An asphalt mixture rutting test device

A technology for asphalt mixture and rutting test, which is applied in the direction of material inspection products to achieve the effects of reducing mechanical fatigue damage, wide test temperature range and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

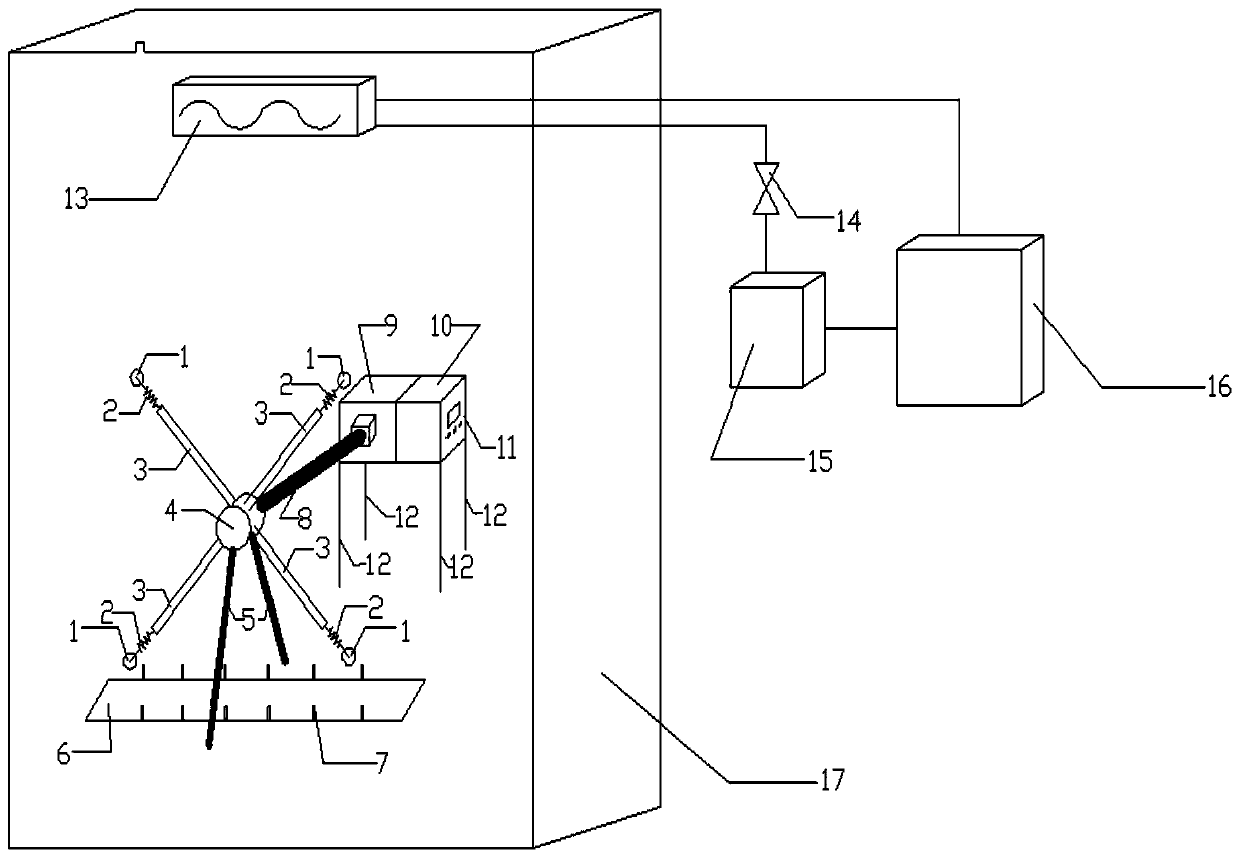

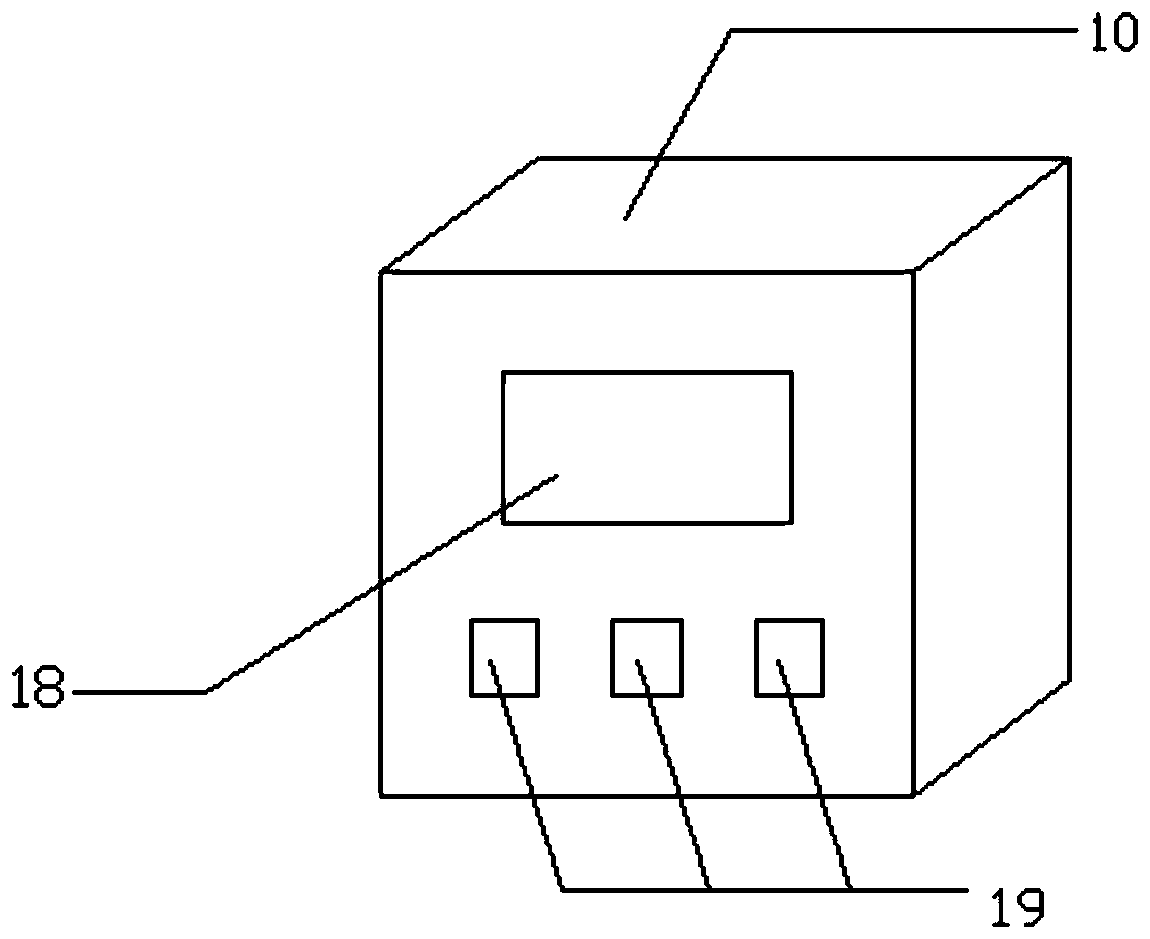

[0026] The invention provides an asphalt mixture rutting test device, such as figure 1 As shown, the main body 17 comprising a sealed structure, the main body 17 is connected with the temperature control structure, the temperature control structure includes the heating wire radiator 13 arranged inside the main body 17, the heating wire radiator 13 is arranged on the outside of the main body 17 and the condenser 15 and An expansion valve 14 is arranged on the pipeline between the refrigeration compressor 16, the condenser 15 and the heating wire radiator 13, and the temperature control structure can control the temperature inside the main body 17, so that the range of the test temperature is wider.

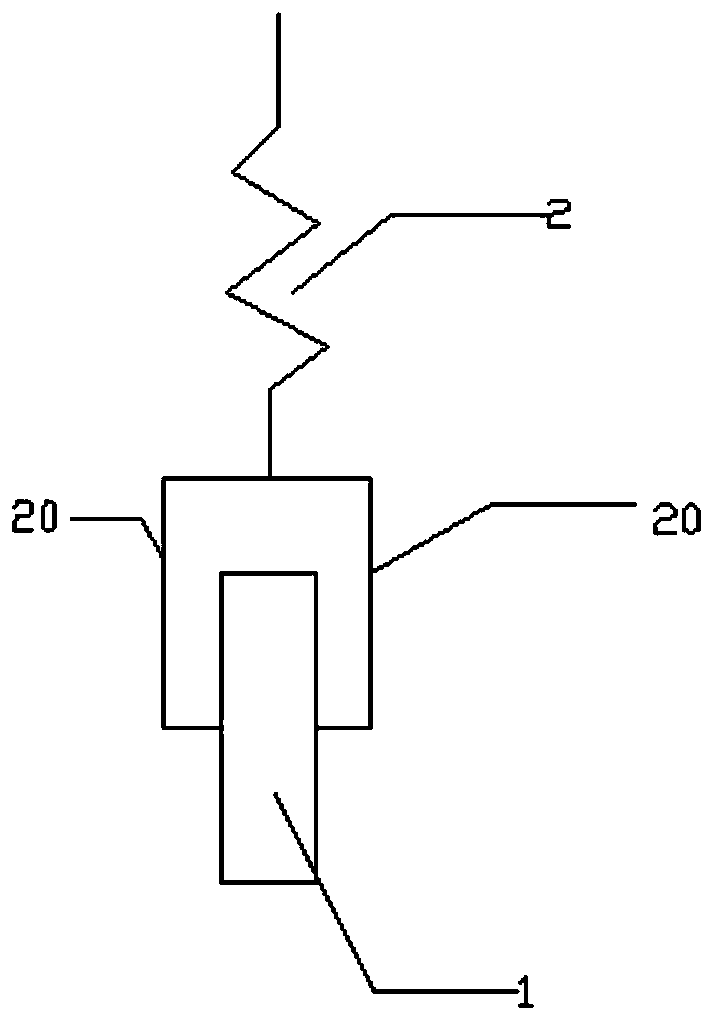

[0027] Wherein the inside of main body 17 is provided with main shaft 4, and motor 9 provides main shaft 4 to rotate, and main shaft 4 is connected with a plurality of hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com