Balance weight type variable contact force piezoelectric motor

A technology of piezoelectric motor and variable contact, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., which can solve the problem of wear at both ends of the clamp unit and the inability to achieve clamping , Difficulty in parallelism and other problems, to achieve the effect of improving service life, realizing mass production and improving driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

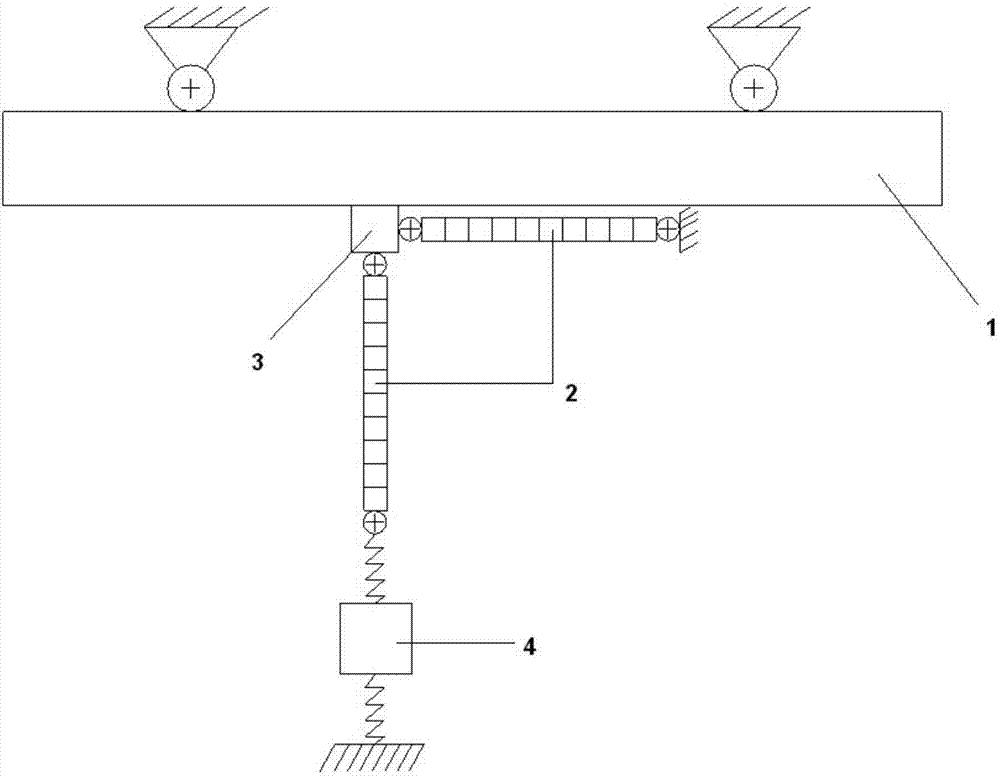

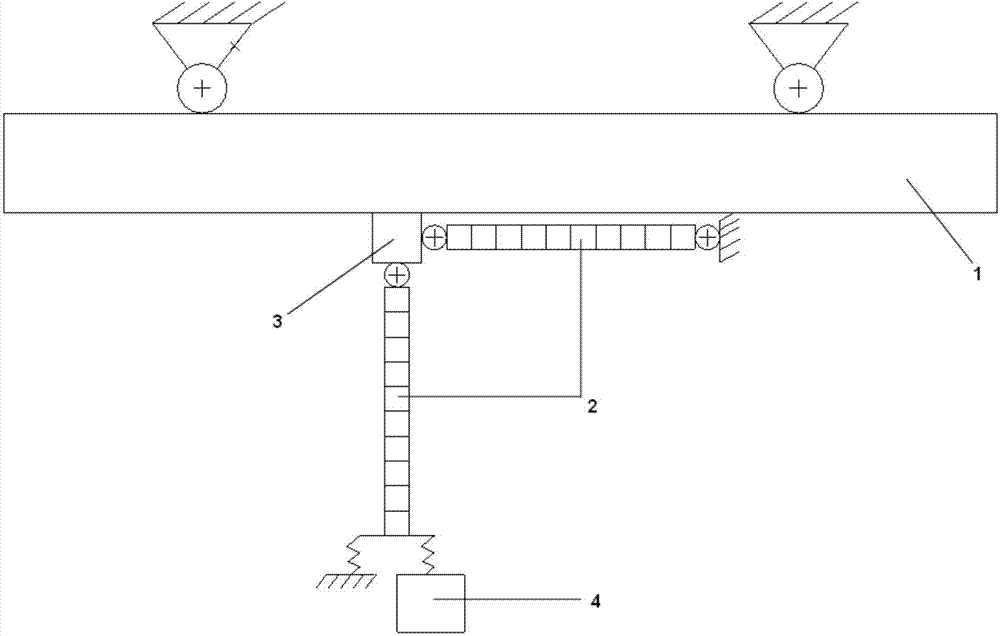

[0025] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 and figure 2 As shown, the counterweight variable contact force piezoelectric motor of the present invention includes a piezoelectric body and a moving part, and the piezoelectric body contacts the moving part through the elastic restoring force generated by the elastic preloading element. , the piezoelectric body is connected to the longitudinal base through an elastic preloading element, and the elastic expansion and contraction direction of the elastic preloading element is perpendicular to the actuating direction of the piezoelectric motor; meanwhile, the piezoelectric body is hinged to the transverse base, And the connecting line between the piezoelectric bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com