System for package container constant temperature airtight test

An airtight test and packaging container technology, which is applied in the direction of using liquid/vacuum to measure the liquid tightness and detecting the appearance of fluid at the leakage point, can solve the problem of inability to accurately judge the leakage of the packaging container, and save production costs , stable operation, and the effect of reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

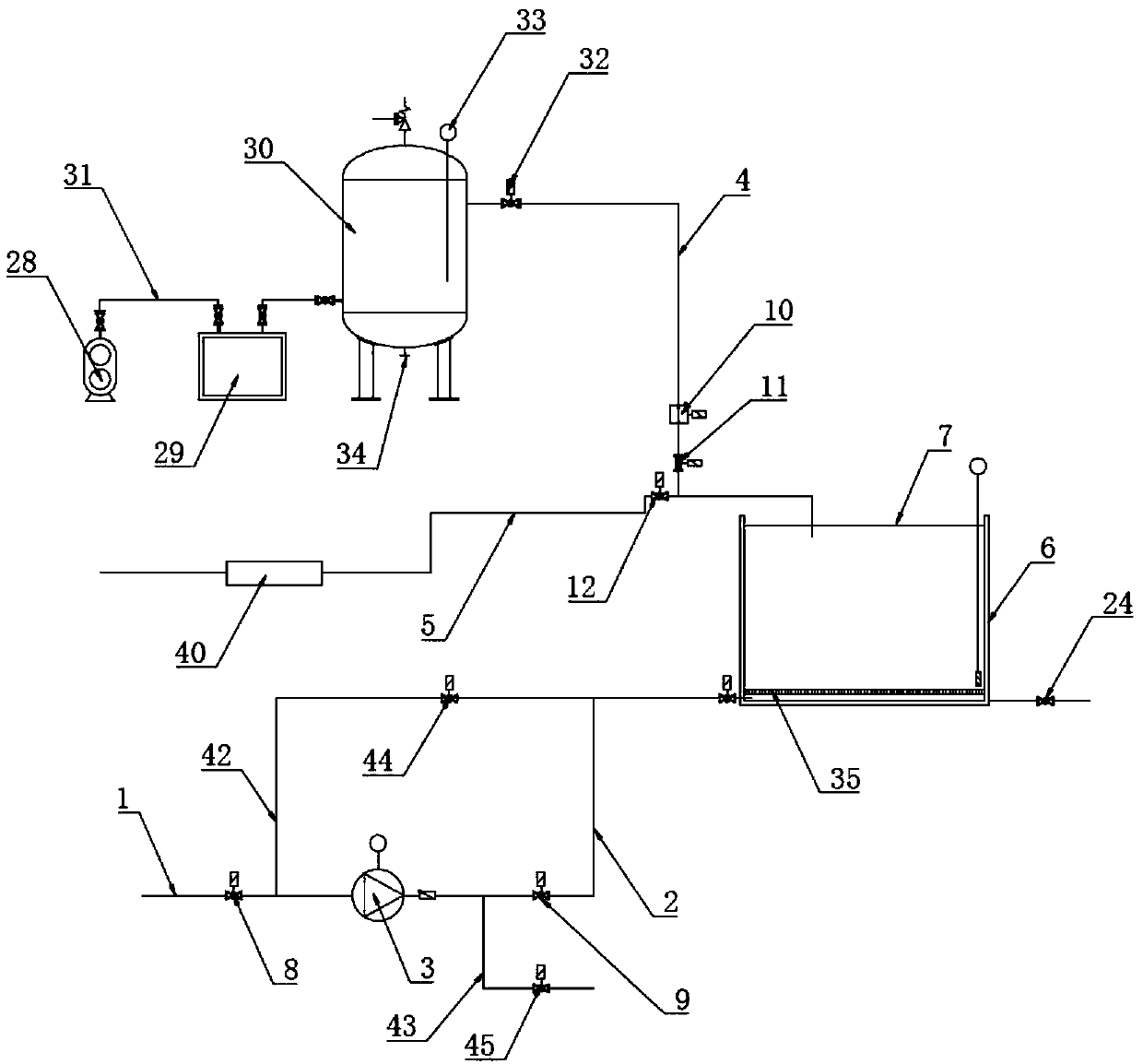

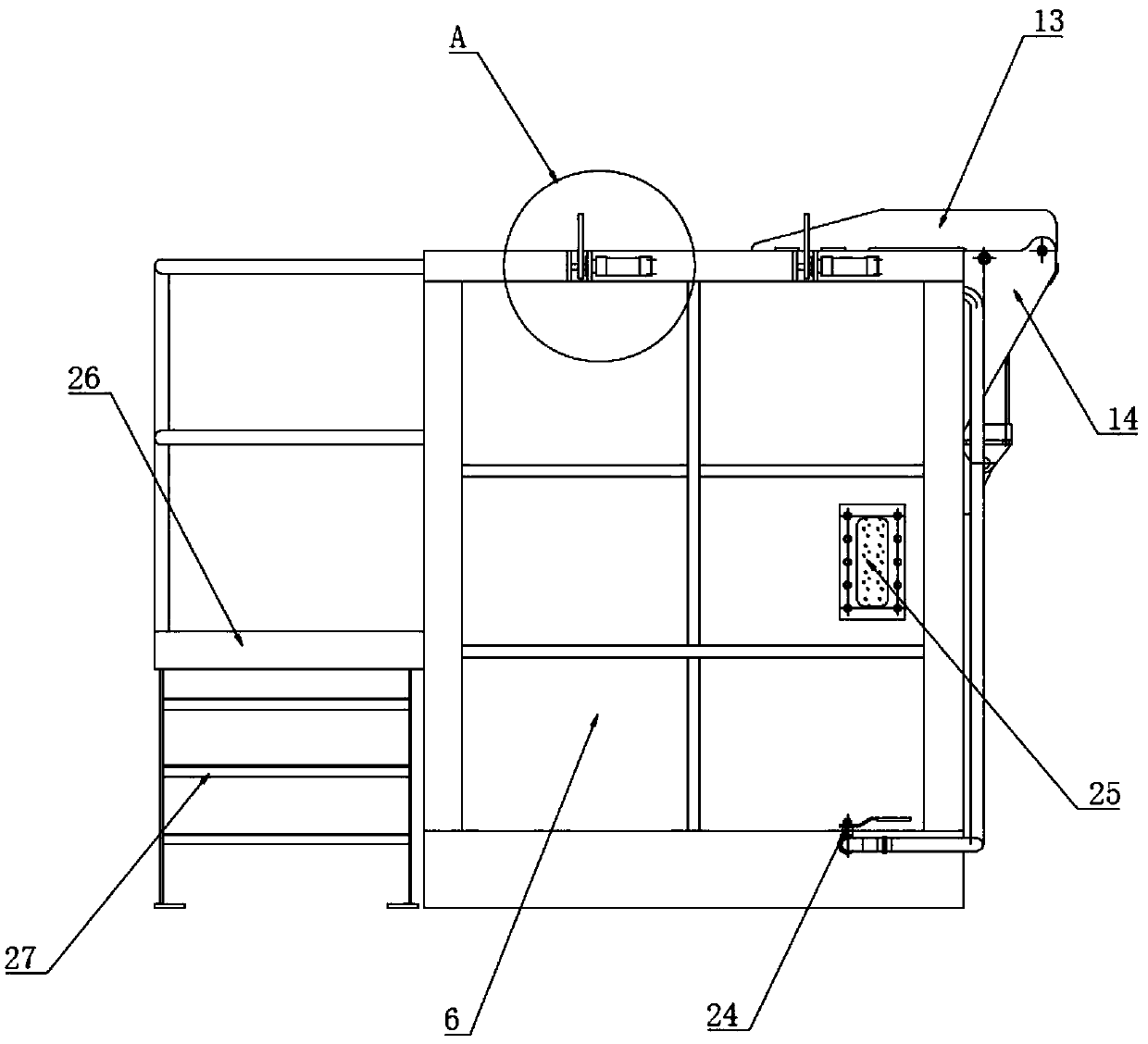

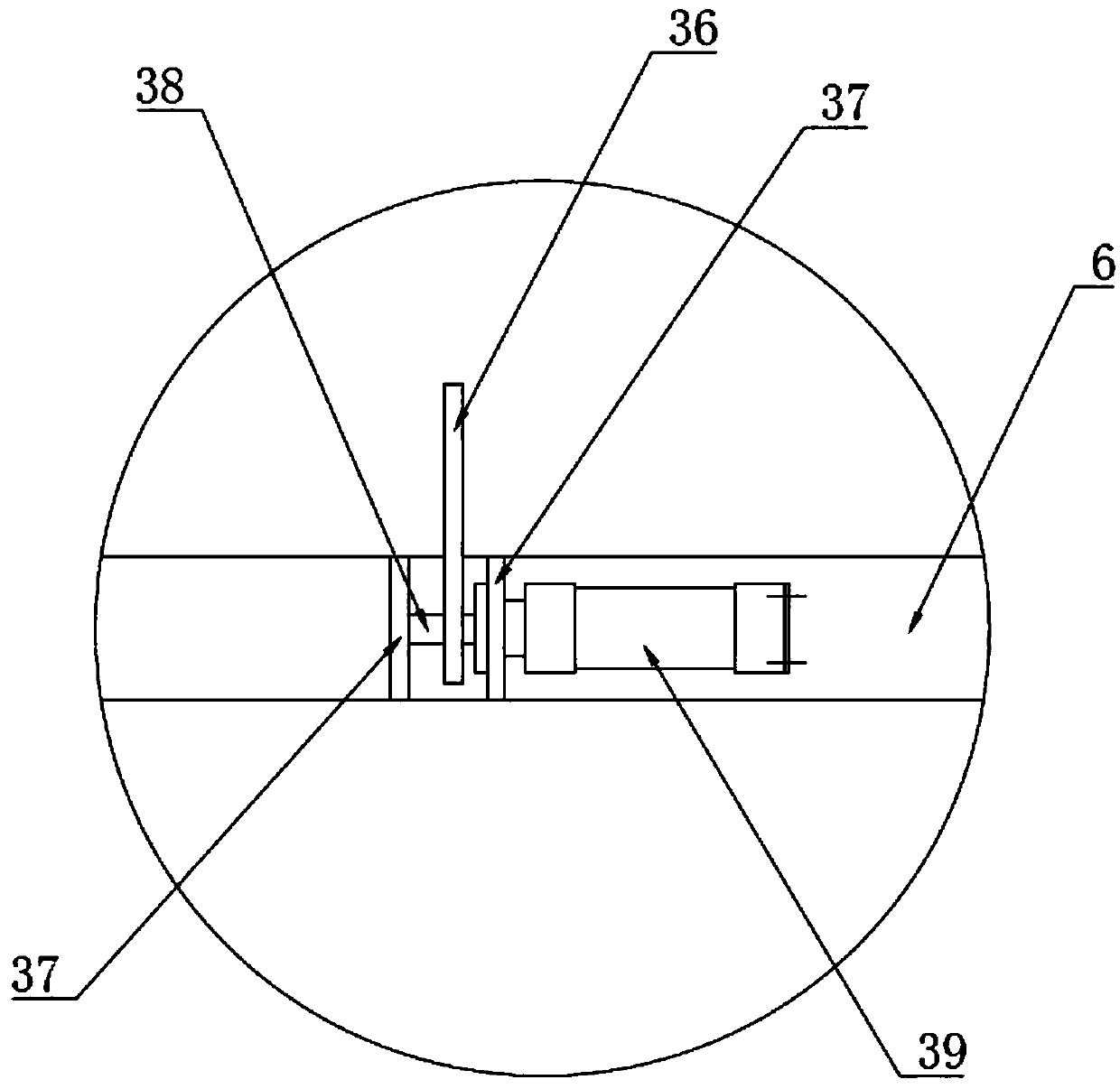

[0069] Example: such as Figure 1 to Figure 10 As shown, a system for a constant temperature airtight test of a packaging container includes a first water supply pipeline 1, a second water supply pipeline 2, a first water pump 3, a water tank, a first air supply pipeline 4, a first exhaust pipeline 5, controller, display and water supply device, the water tank includes a water tank 6 and an upper cover 7, the inlet of the first water pump 3 communicates with the output end of the first water supply pipeline 1, and the outlet of the first water pump 3 communicates with the water tank 6 It communicates with the second water supply pipeline 2, the first water supply pipeline 1 is provided with a first control valve 8, the second water supply pipeline 2 is provided with a second control valve 9, and the water tank 6 is provided with a first A liquid level sensor, the first liquid level sensor is used to collect the liquid level signal in the water tank 6, and transmit the liquid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com