Testing device of pressure-torsion shear failure performance of asphalt mixture

A technology of asphalt mixture and shear failure, which is applied to measuring devices, using stable shear force to test material strength, and analyzing materials. Problems such as tensile failure of test pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

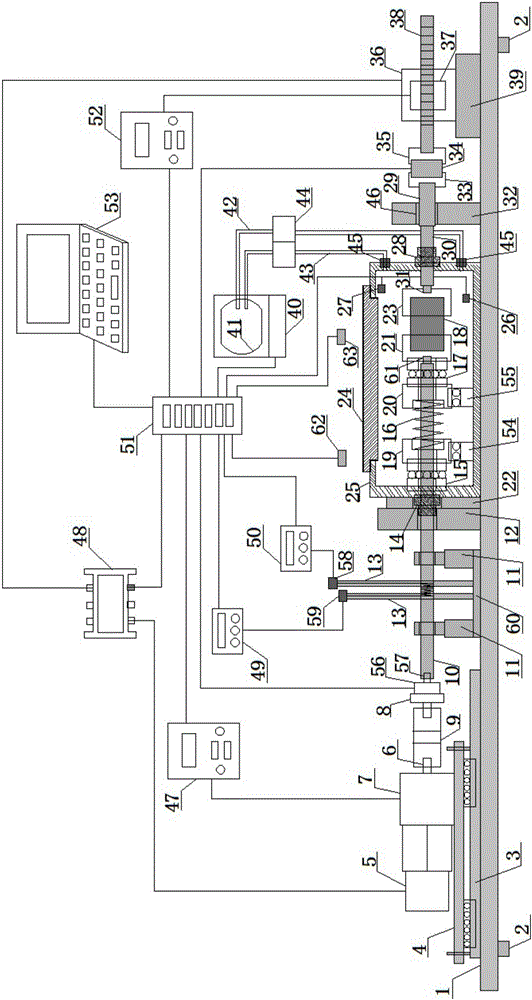

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0024] Such as figure 1 Shown is a test device for compressive torsional shear failure performance of asphalt mixture. When the device works, start the program-controlled high and low temperature test chamber 40, so that the temperature of the thermal insulation liquid in the constant temperature water tank 41 reaches the test requirements; In the water tank 41, curing is carried out according to the temperature and time specified in the test.

[0025] Left fixed plate 12 is installed on foundation platform 1, fixed rubber backing plate 22 on the right side of left fixed plate 12, heat preservation room 25 is placed on the right side of rubber backing plate 22, No. 1 motor is installed and fixed on motor platform 4, in Install and fix No. 2 motor and vertical screw rod on the No. 2 just cushion block 39, square rigid plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com