Reinforcing method for long-distance tunnel inner wall

A long-distance, in-tunnel technology, used in tunnels, tunnel linings, earth-moving drilling, etc., can solve problems such as jamming, boulders falling easily, ground collapse, etc., to ensure stability, eliminate longitudinal impact, and ensure resistance to impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for strengthening the inner wall of a long-distance tunnel, which is characterized in that: it includes the following steps, step A: first grouting the reinforcement layer, which is a cylindrical structure obtained by construction on the surrounding rock excavation surface of the fault fracture zone; the grouting reinforcement layer also includes Several anchor rods are seamless steel pipes. The energy-dissipating and shock-absorbing layer covers the bottom of the grouting reinforcement layer; the material of the energy-dissipating and shock-absorbing layer is rubber material, the thickness of which is 10-30cm. become.

[0026] Step B: Use the steel arch again and set it above the prefabricated tunnel lining structure. distance.

[0027] Step C: Install a monitoring reinforcement instrument on the inner wall of the grouting reinforcement layer, the monitoring reinforcement instrument includes a monitoring device and a nozzle, the monitoring device is installe...

Embodiment 2

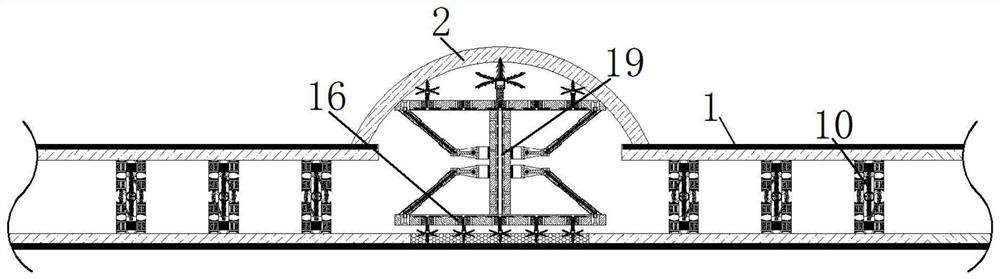

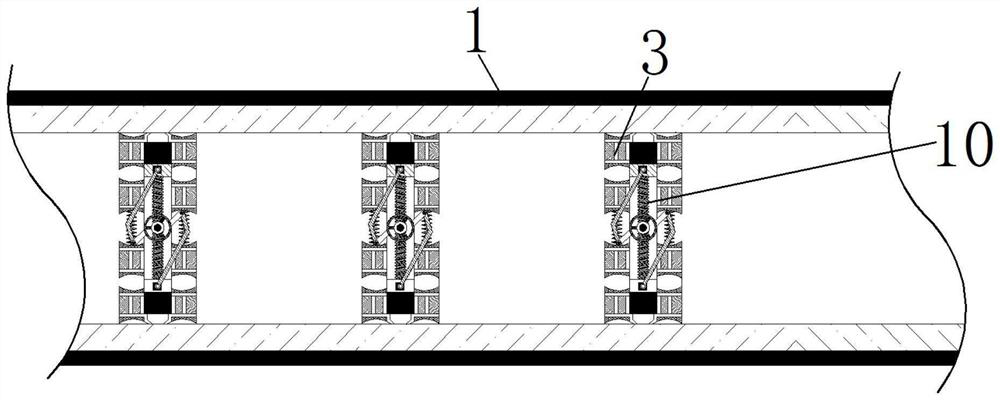

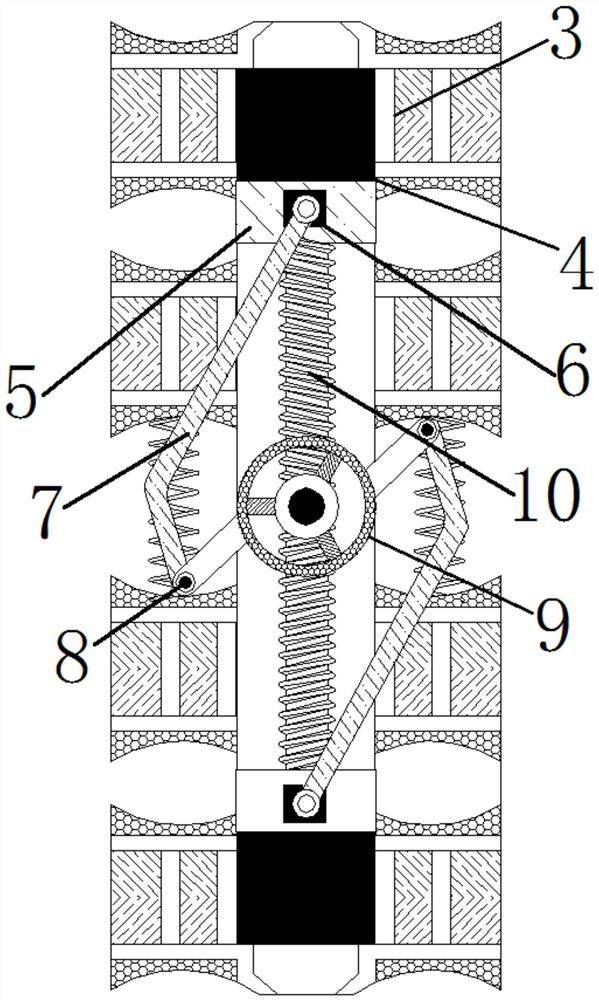

[0029] see Figure 1-6 , a long-distance tunnel inner wall reinforcement mechanism, including a tunnel inner wall 1 and a tunnel inner arch bridge 2, a tunnel load-bearing block 3 is fixedly installed on the inner wall of the tunnel inner wall 1, and a force-bearing block 4 is fixedly installed inside the tunnel load-bearing block 3, and the force-bearing block The inner side of 4 is movably connected with a lower pressing block 5, and the inner side of the lower pressing block 5 is fixedly equipped with a stressed axis 6, and the outer side of the stressed axis 6 is movably installed with a shaft rod 7, and the inner side of the shaft rod 7 is movably installed with an adapter The axis 8 and the top of the shaft 7 are movably connected with a centripetal disk 9; when the tunnel inner wall 1 is impacted longitudinally, the impact force compresses the tunnel load-bearing block 3, and the tunnel load-bearing block 3 deforms, pressing the force-bearing block 4 downward , the forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com