Stock bin weighing device

A weighing device and silo technology, applied in the field of silo weighing device, can solve the problems that affect the measurement accuracy of the sensor, the sensor is prone to movement, adjustment, and inconvenient calibration, etc. To force influence, the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described below in conjunction with embodiment and accompanying drawing.

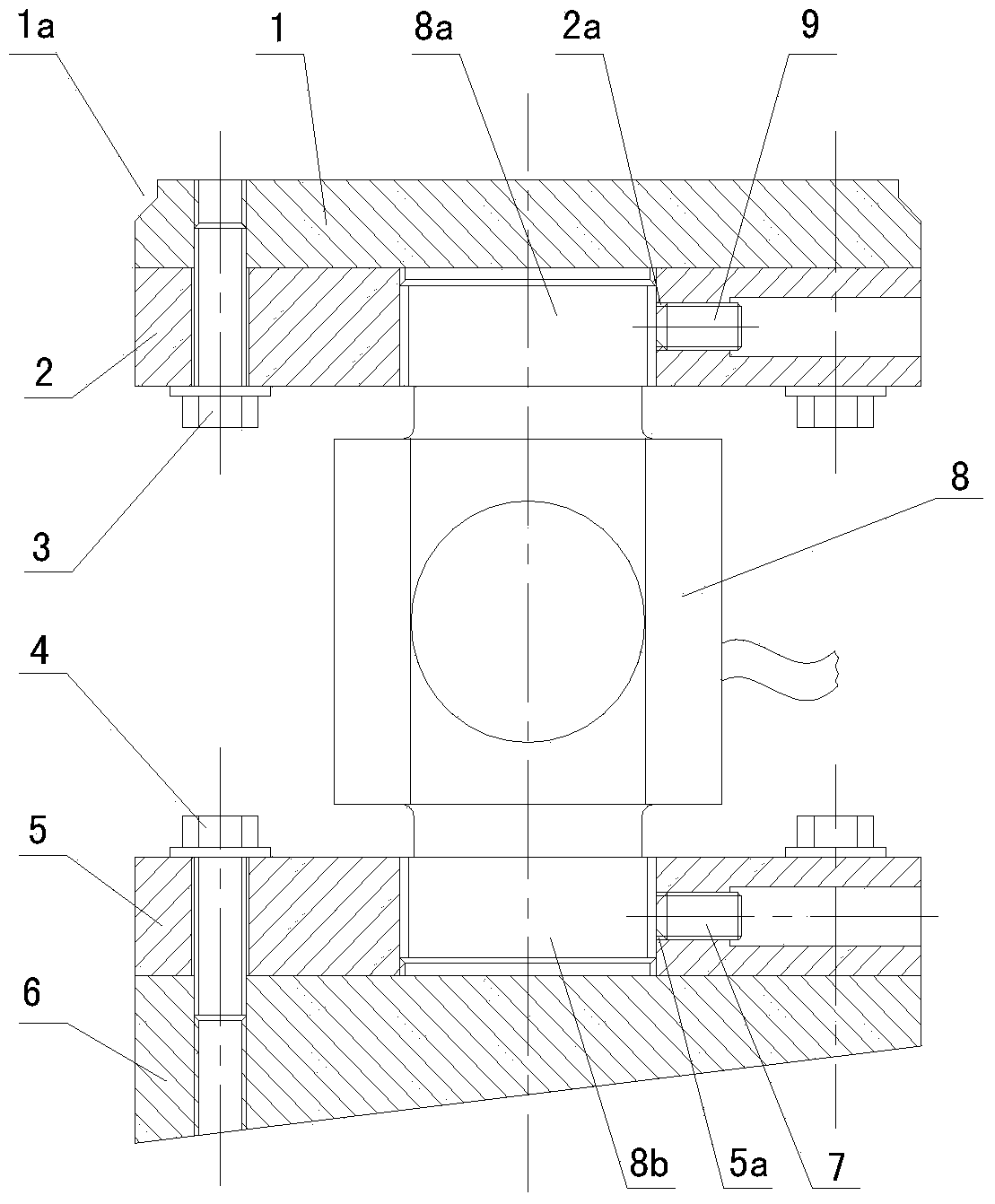

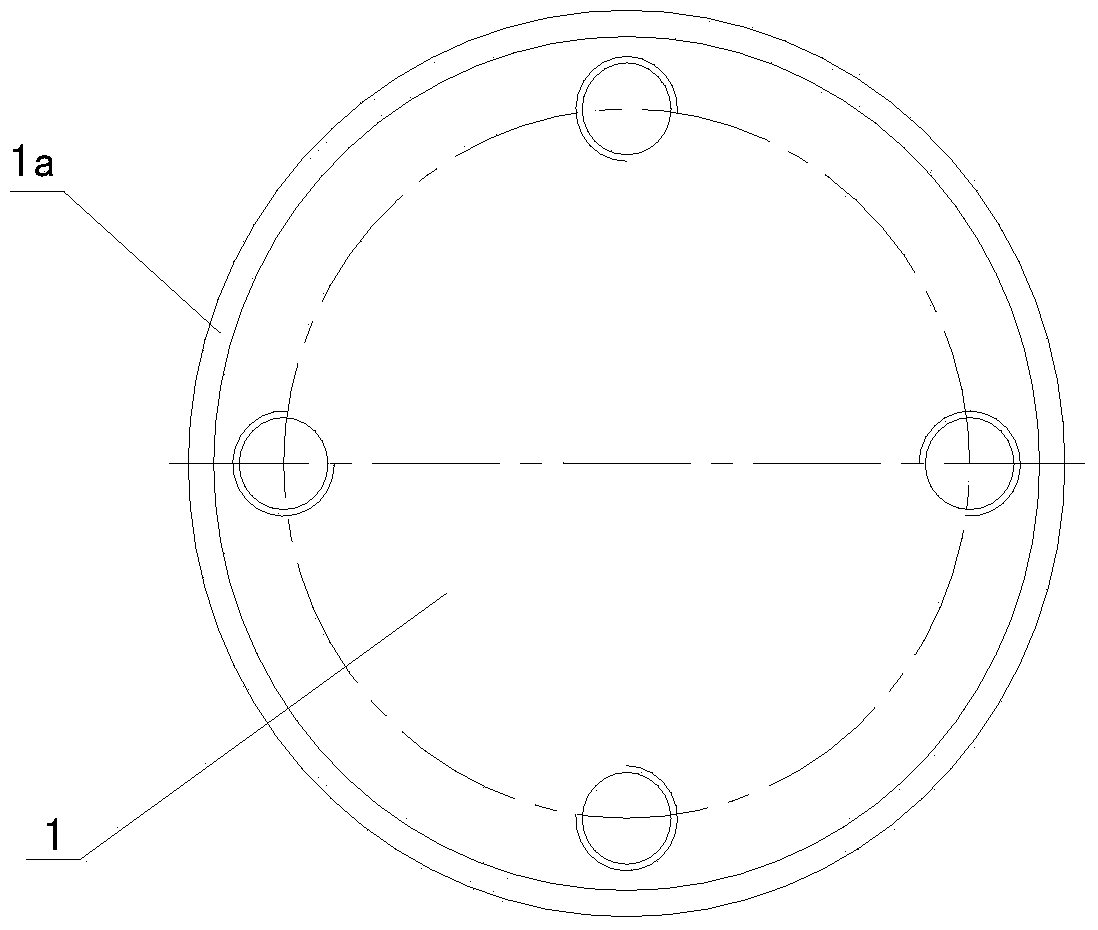

[0010] see figure 1 , figure 2

[0011] The silo weighing device provided by the present invention has a column type load cell 8, and the upper and lower ends of the column type load cell 8 respectively have a protruding bearing head 8a and a connecting head 8b, and the loading head 8a and the connecting head 8b are respectively The upper flange 2 and the lower flange 5 are connected, the bearing head 8a and the connecting head 8b both have external threads, the space between the bearing head 8a and the upper flange 2, and the connection between the connecting head 8b and the lower flange 5 are threads Connection, a disc-shaped supporting platform 1 is connected to the upper end of the upper flange 2, the edge of the upper end of the supporting platform 1 has a shrinking positioning step 1a, and a supporting seat 6 is connected to the lower end of the lower fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com