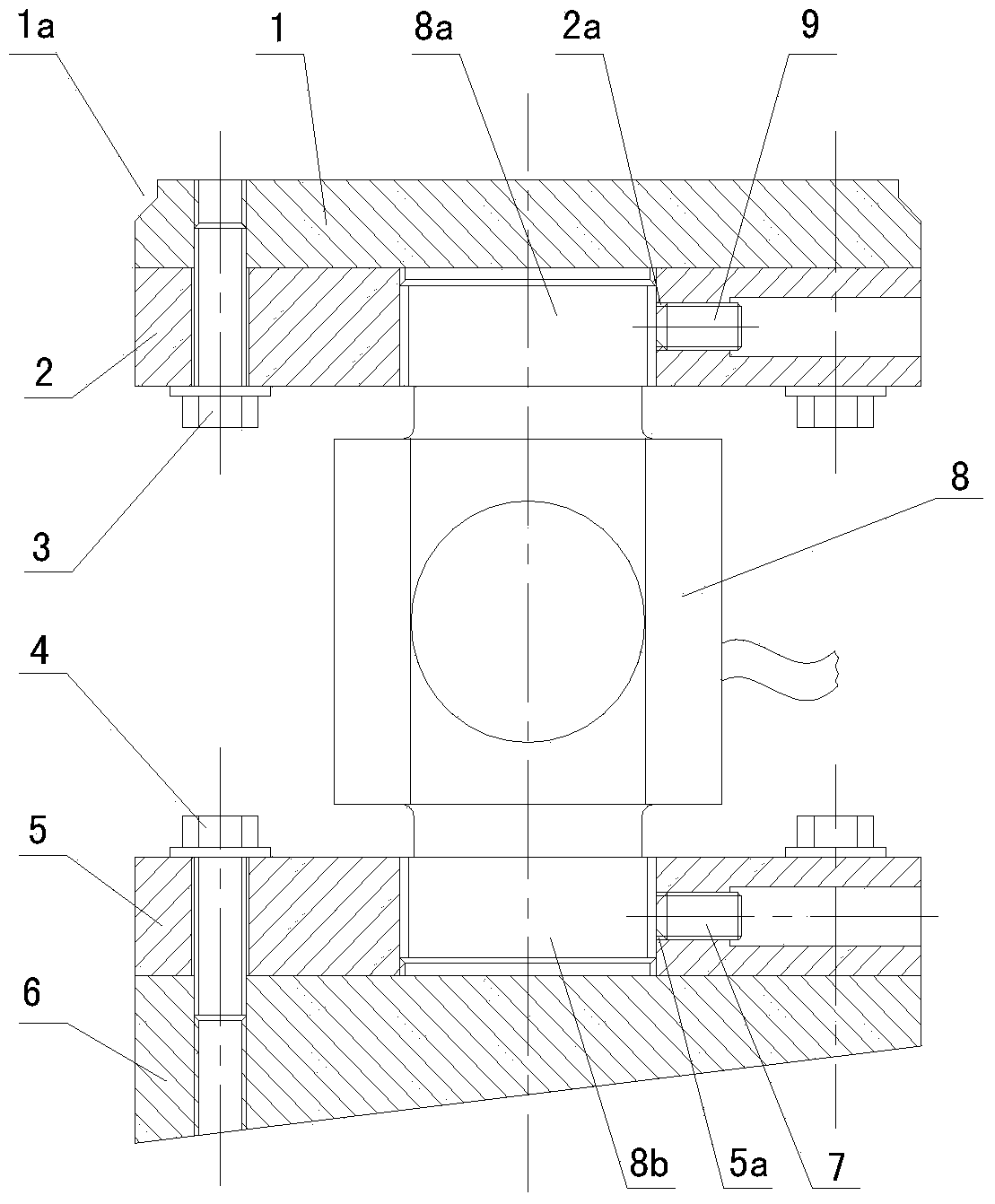

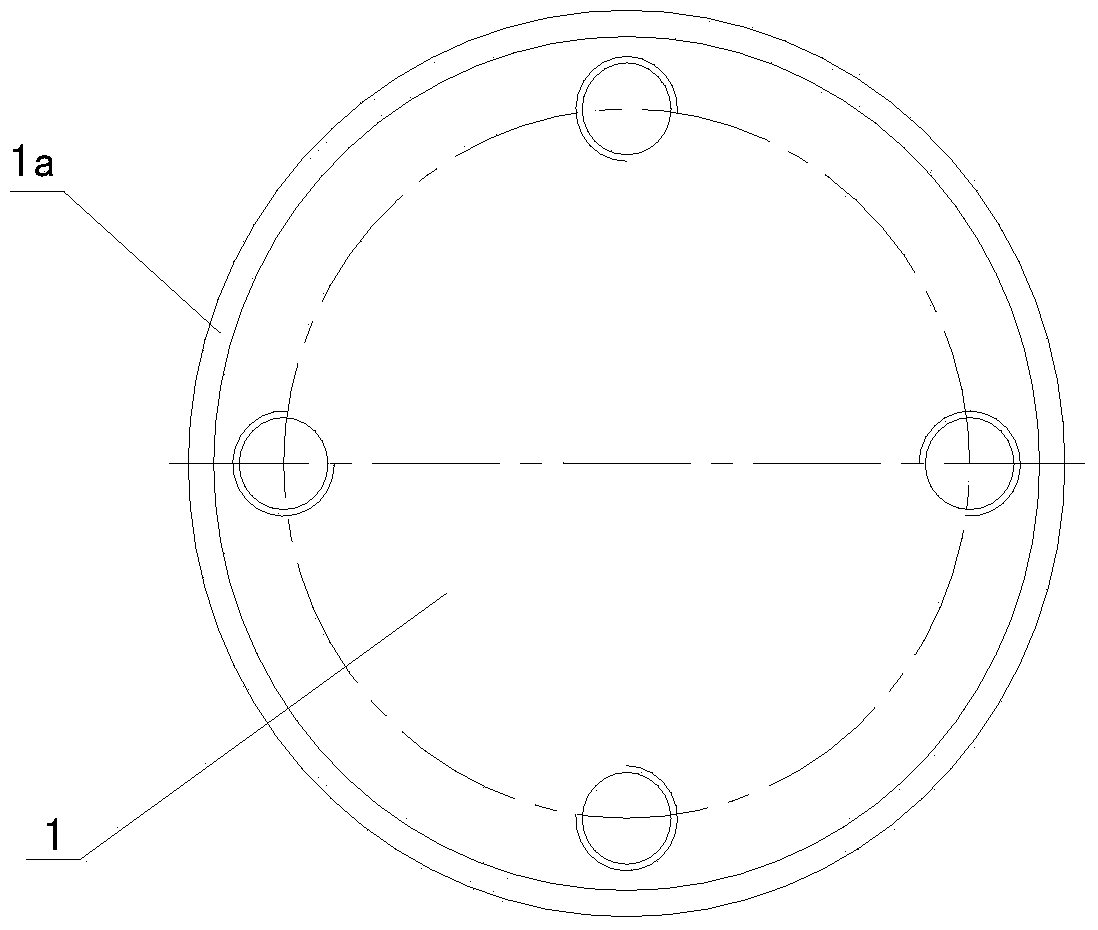

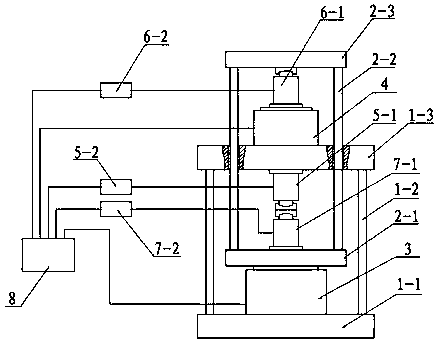

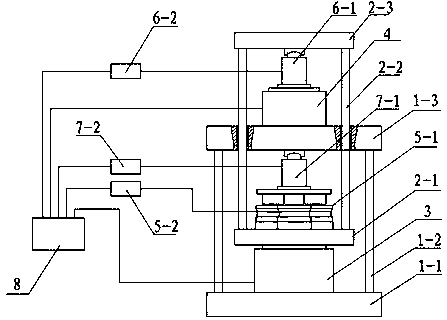

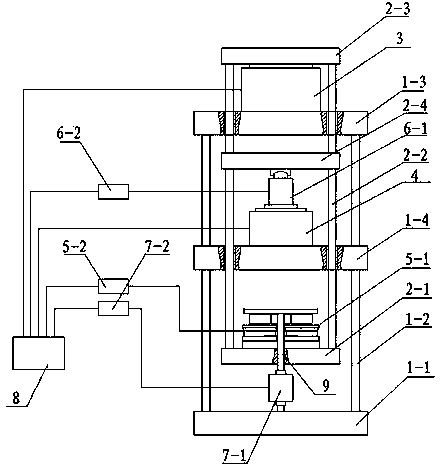

Build-up force standard machine with wide range,

ActiveCN102564557AReduce manufacturing costSimple structureWeighing apparatus testing/calibrationForce/torque/work measurement apparatus calibration/testingLower limitEngineering

The invention discloses a build-up force standard machine with a wide range, belongs to the technical field of force standard machinery, and is characterized in that the build-up force standard machine comprises a first detecting unit and a second detecting unit, wherein the upper limit of the range of the first detecting unit is in accordance with that of the build-up force standard machine; the lower limit of the range of the first detecting unit is in accordance with the upper limit of the range of the second detecting unit; the lower limit of the second detecting unit is in accordance with that of the build-up force standard machine; the force output directions of the first and the second detecting units are in accordance with each other; and the stress axis of a to-be-detected sensor is overlapped with those of the first and the second detection units. The build-up force standard machine has the advantages of large range, low manufacturing cost and the like.

Owner:绍兴市肯特机械电子有限公司

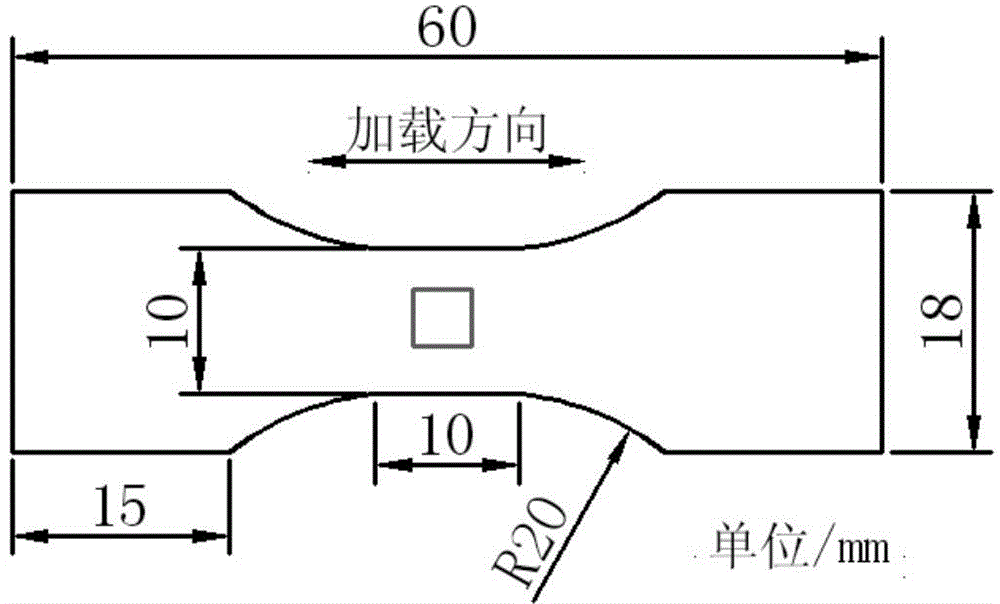

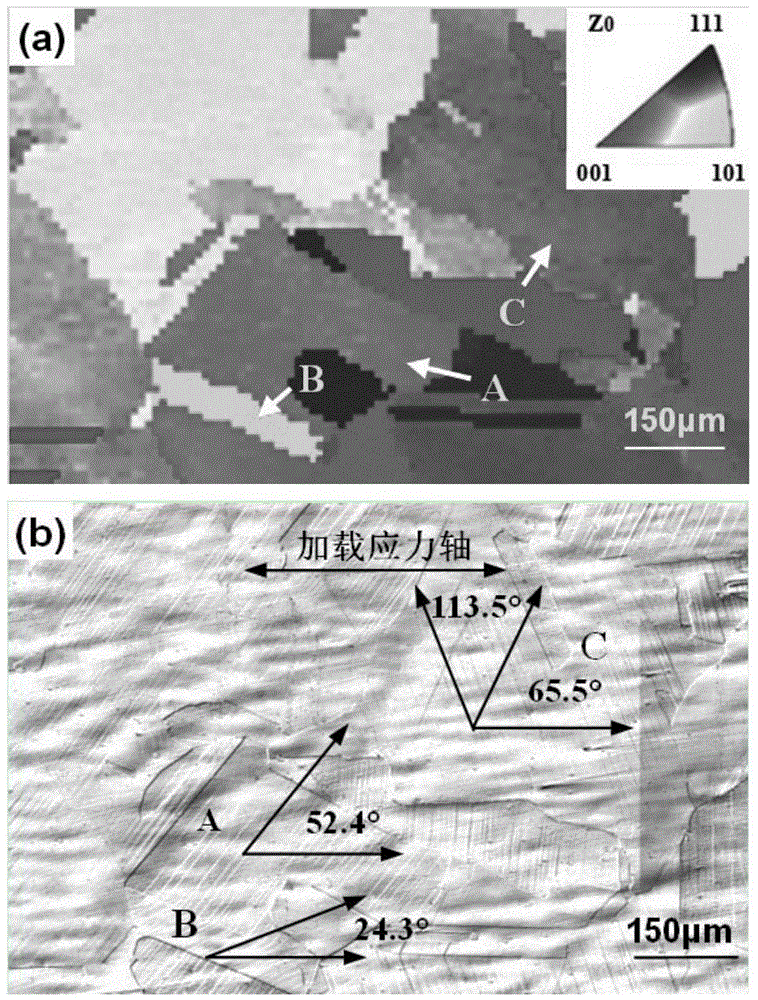

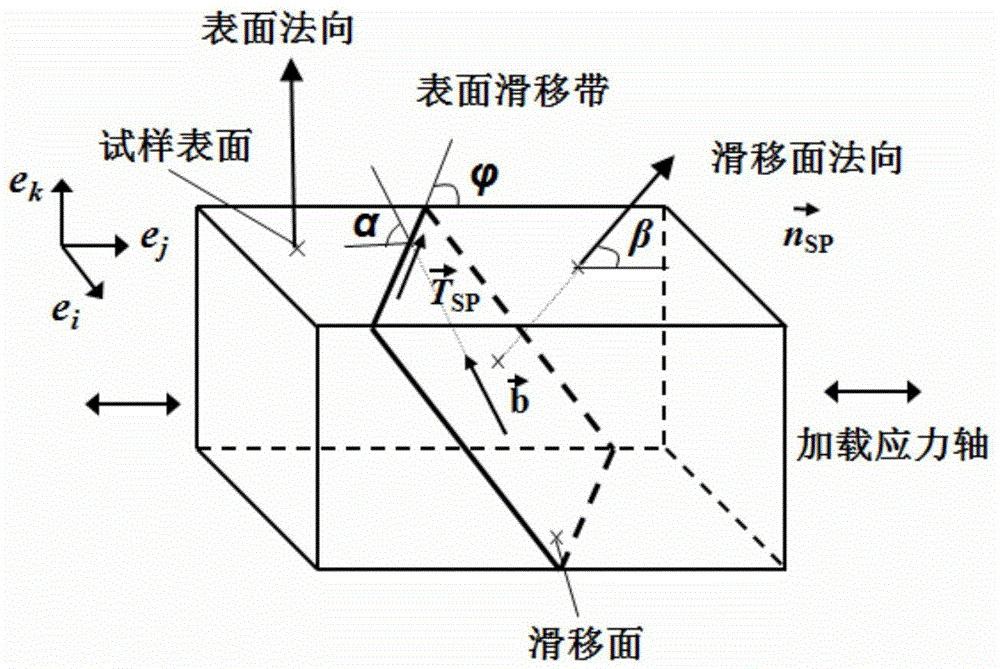

Method for determining polycrystalline metal deformation activation slippage system

InactiveCN104569012AOvercome damage morphologyOvercoming the difficulty of corresponding crystal orientationMaterial analysis using wave/particle radiationMaterial analysis by optical meansX-rayCrystal orientation

The invention provides a method for determining a polycrystalline metal deformation activation slippage system and belongs to the field of analysis of a material mechanical property. The method comprises the following steps: carrying out crystal orientation analysis on the surface of a test sample by adopting an EBSD analyzer; analyzing a loaded slippage band appearance by adopting a laser co-focusing microscope; calculating an included angle between a slippage band and a loading stress axis and comparing with an actual measurement value to determine a slippage surface; calculating a Schmid factor of a possible slippage system corresponding to the slippage surface; and determining a slippage direction according to a Schmid principle. Existing analysis methods mainly comprise five methods including an accrual method, a diagrammatizing method, a tensile axis index observation method, an X-ray diffraction method and a transmission electron microscope method. The first three methods are used for speculating a theoretical slippage system, and cannot be used for determining an actual activation slippage system; and the last two methods cannot be used for analyzing crystal orientation and damage appearance at the same time. The method can be used for analyzing the orientation of grain crystals and the corresponding slippage band appearance, and is relatively suitable for activation slippage system analysis after polycrystalline metal mechanical deformation.

Owner:DALIAN UNIV OF TECH

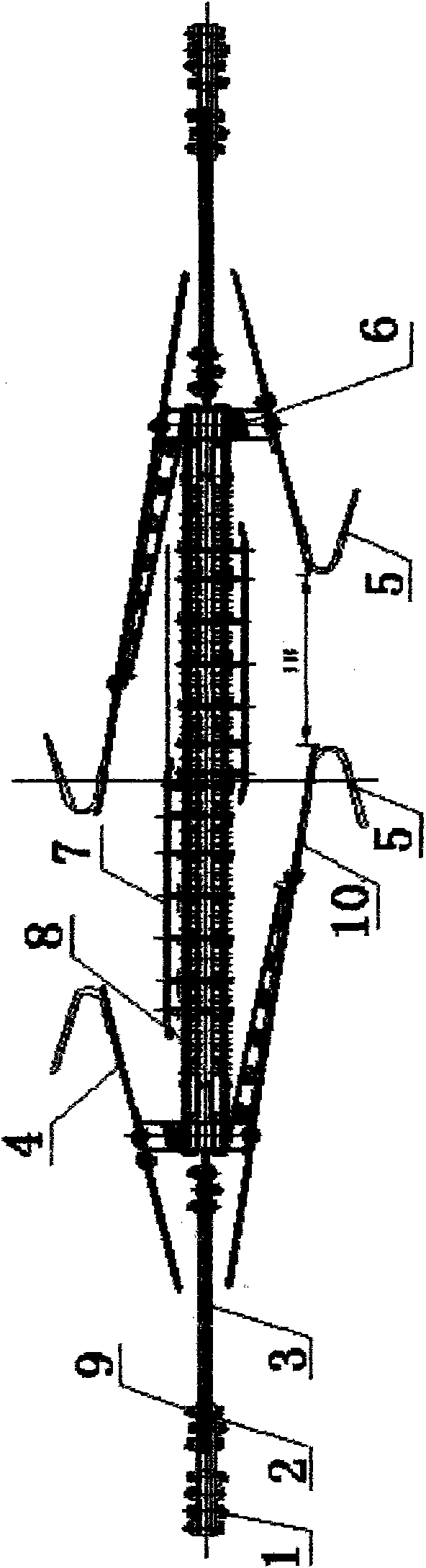

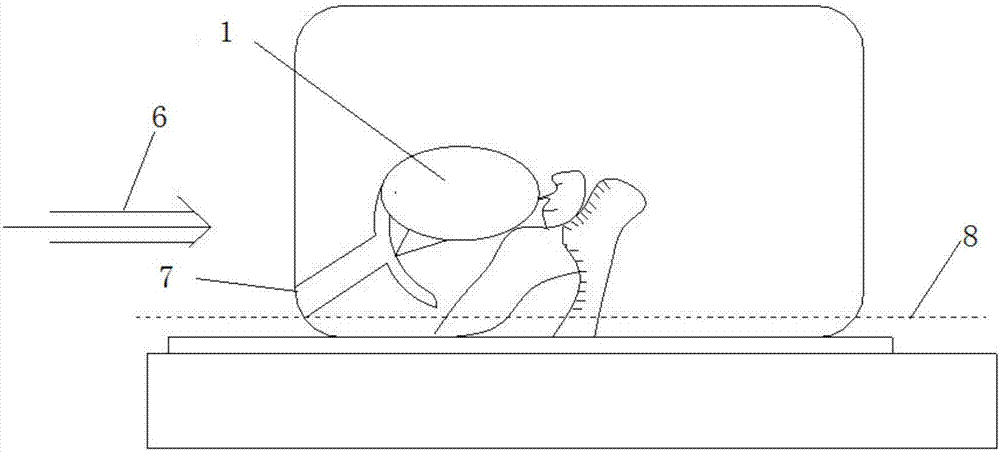

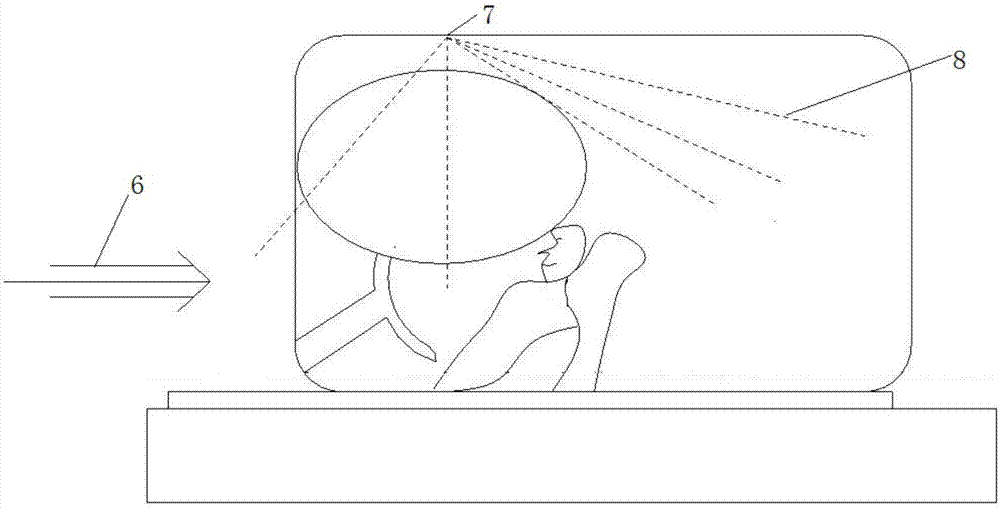

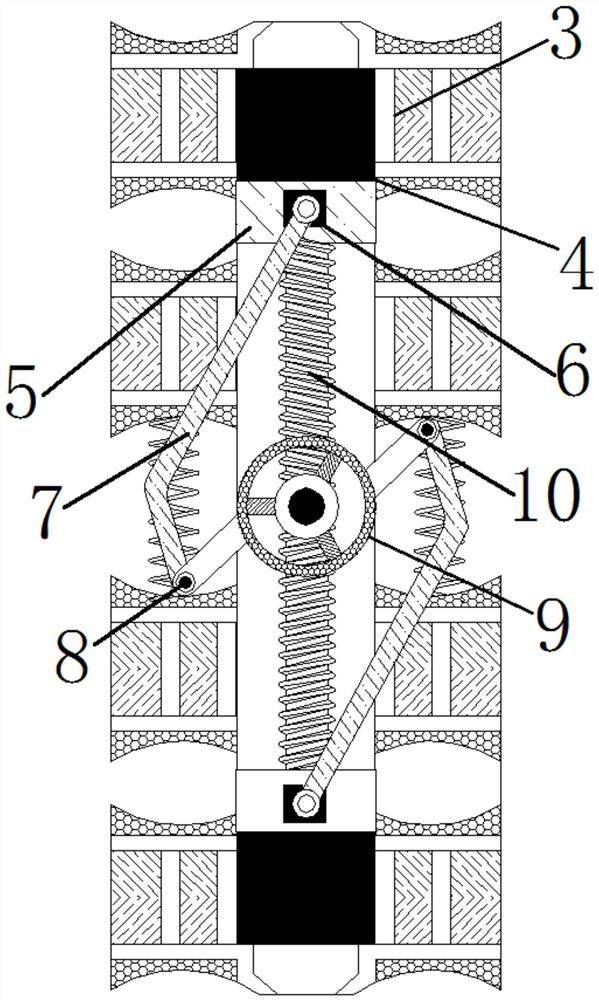

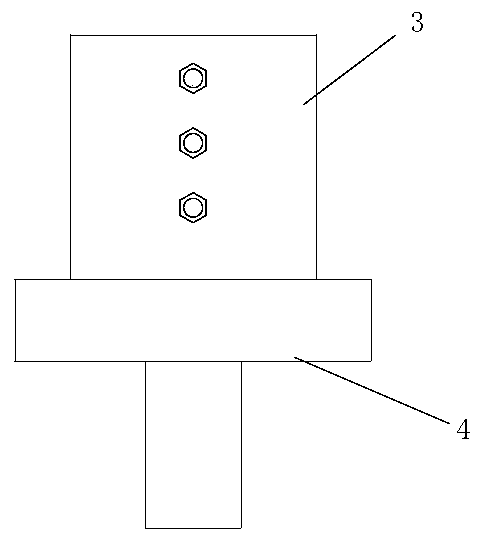

Bending moment-free anti-pollution high-speed segmenting and phase-splitting isolator

The invention belongs to equipment used in an electrified railway contact system, in particular to a bending moment-free anti-pollution high-speed segmenting and phase-splitting isolator, which is characterized by comprising a joint wire clamping plate (1), a joint wire clamp connecting plate (2), a connecting plate (3), a short sliding plate (4), a long sliding plate (10), a starting rod A (5), astarting rod B (5), a frame (6), an insulating sliding plate (7), silicon rubber isolators (8) and a fastening standard component (9), wherein the joint wire clamping plate (1) clamps a contact wire;and stressed axes of two silicon rubber isolators (8), the axes of connecting bolts at two ends of the connecting plate (3) and the groove of a contact lead are in the same axis. A pantograph of thebending moment-free anti-pollution high-speed segmenting and phase-splitting isolator can smoothly pass through at a high speed without generating bending moment, pantograph scratch and pantograph drilling. The bending moment-free anti-pollution high-speed segmenting and phase-splitting isolator cannot worn by the pantograph, has no pollution and cannot be burnt out by an electric arc.

Owner:周建科

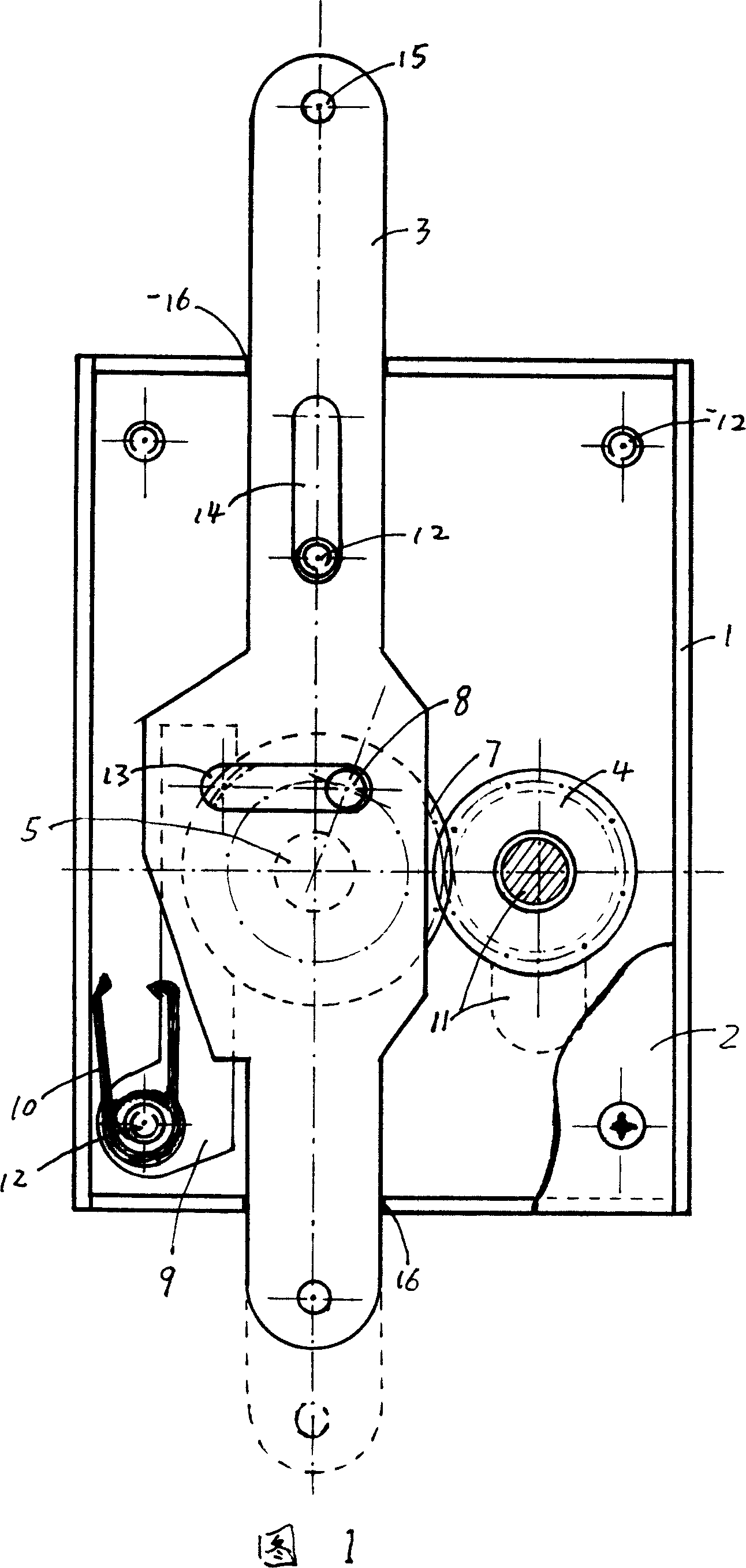

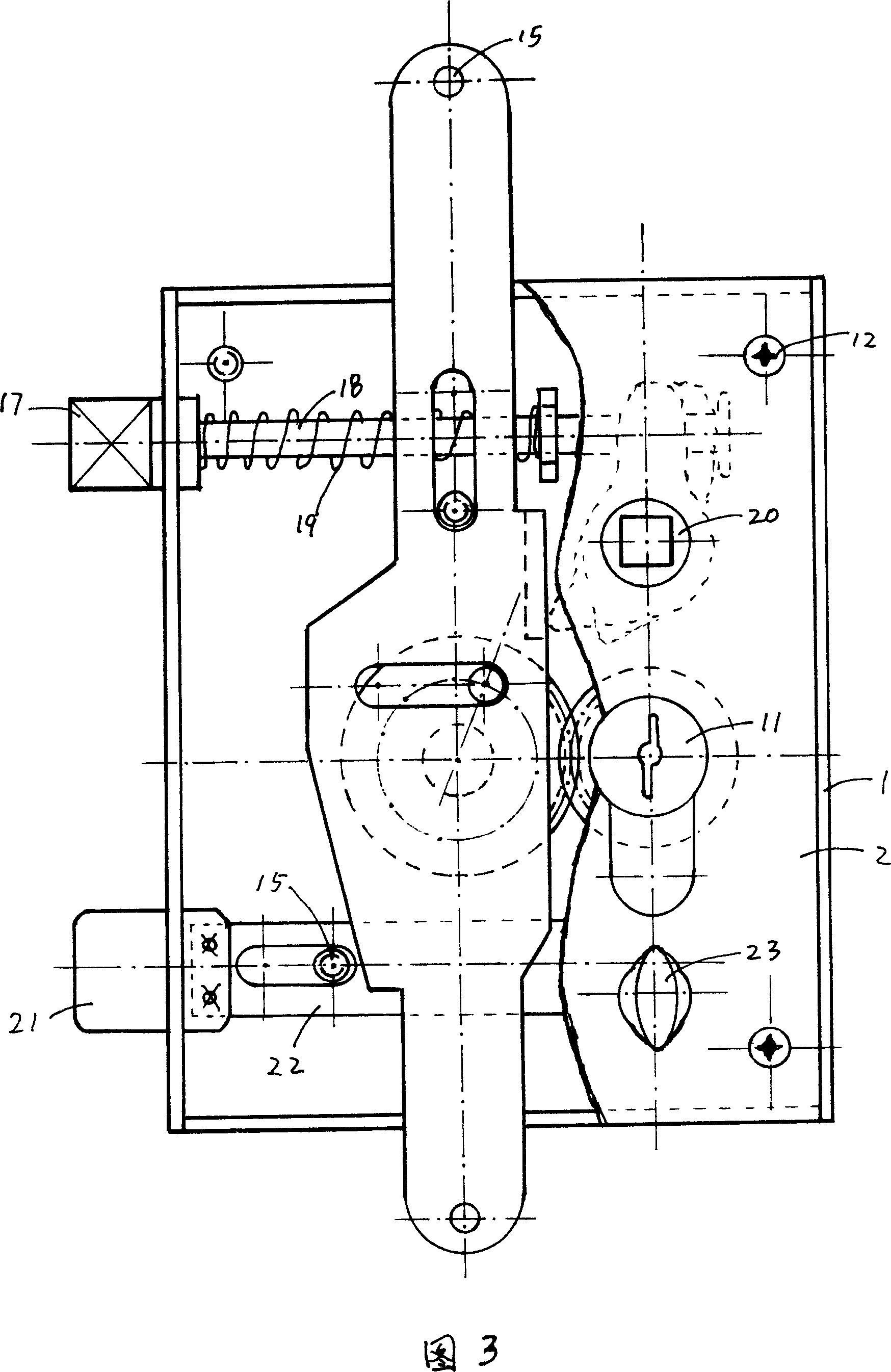

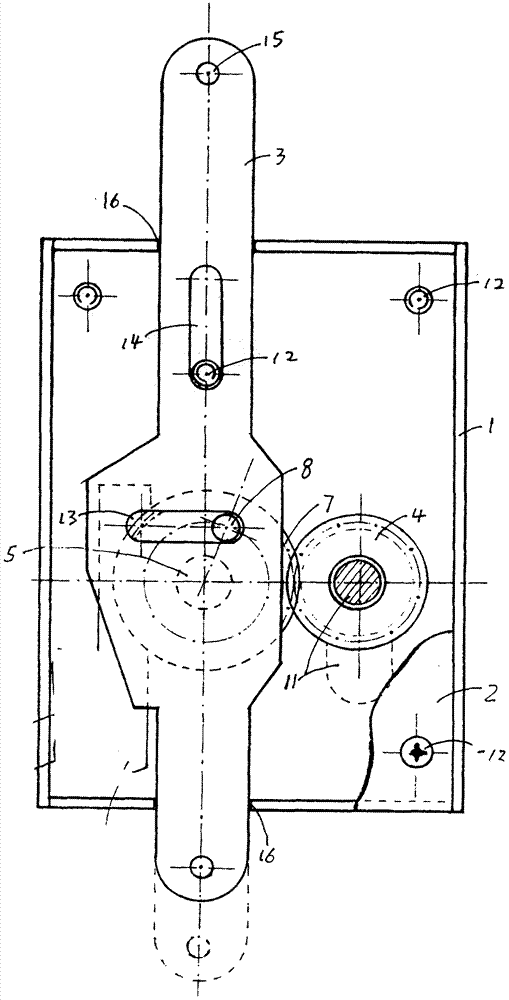

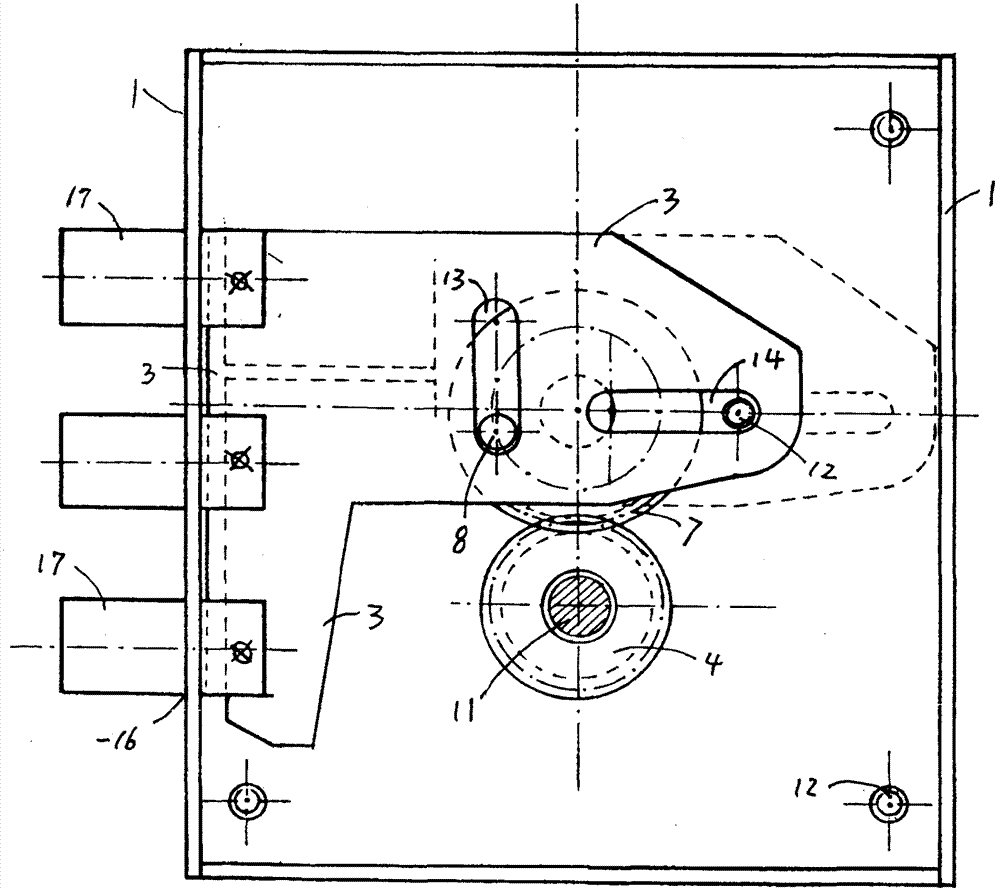

Stress controlled lock in lock

This invention relates to stress balance relation lock, which comprises the following parts: lock case, case cover, main control drive structure, stress executive structure, semi-axis, locking stress axis, reset sensor device. The invention is characterized by the following: the stress executive structure an lock stress axis form mechanic stress relationship through main control drive structure main gear and passive gear; the bearing dial bolt lifts or contracts through stress axis, lock bolt; the passive stress gear axis line and lock stress axis vertical middle line are overlapped to generate lock dead angle at 15 degrees.

Owner:TIANJIN HAIZHOU BRANCH TRADE & IND +1

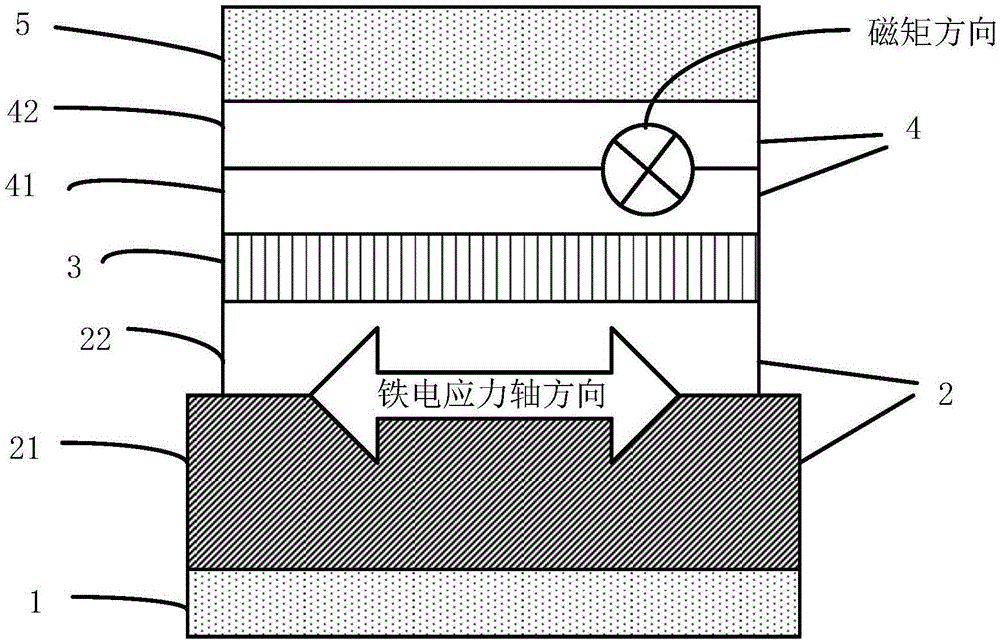

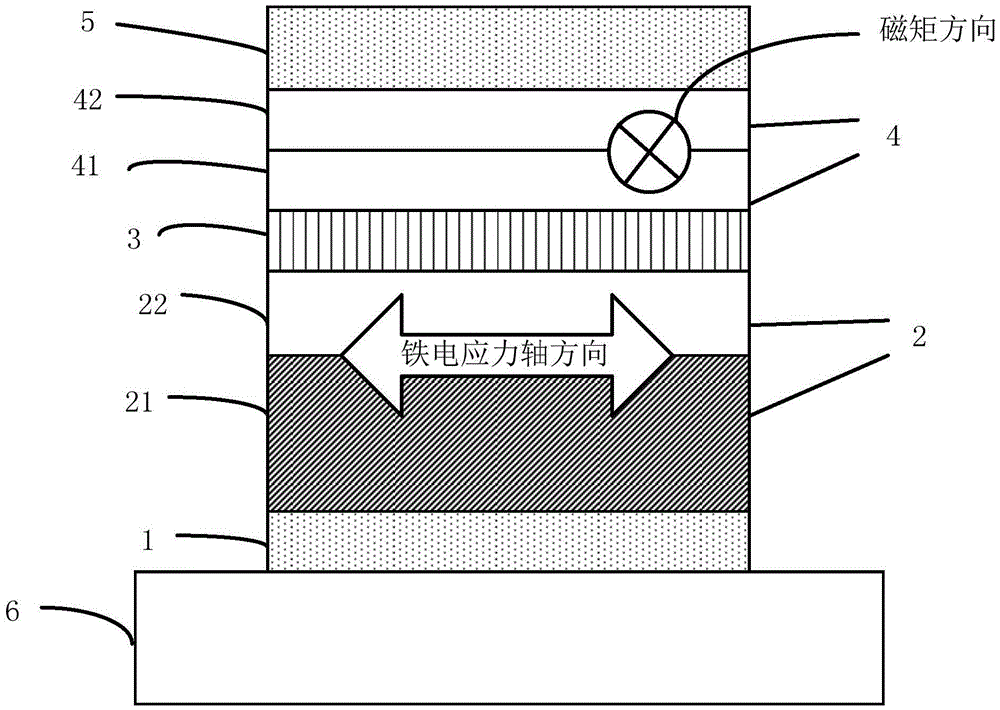

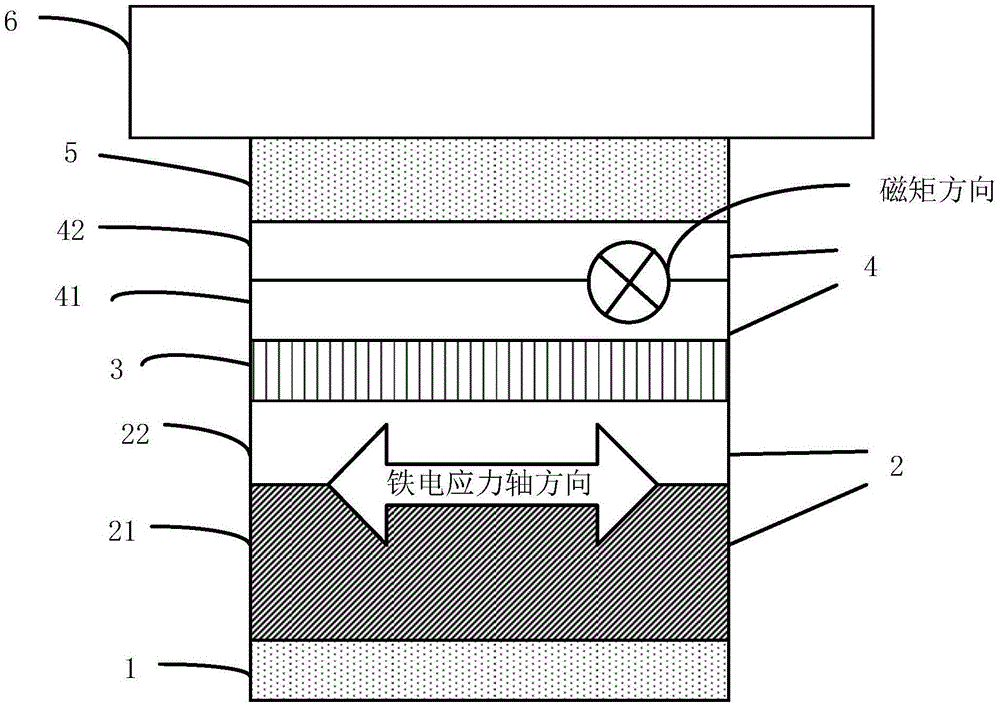

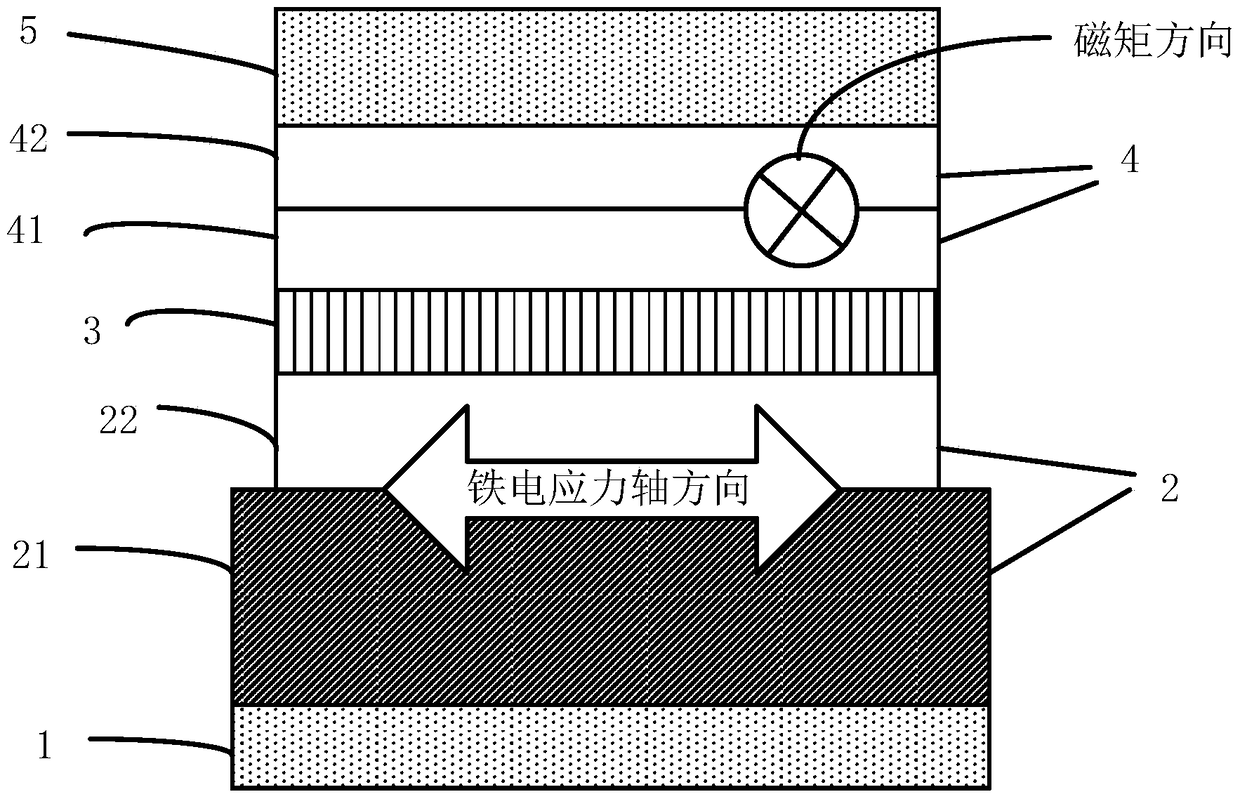

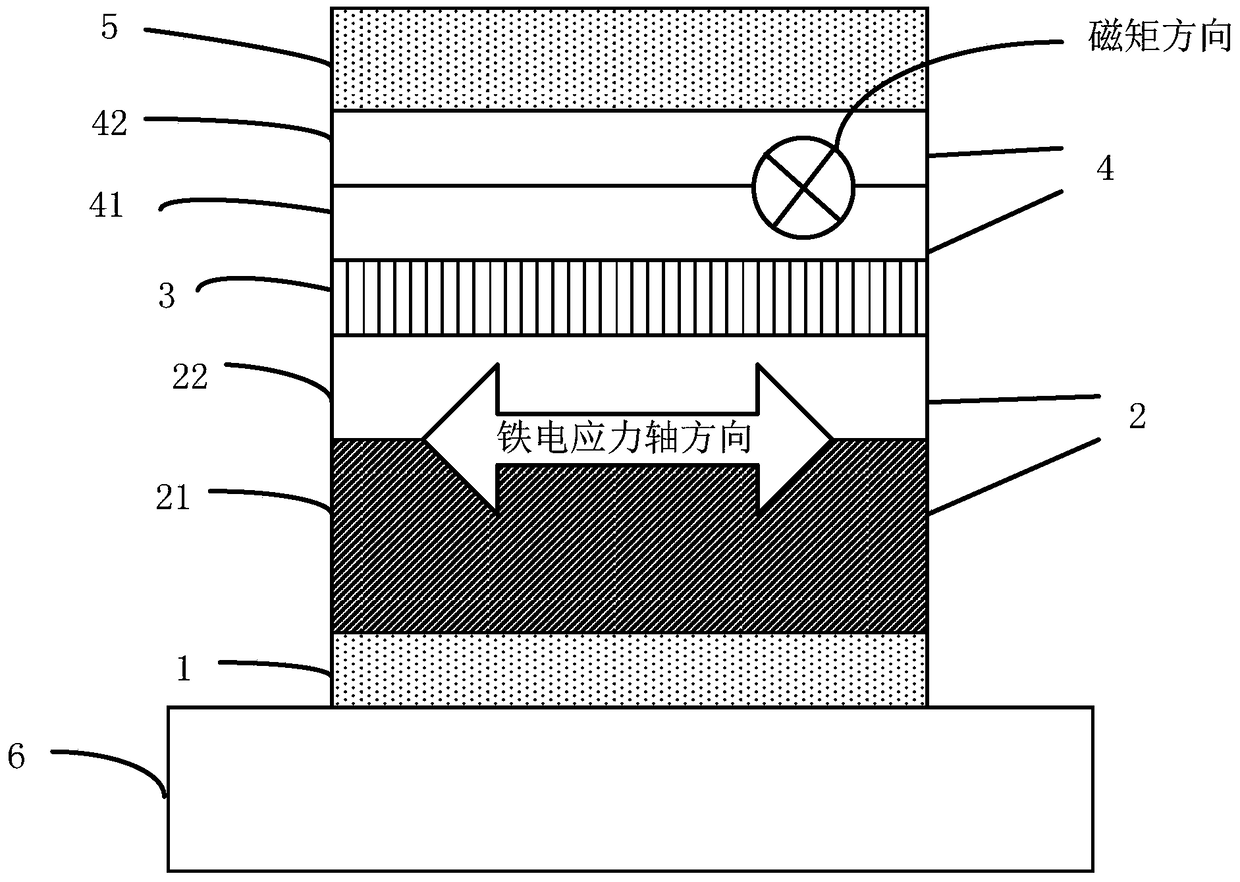

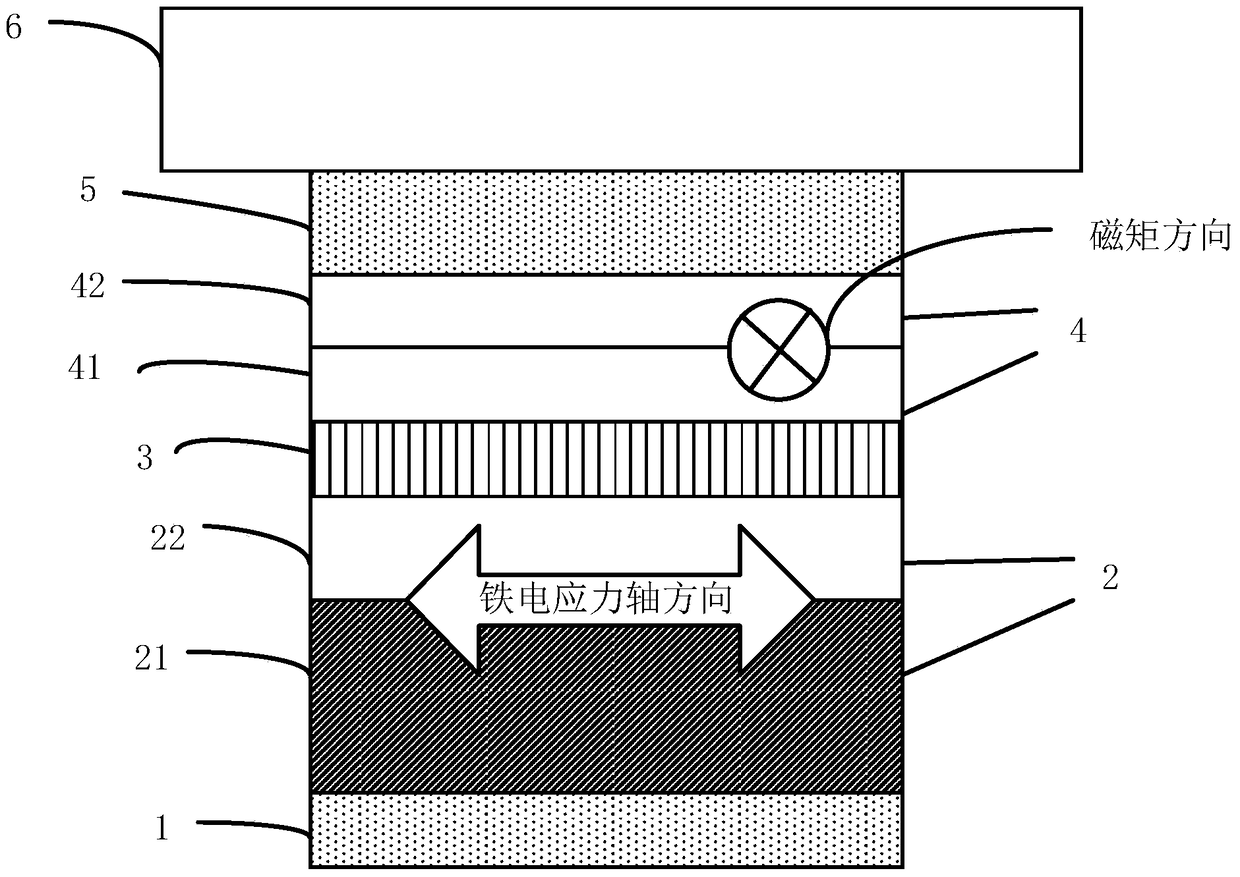

Multi-iron-heterogeneous magnetic field sensor adjustable in measuring range and measuring range adjusting method

ActiveCN105572609ASimple structureSpan adjustmentMagnetic measurementsIsolation layerMetal electrodes

The invention discloses a multi-iron-heterogeneous magnetic field sensor adjustable in measuring range and a measuring range adjusting method. The magnetic field sensor comprises a bottom metal electrode layer, a free layer, an isolation layer, a pinning layer and a top metal electrode layer which are arranged from bottom to top in sequence. The free layer is of a multi-iron-heterogeneous multi-layer structure and comprises a ferroelectric layer and a first ferromagnetic layer from bottom to top in sequence. The pinning layer is of a multi-layer structure and comprises a second ferromagnetic layer and a reverse ferromagnetic layer from bottom to top in sequence. A ferroelectric stress axis direction of the free layer is perpendicular to a magnetic moment direction of the pinning layer in horizontal projection. The measuring range adjusting method comprise the steps that: a measuring range switching voltage V is applied to the ferroelectric layer of the magnetic field sensor, the ferroelectric layer is enabled to generated an electric field stress, the first ferromagnetic layer is under the effect of the electric field stress, and a saturated magnetic field is changed, so that the measuring range of the magnetic field sensor is changed. The invention provides the multi-iron-heterogeneous magnetic field sensor simple in structure, small in size and convenient and flexible, and the measurement precision of the sensor in a low magnetic field is ensured.

Owner:NAT UNIV OF DEFENSE TECH

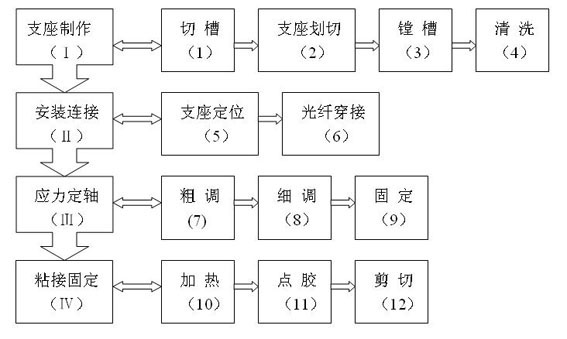

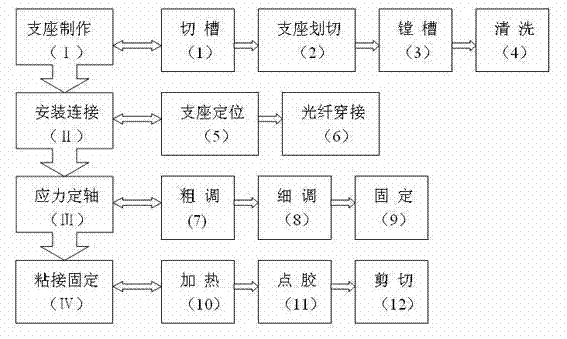

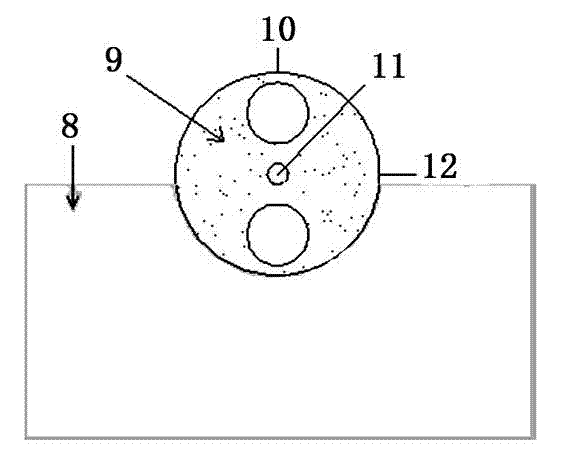

Stress axis fixation method of polarization-maintaining fiber

ActiveCN101923188AHigh precisionHigh extinction ratioOptical fibre with polarisationPolarization-maintaining optical fiberFixation method

The invention relates to the technical field of optical waveguide and polarization-maintaining fiber coupling in integrated optical devices, in particular to a stress axis fixation method of a polarization-maintaining fiber before the polarization-maintaining fiber is bonded with a fiber support. The method comprises the following steps of: (a) connecting an extinction ratio meter to one end of the polarization-maintaining fiber and inputting linearly polarized light with a high extinction ratio to the other end of the polarization-maintaining fiber; (b) applying normal force to the polarization-maintaining fiber in any directions and changing the size of the normal force; and (c) observing a numerical value displayed by the extinction ratio meter to determine the slow axis direction of the polarization-maintaining fiber. The method has the advantages that by applying the working principle to carrying out axis fixation of the polarization-maintaining fiber, the method greatly improves the accuracy of axis fixation, thereby further improving the extinction ratio of the devices.

Owner:上海傲世控制科技股份有限公司

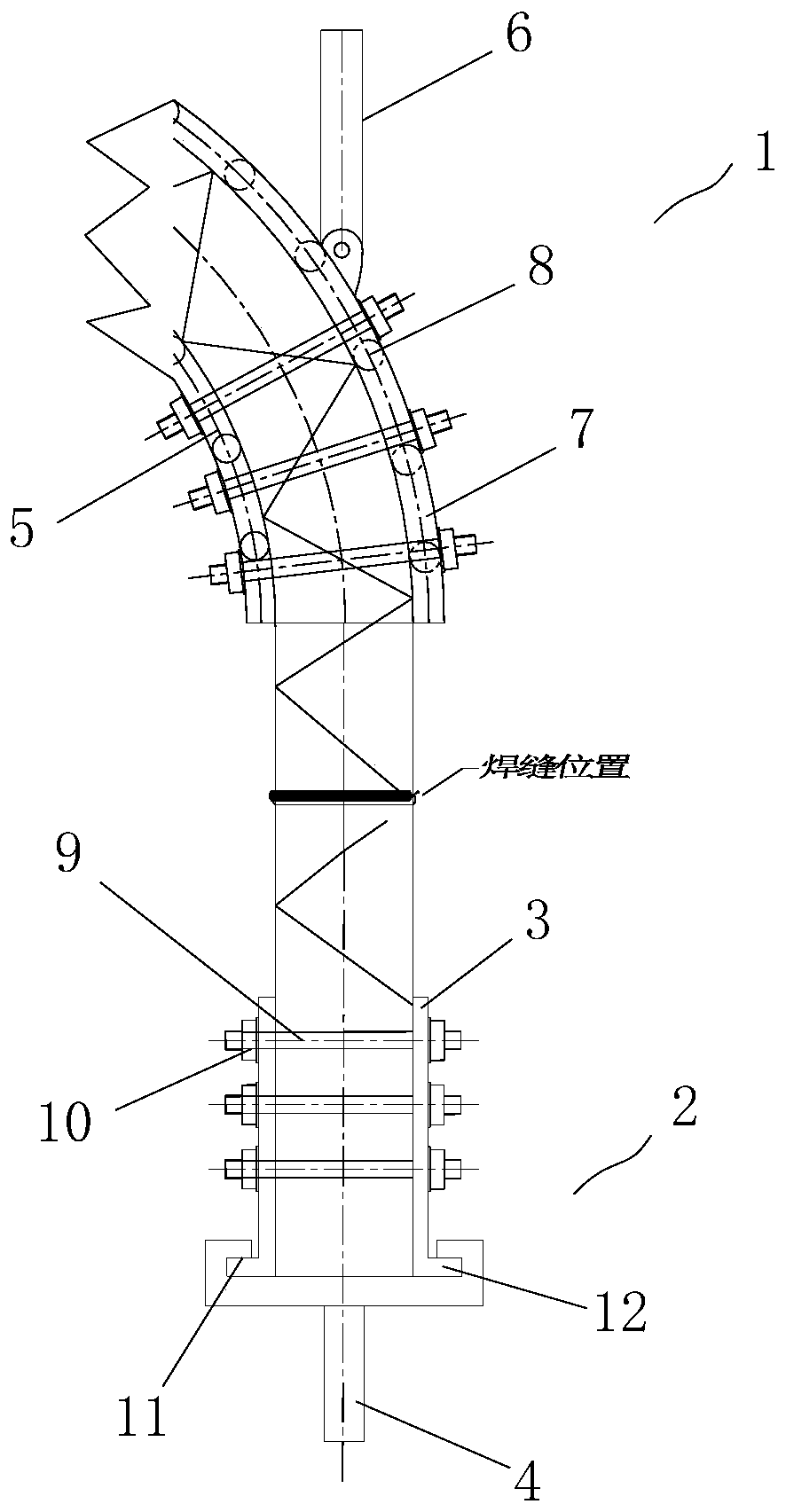

Fatigue testing method for rail transportation vehicle body welding structure

ActiveCN106680118AAccurately measure fatigue levelsEffective immobilizationMaterial strength using repeated/pulsating forcesCombined testTest sample

The invention discloses a fatigue testing method for a rail transportation vehicle body welding structure, and belongs to the technical field of fatigue testing. The method comprises the following steps: 1, making preparations before testing: performing numerical simulation analysis to determine a load value; 2, assembling a test sample and a fixture: rigidly clamping and fixing a straight vehicle body section of the vehicle body welding structure test sample by adopting a rigid clamping end and elastically clamping and fixing an irregularly-shaped vehicle body section by adopting an elastic clamping end, to form a combined test body; 3, fixing the combined test body on a fatigue tester; 4, performing loading test according to the load value; 5, performing detection. According to the method, any shape can be effectively fixed and clamped by rigid and flexible combination, and the actual stress centerline of the welding structure is overlapped with the loading stress axis of the fatigue tester, so that the fatigue level of the rail transportation vehicle body welding structure can be accurately measured.

Owner:辽宁忠旺铝合金精深加工有限公司

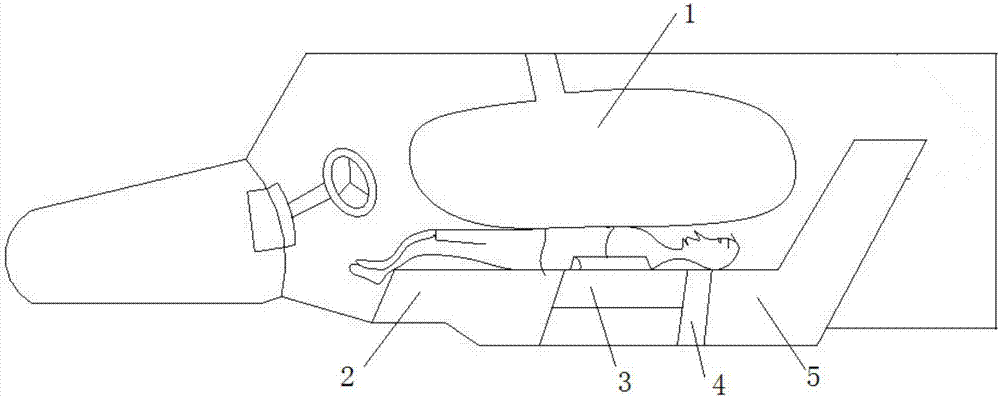

Vertical pressing type automotive airbag

PendingCN107380113AAbsorbs lateral overall impactVehicle seatsPedestrian/occupant safety arrangementRear-end collisionWhole body

The invention discloses a vertical push-down automobile airbag, which comprises an airbag installed on the roof of the automobile. The stress direction of the airbag is a vertical direction from directly above to downward. The force axis, the symmetry axis of the fan-shaped multi-axial force bearing axis is the vertical downward axis. Its stress axis is scattered, and after the impact, it can effectively buffer the overall horizontal impact force in the horizontal direction or close to the horizontal direction. In the event of a car accident, especially when it collides with a large truck or the brake fails, it can effectively protect the human head. Neck, chest and body.

Owner:刘哲

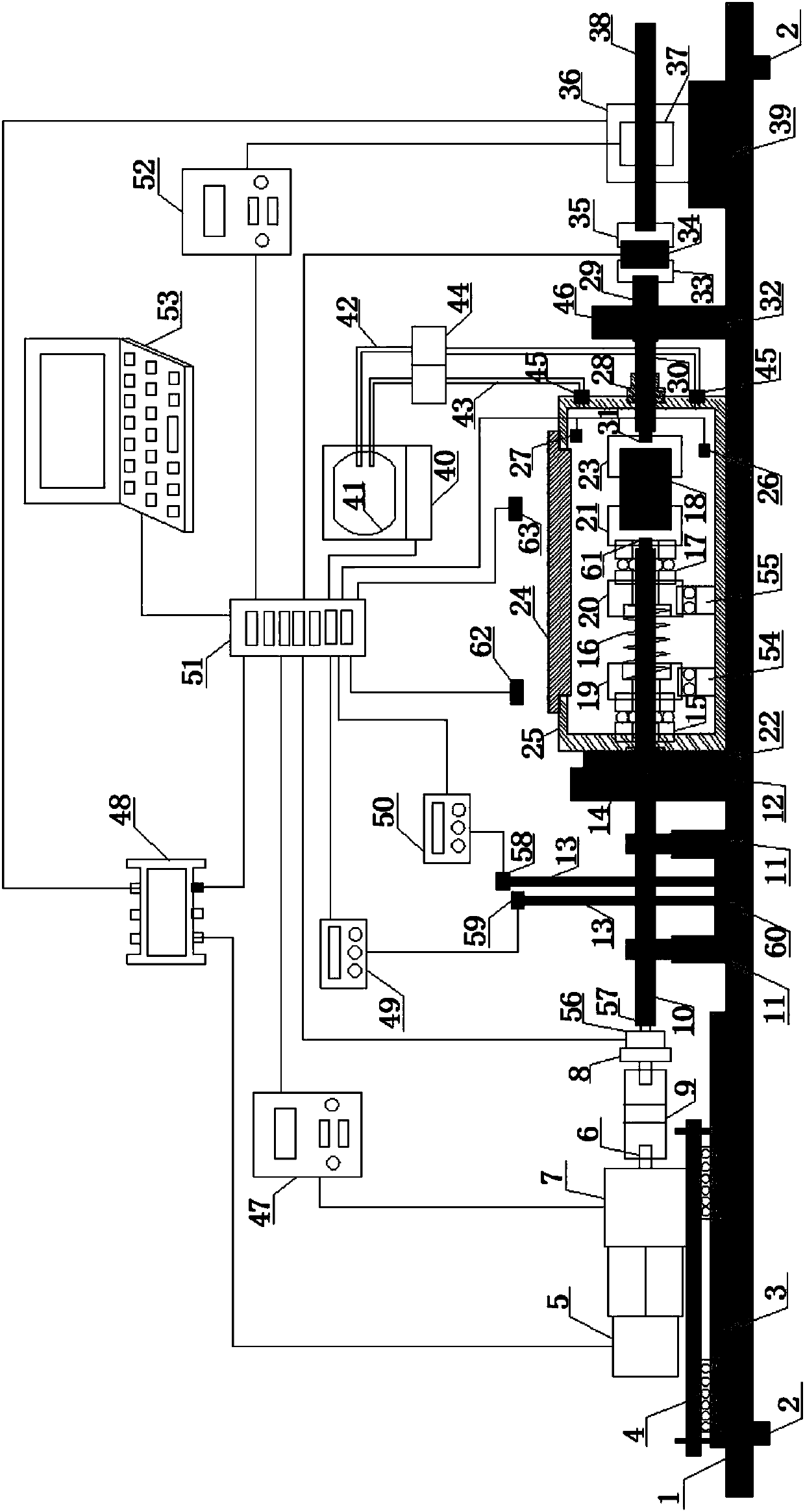

Testing device of pressure-torsion shear failure performance of asphalt mixture

InactiveCN106153462AControl test temperatureReal simulated force stateMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesBall bearingAxial pressure

The invention belongs to the technical field of asphalt mixture shear behavior testing, and relates to a testing device of the pressure-torsion shear failure performance of an asphalt mixture. The device provides a constant-temperature environment through an outer circulating heat preservation system and exerts axial pressure and torsion loads on asphalt mixture test pieces in an independent or combination mode. A dual-layer plane ball bearing is arranged, transmits axial pressure to a left fixed plate and releases torsion loads; a square-section section is arranged at the right end of an axial pressure loading shaft, and torsion loads are borne by a square hole of a right fixed plate; a spring is arranged to buffer axial pressure loads. A torque sensor and a pressure sensor which are completely separated spatially are adopted, the measuring ranges of the two sensors do not need to be matched, and the two sensors do not influence each other. By means of the device, the failure process of the asphalt mixture in the moderate and high temperature environment and the complicated torsion stress state can be simulated; when the torsion loads continuously change, the direction of the main stress axis of a test piece continuously changes, and the change characteristic of the real stress state of a road surface is met.

Owner:DALIAN UNIV OF TECH

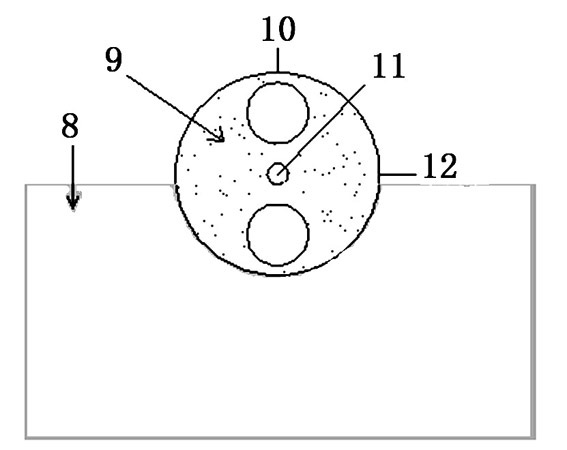

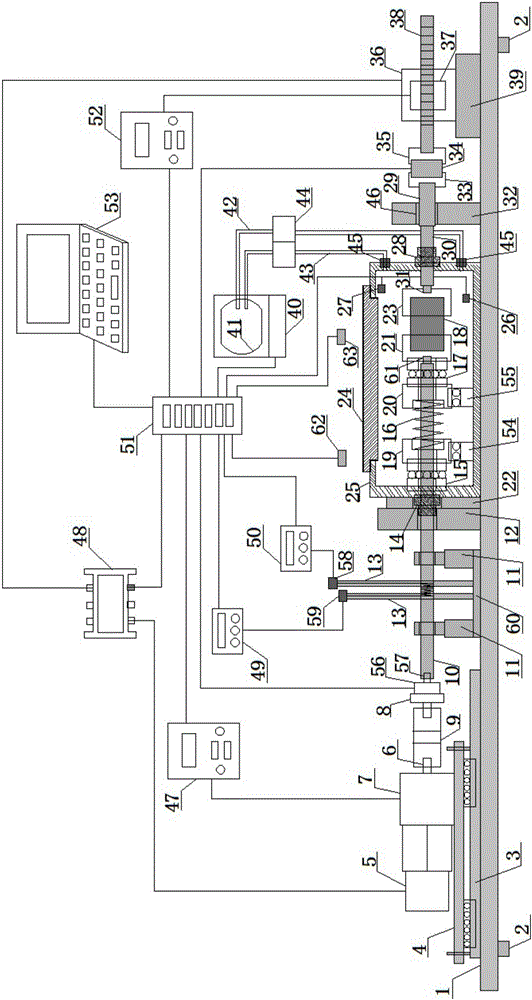

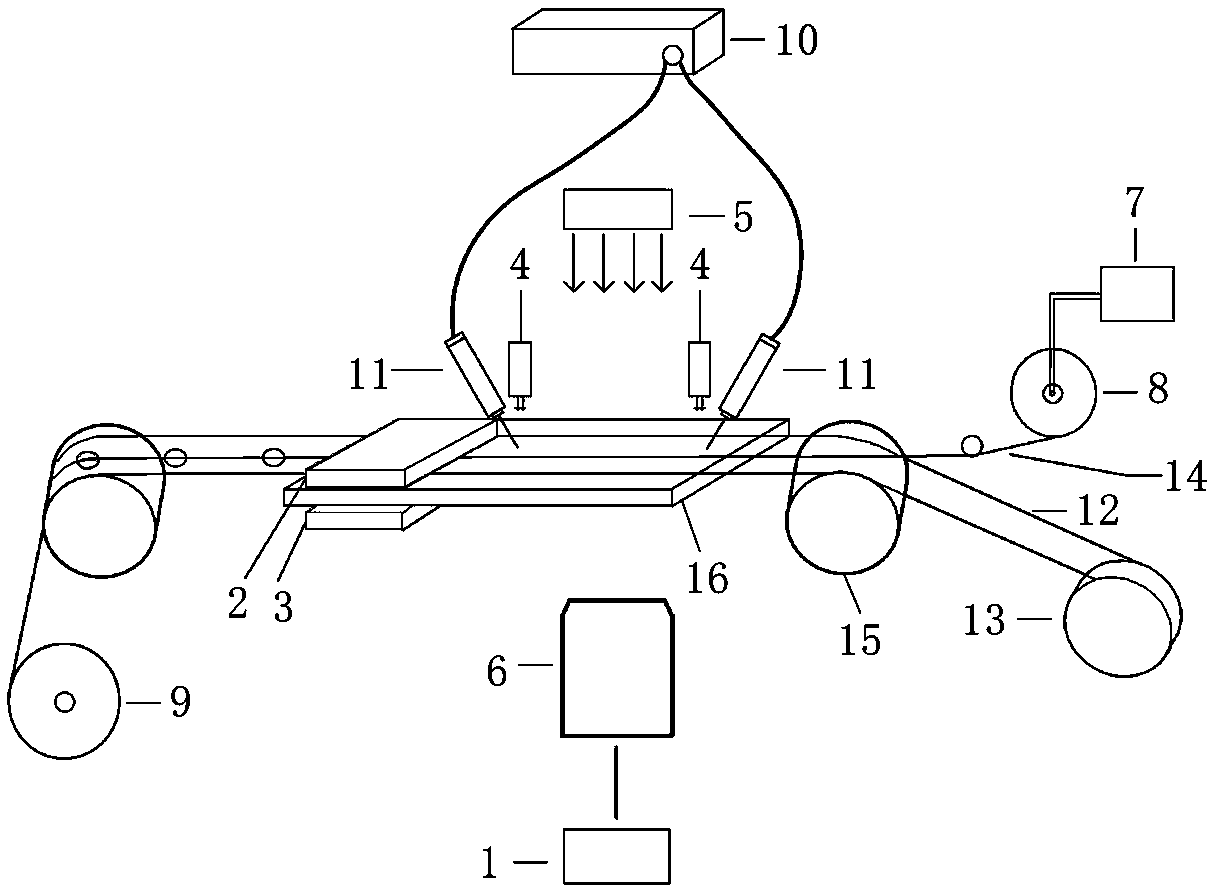

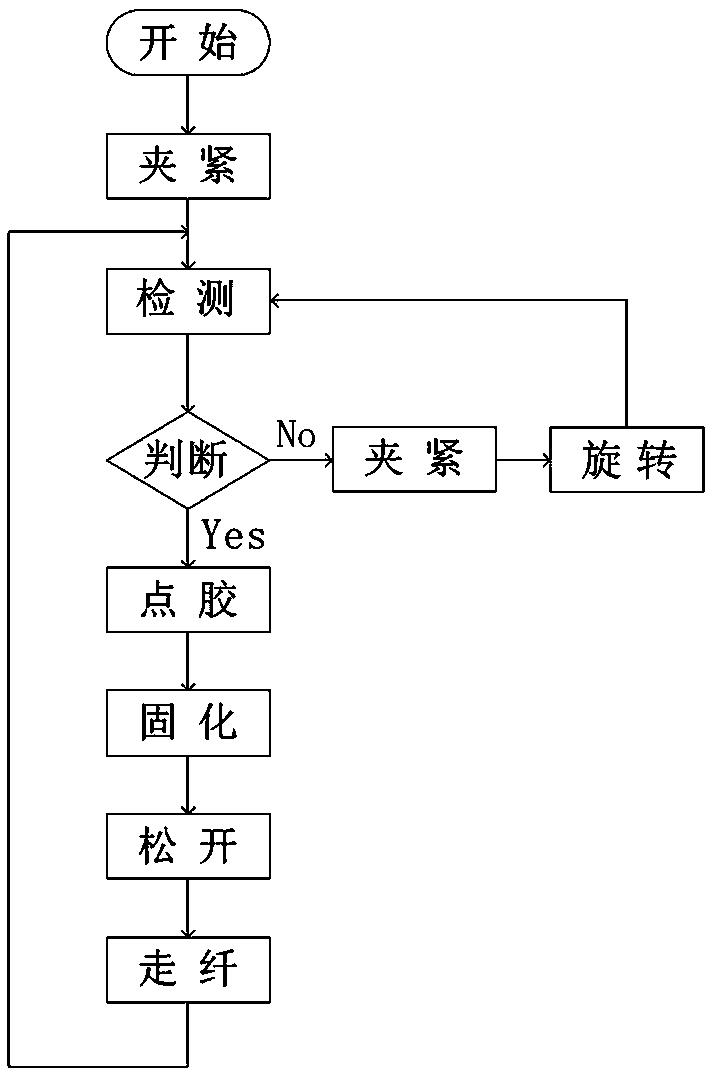

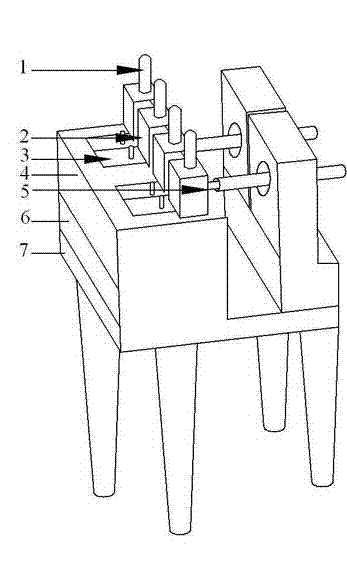

Fixed-axis fiber distributing device of polarization-maintaining optical fiber and method thereof

ActiveCN109883587AHigh precisionHigh light transmittanceOptical fibre with polarisationForce measurement by measuring optical property variationImaging processingPolarization-maintaining optical fiber

The invention provides a fixed-axis fiber distributing device of polarization-maintaining optical fiber and a method thereof. The fixed-axis fiber distributing device of the polarization-maintaining optical fiber comprises a stress axis angle detection mechanism, a stress axis control mechanism, an automatic glue dispensing mechanism, a fiber moving mechanism, an image processing unit and a control unit, wherein the stress axis angle detection mechanism is used for detecting light intensity information of light transmitting through a base belt and the polarization-maintaining optical fiber inreal time; the image processing unit is used for calculating an azimuth angle of an optical fiber stress axis according to the light intensity information; the control unit is used for judging whetherthe azimuth angle of the optical fiber stress axis meets the requirement or not, rotating the angle of optical fiber through the stress axis control mechanism if the azimuth angle of the optical fiber stress axis does not meet the requirement; carrying out a glue dispensing operation through the automatic glue dispensing mechanism if the azimuth angle of the optical fiber stress axis meets the requirement, and subsequently driving the base belt and the optical fiber to move through the fiber moving mechanism. Through the fixed-axis fiber distributing device of polarization-maintaining opticalfiber and the method thereof, the polarization-maintaining optical fiber can be paved on the base belt according to the set angle to form a pressure sensor; the accuracy of a sensing unit of the pressure sensor can be ensured.

Owner:HEBEI UNIVERSITY +1

Multi-wavelength tunable filer based on polarization maintaining chirped fiber grating

InactiveCN105676347AIncrease wavelengthChange penetration depthOptical fibre with polarisationOptical waveguide light guideFrequency spectrumGrating

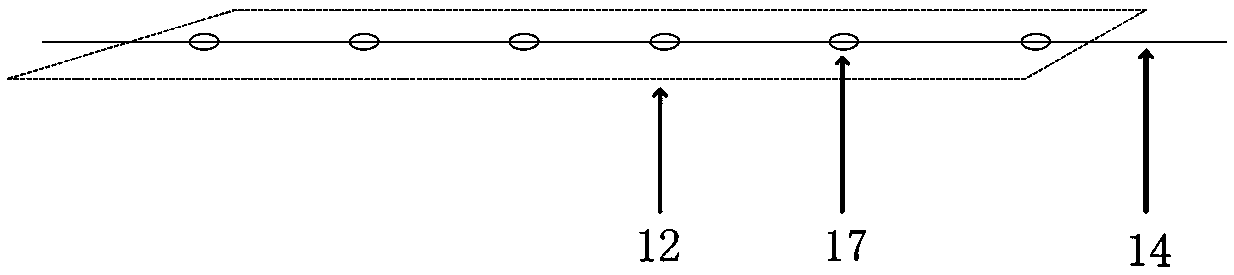

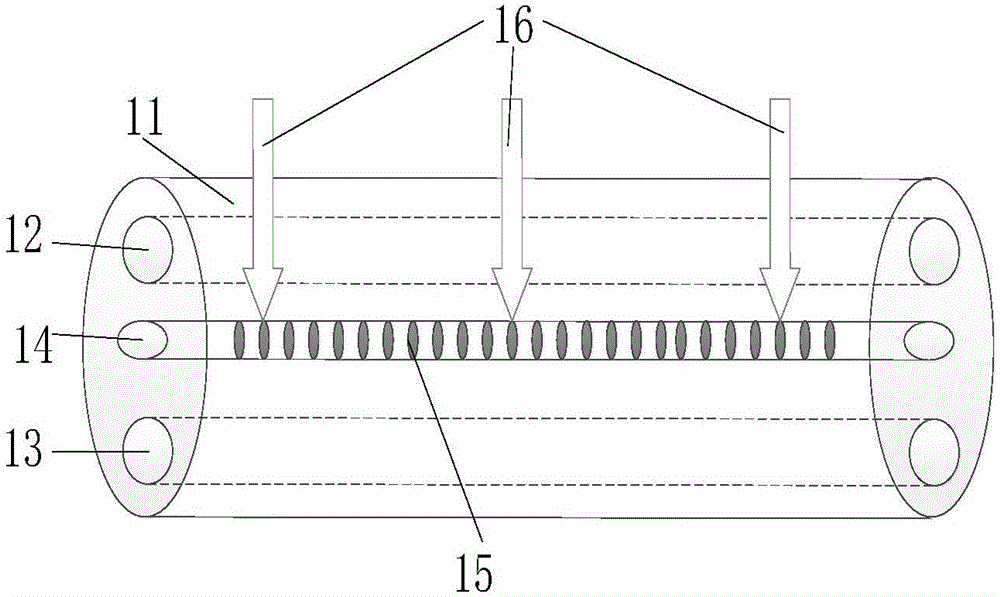

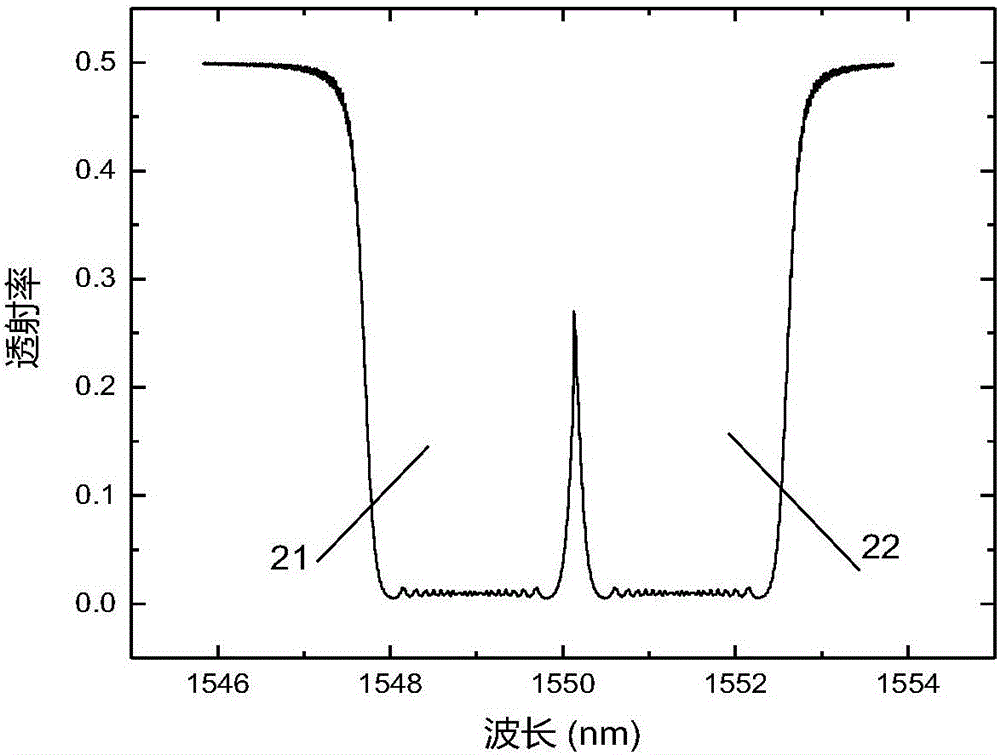

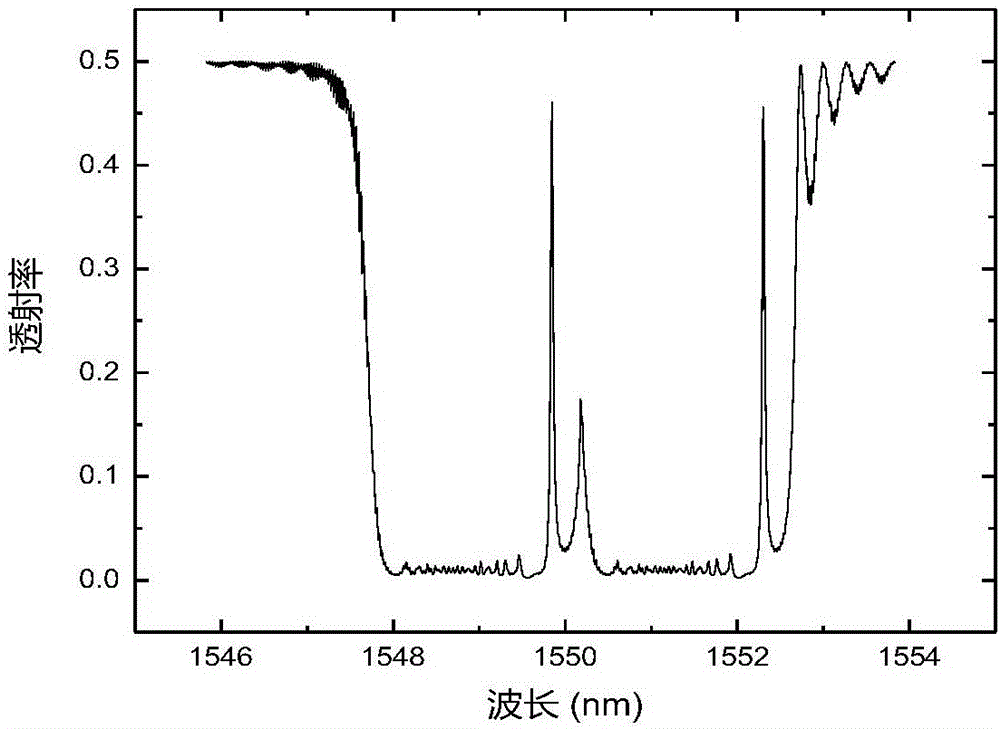

The invention relates to a multi-wavelength filter based on a polarization-maintaining fiber grating, which belongs to the fields of optical fiber communication and instrumentation. A chirped fiber grating (15) is written on a polarization-maintaining fiber (11), and a phase shift (16) is introduced into the chirped fiber grating. Under the action of the stress axis X (12) and the stress axis Y (13) of the polarization-maintaining fiber, the refractive index of the fiber core (14) on the X-axis and the Y-axis is different, forming birefringence, from the polarization-maintaining chirped fiber grating ( The spectrum of 15) has two mutually symmetrical polarization transmission peaks (21) and (22), and the bandwidth of each polarization transmission peak is consistent with the bandwidth of a chirped fiber grating on an ordinary optical fiber. When a phase shift (16) is introduced into the chirped fiber grating (15), corresponding extremely narrow narrow The position of the slit in the bandwidth range can be changed by changing the position of the phase shift introduced, and the transmission depth of the slit can be changed by changing the phase shift amount θ introduced by the phase shift, and the filter wavelength of the slit can also be finely adjusted at the same time, changing The number m of phase shifts can be introduced to change the filtering number of the filter.

Owner:BEIJING JIAOTONG UNIV

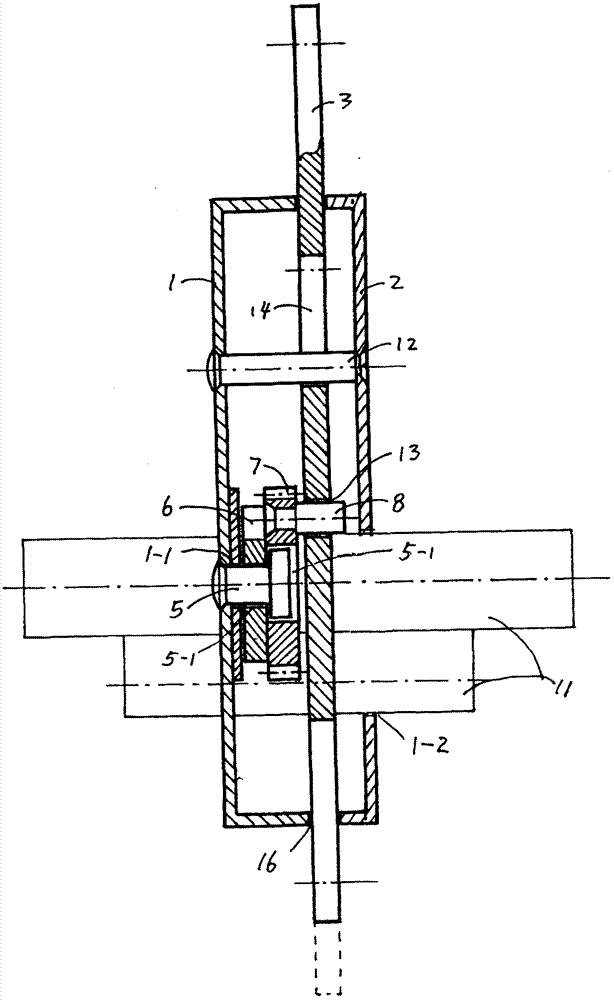

Lead screw guiding device

InactiveCN103411823AGuaranteed accuracyMeet the requirements of coaxialityStrength propertiesScrew threadStress axis

The invention discloses a lead screw guiding device used on a testing machine. The lead screw guiding device comprises an upper cross beam and a lead screw; the lead screw comprises a lead screw thread part and a positioning shaft part; the lead screw guiding device is characterized in that a guiding positioning hole matched with the positioning shaft part is formed in the upper cross beam; the positioning shaft part is arranged in the guiding positioning hole; a bearing hole is formed in the inner upper end of the guiding positioning hole; a self-lubricating bearing is mounted in the bearing hole; a bearing end cover is arranged at the upper end of the self-lubricating bearing; the bearing end cover is fixedly connected with the upper cross beam through bolts. The lead screw guiding device is simple in structure; the arrangement of the self-lubricating bearing ensures the accuracy in positioning and guiding of the lead screw, so that the coaxiality requirement of a stress axis and a host axis during the testing process of a sample can be met, and simultaneously, the friction received by the upper cross beam during the up and down movement process can be reduced.

Owner:JINAN KEHUI TESTING INSTR

Pulling force metering device for micro-force value measuring instrument

ActiveCN105115661AGuaranteed Calibration MetrologyHas social promotion valueForce/torque/work measurement apparatus calibration/testingPull forceMeasuring instrument

The invention provides a pulling force metering device for a micro-force value measuring instrument. The device comprises an equal arm balance, and the equal arm balance comprises a balance cross beam, a left pallet and a right pallet. The right side of the balance cross beam is provided with a light support, and the lower part of the light support is provided with a small hole through drilling. The central axis of the small hole is required to be consistent with a stress axis of a right edge of the equal arm balance. A working platform is fixed above the right pallet, and is provided with a three-dimensional workbench. The micro-force value measuring instrument is fixed on the three-dimensional workbench, and a force bearing point of the micro-force value measuring instrument is connected with a balance hook for hooking the right pallet through a fine rope. The device can guarantee that the pulling force metering of the micro-force value measuring instrument with the range from 2mN to 10N meets force value metering requirements, and solves a key technical difficulty in building a (pulling) metering standard device for the verification / correction of the micro-force value measuring instrument.

Owner:JIANGXI HONGDU AVIATION IND GRP

A test device for compressive torsional shear failure performance of asphalt mixture

InactiveCN106153462BControl test temperatureMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesBall bearingAxial pressure

The invention belongs to the technical field of asphalt mixture shear behavior testing, and relates to a testing device of the pressure-torsion shear failure performance of an asphalt mixture. The device provides a constant-temperature environment through an outer circulating heat preservation system and exerts axial pressure and torsion loads on asphalt mixture test pieces in an independent or combination mode. A dual-layer plane ball bearing is arranged, transmits axial pressure to a left fixed plate and releases torsion loads; a square-section section is arranged at the right end of an axial pressure loading shaft, and torsion loads are borne by a square hole of a right fixed plate; a spring is arranged to buffer axial pressure loads. A torque sensor and a pressure sensor which are completely separated spatially are adopted, the measuring ranges of the two sensors do not need to be matched, and the two sensors do not influence each other. By means of the device, the failure process of the asphalt mixture in the moderate and high temperature environment and the complicated torsion stress state can be simulated; when the torsion loads continuously change, the direction of the main stress axis of a test piece continuously changes, and the change characteristic of the real stress state of a road surface is met.

Owner:DALIAN UNIV OF TECH

A multiferroic heterogeneous magnetic field sensor with adjustable range and its range adjustment method

ActiveCN105572609BSimple structureSpan adjustmentMagnetic measurementsIsolation layerMetal electrodes

The invention discloses a multi-iron-heterogeneous magnetic field sensor adjustable in measuring range and a measuring range adjusting method. The magnetic field sensor comprises a bottom metal electrode layer, a free layer, an isolation layer, a pinning layer and a top metal electrode layer which are arranged from bottom to top in sequence. The free layer is of a multi-iron-heterogeneous multi-layer structure and comprises a ferroelectric layer and a first ferromagnetic layer from bottom to top in sequence. The pinning layer is of a multi-layer structure and comprises a second ferromagnetic layer and a reverse ferromagnetic layer from bottom to top in sequence. A ferroelectric stress axis direction of the free layer is perpendicular to a magnetic moment direction of the pinning layer in horizontal projection. The measuring range adjusting method comprise the steps that: a measuring range switching voltage V is applied to the ferroelectric layer of the magnetic field sensor, the ferroelectric layer is enabled to generated an electric field stress, the first ferromagnetic layer is under the effect of the electric field stress, and a saturated magnetic field is changed, so that the measuring range of the magnetic field sensor is changed. The invention provides the multi-iron-heterogeneous magnetic field sensor simple in structure, small in size and convenient and flexible, and the measurement precision of the sensor in a low magnetic field is ensured.

Owner:NAT UNIV OF DEFENSE TECH

Stock bin weighing device

InactiveCN103968929AAdjust levelImprove aestheticsWeighing apparatus detailsWeighing apparatus for materials with special property/formEngineeringLoad cell

The invention relates to a stock bin weighing device. The upper end and the lower end of a column type weighing sensor are provided with a bearing head and a connecting head respectively, external threads are formed on the bearing head and the connecting head, the bearing head is in threaded connection with an upper flange plate, a bearing table is connected at the upper end of the upper flange plate, the upper end of the bearing table is provided with a retractable locating step, the connecting head is in threaded connection with a lower flange plate, a supporting seat is connected with the lower end of the lower flange plate, the bottom surface of the supporting seat is oblique relative to the horizontal plane, and a tubular landing leg at the bottom of the stock bin is arranged on the locating step of the bearing table in a sleeved mode for welding on site conveniently, therefore, the aesthetic degree and the connecting strength are improved; the bottom surface of the supporting seat is seated on the ground of the installation site, the stressed axis of the column type weighing sensor in the weighing device is coincided with the stressed direction of the landing leg, so that the influence of lateral force caused by inconsistence of the stressed direction of the tubular landing leg and the weighing sensor is eliminated; and the column type weighing sensor and the upper flange plate or the lower flange plate rotate oppositely, therefore, a distance between the upper flange plate and the lower flange plate can be accurately and conveniently adjusted.

Owner:BENGBU SUNMOON ELECTRONICS TECH

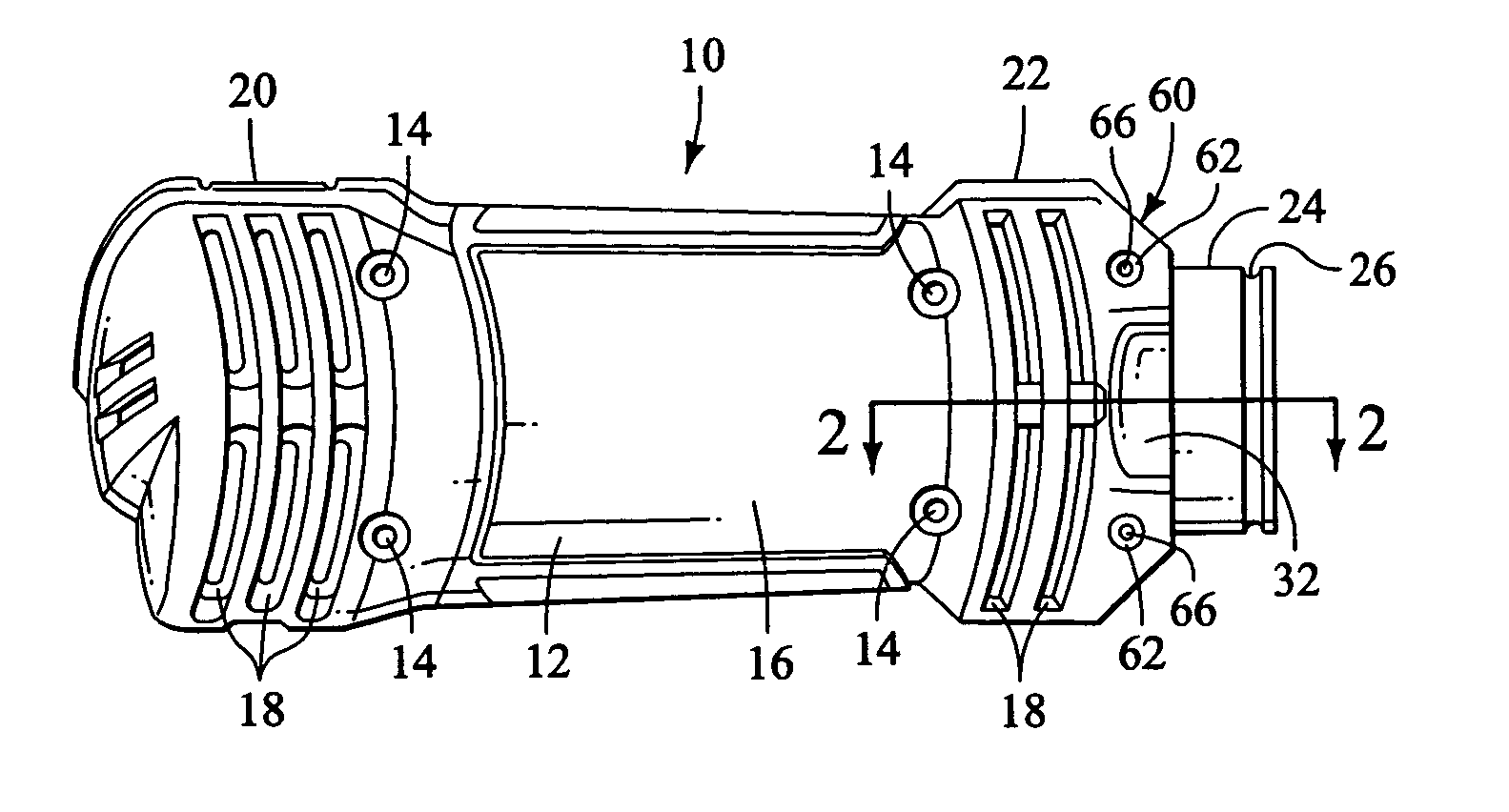

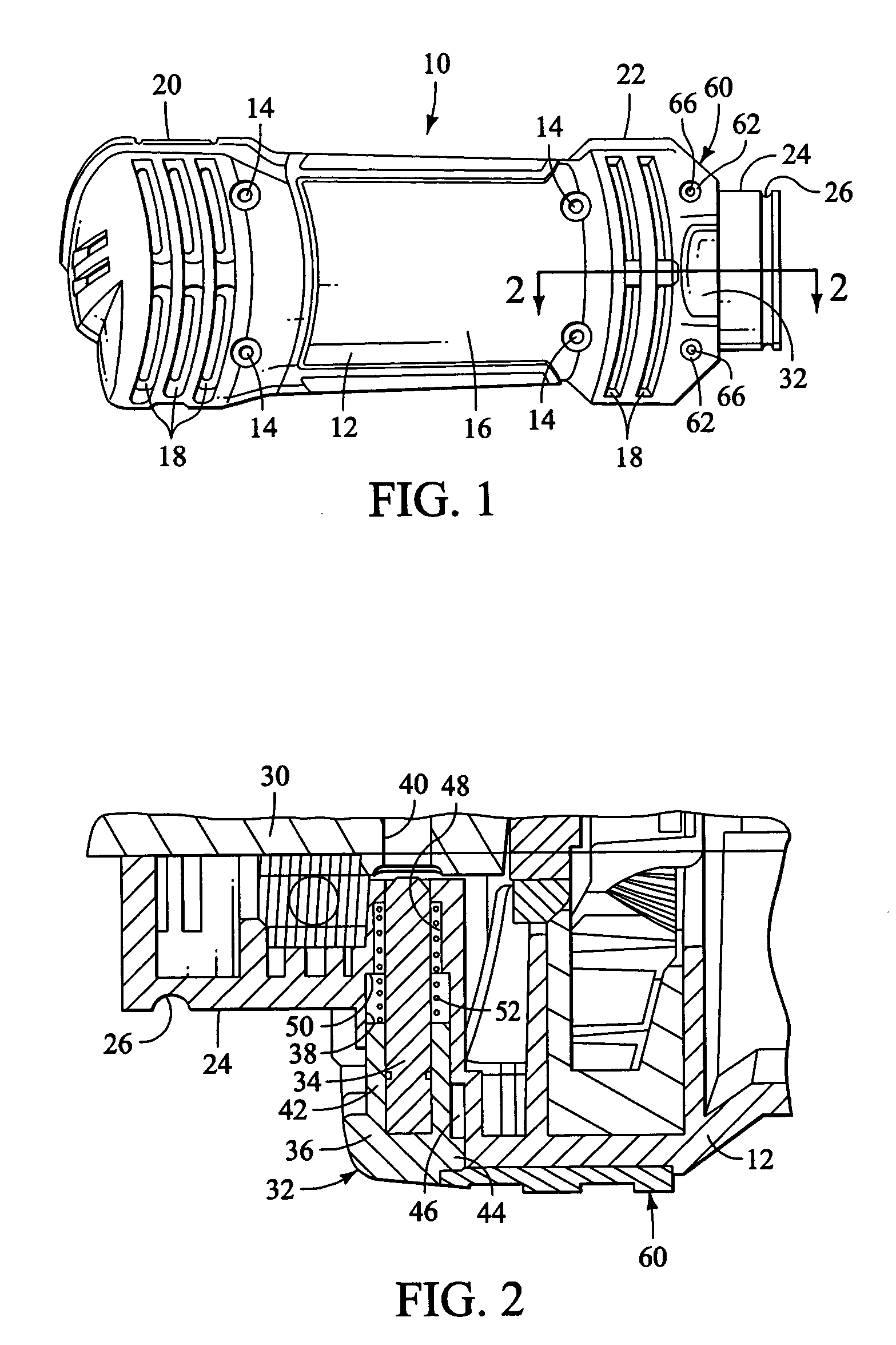

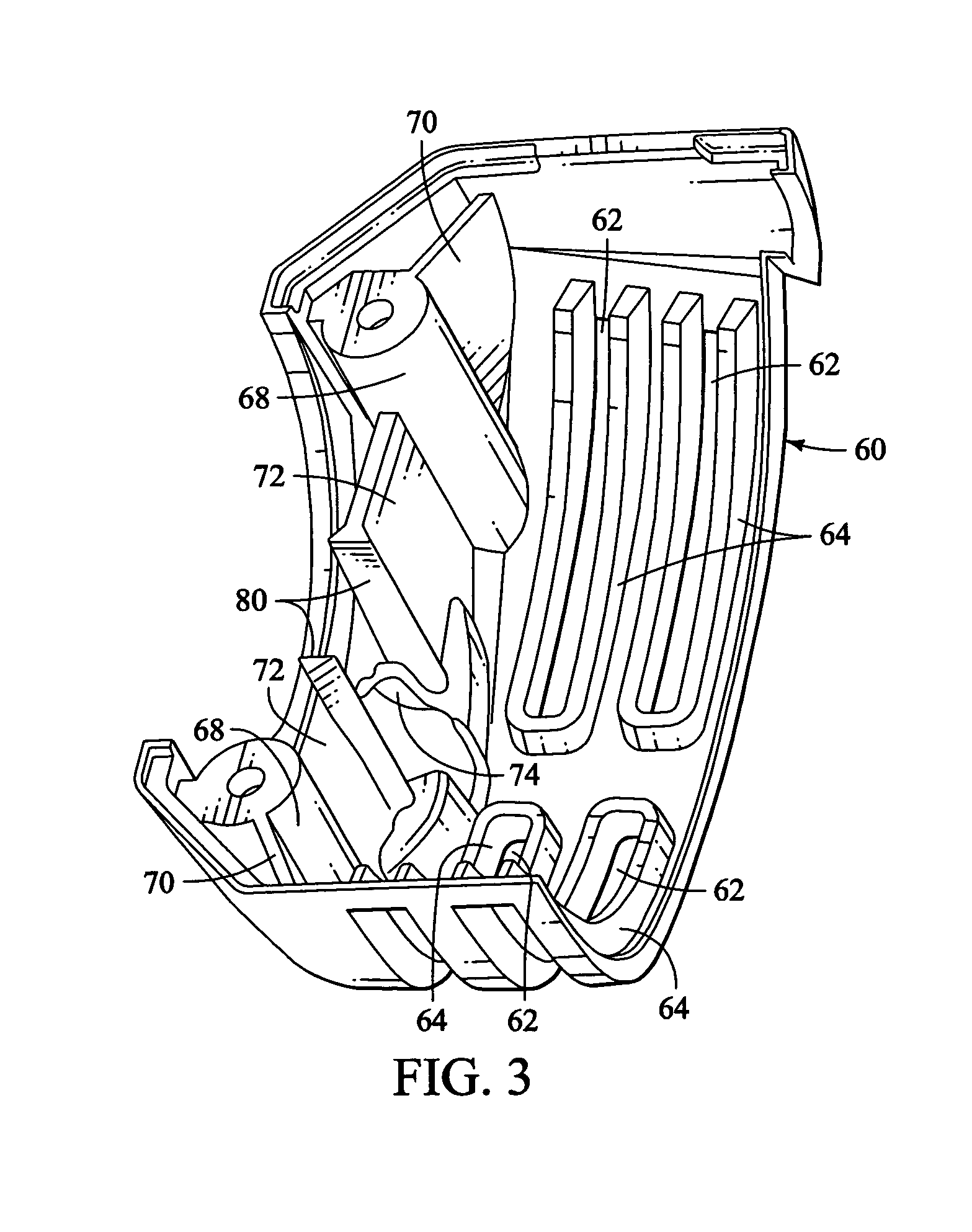

Shaft lock mechanism for a rotary power hand tool

InactiveUS20050051348A1Easily assembled and retainedDrilling rodsConstructionsLocking mechanismElectric machinery

A preferred embodiment comprises a power hand tool of the type which has a generally cylindrical elongated plastic housing with a motor contained within the housing and having an output shaft that extends from the front end portion of the hand tool, and which has a metal front end portion that cooperates with the plastic housing to strengthen a shaft locking mechanism located at the front end of the hand tool. The metal front end portion not only strengthens the outer surface of the housing in the front end portion of the tool, but also has a pair of internal structural ribs positioned to absorb stress that may be present in the housing as a result of force applied to the shaft locking mechanism. The preferred embodiment is also designed to enable the shaft locking pin mechanism to be easily assembled and retained without the need for an E-clip or C-clip as is commonly the practice in commercially available spiral saw hand tools.

Owner:CREDO TECH CORP

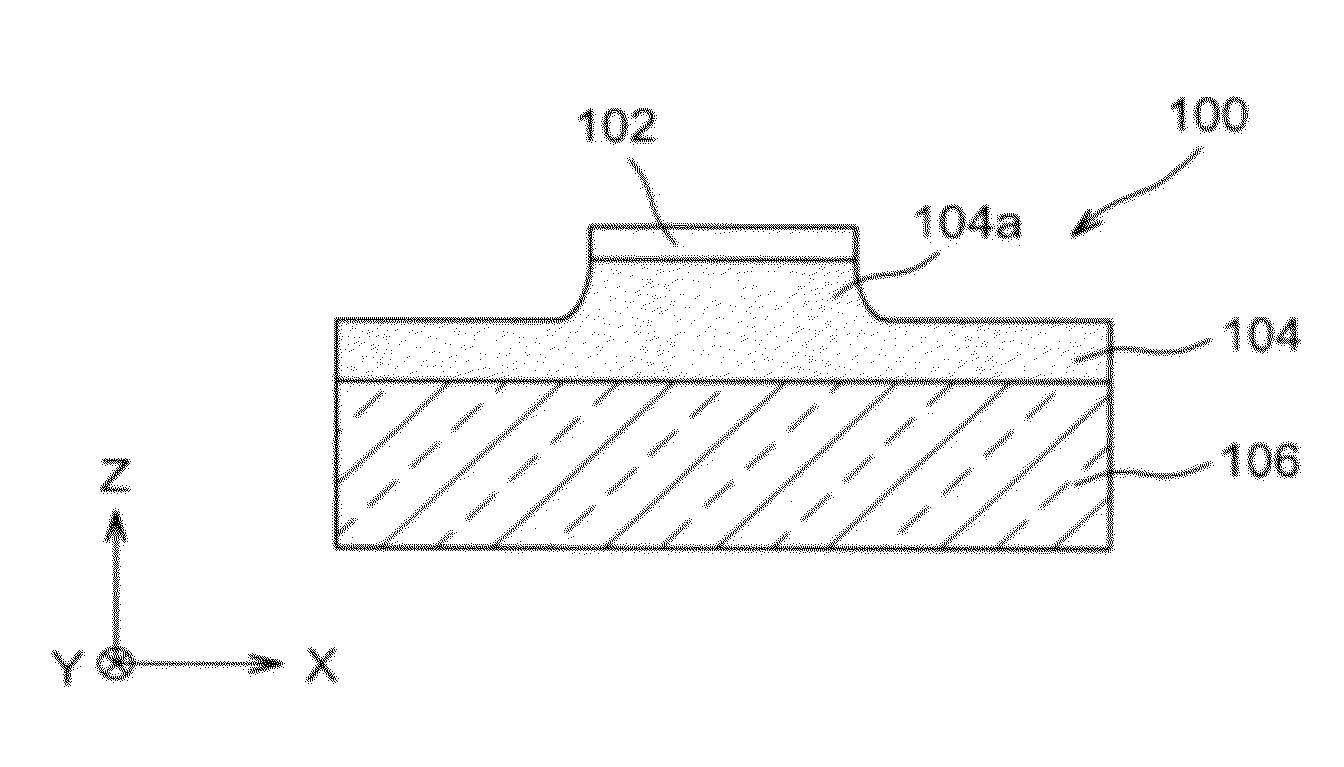

Method for making semi-conductor nanocrystals oriented along a predefined direction

A method for making a semi-conductor nanocrystals, including at least the steps of:making a stack of at least one uniaxially stressed semi-conductor thin layer and a dielectric layer,annealing the semi-conductor thin layer such that a dewetting of the semi-conductor forms, on the dielectric layer, elongated shaped semi-conductor nanocrystals oriented perpendicularly to the stress axis.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

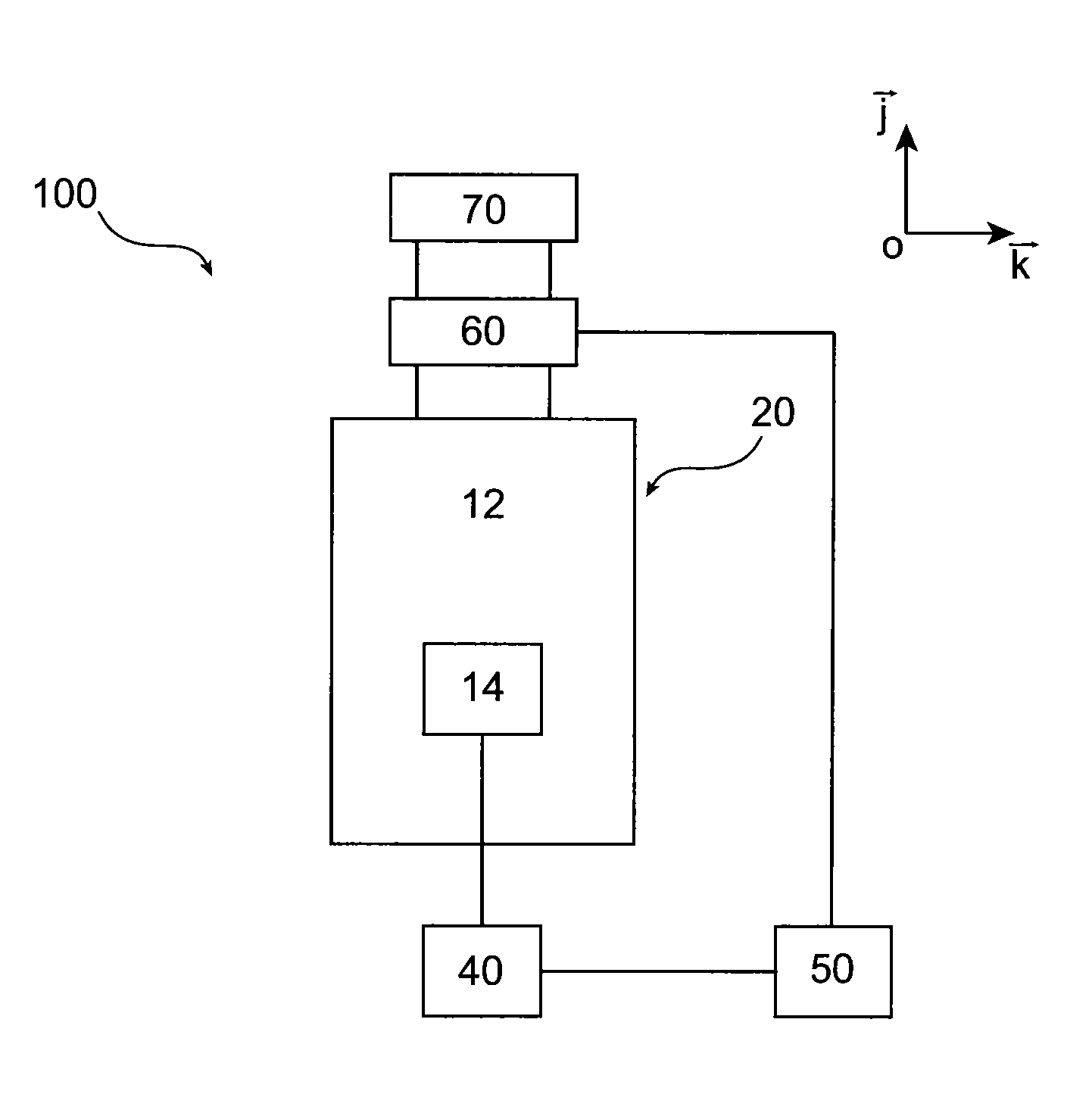

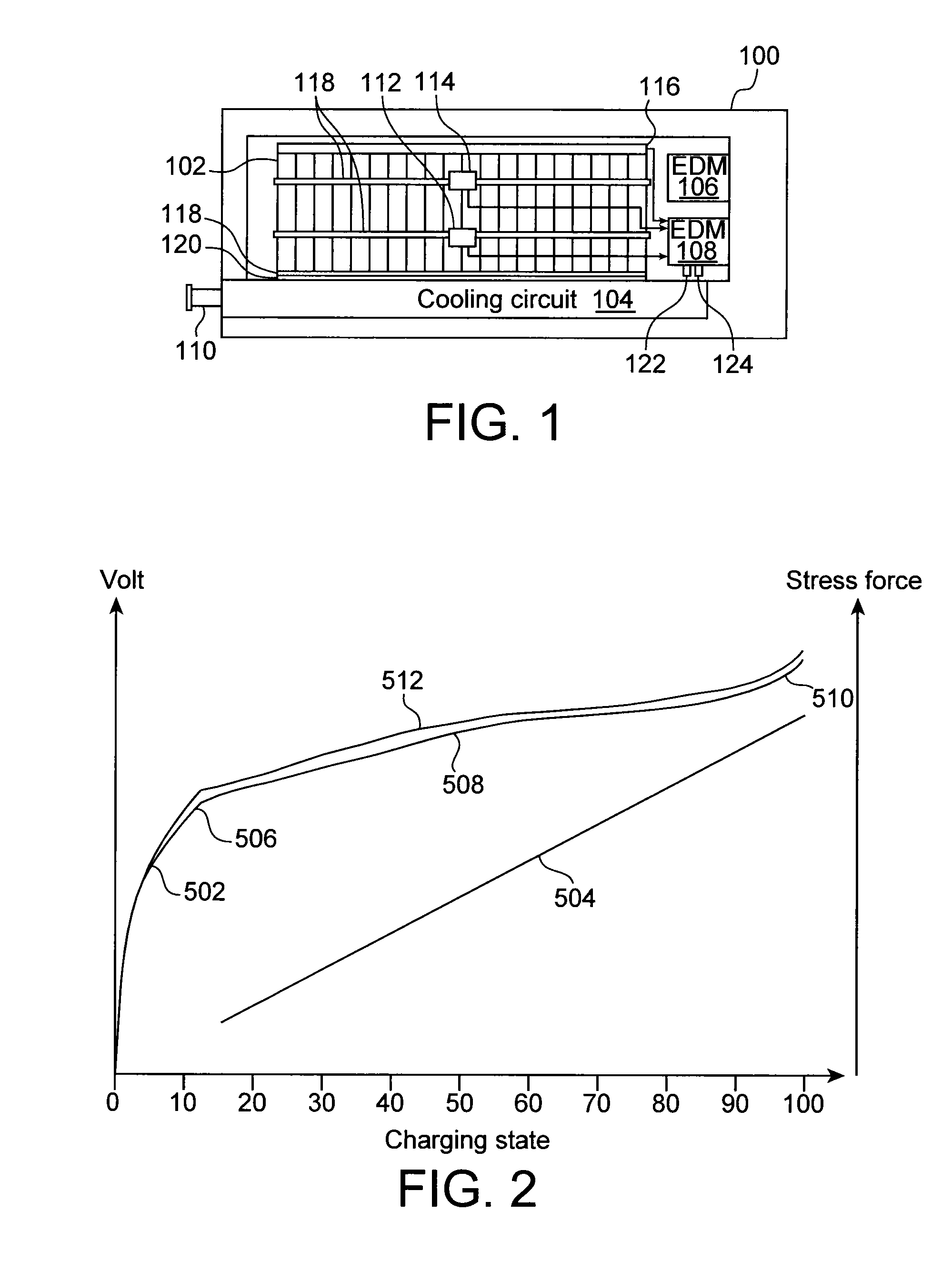

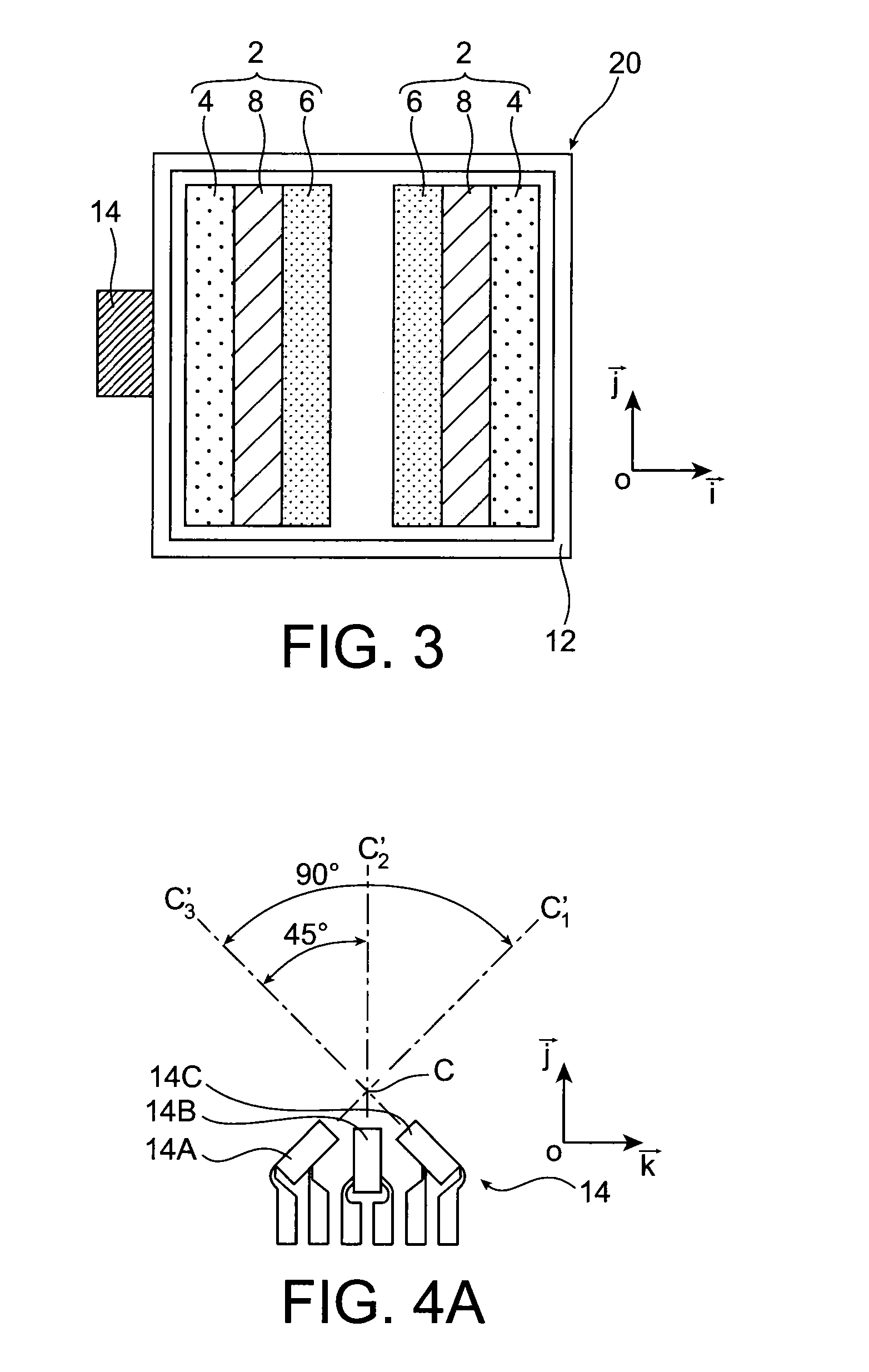

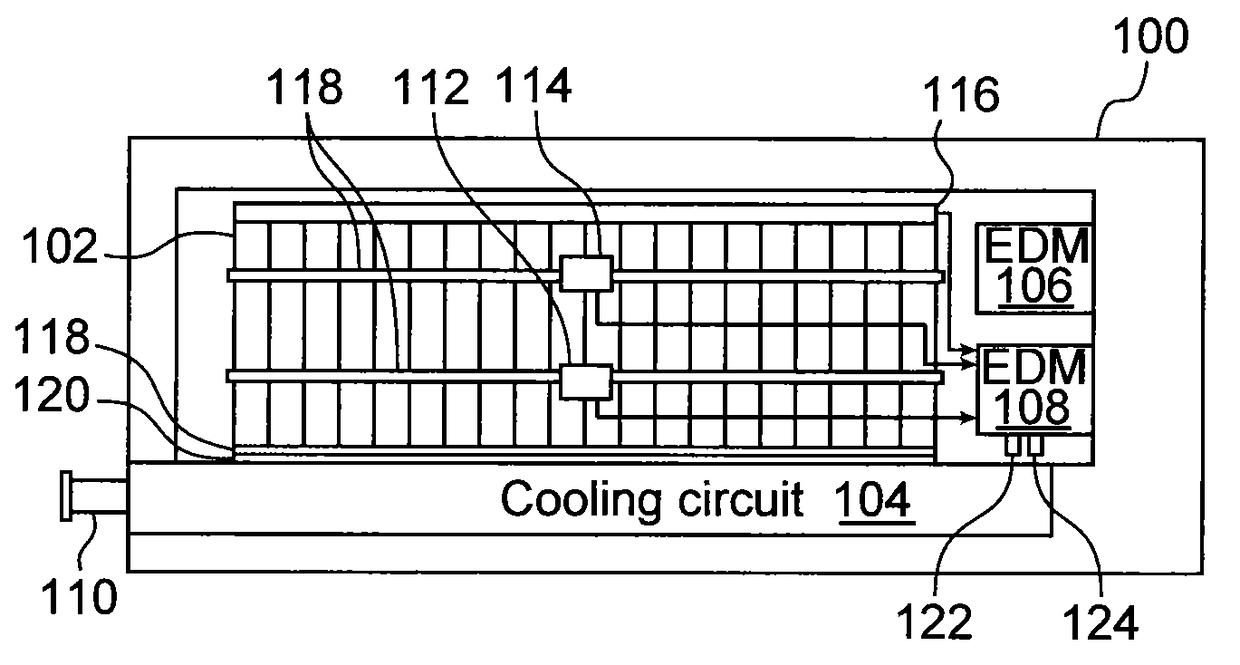

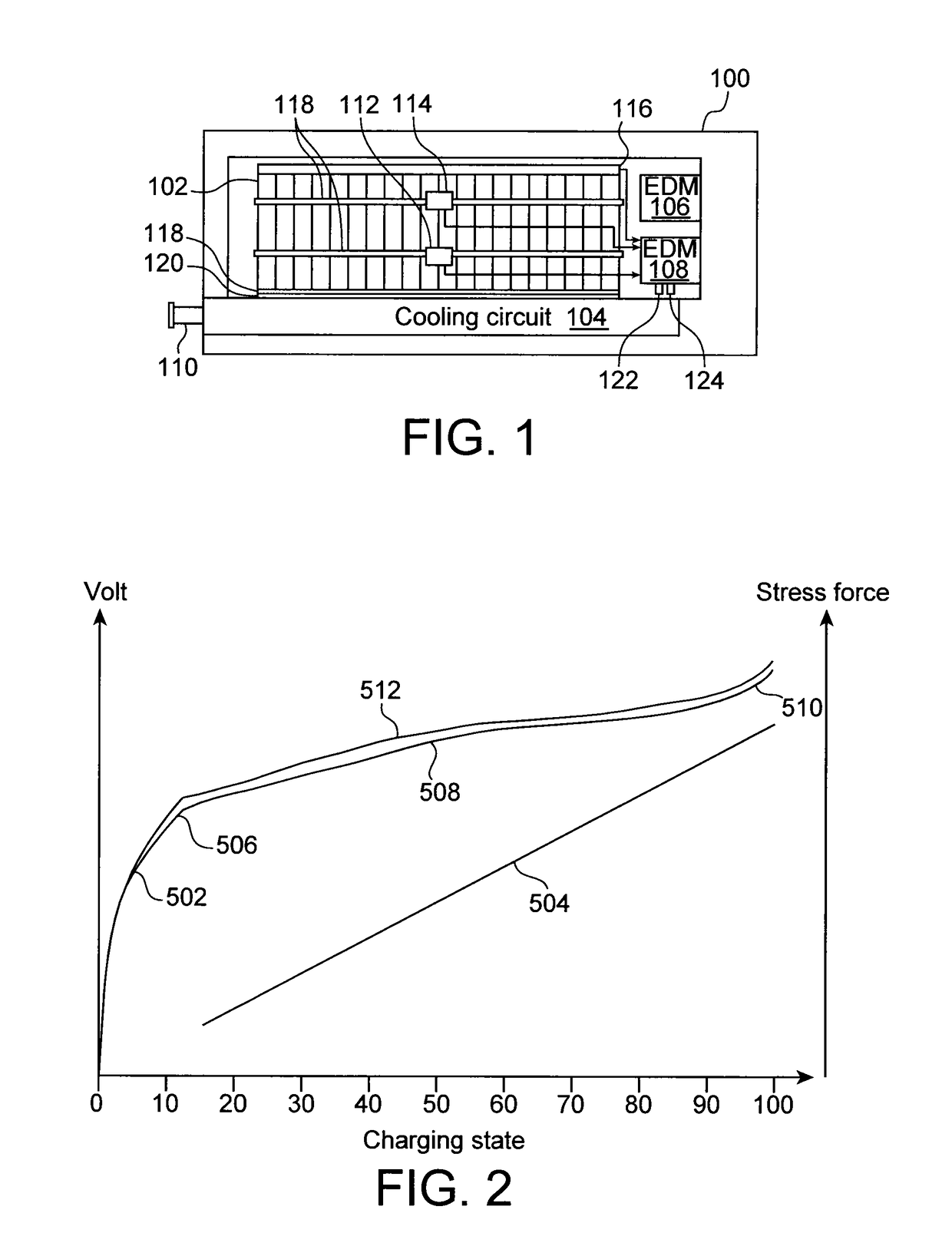

Device for managing an accumulator

ActiveUS20160072158A1Guaranteed true statePrevent irreversible damage of integrityBoards/switchyards circuit arrangementsCells structural combinationStrain gaugeStress axis

A device for managing an accumulator, including: a plurality of strain gauges including at least three strain gauges, the strain gauges being arranged to measure stresses along at least three distinct stress axes; a measuring device measuring strains undergone by each gauge along its stress axis; a reversible electrical switch; a calculating device controlling opening and closing of the electrical switch, depending on measurements carried out by the measuring device.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

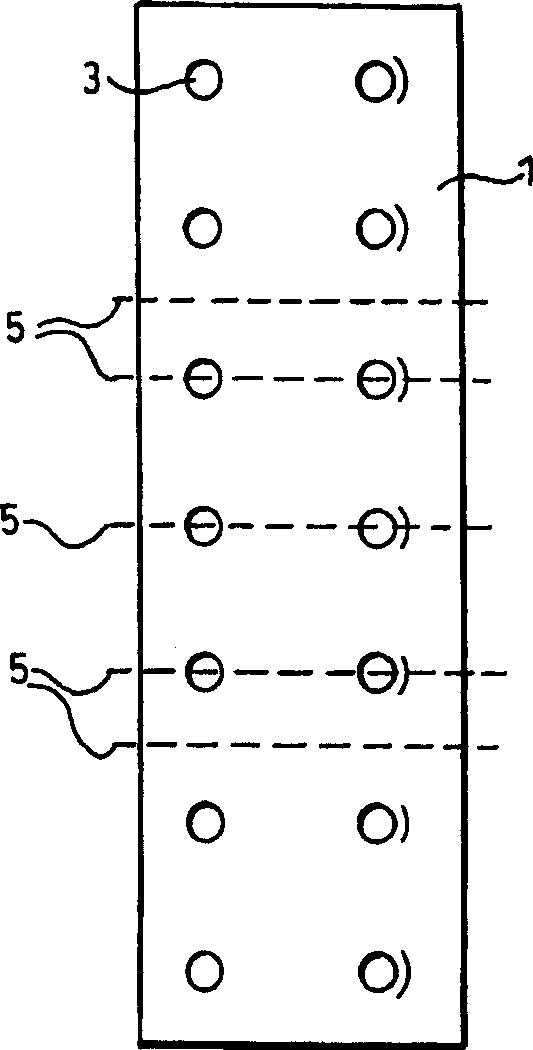

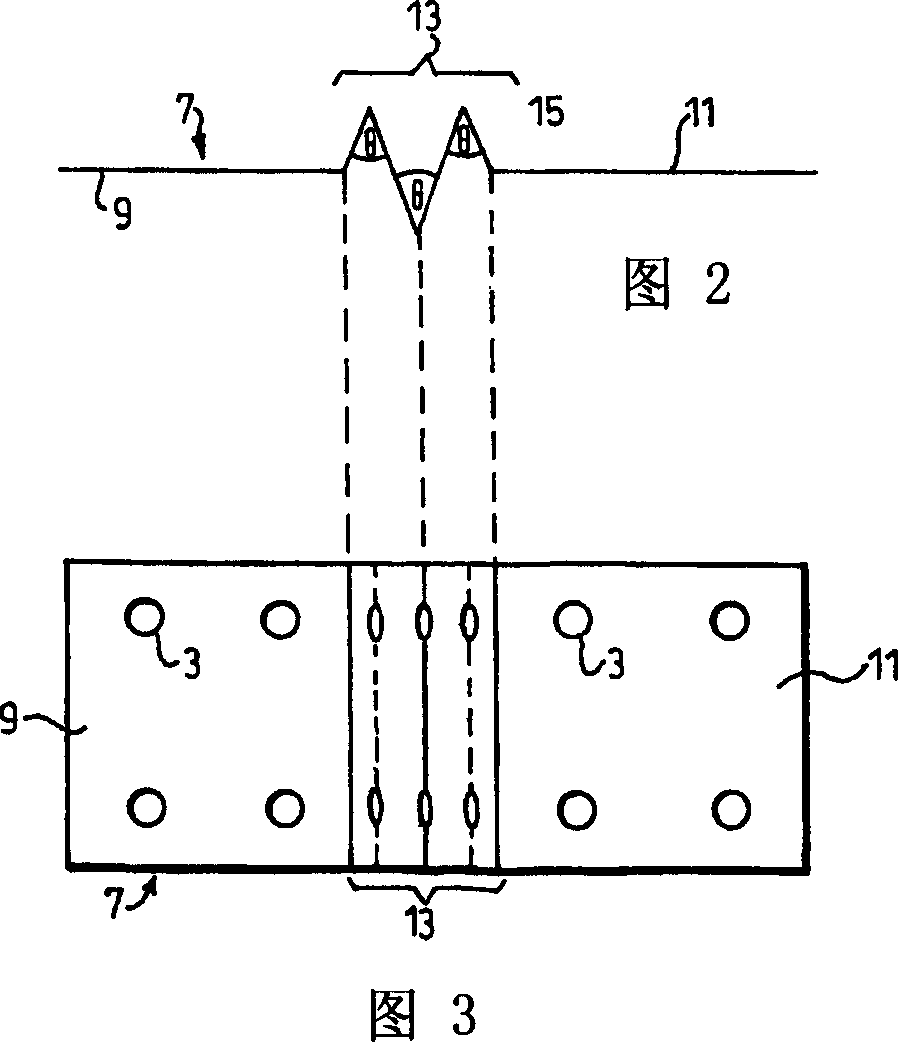

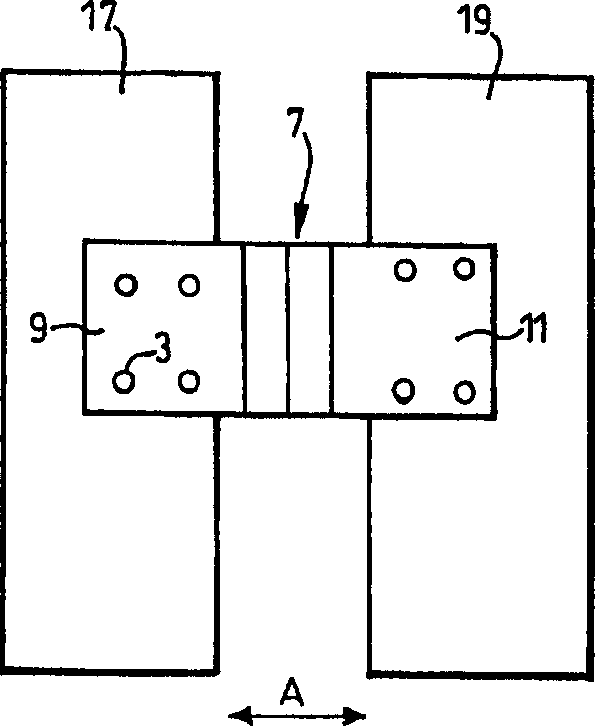

Resilient brace

A resilient brace ( 7 ) has first and second attachment portions ( 9, 11 ) formed at either end and a resilient portion ( 13 ) located therebetween, the resilient portion comprising a plurality of planar sections ( 15 ) orientated in a corrugated manner. The attachment portions lie on the same plane on which a stress axis is also located. The planar sections ( 15 ) are angled relative to one another and to the attachment portions so that each planar section ( 15 ) extends laterally of the stress axis.

Owner:LAFARGE PALTRES SA

Device for managing an accumulator

ActiveUS10020546B2Prevent irreversible damage of integrityEasy to manageCells structural combinationElectric switchesStrain gaugeStress axis

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Reinforcing method for long-distance tunnel inner wall

InactiveCN113107533ALongitudinal Shock EliminationGuaranteed stabilityMining devicesUnderground chambersCircular discImpact

The invention relates to the technical field of buildings, and discloses a reinforcing mechanism for a long-distance tunnel inner wall. The reinforcing mechanism comprises the tunnel inner wall and an arch bridge in a tunnel; a tunnel bearing block is fixedly mounted on the inner wall of the tunnel inner wall; a stress block is fixedly mounted in the tunnel bearing block; a lower pressing block is movably connected with the inner side of the stress block; and a stress axis is fixedly mounted on the inner side of the lower pressing block. According to the reinforcing mechanism for the long-distance tunnel inner wall, when the tunnel inner wall is subjected to longitudinal impact, impact force compresses the tunnel bearing block, the tunnel bearing block deforms and presses the stress block downwards, then the stress block presses the lower pressing block downwards, the stress axis is fixedly installed in the lower pressing block, then the stress axis drives a shaft rod to be bent, then the shaft rod drives a switching axis to rotate, and a centripetal force disc connected with the top end of a shaft rod body rotates immediately, so that longitudinal impact on the tunnel inner wall is eliminated, and meanwhile, the overall stability of the tunnel inner wall is guaranteed.

Owner:江西中昌工程咨询监理有限公司

A security anti-theft locking device

ActiveCN103758402BImprove prevention capabilitiesSuitable for assemblyBuilding locksEngineeringStress axis

A safety and anti-theft lock control device, comprising: a lock body box, a half-type side shaft, a passive stress gear, a force-bearing toggle pin, and a locking stress shaft piece, which is characterized in that the bottom of the lock body box is fixed by a half-type side shaft, and On the half-type side shaft, there is a shaft center hole of the passive stress gear to be dynamically assembled with it, and the passive stress gear is fixed with a load-bearing toggle pin; the locking stress shaft piece is set and operated in the groove of the lock body box, and There is a transverse stress slot on the part suitable for the bearing toggle pin to move. Since the transverse stress slot passes through the extension hole left on the side of the axis line of the passive stress gear, it can be used for the bearing toggle pin to move along with it. The passive stress gear rotates at least 180 degrees, and the margin of the transverse slot on the other side passes through the axis line of the passive stress gear to a dead angle within 15 degrees. When the locking stress shaft is moved in the groove by bearing force When the pin is moved here, it is just blocked by the dead angle, which means that a kind of lock control stress check and balance relationship is satisfied.

Owner:TIANJIN HAIZHOU BRANCH TRADE & IND +1

Stress axis fixation method of polarization-maintaining fiber

ActiveCN101923188BHigh precisionHigh extinction ratioOptical fibre with polarisationPolarization-maintaining optical fiberFixation method

The invention relates to the technical field of optical waveguide and polarization-maintaining fiber coupling in integrated optical devices, in particular to a stress axis fixation method of a polarization-maintaining fiber before the polarization-maintaining fiber is bonded with a fiber support. The method comprises the following steps of: (a) connecting an extinction ratio meter to one end of the polarization-maintaining fiber and inputting linearly polarized light with a high extinction ratio to the other end of the polarization-maintaining fiber; (b) applying normal force to the polarization-maintaining fiber in any directions and changing the size of the normal force; and (c) observing a numerical value displayed by the extinction ratio meter to determine the slow axis direction of the polarization-maintaining fiber. The method has the advantages that by applying the working principle to carrying out axis fixation of the polarization-maintaining fiber, the method greatly improvesthe accuracy of axis fixation, thereby further improving the extinction ratio of the devices.

Owner:上海傲世控制科技股份有限公司

Build-up force standard machine with wide range,

ActiveCN102564557BReduce manufacturing costSimple structureWeighing apparatus testing/calibrationForce/torque/work measurement apparatus calibration/testingLower limitEngineering

The invention discloses a build-up force standard machine with a wide range, belongs to the technical field of force standard machinery, and is characterized in that the build-up force standard machine comprises a first detecting unit and a second detecting unit, wherein the upper limit of the range of the first detecting unit is in accordance with that of the build-up force standard machine; the lower limit of the range of the first detecting unit is in accordance with the upper limit of the range of the second detecting unit; the lower limit of the second detecting unit is in accordance with that of the build-up force standard machine; the force output directions of the first and the second detecting units are in accordance with each other; and the stress axis of a to-be-detected sensor is overlapped with those of the first and the second detection units. The build-up force standard machine has the advantages of large range, low manufacturing cost and the like.

Owner:绍兴市肯特机械电子有限公司

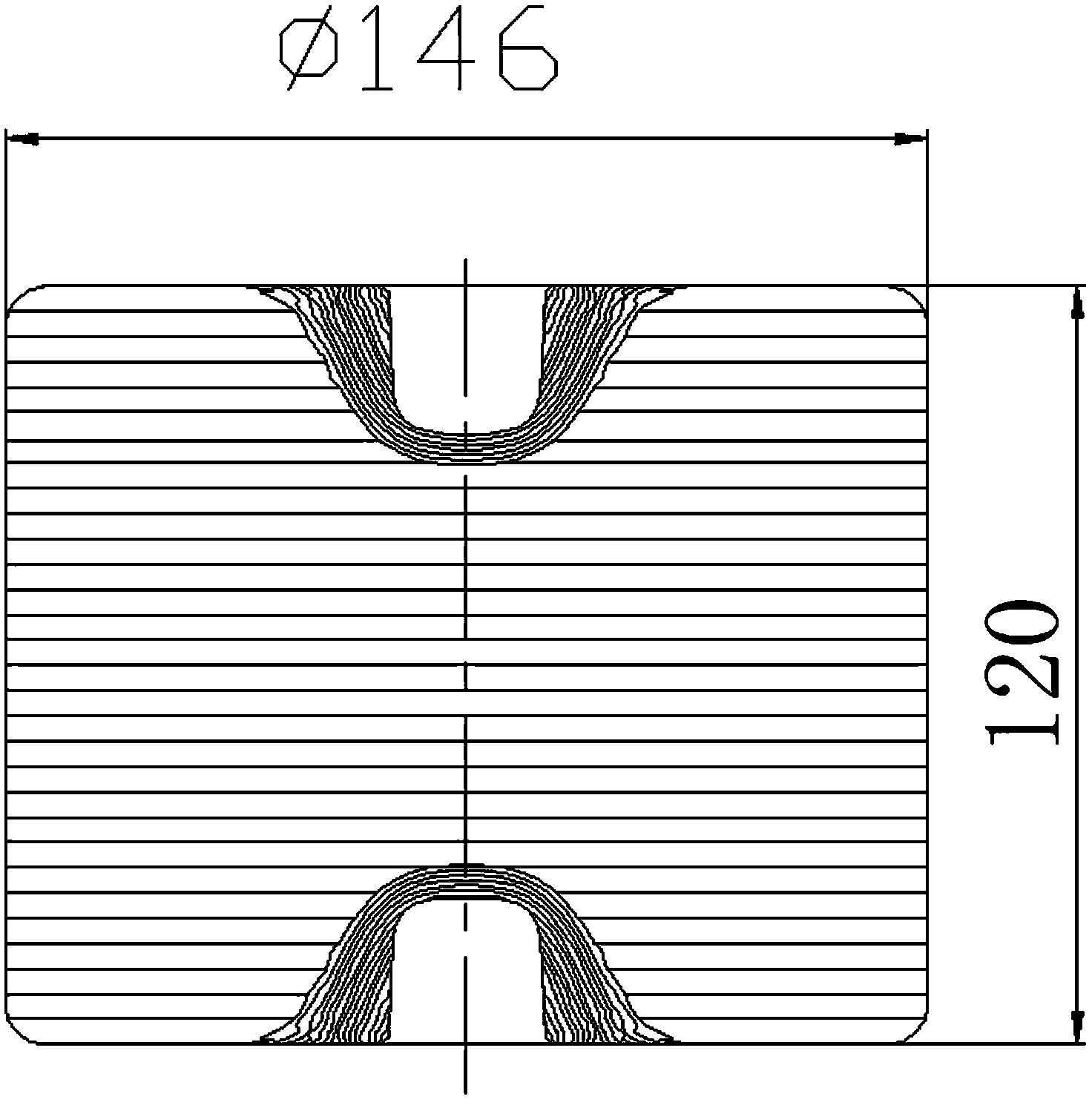

Machining method of profiling lower die blank of 22224 aligning spherical roller

InactiveCN103357803AExtended service lifeImprove work efficiencyMetal-working apparatusMetal fiberEngineering

The invention relates to a machining method of a profiling lower die blank of a 22224 spherical roller. The method is characterized by comprising the following processing steps that: the profiling lower die blank of the 22224 spherical roller takes Gr15 high-carbon chromium high-quality steel as a material; the material is prepared and blanked (a material diameter phi is 120 and a blanking length is 175); start forging temperature is 1100-1130 DEG C. The specific machining method comprises the steps of: upsetting, forging a square, drawing the square, upsetting, forging the square, drawing the square again, upsetting, forging the square, drawing the square again, loading a casing and forming at forging-stop temperature of 800-900 DEG C, forming potholes in the end faces of a die with a forming punch, allowing a metal fiber direction of the material to be perpendicular to a stress axis direction of the lower die, and allowing fiber directions of the material around the potholes to be perpendicular to a stress direction during profiling, wherein an allowance between the dimensions of each pothole and a cavity is 1.5-2mm. The service life of the profiling lower die machined by the method can be prolonged by 2-3 times.

Owner:DALIAN METALLURGICAL BEARING

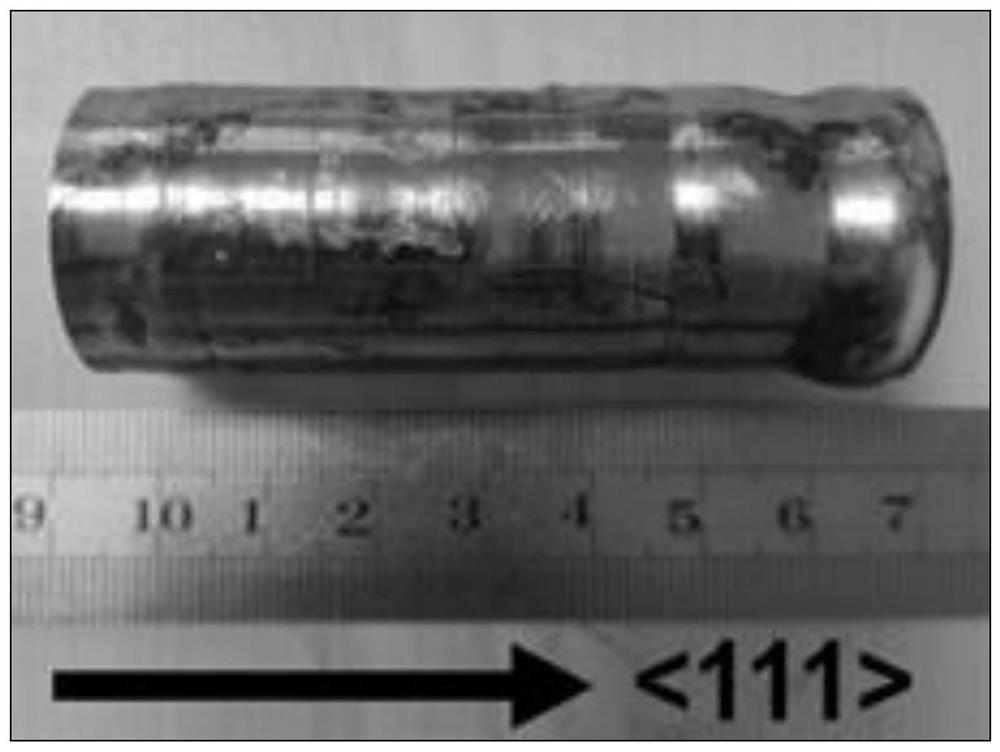

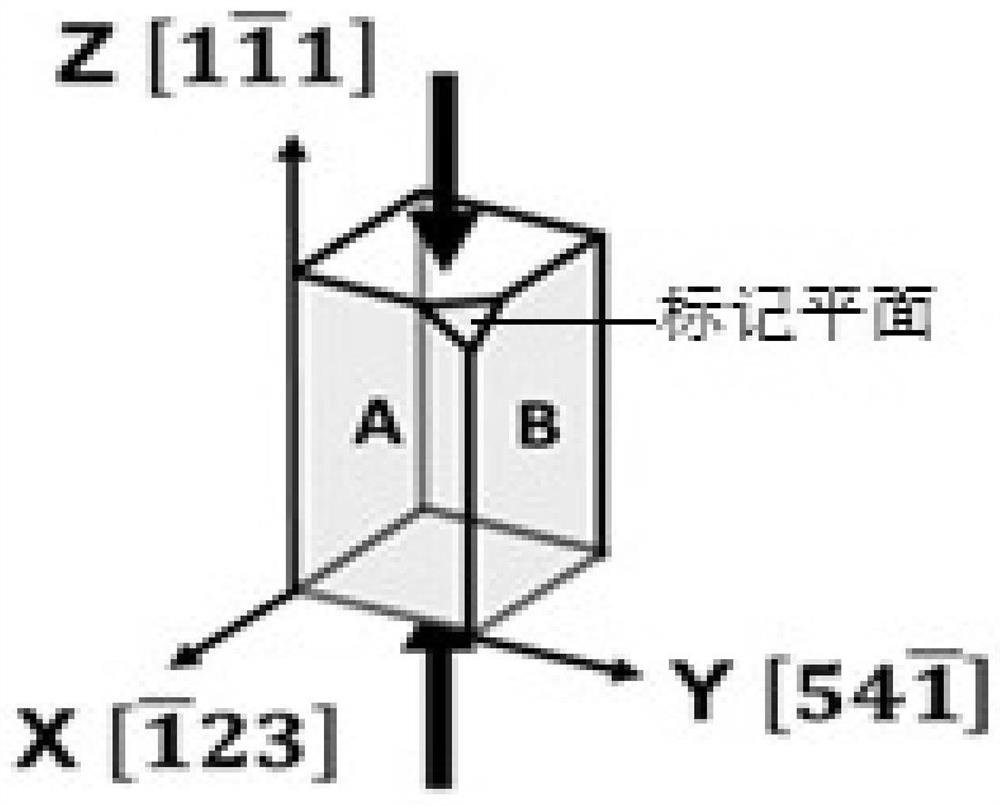

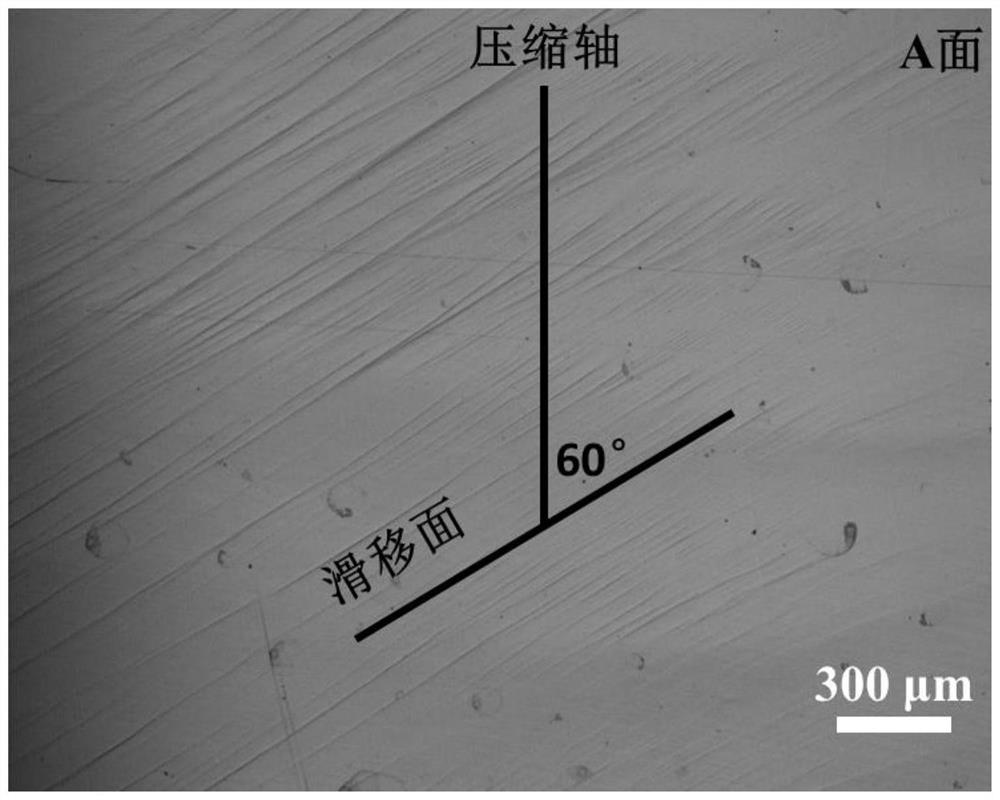

Method for determining molybdenum alloy single crystal slip plane

InactiveCN113740337AGuaranteed accuracyAvoid measurement errorsMaterial analysis using wave/particle radiationPreparing sample for investigationSlip lineCrystal orientation

The invention discloses a method for determining a molybdenum alloy single crystal slip plane, which comprises the following steps: cutting a sample on a molybdenum alloy single crystal rod by linear cutting, polishing a small plane at the intersection vertex of two side surfaces of the sample as a marking plane, determining the crystal orientation of the side surfaces of the sample, performing deformation treatment on the sample to obtain a deformed sample, analyzing the slip lines of the two adjacent side surfaces of the marked plane in the deformed sample, determining the included angle between the slip lines of the two adjacent side surfaces and the stress axis, and calculating by adopting a two-surface method to obtain the slip plane of the molybdenum alloy single crystal. The side crystal orientation of the molybdenum alloy sample is determined before deformation treatment of the molybdenum alloy sample, and the sliding lines after deformation of the two side surfaces are distinguished by grinding the marking planes at the intersection fixed points of the two side surfaces of the sample, so that measurement errors caused by sample deformation are avoided, the accuracy of measurement of the sliding plane after deformation of the molybdenum alloy single crystal is ensured, the operation is simple, consumed time is short and efficiency is high.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Fatigue test method for rail transit car body welded structure

ActiveCN106680118BAccurately measure fatigue levelsEffective immobilizationMaterial strength using repeated/pulsating forcesCombined testTest sample

Owner:辽宁忠旺铝合金精深加工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com