Bending moment-free anti-pollution high-speed segmenting and phase-splitting isolator

An insulator, anti-fouling technology, applied in the direction of overhead lines, etc., can solve the problems of easy burning of segmented insulators, wear of PTFE jacket, easy to hit the pantograph, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

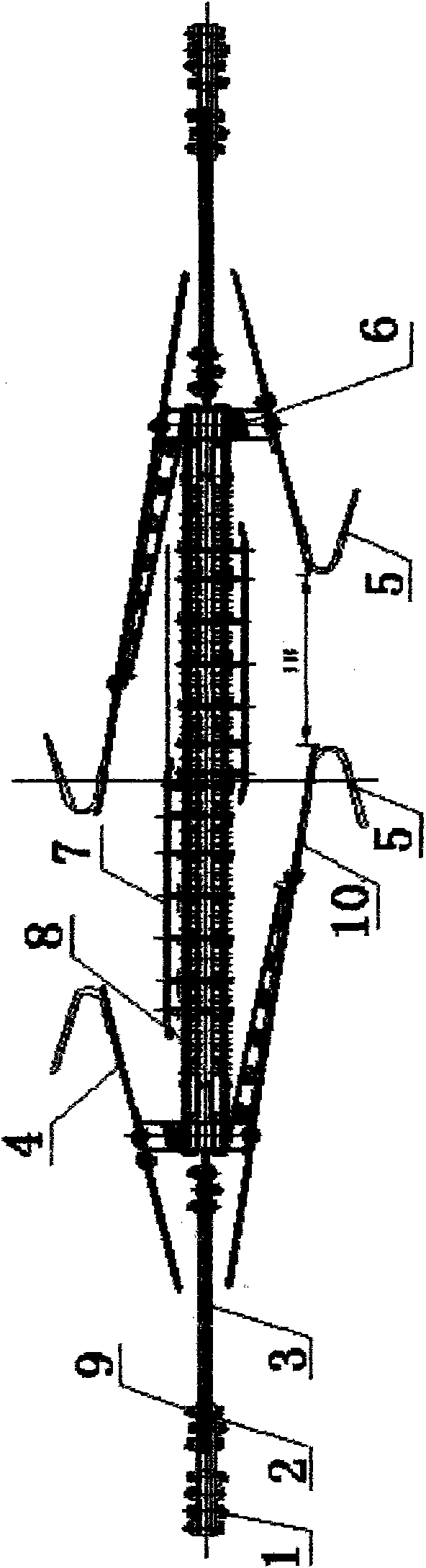

[0023] Such as figure 1 and figure 2 As shown, the joint wire splint 1 clamps the contact wire, the joint wire clamp connecting plate 2 connects the joint wire splint 1 and the connection plate 3 through the fastening standard part 9, and the connection plate 3 is connected to the frame 6 through the fastening standard part 9 One ear is connected. The whole frame 6 is a welded structural part, and the frame 6 is connected with a long slide 10 and a short slide 4 through the fastening standard parts 9, and the long slide 10 and the short slide 4 form a diversion slideway, and the long slide 10 and the short slide 4 are welded with The arc striking rod A5 and the arc striking rod B5 form an arc-extinguishing angle gap. The bottom of the connecting plate 3 is a large-radius arc transition, which can make the pantograph smoothly transition from the bottom of the contact wire to the diversion slideway along a certain slope; the two ends of the middle silicon rubber insulator 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com