Patents

Literature

53results about How to "Achieve reverse motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

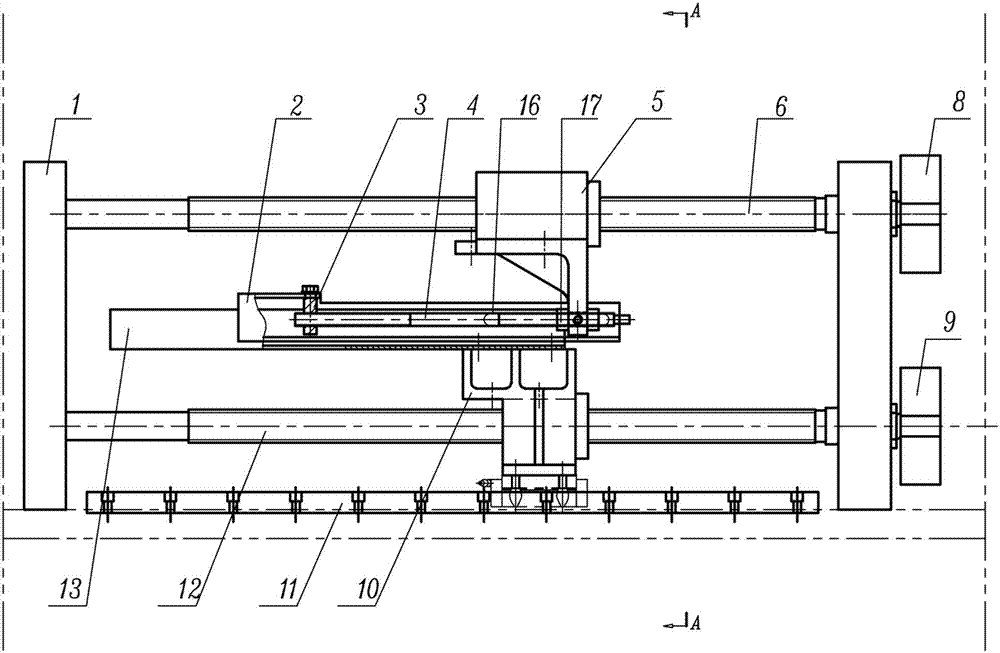

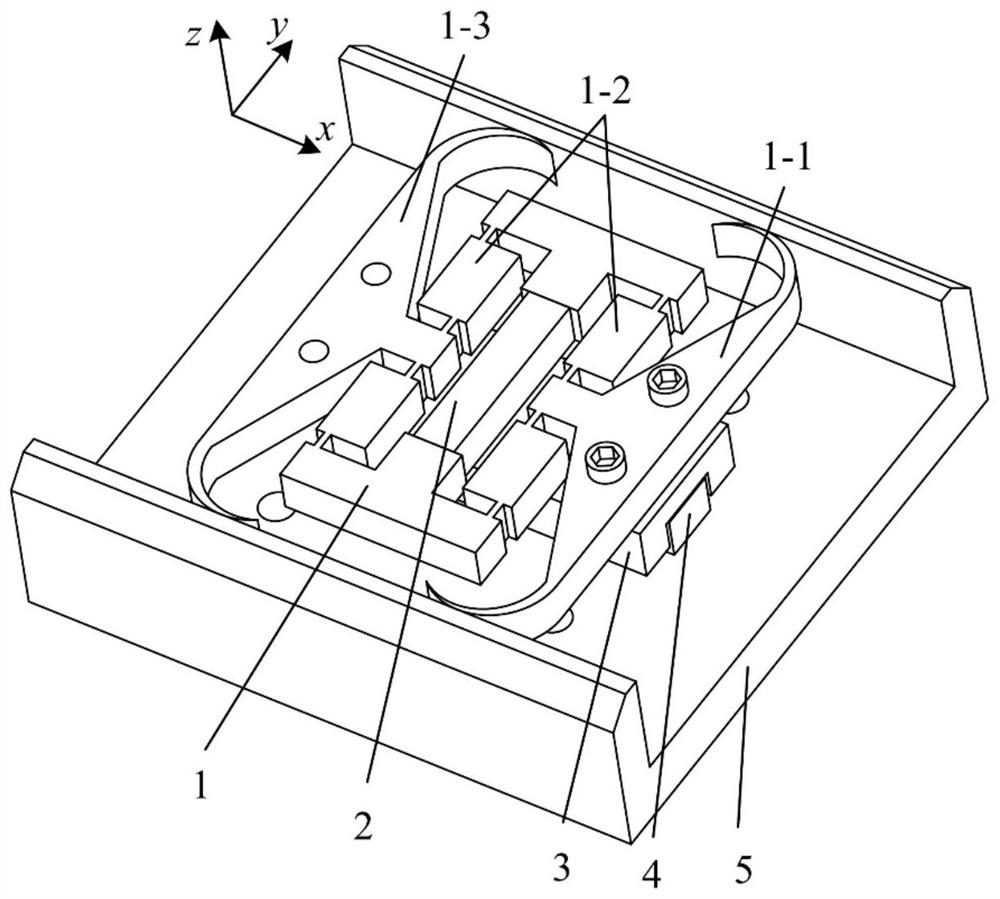

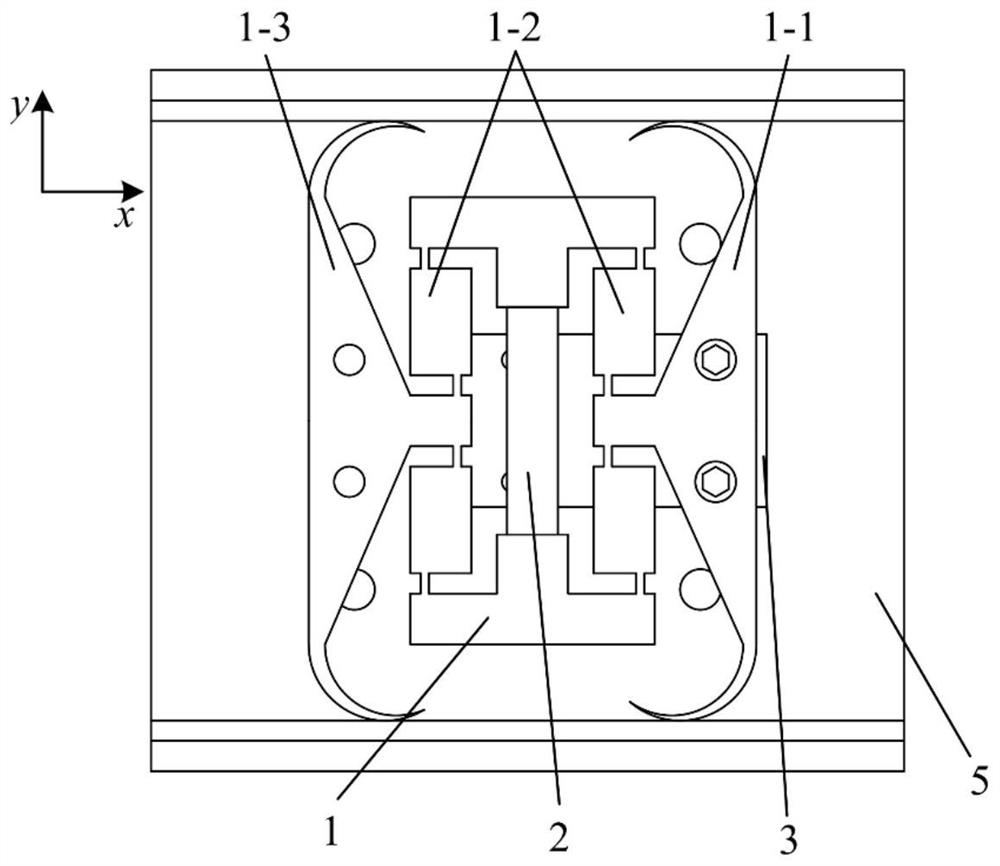

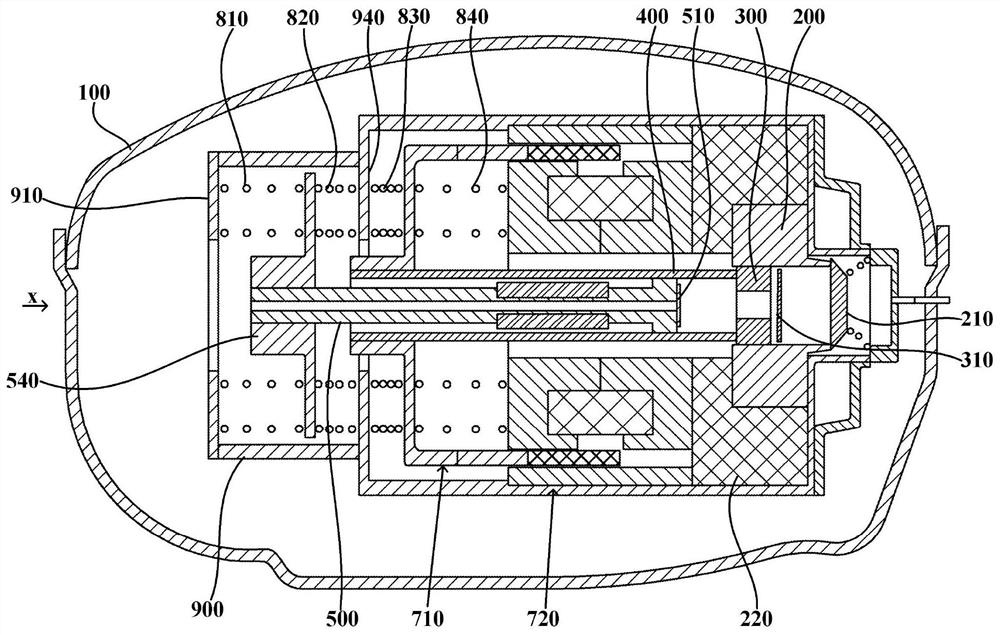

Double-foot driving piezoelectric linear motor and electric excitation mode

InactiveCN103427704AImprove efficiencyIncrease thrustPiezoelectric/electrostriction/magnetostriction machinesElectricitySignal on

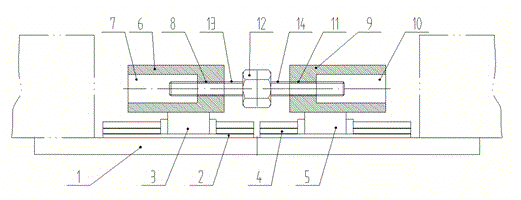

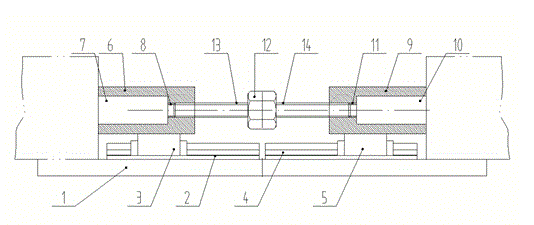

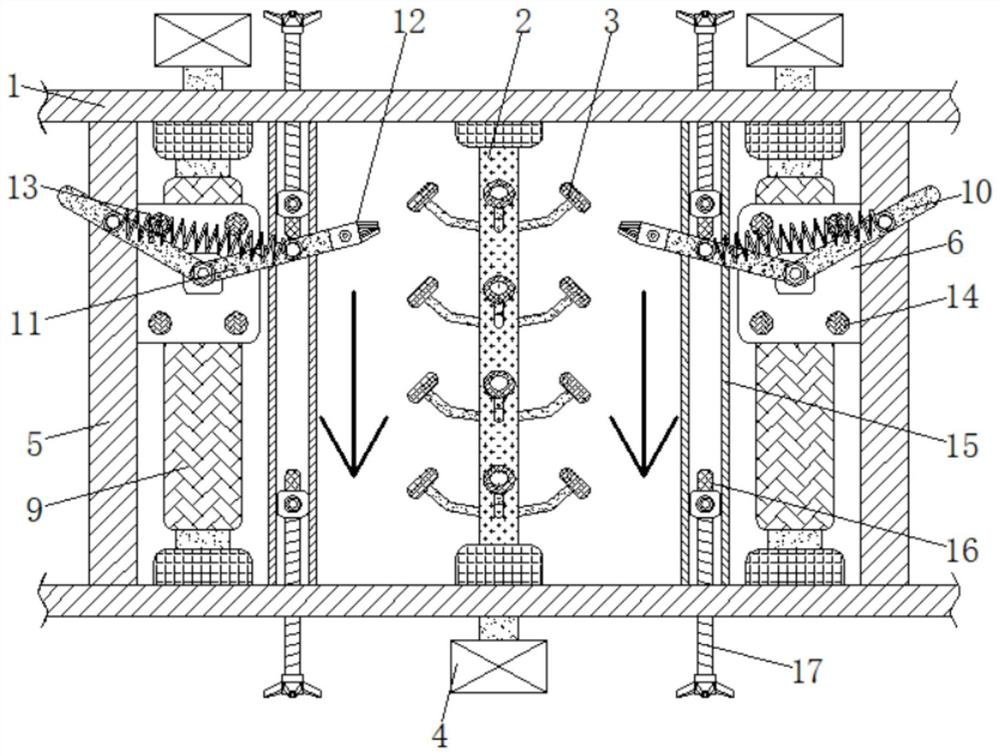

The invention discloses a double-foot driving piezoelectric linear motor and an electric excitation mode. The motor is composed of two stator sets, a rotor / linear guide rail, a pre-pressing guide rail, a pre-pressing spring and a base. The two stator sets are distributed symmetrically along axes, and the ends of the two stator sets are fixedly connected with the pre-pressing guide rail. Under the action of elastic restoring force generated by elastic deformation of the pre-pressing spring, the two stator sets keep in contact with the rotor / linear guide rail, so that an outage self-locking function is provided for the piezoelectric linear motor. Each of the two stator sets is composed of piezoelectric actuation units, flexible connectors and a driving foot, wherein two ends of the piezoelectric actuation units are connected with the driving feet and the base through the flexible connectors. The piezoelectric actuation units serve as modular structures, so that the whole motor structure is simple, the motor assembly efficiency is improved, and batch production is facilitated. According to the double-foot driving piezoelectric linear motor and the electric excitation mode, the rotor / linear guide rail can be driven by the two stator sets alternately to perform rectilinear motion by imposing specific excitation voltage signals on laminated piezoelectric ceramic sets in the piezoelectric actuation units.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

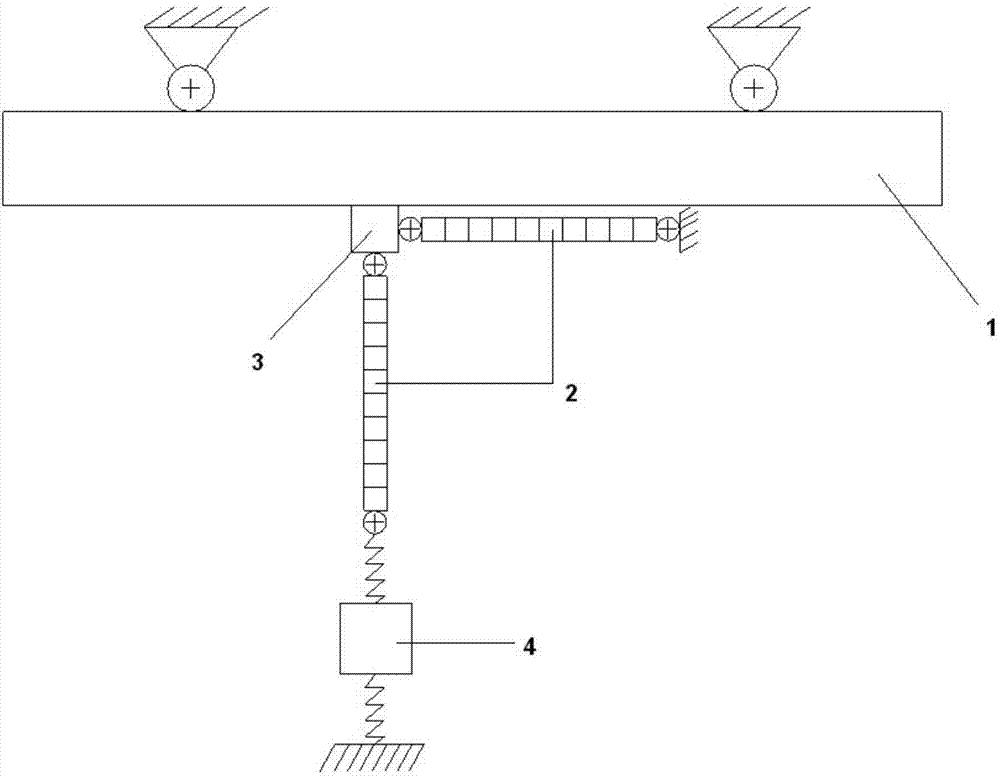

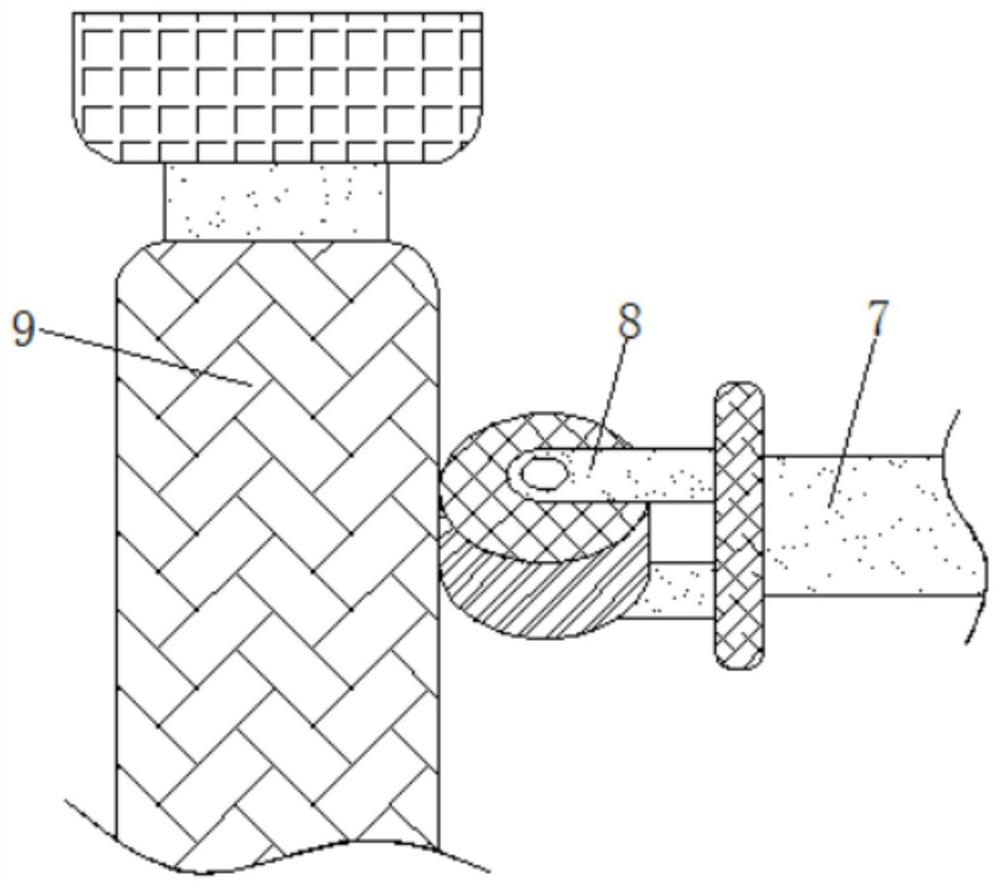

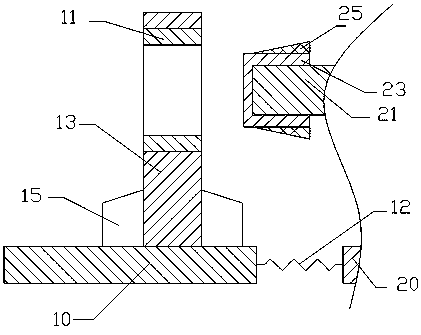

Balance weight type variable contact force piezoelectric motor

InactiveCN103701358AWith power-off self-locking functionExtended service lifePiezoelectric/electrostriction/magnetostriction machinesElectric machineMoving parts

The invention discloses a balance weight type variable contact force piezoelectric motor. The piezoelectric motor comprises a piezoelectric body and a moving part, wherein the piezoelectric body is contact with the moving part through elastic restoring force produced by an elastic prepressing element; the elastic extension direction of the elastic prepressing element is perpendicular to the actuating direction of the piezoelectric motor; in addition, the piezoelectric body is hinged to a transverse base; a connecting line between the piezoelectric body and the transverse base is parallel to the actuating direction of the piezoelectric motor. The piezoelectric motor has high thrust and large stroke, can bilaterally move, has a long service life, and simultaneously has a self-locking function during power off.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

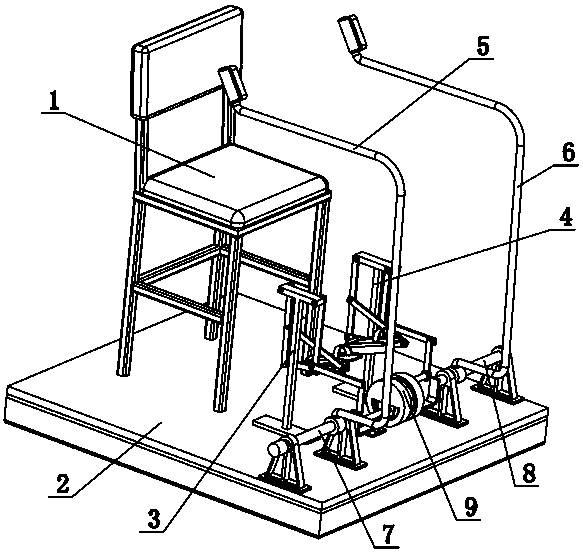

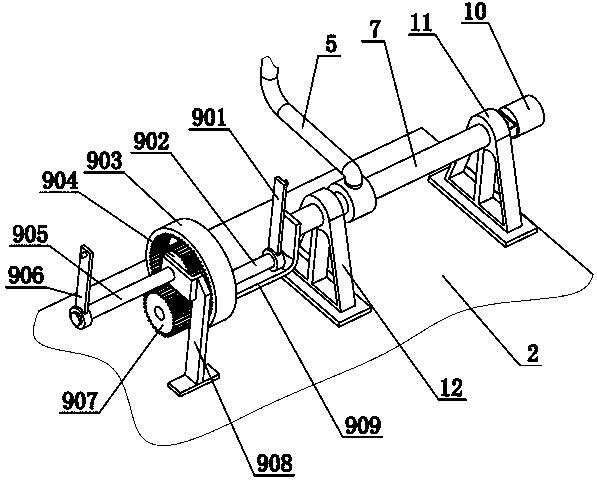

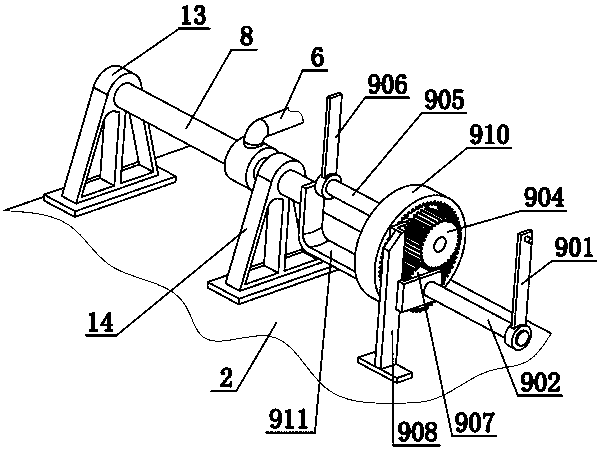

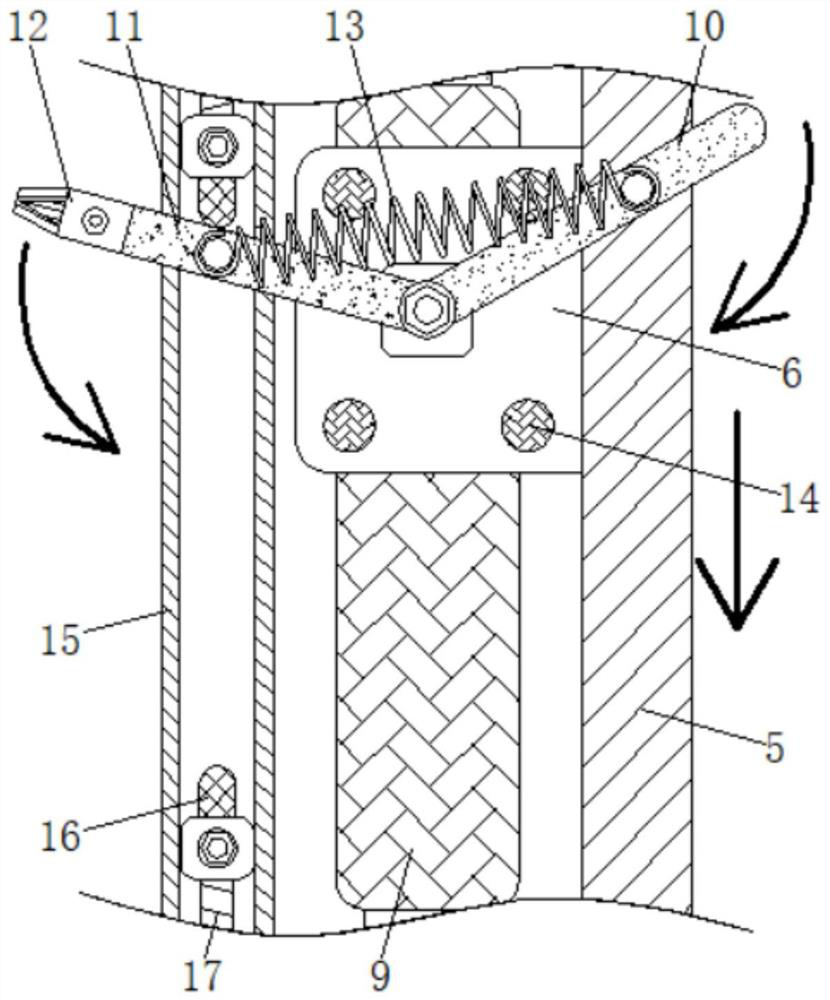

Four-limb rehabilitation training device with function of moving angle detection

InactiveCN108938323AImprove rehabilitation effectRealize directional movementChiropractic devicesDiagnostic recording/measuringDrive shaftControl system

The invention discloses a four-limb rehabilitation training device with a function of moving angle detection. The device comprises a lower right limb mechanism and a control system, left and right hand swing rods are fixed to left and right rotary shafts respectively, rotary supporting members of the left and right rotary shafts are arranged on a base, a rotary encoder is fixed to the right rotaryshaft, the rotary encoder is connected with the control system through a line, the left and right rotary shafts are connected with two inner gears, the two inner gears mesh with two meshed cylindrical gears, the two cylindrical gears are fixed to left and right transmission shafts respectively, left and right rocking rods which are fixed to the left and right transmission shafts are connected with left and right lower limb mechanisms respectively, two revolute four-bar mechanisms are adopted by the left and right lower limb mechanisms to be connected with left and right pedal plates to achieve the swinging of legs in the lower limb moving process of a patient, four limbs move synchronously, and the moving angles of the limbs of the patient are detected by the rotary encoder to perform evaluation feedback on the rehabilitation effect of the patient.

Owner:ANYANG NORMAL UNIV

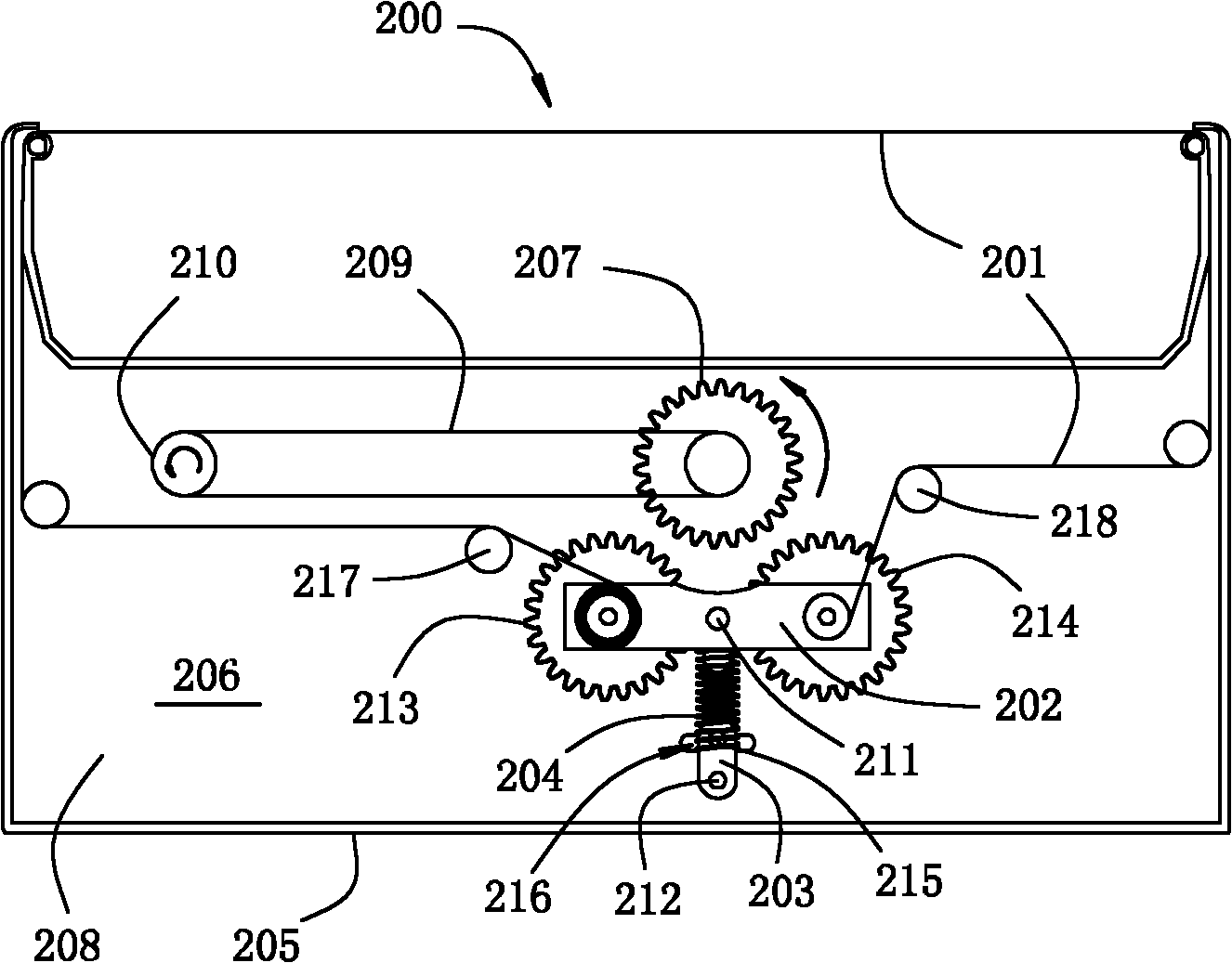

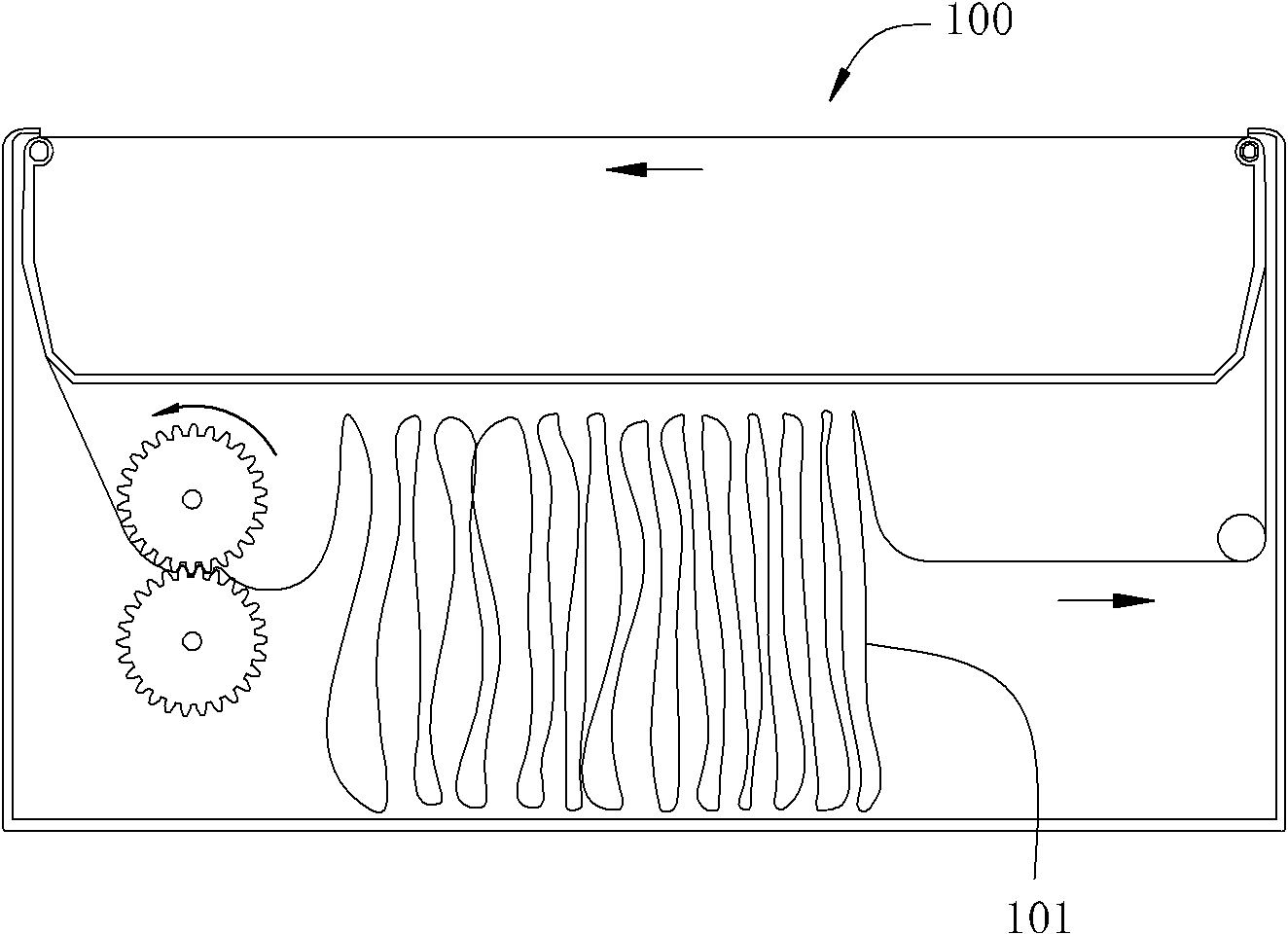

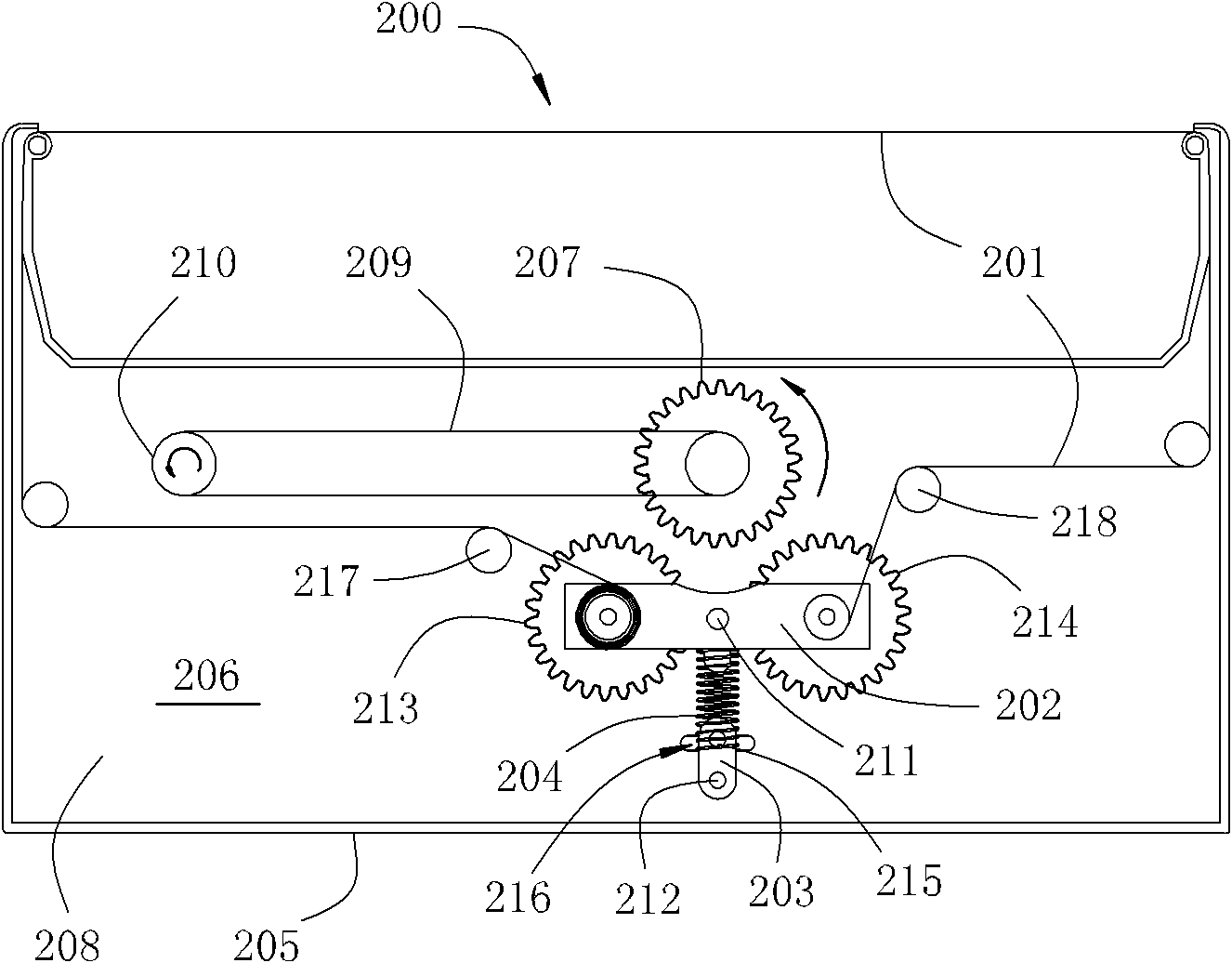

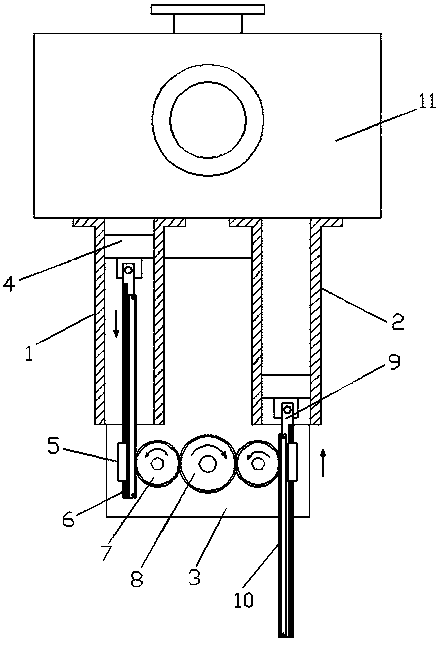

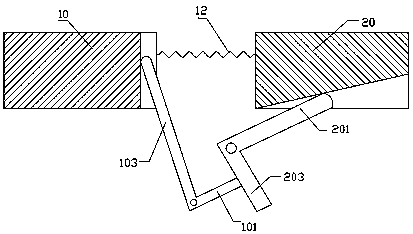

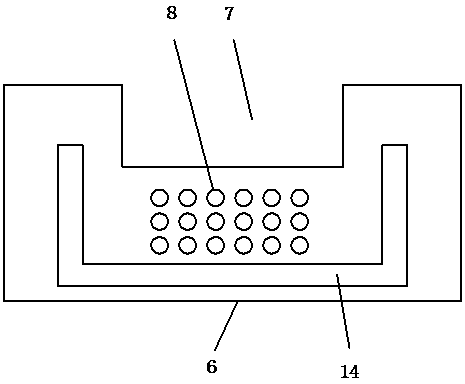

Ribbon cartridge

ActiveCN102092201AAchieve reverse motionExtended service lifeInk ribbon cartridgesSupport pointGear wheel

The invention discloses a ribbon cartridge applied to a needle printer. The ribbon cartridge comprises a ribbon, a seesaw, a connecting rod and a cartridge body. A driving gear is arranged in the cartridge body; the seesaw is rotatably fixed on a first supporting point; a first transmission gear and a second transmission gear are fixed at two ends of the seesaw in a rotatable mode; the connecting rod is rotatably fixed on a second supporting point; a locking block on the connecting rod is inserted into a chute on the cartridge body and can slide; the first supporting point and the second supporting point are positioned on the cartridge body; the first supporting point is positioned between the second supporting point and the driving gear; a compressed spring is fixed between the connecting rod and the seesaw; a first ribbon passing shaft and a second ribbon passing shaft are arranged in the cartridge body; two ends of the ribbon respectively run around either the first ribbon passing shaft or the second ribbon passing shaft and are fixed on middle shafts of the first and second transmission gears; a part of the ribbon positioned between the first ribbon passing shaft and the first transmission gear and a part of the ribbon positioned between the second ribbon passing shaft and the second transmission gear are positioned on one side of the first supporting point facing the driving gear along the direction of a connecting line of the first supporting point and the driving gear. The ribbon cartridge can effectively improve the service life of the ribbon.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD OF ZHUHAI

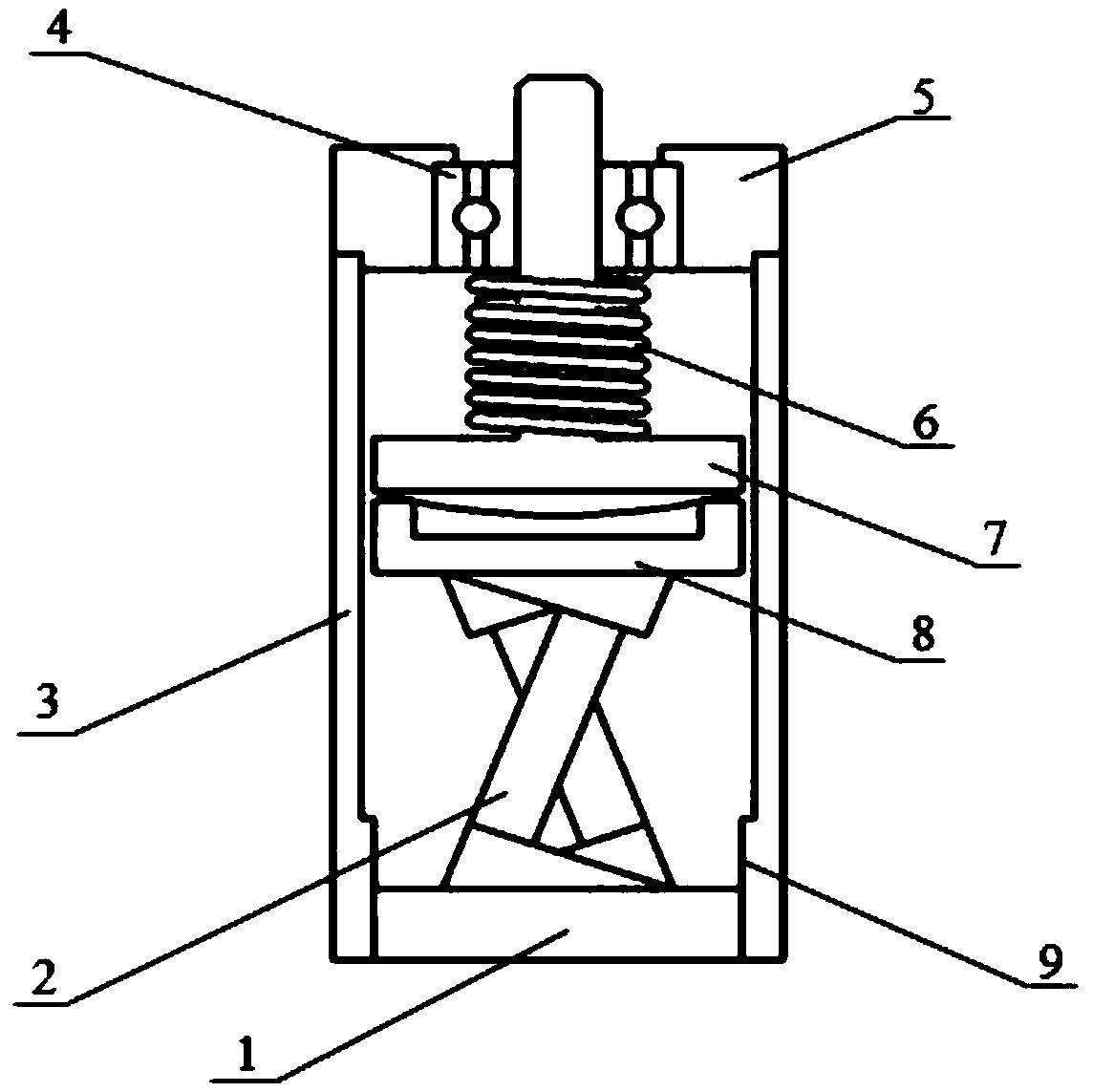

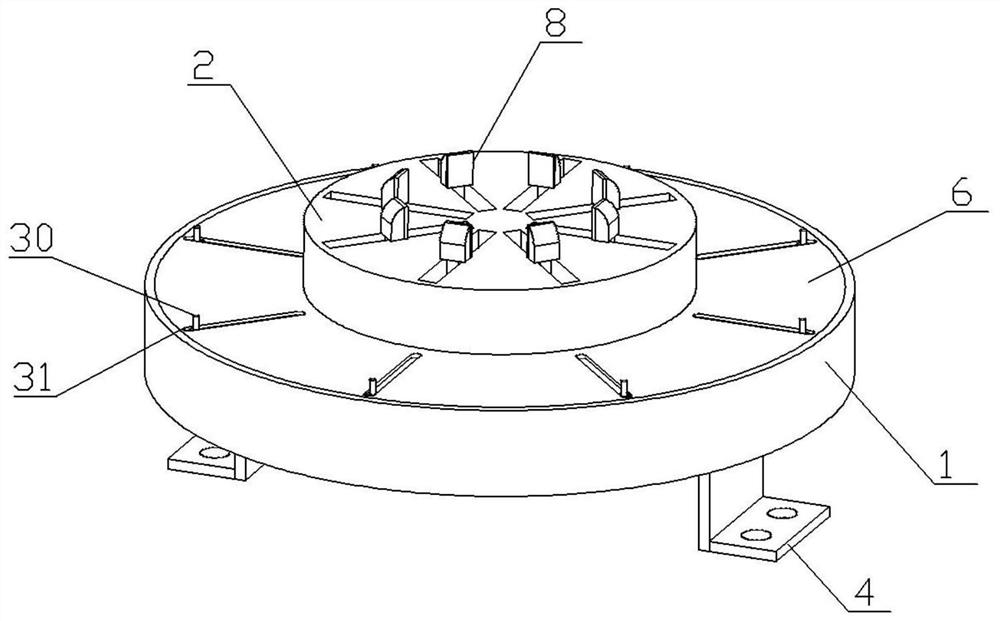

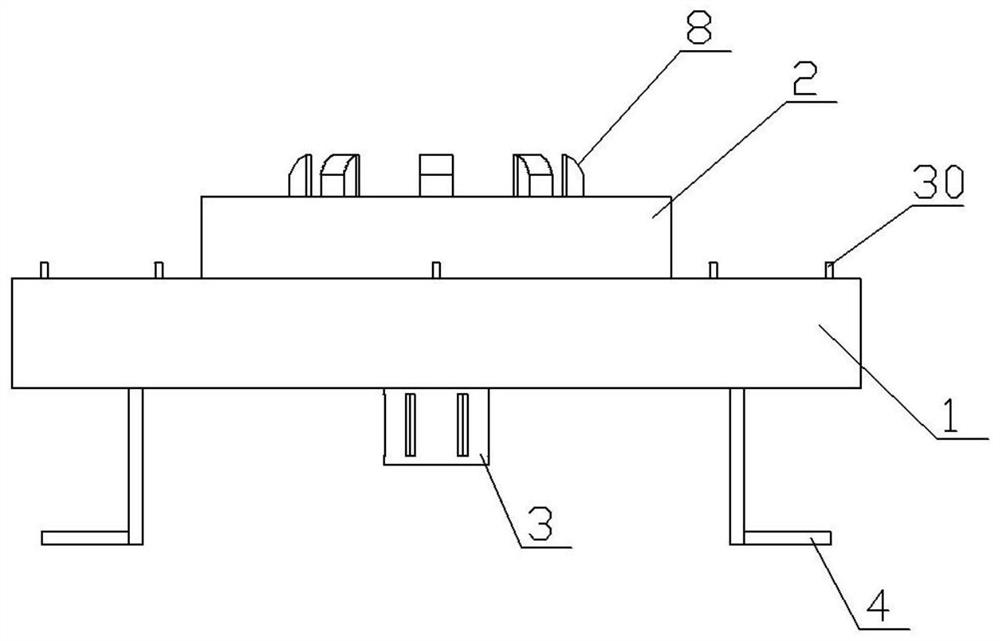

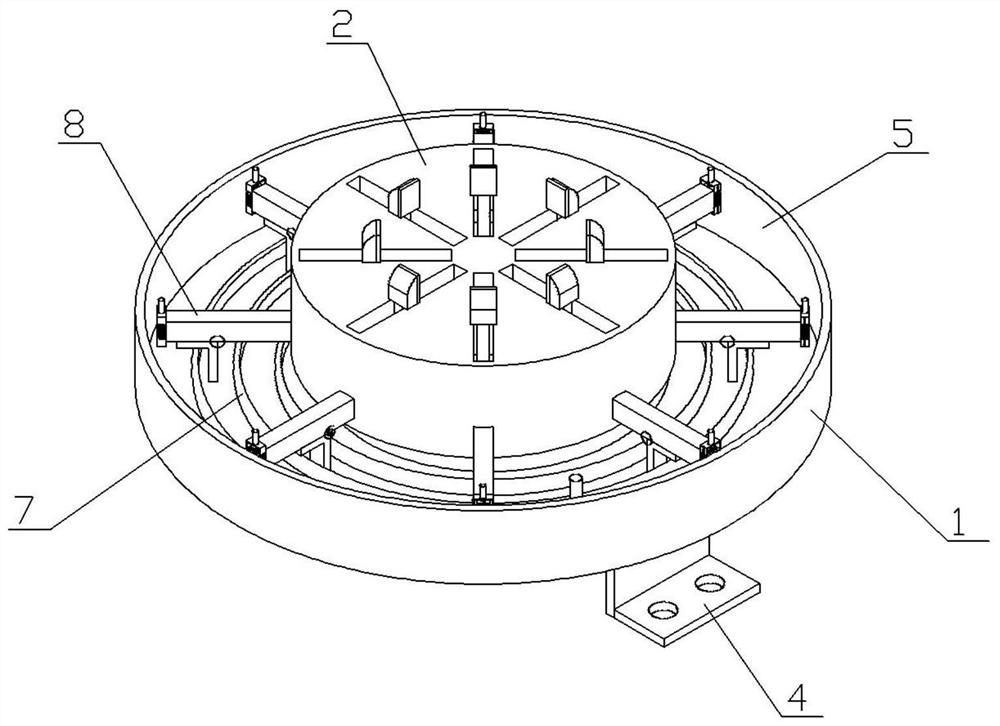

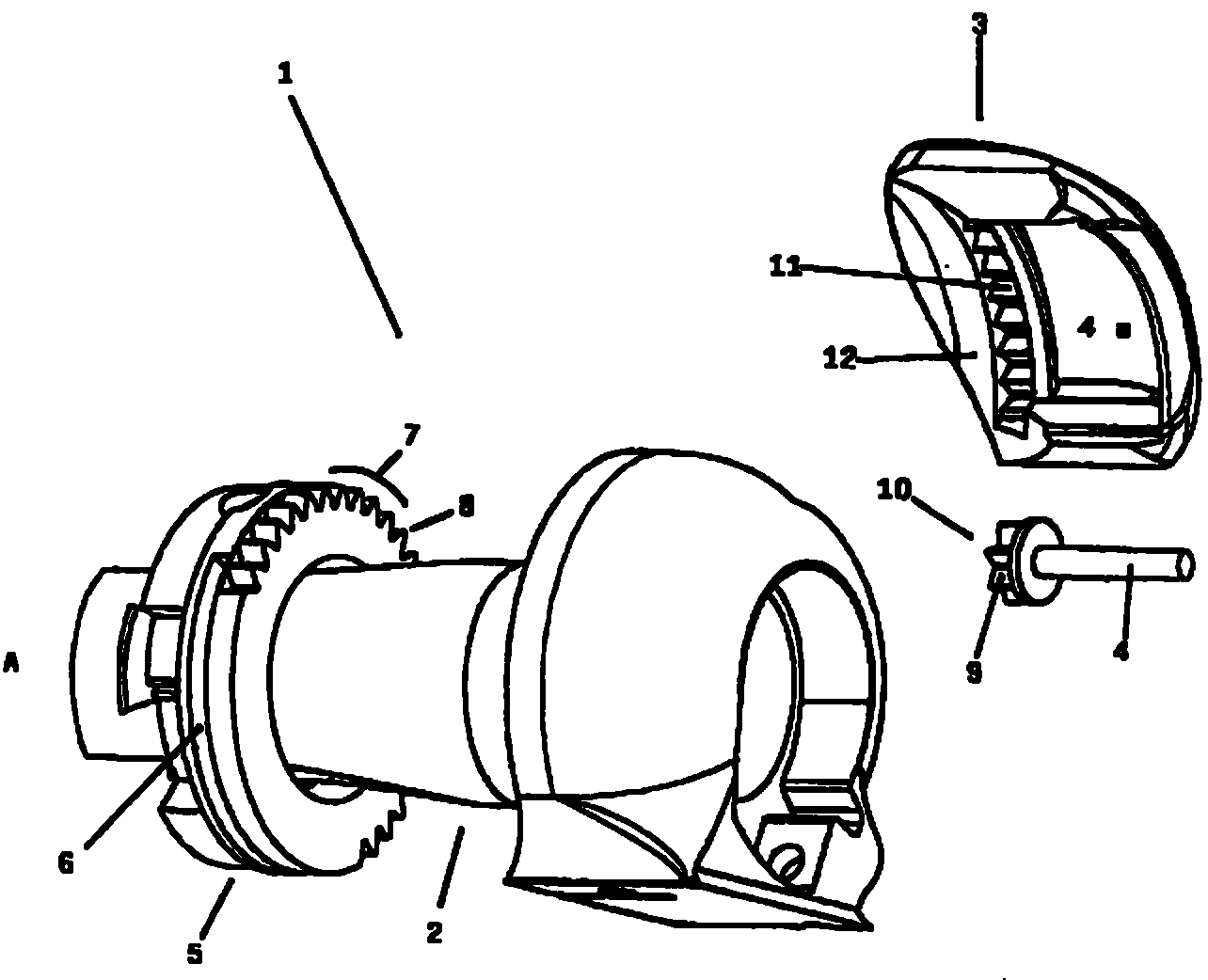

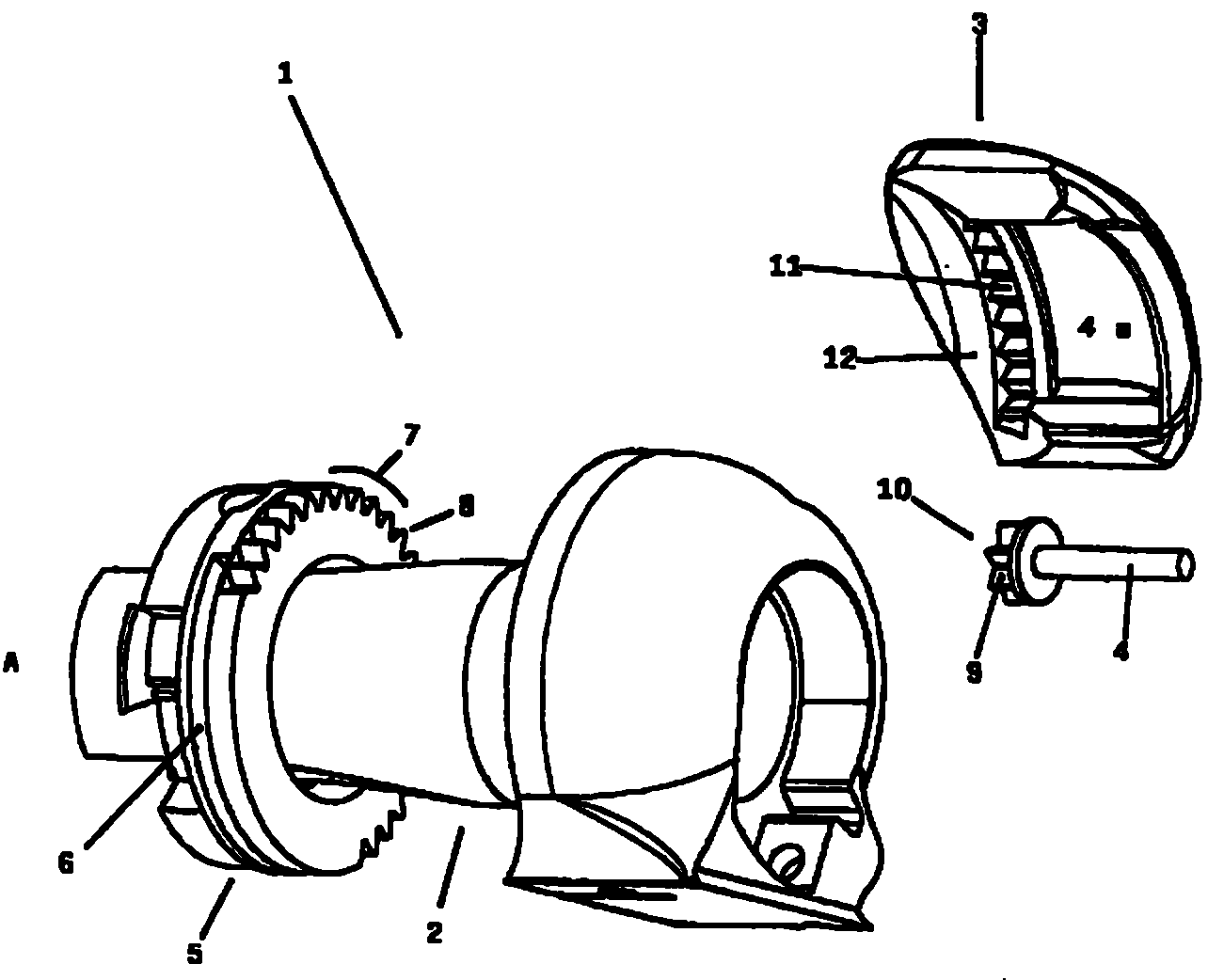

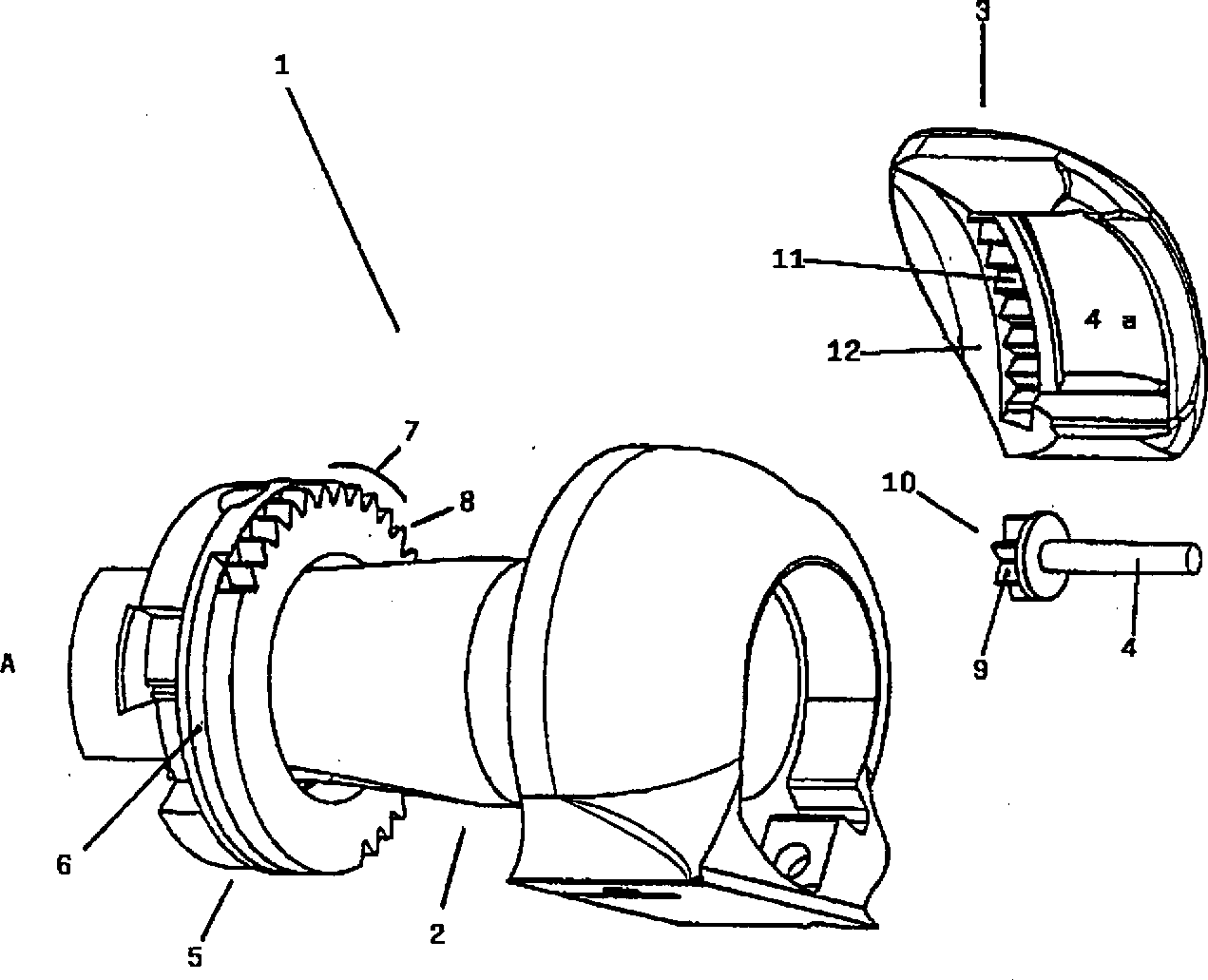

Impact piezoelectric rotary motor

ActiveCN108712103AIncrease frictionAchieve continuous rotationPiezoelectric/electrostriction/magnetostriction machinesMiniaturizationMechanical engineering

The invention discloses an impact piezoelectric rotary motor, which comprises piezoelectric stacks put into a hollow cavity of a cylinder sleeve, a vibration coupler and a rotor, wherein two symmetrically distributed bosses with inclined surfaces are arranged on a bottom fixed plate of the cylinder sleeve; the bosses with the inclined surfaces are arranged on the bottom surface of the vibration coupler in a mirror symmetry manner; two piezoelectric stacks which are symmetric around a center line are obliquely arranged between the bottom fixed plate of the cylinder sleeve and the vibration coupler; two end surfaces of the piezoelectric stacks are arranged at the top ends of the inclined surfaces of the bosses separately; a contact surface in contact with the top end of the vibration coupleris arranged at one end of the rotor and an output shaft is arranged at the other end; a preloaded spring also sleeves the output shaft; and the output shaft extends out of a bearing fixed on an end cover. According to the impact piezoelectric rotary motor, miniaturization of the rotary motor is facilitated, the problems that an existing rotary motor is complicated in structure and difficult to process, manufacture and produce in batches are well solved and the impact piezoelectric rotary motor is suitable for the field of precise control, such as high-precision nano drive.

Owner:HEFEI UNIV OF TECH

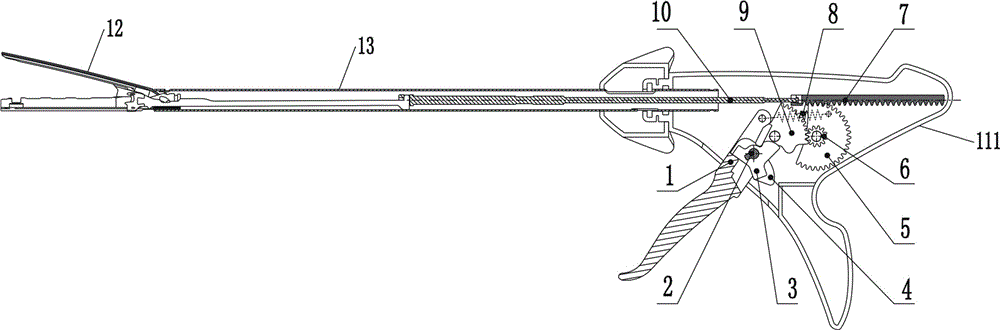

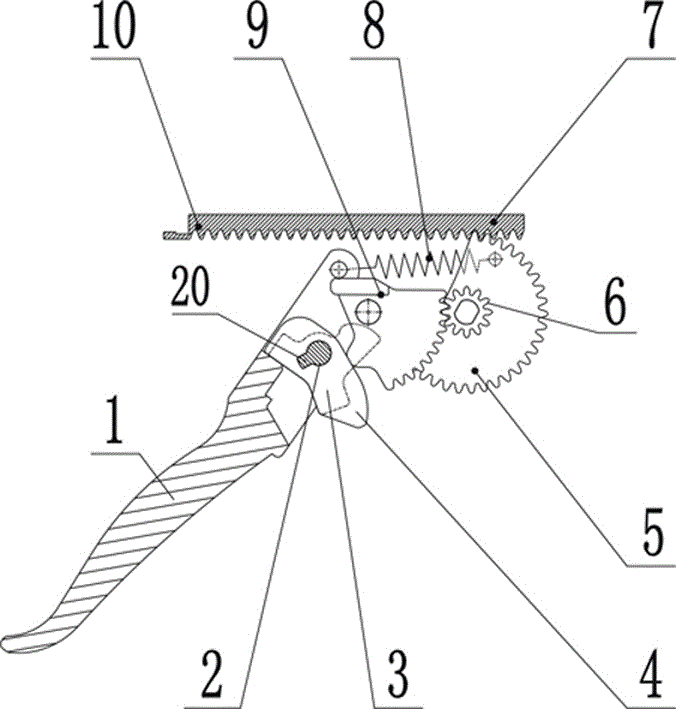

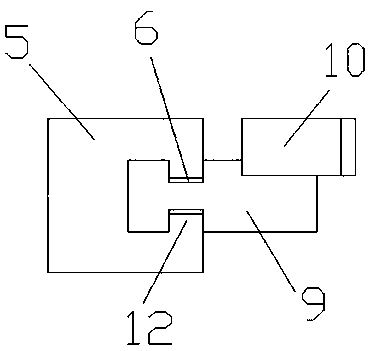

One-part propelling and retreating mechanism and endoscopic cutting stapler comprising same

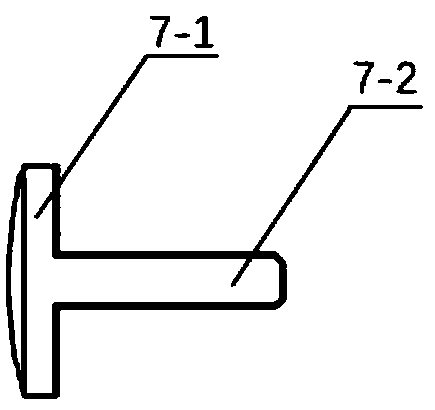

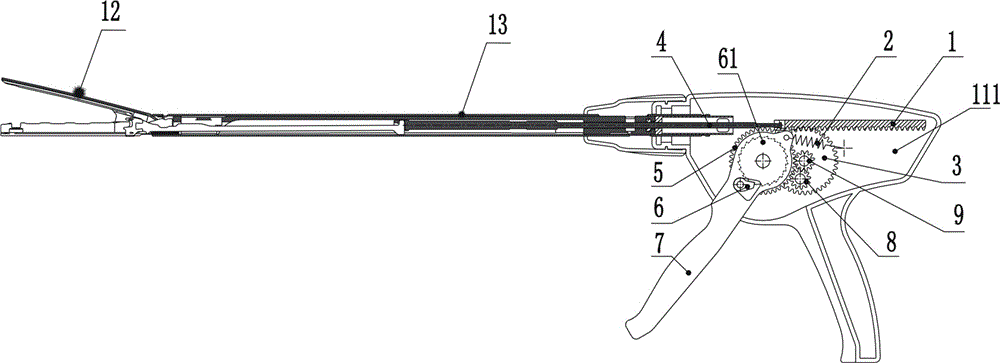

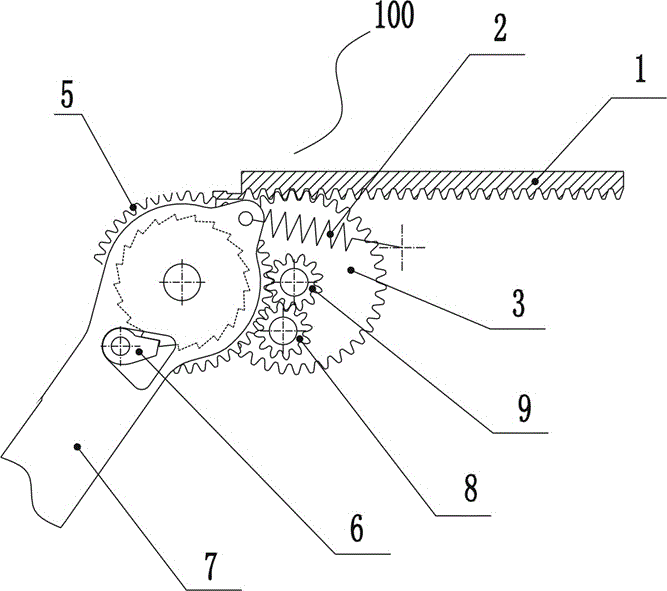

InactiveCN105919640AAchieve the purpose of cutting at one timeImprove reliabilityIncision instrumentsSurgical staplesPull forceGear drive

The invention discloses a one-part propelling and retreating mechanism and an endoscopic cutting stapler comprising the same. The one-part propelling and retreating mechanism comprises a turning rod, a pawl, a driving gear, a transmission gear, a reversing gear, a cutting gear and a cutting rack, wherein the turning rod overcomes tension of a spring to turn, the pawl is fixedly connected with the turning rod, a ratchet wheel is fixed on the turning rod and in transmission connection with the pawl, the driving gear is fixedly connected with the ratchet wheel and is in transmission connection with the transmission gear and the reversing gear, and the cutting rack is in transmission connection with the cutting gear. The stapler comprises the one-part propelling and retreating mechanism, a casing and an ejection rod, wherein the one-part propelling and retreating mechanism is fixedly mounted on the casing. With adoption of a structure of the ratchet wheel and all the gears, cutting is finished once, an operation process is simplified, and the product reliability is improved remarkably.

Owner:HANGZHOU TIANREN BIOLOGICAL TECH CO LTD

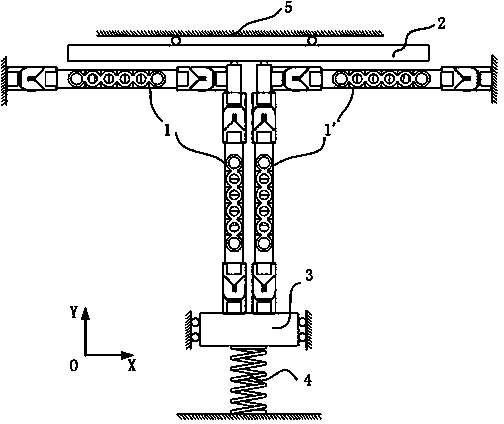

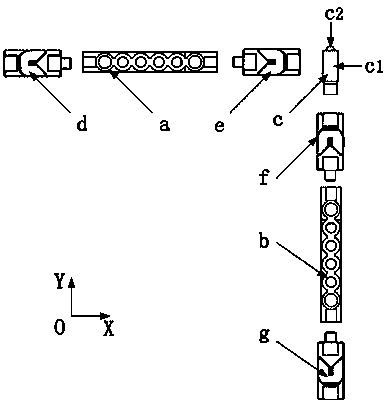

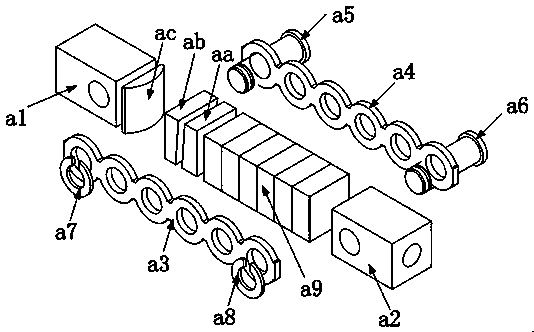

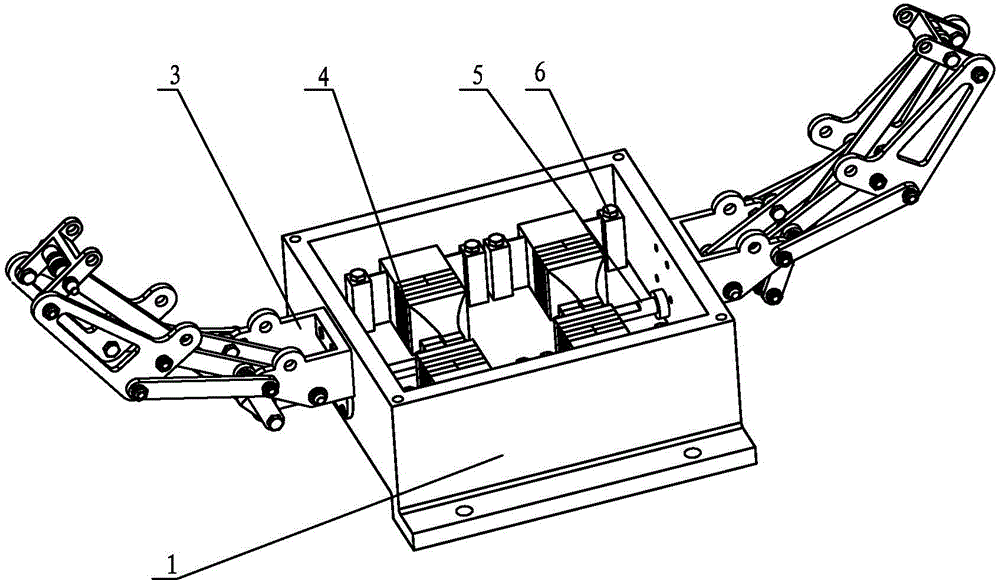

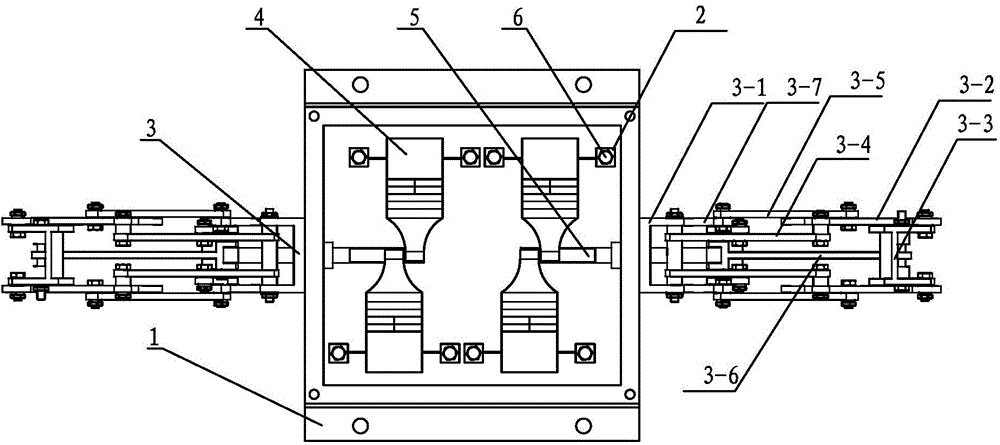

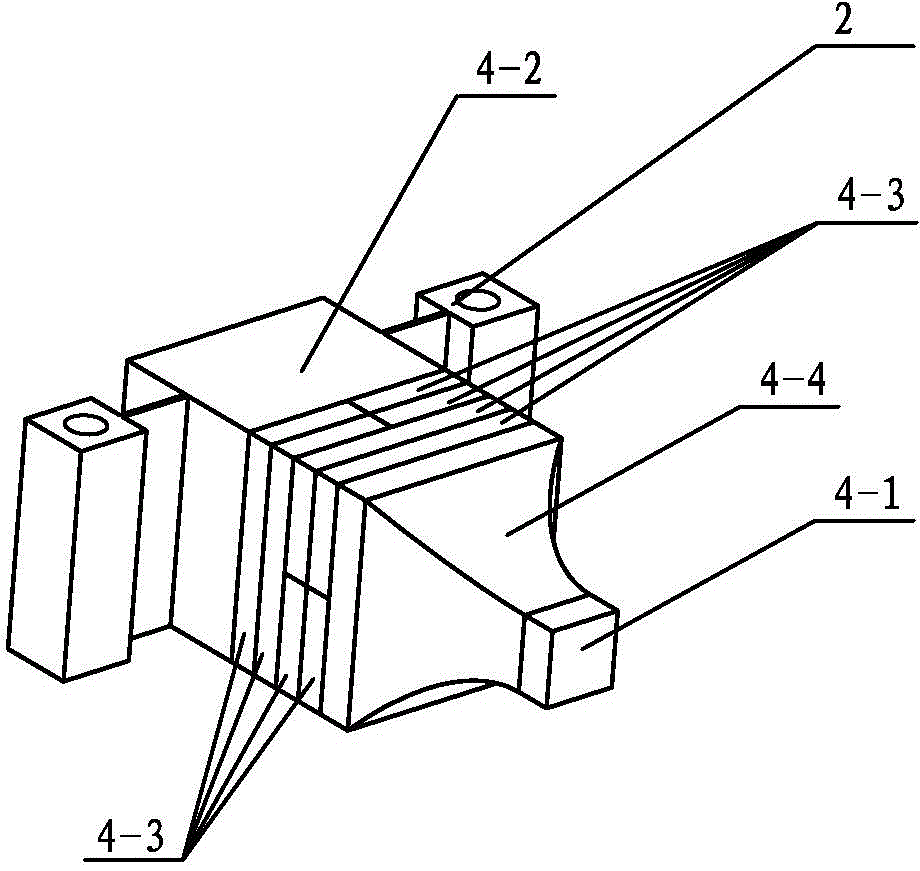

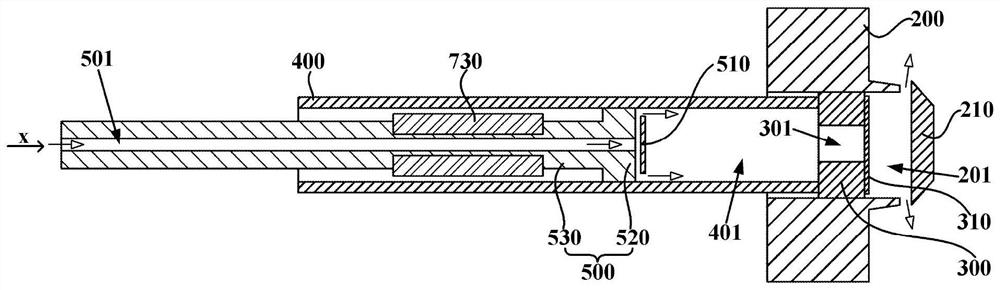

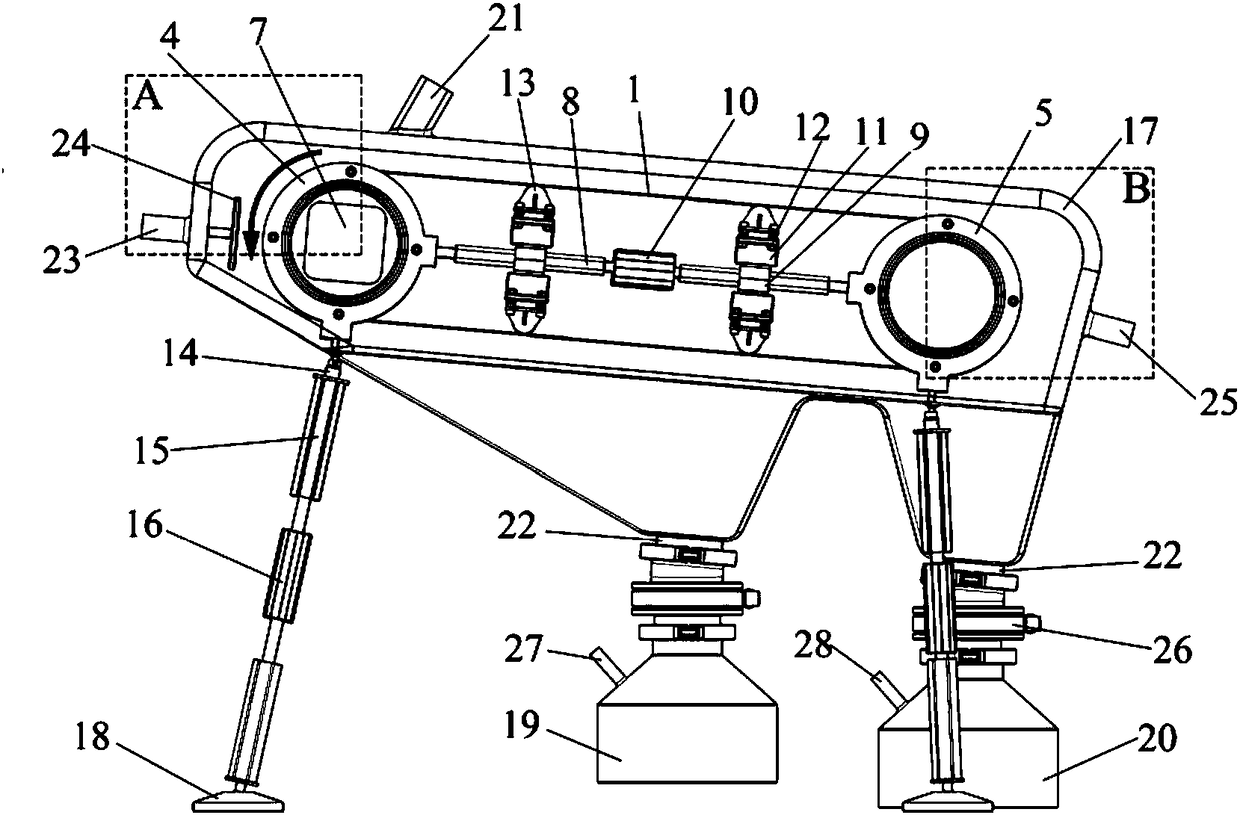

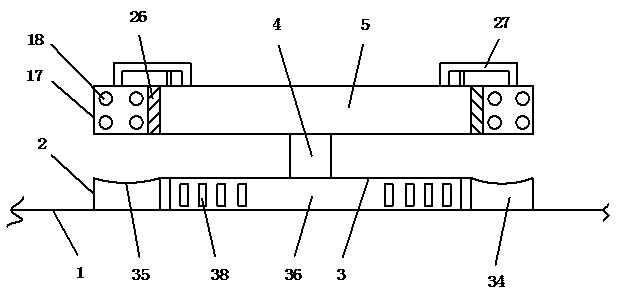

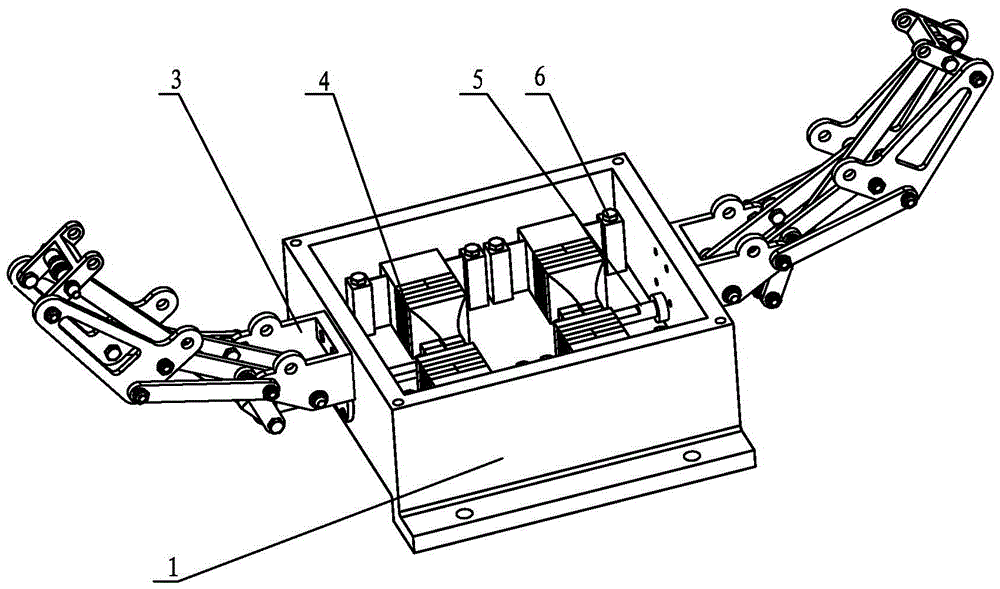

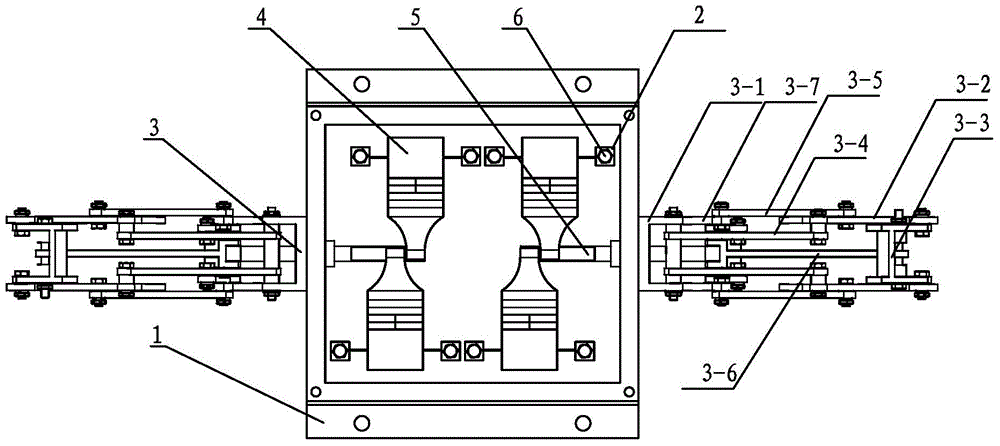

Space deployment mechanism driven based on multi-piezoelectric vibrator step crawling mode

ActiveCN104967357ASimple structureLow costPiezoelectric/electrostriction/magnetostriction machinesElectricityElectromagnetic interference

The invention discloses a space deployment mechanism driven based on a multi-piezoelectric vibrator step crawling mode, which relates to the field of space deployment mechanisms and aims at solving the problems of complicated structure, serious electromagnetic interference and complicated self locking existing in the current electromagnetic motor driving-type space deployment mechanism. The space deployment mechanism driven based on the multi-piezoelectric vibrator step crawling mode comprises a base, two shaft extension sleeves, two deployment mechanisms, four piezoelectric vibrators, two driving shafts and a mounting seat, wherein two opposite side walls of the base are provided with through holes, and the through holes in the two side walls are coaxial; the two shaft extension sleeves are fixed in the two through holes; the two deployment mechanisms are fixed on the two opposite side walls of the base respectively; the four piezoelectric vibrators are fixed inside the base via the mounting seat; and one ends of the two driving shafts are tightly connected with two piezoelectric vibrators via a pretightening force, and the other ends pass through the shaft extension sleeves to be connected with the two deployment mechanisms respectively. Thus, relaxation and contraction of the space deployment mechanism can be realized.

Owner:HARBIN INST OF TECH

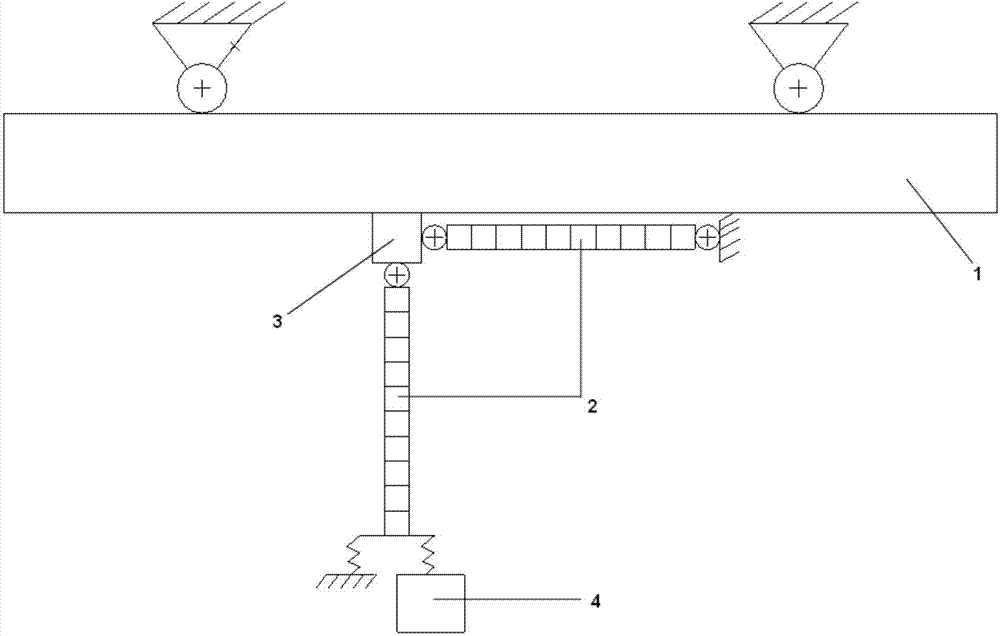

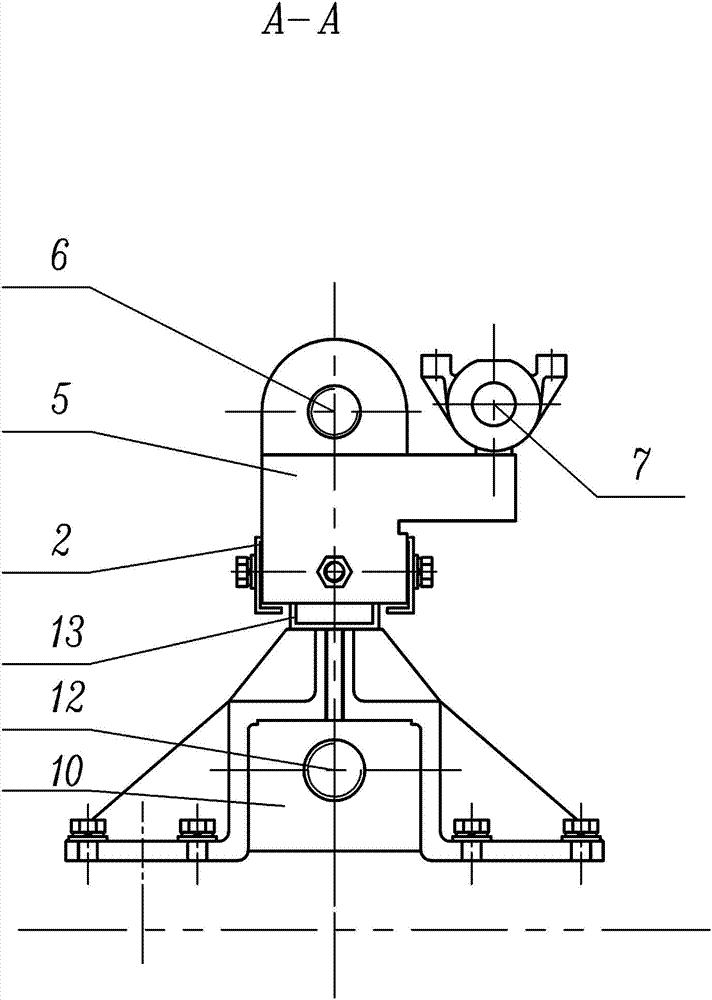

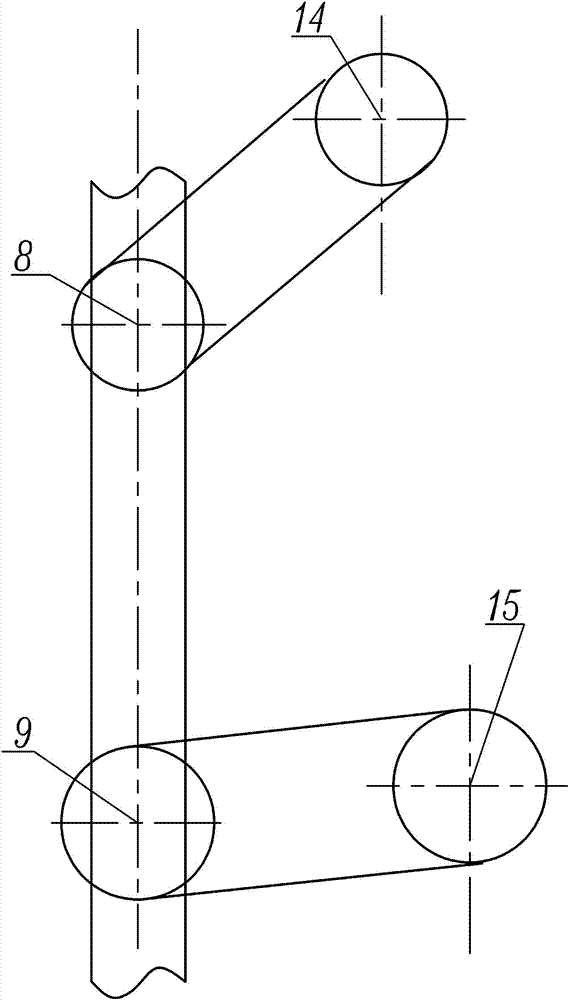

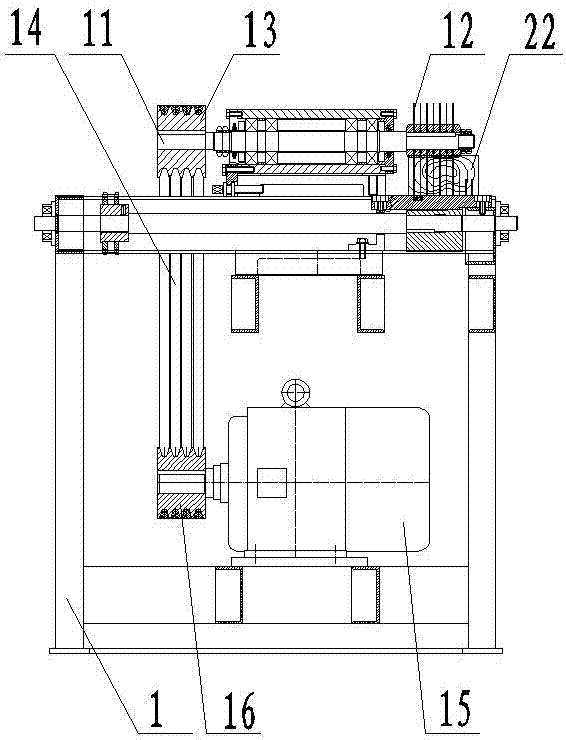

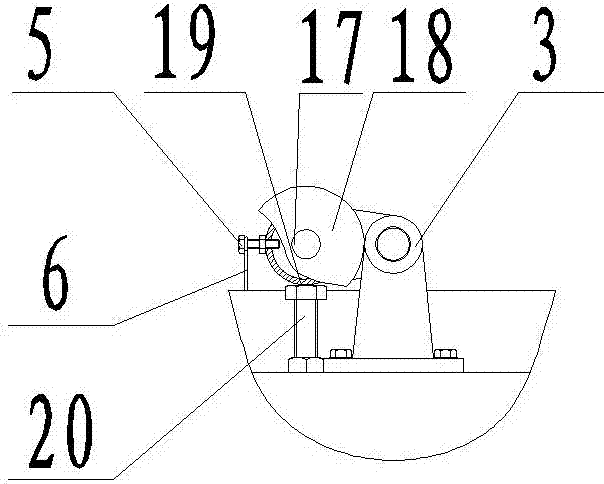

Two-way reciprocating rectilinear movement dual-drive device

ActiveCN102817120AImplementation timeAchieve reverse motionContinuous wound-up machinesEngineeringMechanical engineering

The invention relates to a two-way reciprocating rectilinear movement dual-drive device, which comprises a rack, wherein a fender screw rod nut mechanism and a ring plate screw rod nut mechanism are arranged on the rack in parallel; a ring plate sliding seat is arranged on the ring plate screw rod nut mechanism and is in sliding fit with a ring plate guide rail mechanism; a ring plate pull rod is fixedly connected with the ring plate sliding seat; a fender sliding seat is arranged on the fender screw rod nut mechanism and is in sliding fit with a fender guide rail mechanism; and a fender pull rod can be connected with the fender sliding seat through a manner that the length can be adjusted along an axial direction of a fender guide rail. According to the two-way reciprocating rectilinear movement dual-drive device, through adopting the structure, the movement accuracy is improved, and the aim that the fender pull rod and the ring plate pull rod are simultaneously moved in the same direction or the opposite direction is realized. An axial position of the fender pull rod can be adjusted through rotating an adjusting screw rod. Therefore, reasonable doffing is realized, a user can use conveniently, and the product quality is improved.

Owner:YICHANG JINGWEI TEXTILE MACHINERY

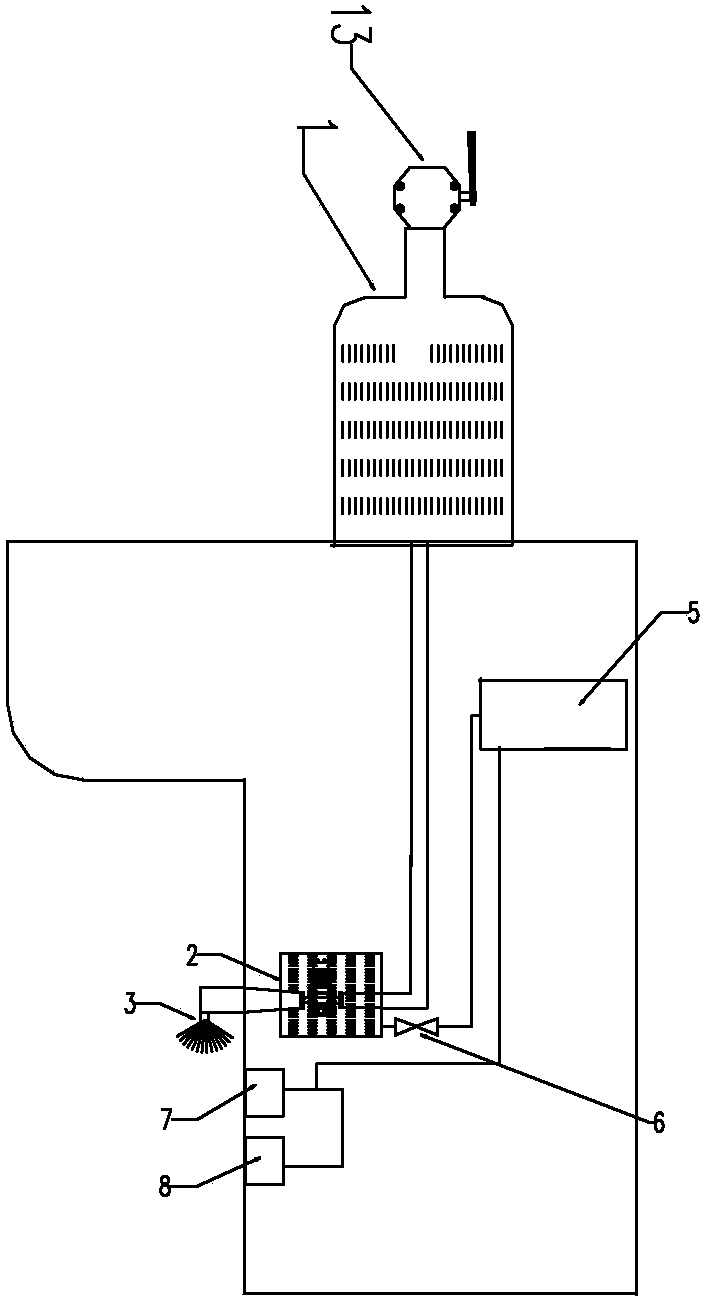

Inductive disinfection equipment and disinfection method applying same

ActiveCN108543214AExtended service lifeSimple manufacturing methodAntisepticsMedical devicesPortion sizeEngineering

The invention discloses inductive disinfection equipment and a disinfection method applying the same. The disinfection equipment adopts the inductive disinfection method. The disinfection equipment comprises a disinfection device and an inductive control device; the disinfection device contains a sterilizing and disinfecting solution, a jet orifice is arranged on the disinfection device for jetting the sterilizing and disinfecting solution, and the human portions are disinfected; the inductive control device comprises an induction module, a control module and a humidity detection module; the induction module obtains the human portion size to be disinfected, the control module is connected with the induction module, and according to the obtained human portion size data, the jet amount of the sterilizing and disinfecting solution of the disinfection device is regulated. The inductive disinfection equipment is simple in structure, hypochlorous acid is adopted for disinfecting, the using cost is lowered, and due to adjustable disinfection of the disinfection device, comprehensive disinfection is ensured.

Owner:广州泰道安医疗科技有限公司

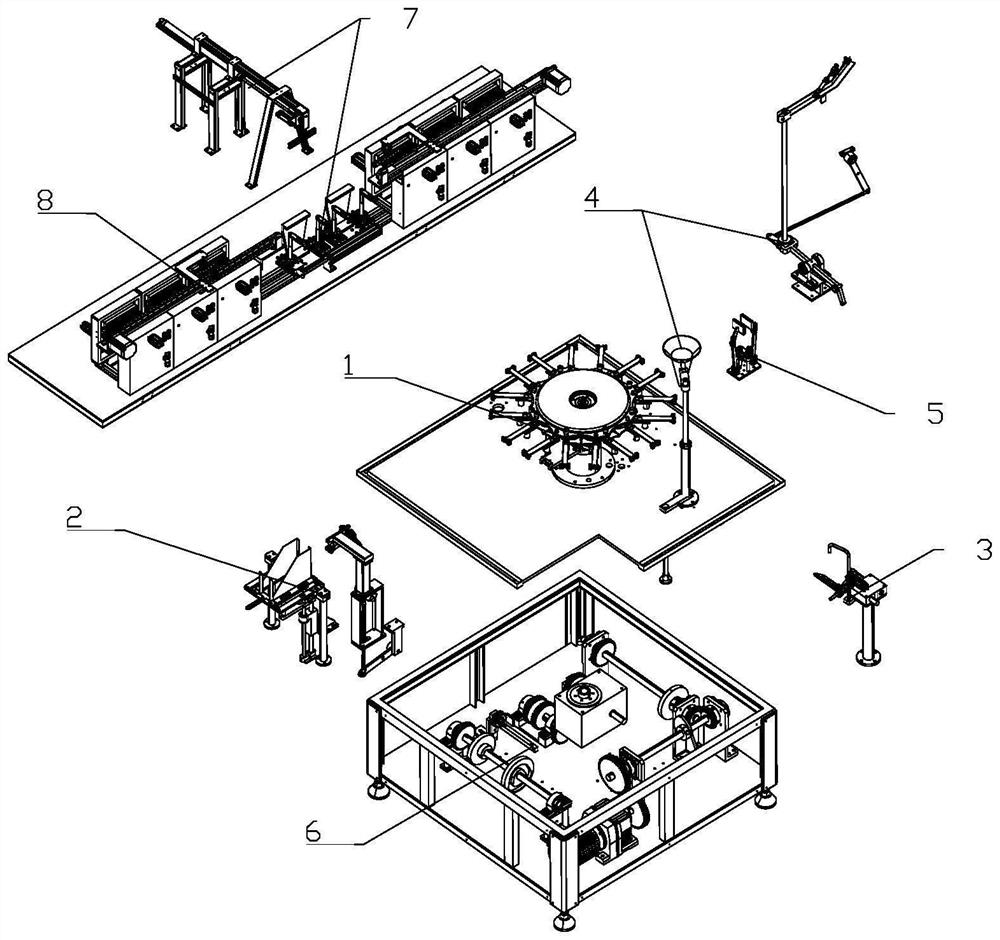

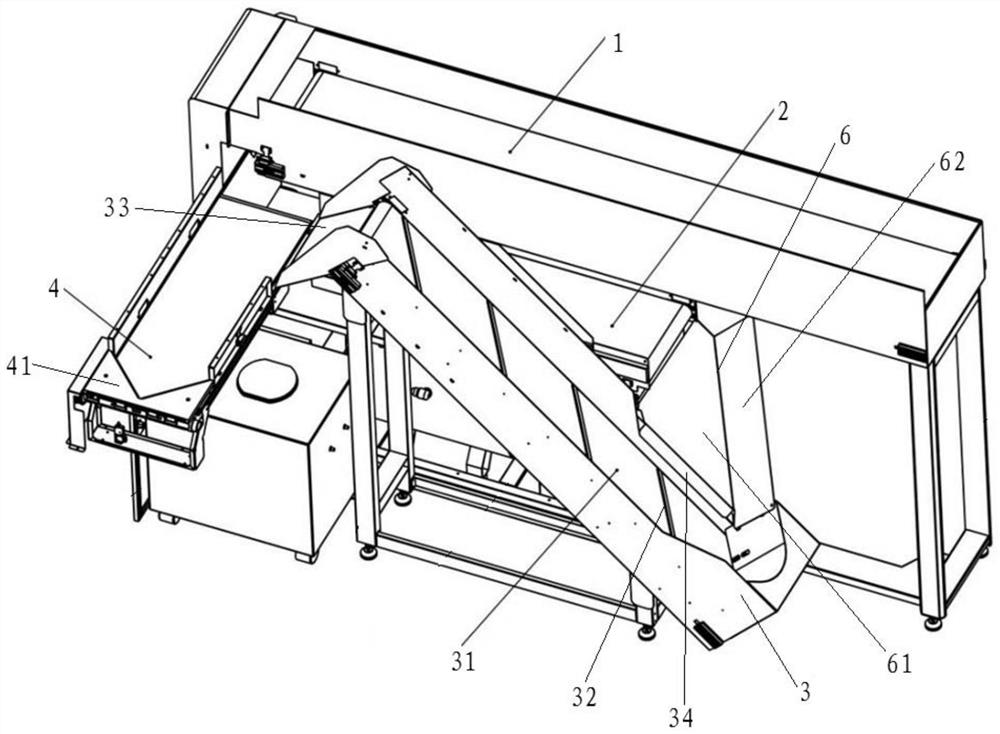

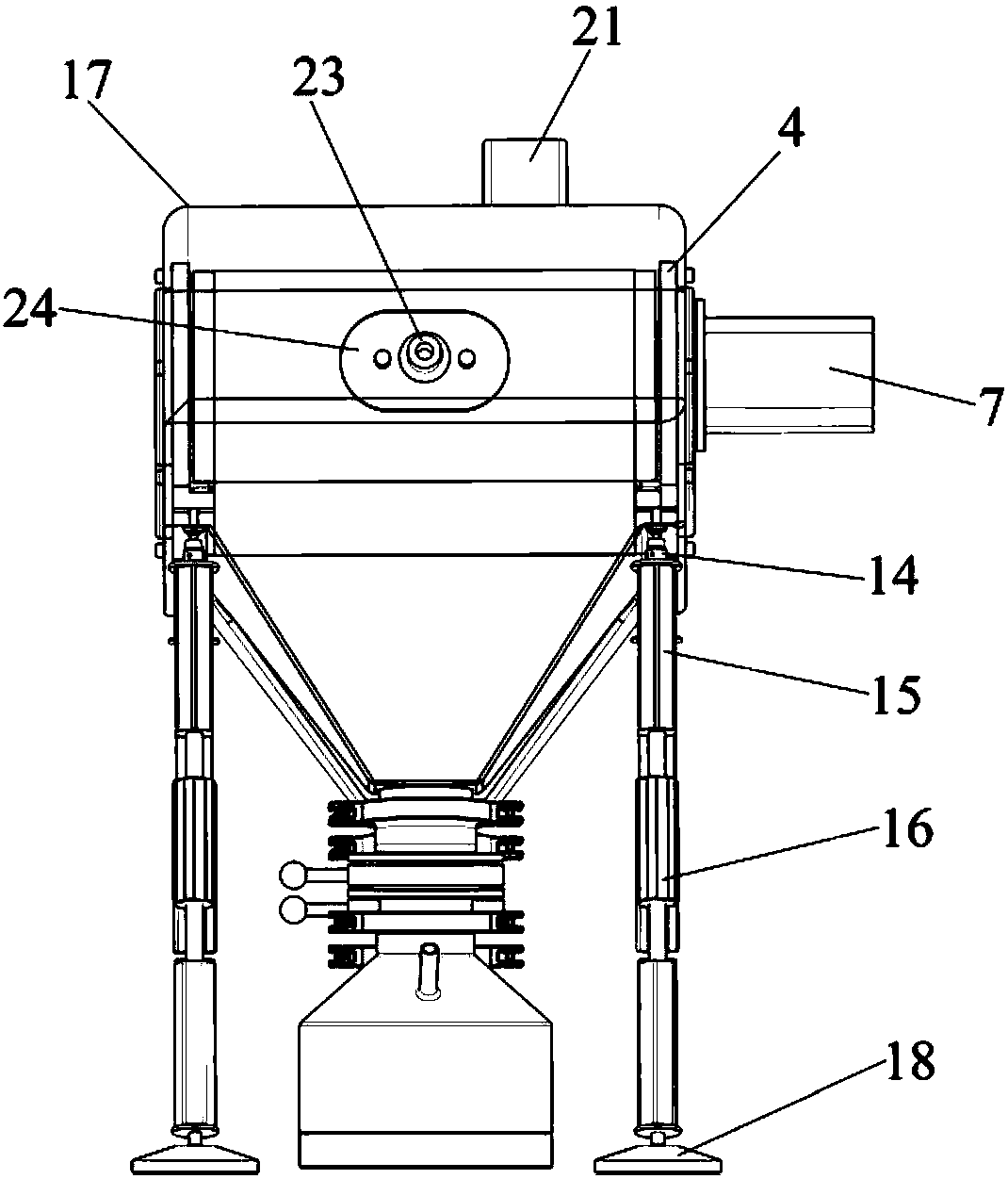

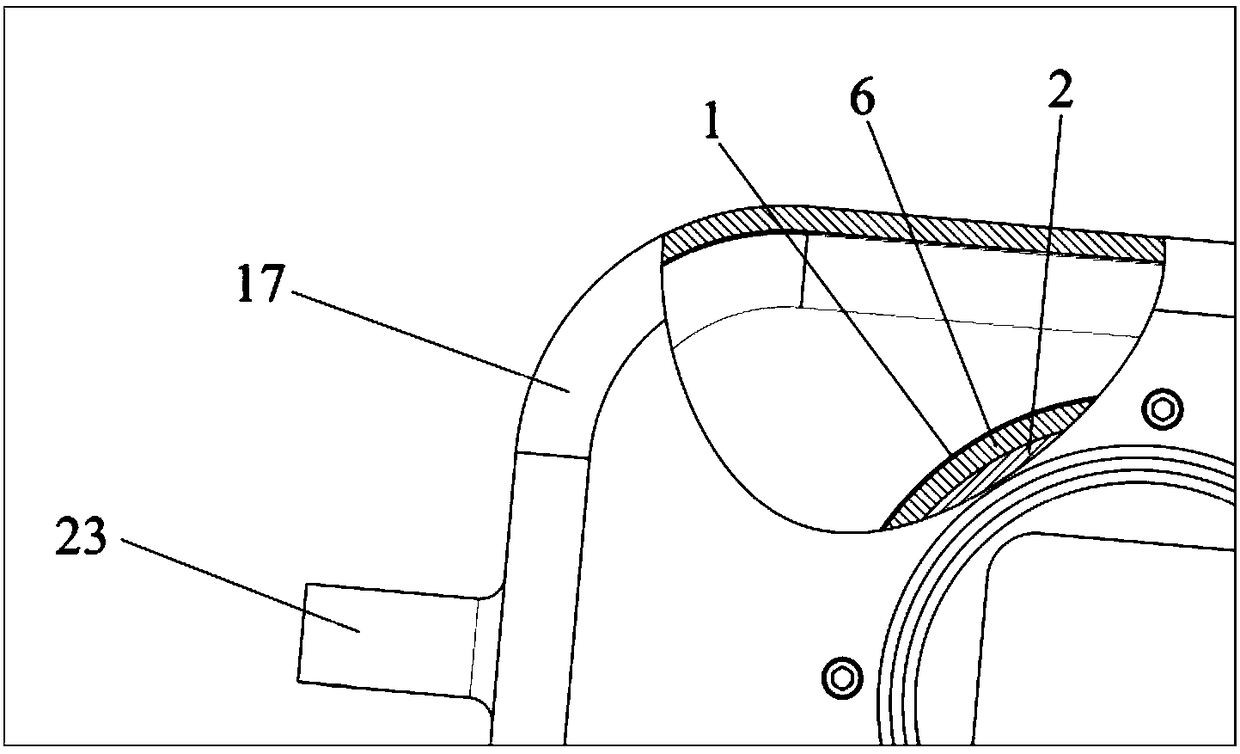

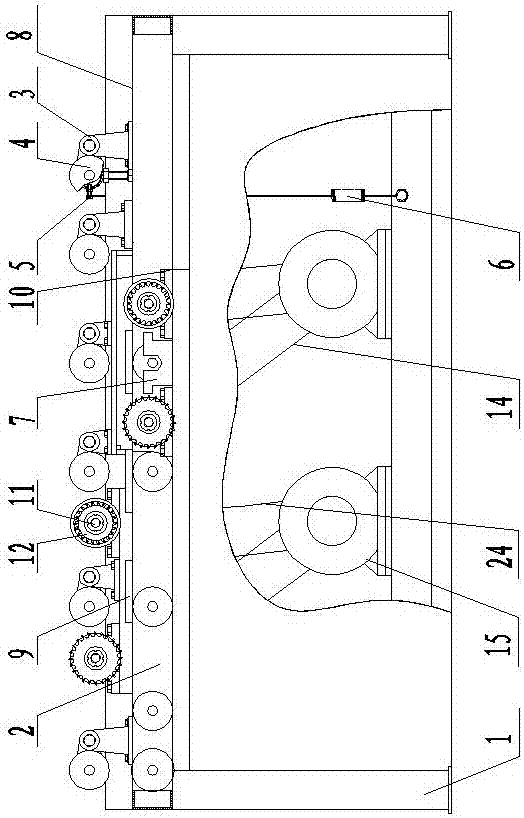

Automatic food bagging machine and working method thereof

InactiveCN113800048AImprove work efficiencySimple structurePackaging by pressurising/gasifyingWrapper twisting/gatheringProcess engineeringPower apparatus

The invention relates to an automatic food bagging machine. The automatic food bagging machine comprises a rack, a rotary bag clamping device, a bag feeding device, a bag opening device, a discharging device, a bag clamping device, a power device, a moving and taking device and heat sealing devices, wherein the rotary bag clamping device, the bag feeding device, the bag opening device, the discharging device, the bag clamping device, the power device, the moving and taking device and the heat sealing devices are mounted on the rack; and the power device is arranged below the rack, the moving and taking device is connected with the rotary bag clamping device and the heat sealing devices, and the heat sealing devices are arranged on the two sides of the moving and taking device respectively. The automatic food bagging machine has the advantages that packaging bag clamping is reliable and efficient; a connecting rod mechanism carries a packaging bag, and the carrying efficiency is high; the packaging bag is opened reliably and fully; food discharging is accurate and controllable; driving components are few, and transmission is compact and efficient; the packaging bags are moved and taken in order, and the moving and transporting efficiency is high; and the packaging quality is high, and the sealing performance is good.

Owner:伍福庆

Waste plastic recovery device

The invention relates to the technical field of plastic recovery processing, and in particular discloses a waste plastic recovery device. The waste plastic recovery device comprises a telescopic air cylinder and a pressure-bearing table, wherein the output end of the telescopic air cylinder is connected to a first pressure plate, the first pressure plate is provided with two oppositely formed chutes, slide plates are slidably connected in the chutes, and the slide plates are connected to the inner walls of the chutes through springs; two sides of the first pressure plate are separately connected to a first rack and a third rack, the first rack is engaged to a first gear, and the first gear is engaged to a second rack; the pressure-bearing table is connected to a first baffle plate and an air bag filled with gas, and the first baffle plate is slidably connected to a second pressure plate connected to the second rack; the pressure-bearing table is connected to a special-shaped tube for bearing a plastic, the third rack is engaged to the second gear, the second gear is engaged to a third gear, and the third gear is coaxially connected to a first rotating roller for pushing plastics. The waste plastic recovery device provided by the invention can compress the waste plastics and collect the compressed plastic bottles automatically, so that the sizes of the plastic bottles are reduced, and the utility rate of space is improved.

Owner:宁波隆锐机械制造有限公司

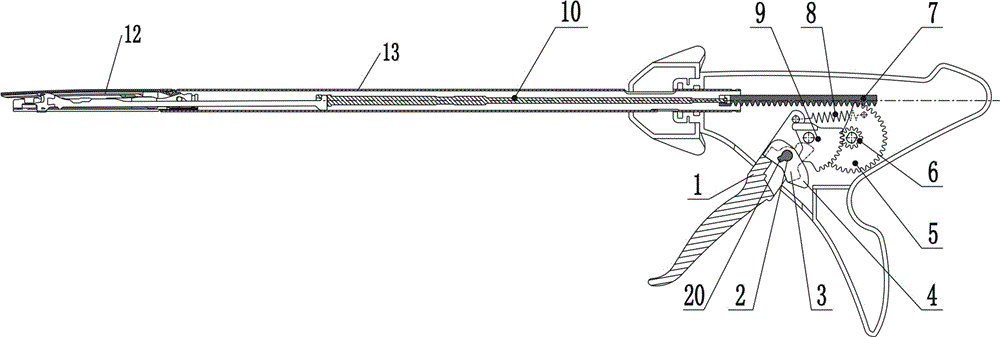

One-part propelling and back-off mechanism and endoscope lower cutting anastomat formed by same

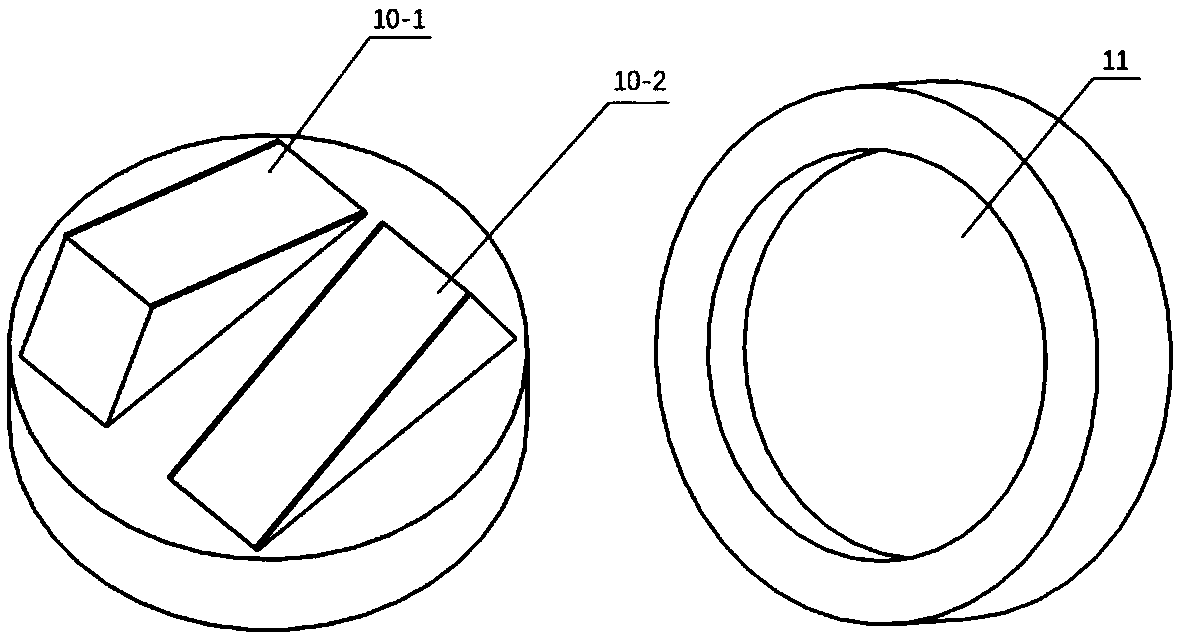

ActiveCN105816213ARealize enlarged travelRealize functionEndoscopic cutting instrumentsSurgical staplesEngineeringEndoscope

The invention discloses a one-part propelling and back-off mechanism and an endoscope lower cutting anastomat formed by the same. The one-part propelling and back-off mechanism comprises a rotating rod, a driving shifting block, a return shifting block, a driving toothed plate, a transmission gear, a cutting toothed plate and a cutting rack, wherein the rotating rod rotates by overcoming tension of a spring, the driving shifting block and the return shifting block are fixedly connected with the rotating rod and connected with a driving toothed plate in a transmission mode, the driving toothed plate is connected with the transmission gear in a transmission mode, the cutting toothed plate and the transmission gear are coaxially installed, and the cutting rack is connected with the cutting toothed plate in a transmission mode. The endoscope lower cutting anastomat comprises the one-part propelling and back-off mechanism, a shell and an ejector rod, one end of the spring is fixedly connected with the rotating rod, and the other end of the spring is fixedly connected to the shell. The traditional process of propelling a cutting head three times is avoided, and the cutting head is propelled in place at a time.

Owner:HANGZHOU TIANREN BIOLOGICAL TECH CO LTD

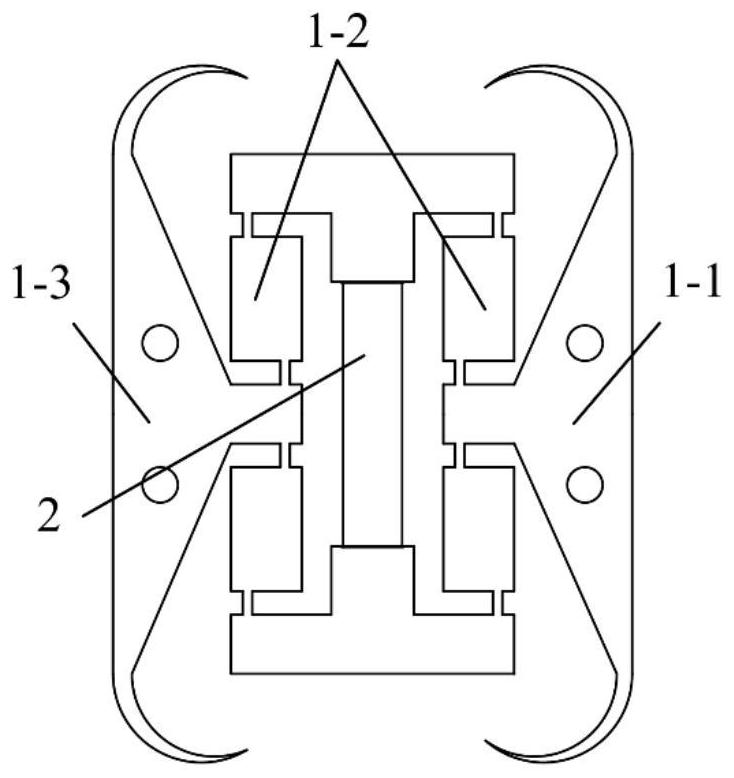

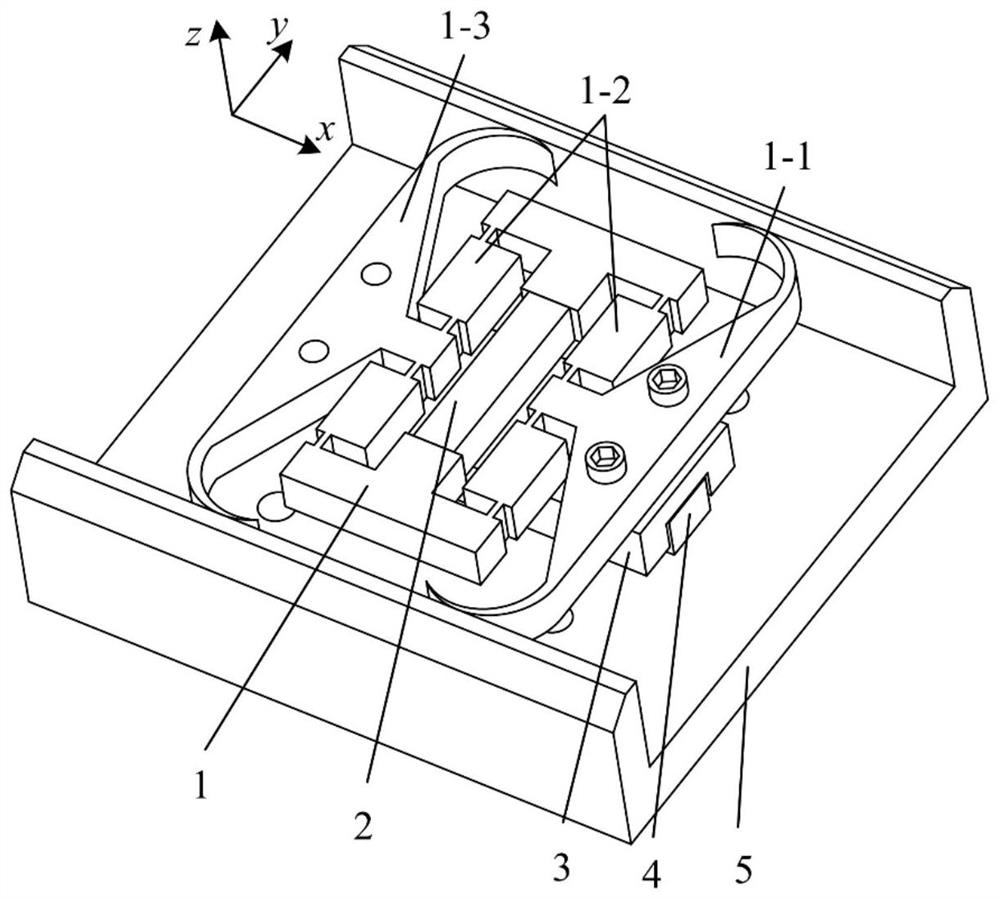

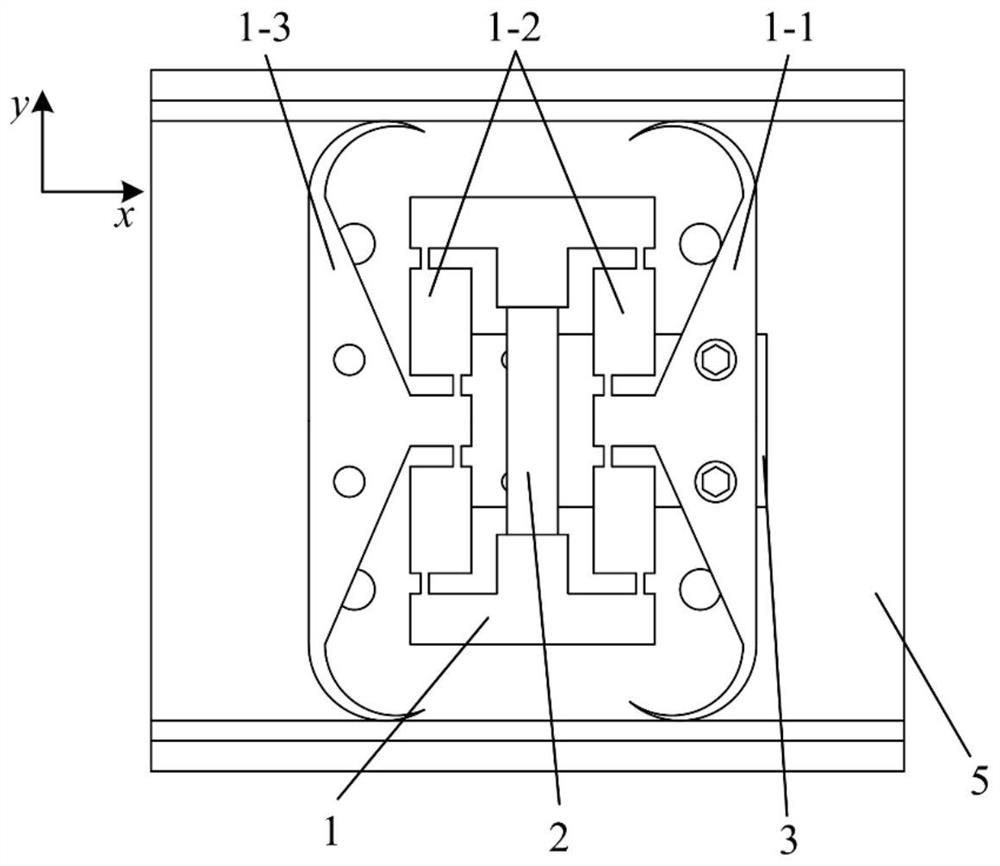

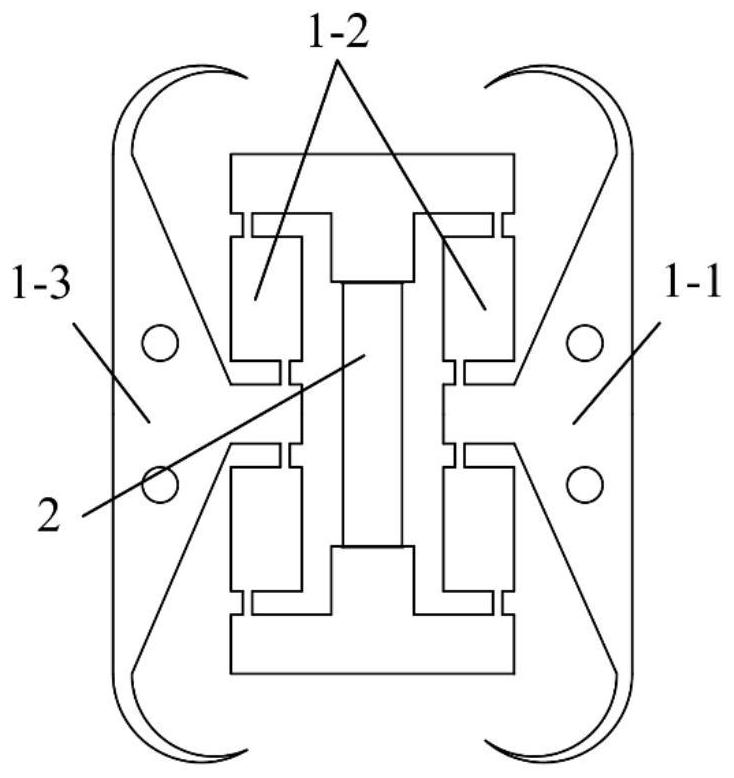

Friction asymmetric inertial piezoelectric linear driving device and method

ActiveCN112803829AMotion speed regulationAchieve reverse motionPiezoelectric/electrostriction/magnetostriction machinesInterference fitDrive by wire

The invention relates to a friction asymmetric inertial piezoelectric linear driving device and method, and belongs to the field of precision machinery. The driving device comprises a base unit, a driving unit and a sliding block. The driving unit is an asymmetric flexible hinge mechanism which is provided with a bridge type displacement amplification hinge and left and right pairs of driving feet with different rigidities, and is connected with the sliding block through a screw; the sliding block slides on a guide rail of the base unit; and the driving unit is installed in the U-shaped groove of the base unit in an interference fit mode. The driving method of the device comprises the steps that the rigidity of the left pair of driving feet and the rigidity of the right pair of driving feet are different, the maximum static friction force borne by the left pair of driving feet and the U-shaped groove is different, and when continuous sawtooth-shaped driving voltage is applied to a piezoelectric stack, the sliding block generates linear stepping motion based on the inertial impact principle. The device and the method have the advantages of simple structure, easiness in processing, assembly and control, capability of realizing high-speed large-stroke and high-load output, and no rollback displacement. The device and the method have good application prospects in the fields of micro-nano operation, precise instruments, precision machining and the like.

Owner:JILIN UNIV

Multi-layer medicine supplementing buffer device

The invention discloses a multi-layer medicine supplementing buffer device which comprises a medicine box separation belt, a two-way conveying belt and multi-layer horizontal medicine supplementing belts. The multi-layer horizontal medicine supplementing belts are sequentially arranged from low to high, and in every two adjacent layers of horizontal medicine supplementing belts, the discharging end of the horizontal medicine supplementing belt at the high position is connected with the feeding end of the horizontal medicine supplementing belt at the low position; the medicine box separation belt is obliquely arranged, the lower end of the medicine box separation belt is a feeding end, and the upper end of the medicine box separation belt is a discharging end; the feeding end of the medicine box separation belt is located on the front side below the discharging end of the lowest horizontal medicine supplementing belt, and the discharging end of the lowest horizontal medicine supplementing belt is connected with the feeding end of the medicine box separation belt through a discharging groove; and the two-way transmission belt is longitudinally arranged. The multi-layer medicine supplementing buffer device is provided with the multi-layer horizontal medicine supplementing belts and the two-way conveying belt, and the two-way conveying belt can achieve reverse movement of medicine boxes to conduct medicine supplementing buffer.

Owner:韦乐海茨(上海)医药设备科技有限公司

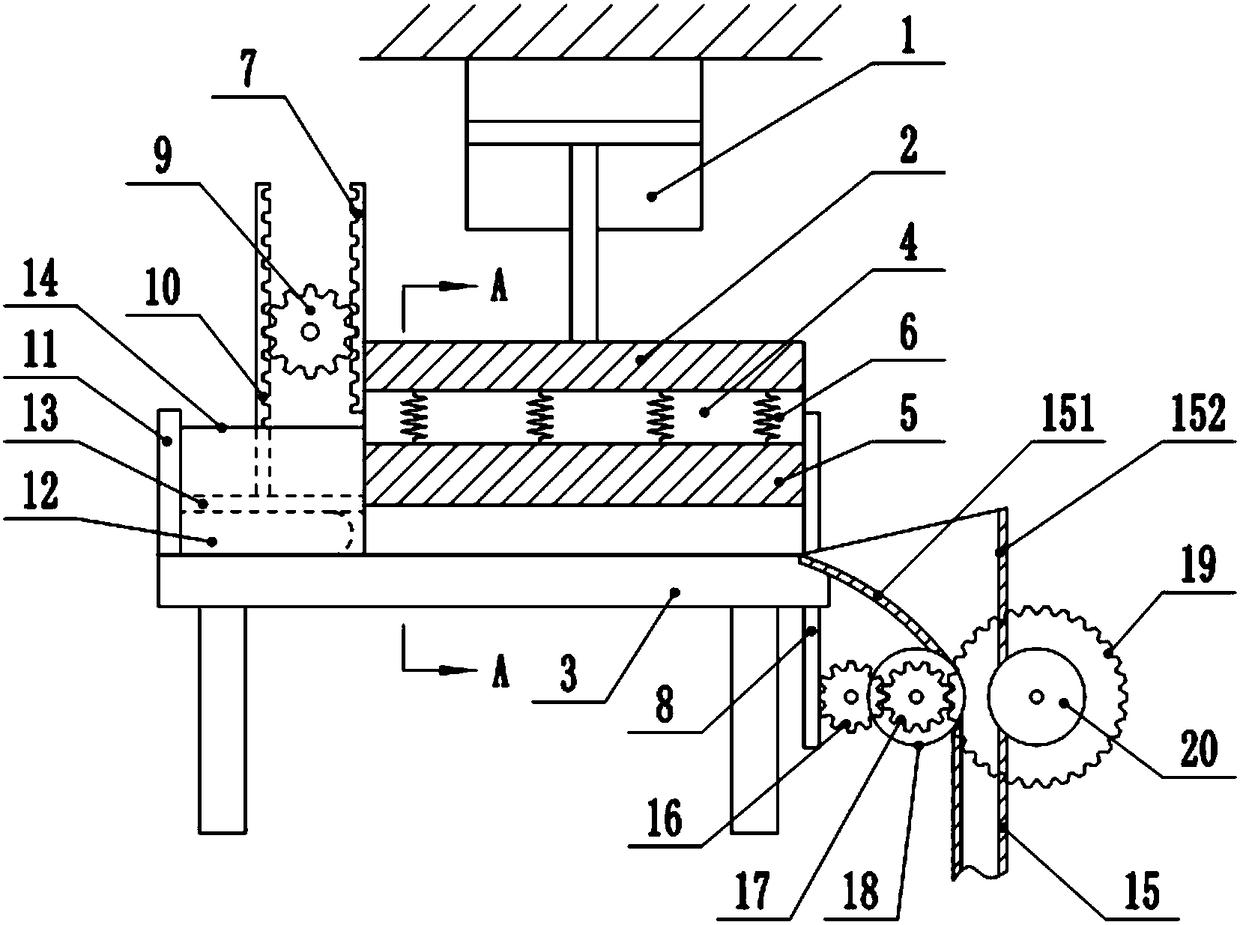

Automatic mechanical part machining clamp

PendingCN112318402AReduce reset timeAchieve reverse motionWork holdersMachine partsElectric machinery

The invention discloses an automatic mechanical part machining clamp which comprises a clamp main body, a guide plate and a motor, a pair of fixing frames is arranged on the bottom surface of the clamp main body, a cavity is formed in the clamp main body, a buckle plate is arranged on the upper side of the cavity, and a mainspring and multiple groups of clamping main bodies are arranged in the cavity; and each of the clamping main bodies comprises a sliding rod I and a sliding rod II arranged on the outer side of the sliding rod I in a sleeving mode. The automatic mechanical part machining clamp has the beneficial effects that a machining part is independently clamped in multiple directions, particularly, the automatic mechanical part machining clamp has good clamping force on a groove part and a machining part with an irregular shape, and the overall fixing performance of the machining part is improved.

Owner:LINYI YINXIN ENG MACHINERY CO LTD

Bag opening device for food packaging bag

InactiveCN111645936AAchieve reverse motionIncrease success ratePackagingStructural engineeringFood packaging

The invention relates to a bag opening device for a food packaging bag. The device comprises a fixed seat, an intermediate gear, a first rack, a second rack, a cross clamping block, an inner suction tube, an outer suction tube, an upper blowing tube, a bag opening cylinder and a transmission plate; the fixed seat is arranged on a frame, the intermediate gear is hinged to the fixed seat, the firstrack and the second rack are movably connected on the fixed seat, and the first rack and the second rack are meshed with the intermediate gear from the two sides; the inner suction tube is installed on the second rack through the cross clamping block, and the outer suction tube is installed on the first rack through the cross clamping block; the upper blowing tube is installed on the fixed seat; and the bag opening cylinder is installed on the fixed seat. The device has the advantages of reliable bag opening and sufficient bag opening through adsorption-type bag opening and blowing-type bag bulging.

Owner:伍福庆

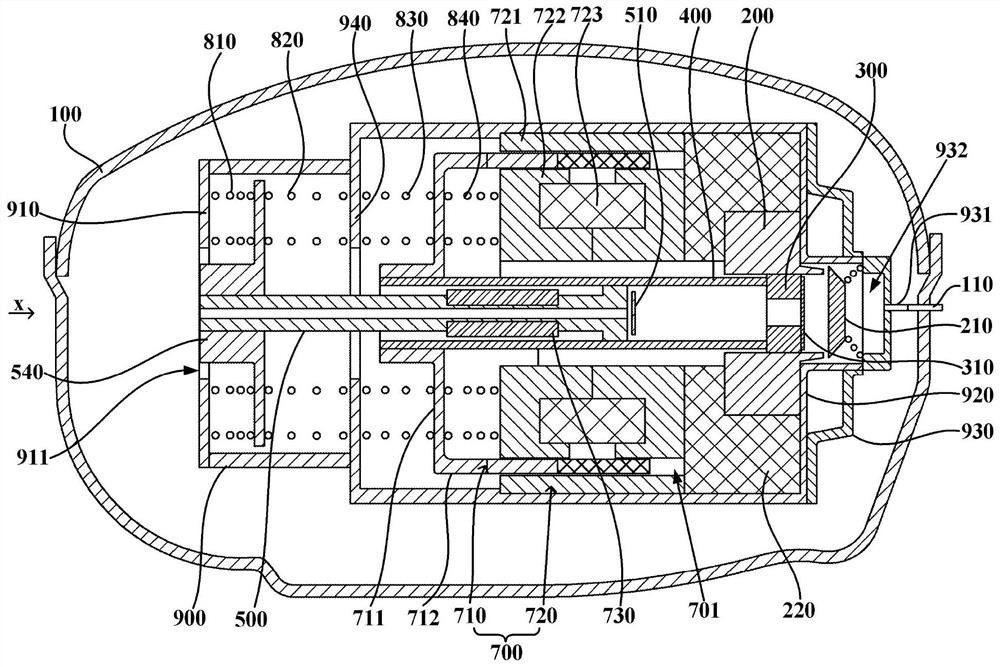

Linear compressor

ActiveCN112392686AImprove energy efficiencyIncrease inspiratory pressurePositive displacement pump componentsPiston pumpsExhaust valveLinear compressor

The invention provides a linear compressor. The linear compressor comprises a machine shell, a linear motor, an air cylinder, a first piston, a connecting rod and a second piston. The linear motor comprises a stator, a first rotor and a second rotor. The air cylinder defines a first compression cavity and is provided with a first exhaust valve. The first piston is arranged in the first compressioncavity, provided with a first air suction hole and provided with a first air suction valve. The connecting rod is connected with the first piston, is driven by the first rotor to drive the first piston to reciprocate and is provided with a second compression cavity communicating with the first air suction hole. The second piston is inserted into the second compression cavity, provided with a second air suction hole and provided with a second air suction valve. When the first piston moves towards the first exhaust valve, the second piston is driven by the second rotor to gradually get away from the first piston, so that gas in the second air suction hole pushes the second air suction valve to enter the second compression cavity; and when the first piston moves away from the first exhaust valve, the second piston gradually gets close to the first piston, so that gas in the second compression cavity is compressed by the second piston to push the first air suction valve to enter the firstcompression cavity. By means of the linear compressor, the air suction amount is increased through multi-stage compression.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Rack-based concrete pumping device

PendingCN110594120AImprove pumping efficiencyAchieve reverse motionPiston pumpsPositive-displacement liquid enginesEngineeringCylinder block

The invention discloses a rack-based concrete pumping device. The device comprises a workbench, a first cylinder body, a second cylinder body, a gear set and a rack; the first cylinder body and the second cylinder body are arranged on the workbench in parallel at intervals, pistons are arranged in the first cylinder body and the second cylinder body correspondingly, and driving rods extending to the corresponding rear of the first cylinder body or the corresponding rear of the second cylinder body are arranged at the tail parts of the pistons; the gear set is arranged on the workbench and located between the two driving rods, and the gear set comprises a driving gear and a driven gear meshing on the two sides of the driving gear; and the rack is arranged on one side of the driving rod andmeshes with the corresponding driven gear. By this way, according to the rack-based concrete pumping device, through the cooperation between the gear set and the rack, reverse movement of the pistonsin the first cylinder body and second cylinder body is achieved, the action precision is high, the high-speed movement of the pistons is facilitated, and the concrete pumping efficiency is improved.

Owner:SHAZHOU PROFESSIONAL INST OF TECH

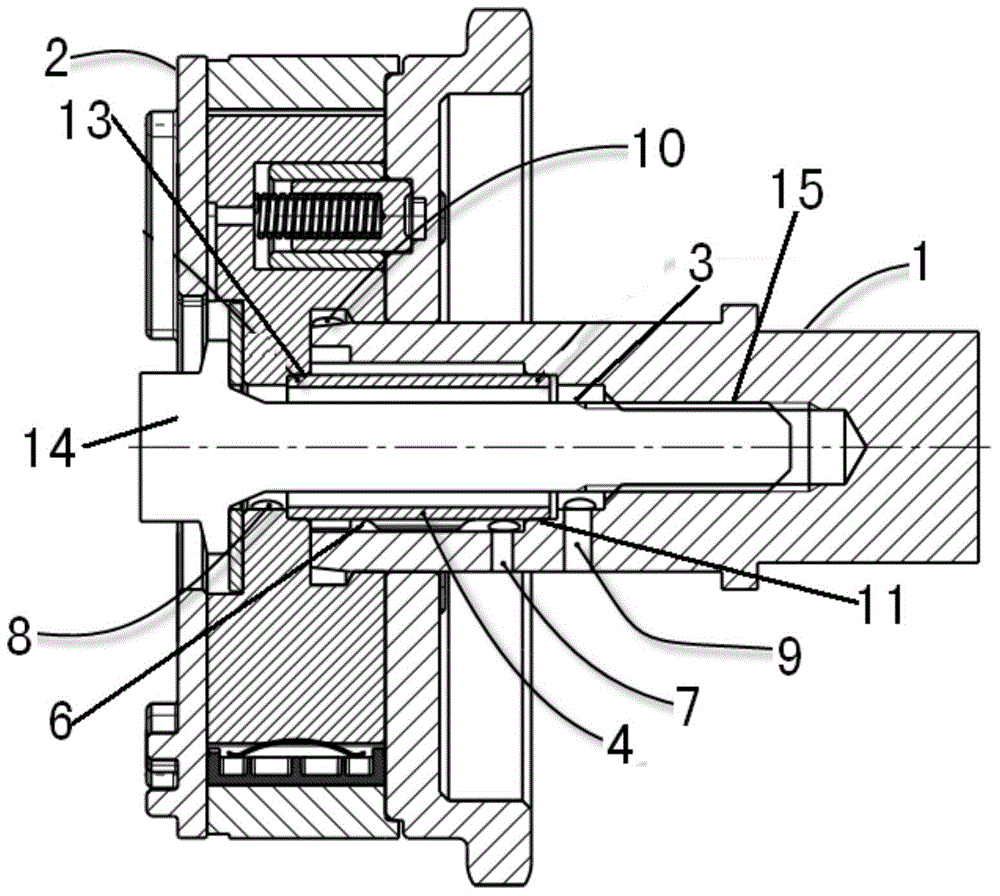

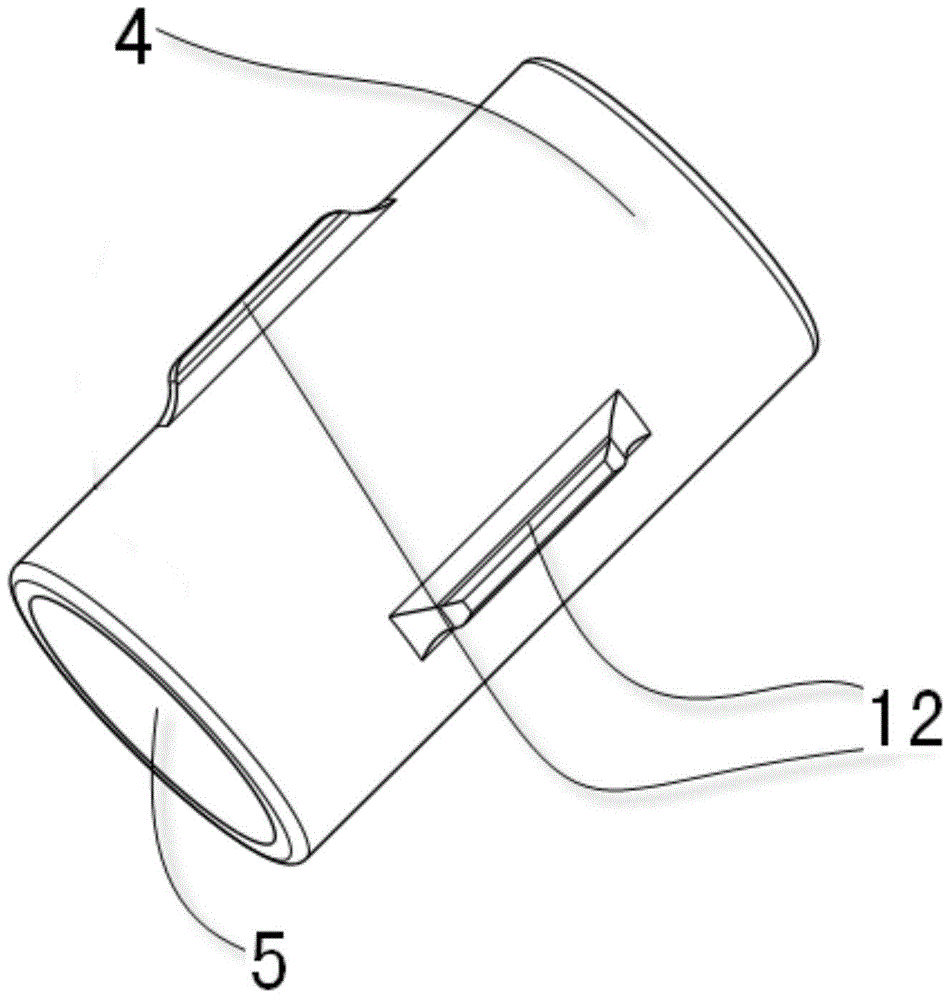

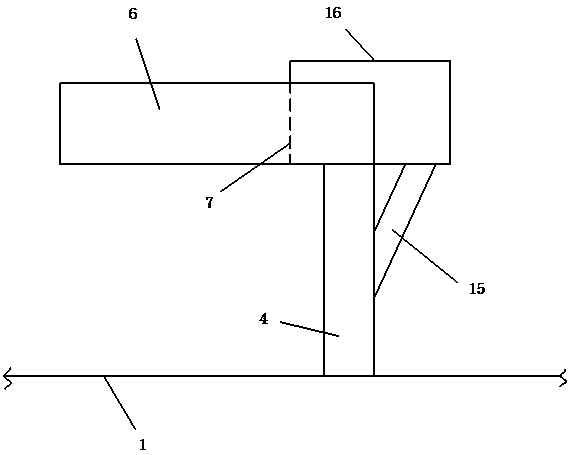

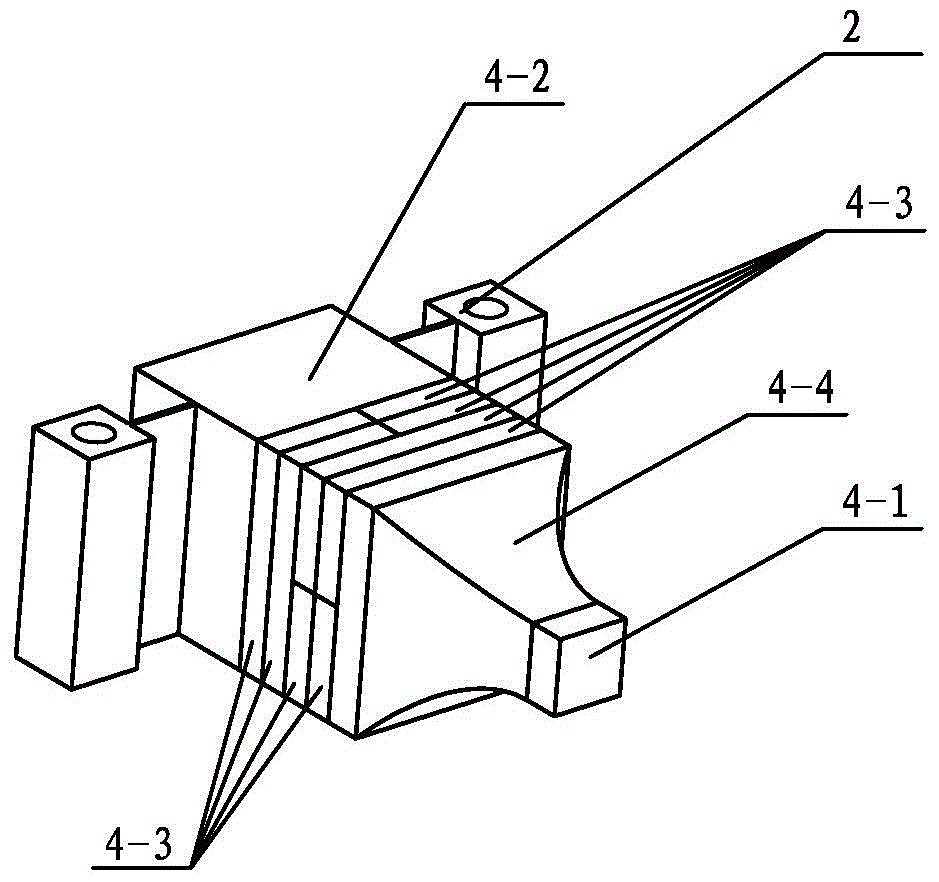

Automobile engine camshaft phase modulator oil channel separation device

InactiveCN104819024ARealize Regulatory ControlSimple structureValve arrangementsMachines/enginesCamshaftAutomotive engine

The invention provides a camshaft phase modulator oil channel separation device in the technical field of valve timing. A phase modulator (2) is connected to a camshaft (1). A middle hole (5) is formed in the middle portion of the separation device (4) arranged in a cavity (3) at the end of the camshaft (1). One end of the separation device (4) is movably connected to the bottom of the cavity (3) of the camshaft (1), and the other end of the separation device (4) is fixedly connected to the phase modulator (2). Both ends of a channel (6) between the separation device (4) and the cavity (3) are respectively communicated with a second oil channel (7) and a phase modulator oil channel A (10). Both ends of the middle hole (5) of the separation device (4) are respectively communicated with a first oil channel (9) and a phase modulator oil channel B (8). The camshaft phase modulator oil channel separation device can regulate and control the operating state of the phase modulator as well as ensure the automobile engine performance. The camshaft phase modulator oil channel separation device can reduce the complexity of an engine camshaft machining technology.

Owner:JAPHL POWERTRAIN SYST

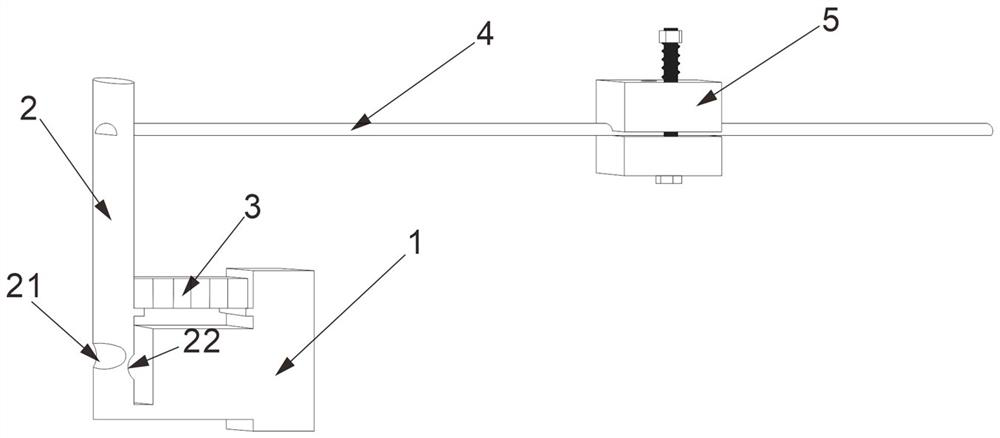

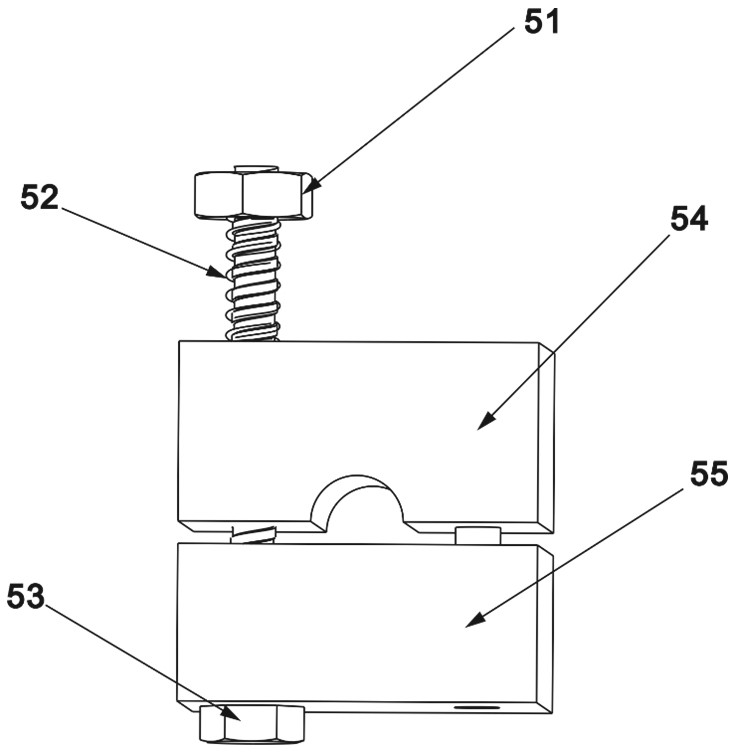

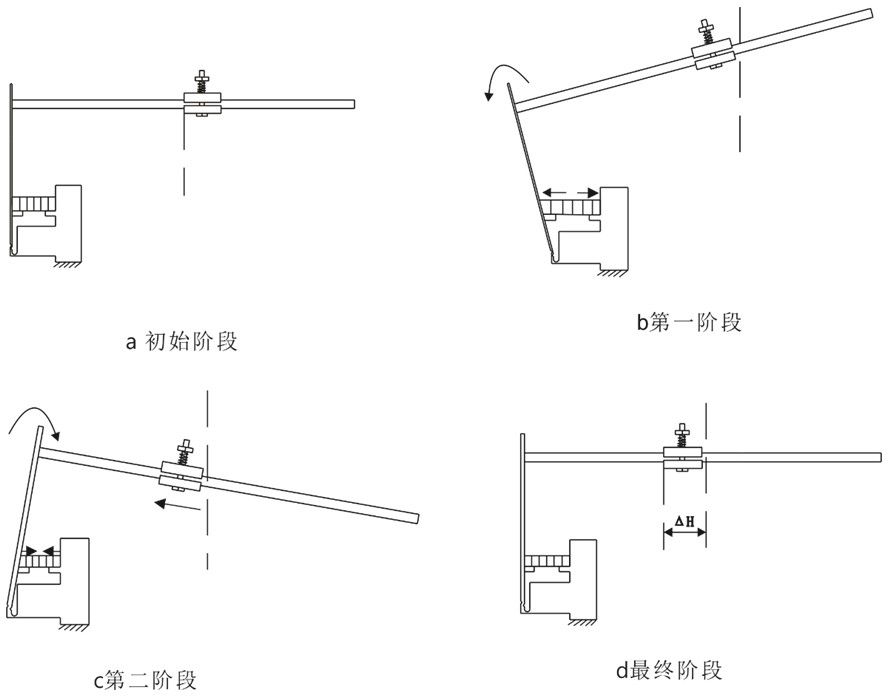

An Inertial Impact Linear Piezoelectric Motor Based on Cantilever Beam Structure

ActiveCN111969889BHigh displacement resolutionUniform and stable running speedPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamEngineering

The invention relates to an inertial impact linear piezoelectric motor based on a cantilever beam structure, and belongs to the technical field of precision driving and positioning. It includes a base, a vertical rod, a piezoelectric stack, a guide rod and a moving slider; the lower part of the outer end of the horizontal block of the base is connected to the lower end of the vertical rod through a flexible hinge, and the upper part of the vertical rod is fixedly connected to one end of the guide rod. The other end of the rod is in the shape of a cantilever, and the moving slider is slidably fitted on the guide rod; the piezoelectric stack is located parallel to the top of the horizontal block of the base, and is fixedly connected between the middle of the vertical rod and the vertical block of the base; When working, the piezoelectric stack is not energized at the initial length; the piezoelectric stack is energized under the action of the positive sawtooth frequency voltage, which drives the upper part of the vertical rod to swing, and drives the moving slider to move along the guide rod by static friction; When the electric stack recovers to the initial length, the moving slider completes a step ΔH movement, and a positive periodic motion is completed at this time; under the action of the reverse sawtooth frequency voltage, the moving slider realizes the reverse movement.

Owner:HEFEI UNIV OF TECH

Bidirectional compression-type compression device

InactiveCN106312862ASimple structureAchieve forward and backward movementWork holdersBiomedical engineeringCompression device

The invention discloses a bidirectional compression-type compression device. The bidirectional compression-type compression device comprises a fixing device and a compressing device, wherein a bottom plate, a first guide rail, a first slide block, a second guide rail and a second slide block are arranged on the fixing device; a first tightening block, a first unthreaded hole, a first internal thread, a second tightening block, a second unthreaded hole, a second internal thread, a bolt, a first external thread and a second external thread are arranged on the compressing device. The device disclosed by the invention is simple in structure and convenient and practical. By rotating the bolt, the tightening block can be moved front and back under the action of the slide blocks of the guide rails; under the action of right-hand and left-hand threads, the first tightening block and the second tightening block can move in reverse directions, so that a purpose of bidirectional compression can be achieved.

Owner:崔高银

Powder sorting unit

The invention relates to a powder sorting unit which comprises a sorting plane, a driving wheel shaft, a driven wheel shaft, a motor, a vibration source, a dustproof cover, a powder recovering tank and a powder collecting tank. The sorting plane is formed by connecting metal thin belts end to end and is supported by the driving wheel shaft and the driven wheel shaft, the driving wheel shaft is connected with the motor, the driving wheel shaft, the driven wheel shaft and the sorting plane form a conveying belt type motion mechanism, the driving wheel shaft is driven by the motor to rotate, thesorting plane is driven to move, the inner sides of the upper plane and the lower plane of the sorting plane are in contact with the vibration source, the exterior of the motion mechanism is providedwith the dustproof cover, the powder recovering tank and the powder collecting tank are connected with the dustproof cover, and the included angle formed between the sorting plane and the ground is adjustable. Powder sorting is achieved by adjusting the included angle formed between the sorting plane and the ground, the vibration frequency and the vibration intensity of the vibration source and the rotating speed of the motor. Compared with the prior art, the powder sorting unit conducts powder sorting according to the degree of sphericity and the mobility, and irregular powder can be effectively removed.

Owner:东莞市博耐特精密模具有限公司

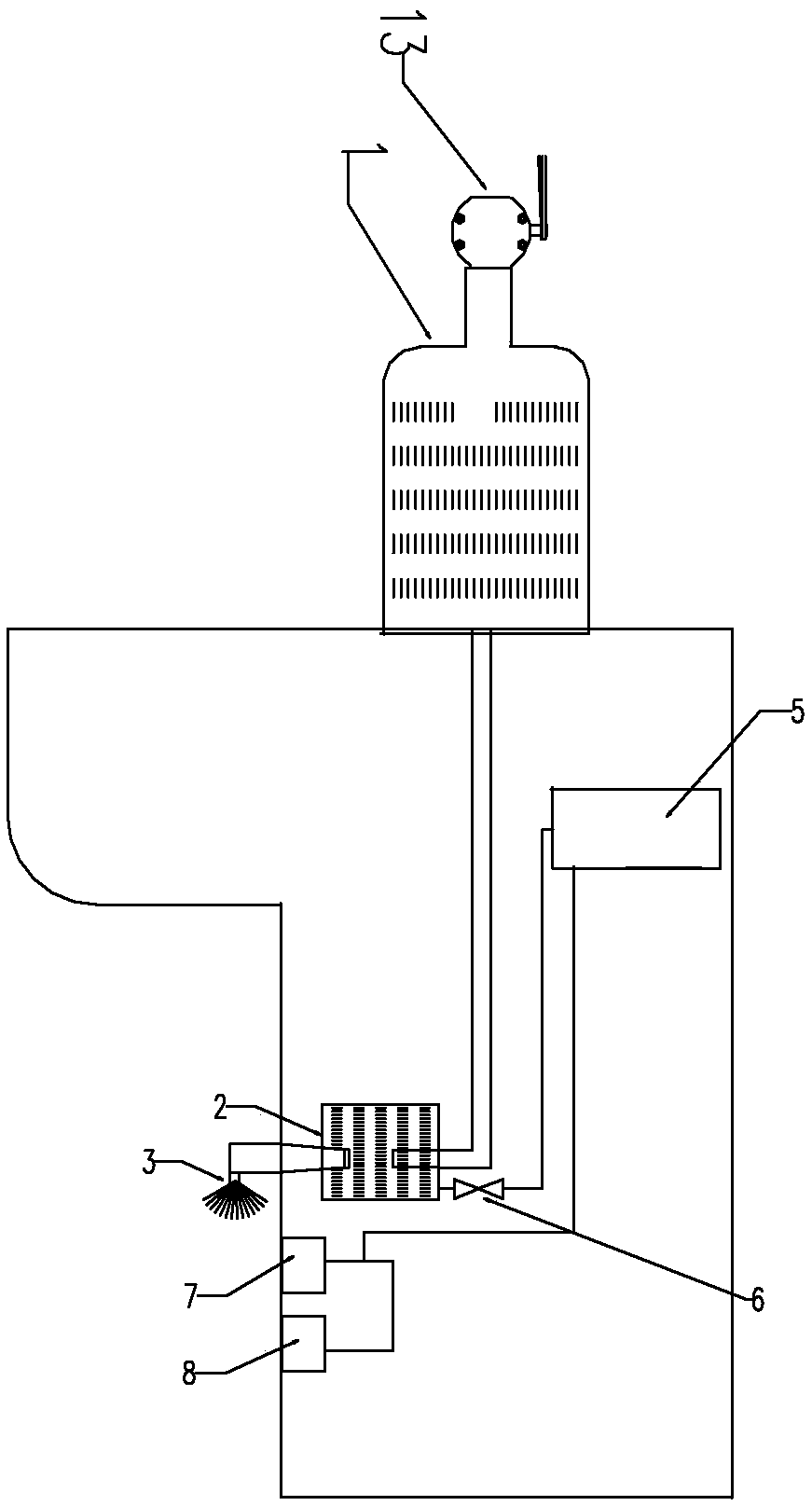

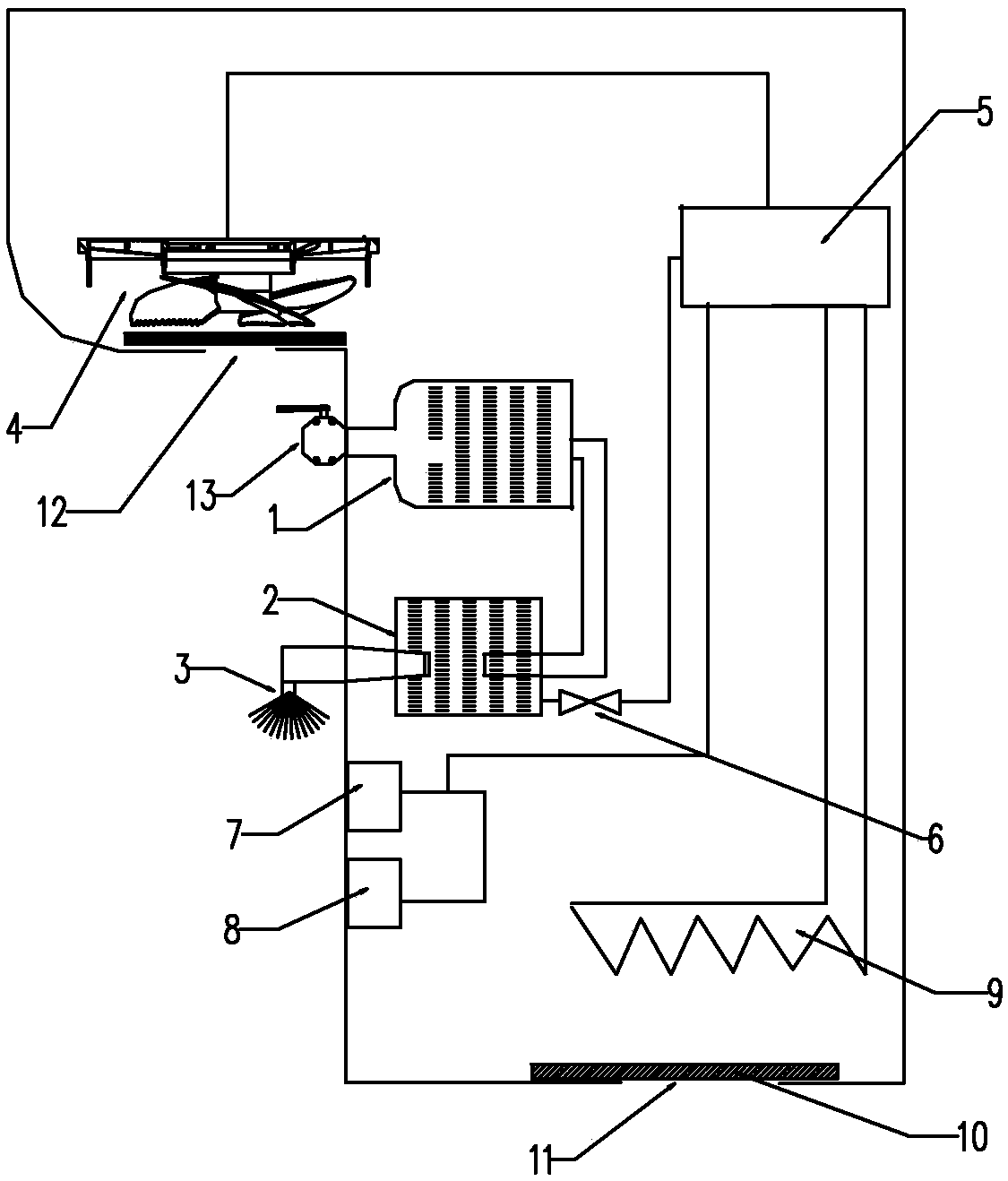

Efficient hardware mechanical workpiece paint spraying device capable of uniformly spraying paint

InactiveCN112892937AEvenly paintedAchieve reverse motionSpraying apparatusElectric machineryStructural engineering

The invention relates to the technical field of hardware mechanical workpiece paint spraying equipment, and discloses an efficient hardware mechanical workpiece paint spraying device capable of uniformly spraying paint. The device comprises a box body, a rotating shaft is rotatably connected in the box body, a fixing part is fixedly mounted on the outer side of the rotating shaft, and a motor is fixedly mounted at the bottom end of the rotating shaft. A sliding groove is fixedly formed in the box body, and a fixing plate is slidably connected to the side face of the sliding groove. According to the efficient hardware mechanical workpiece paint spraying device capable of uniformly spraying paint, a roller rotates to drive a guide wheel to move on the surface of the roller, then a driving rod is pushed to change the angle between the guide wheel and the roller, reverse movement of the guide wheel is achieved, thus, paint spraying can be uniformly conducted on a workpiece through a spraying head, the paint spraying speed is higher, and the paint spraying effect is better; and through uniform rotation of the workpiece, paint spraying of the workpiece is more uniform, time is saved, meanwhile, waste of the paint is greatly reduced, and compared with existing equipment, the paint spraying device is more energy-saving and environmentally friendly.

Owner:闫俊伟

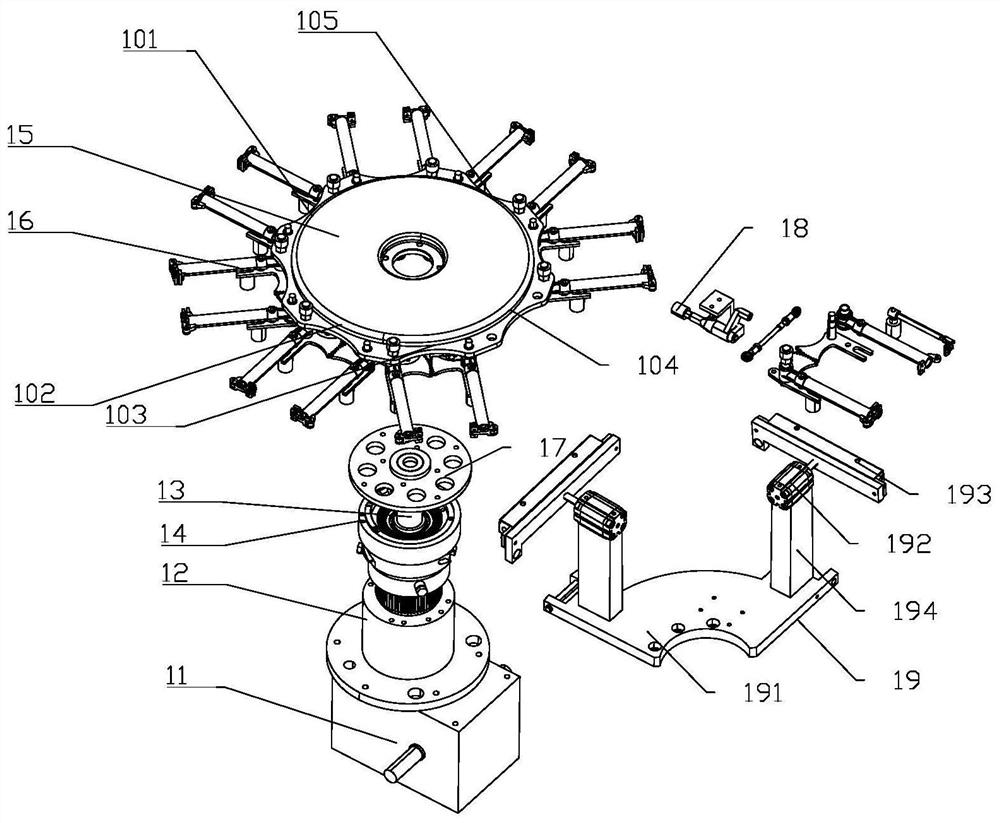

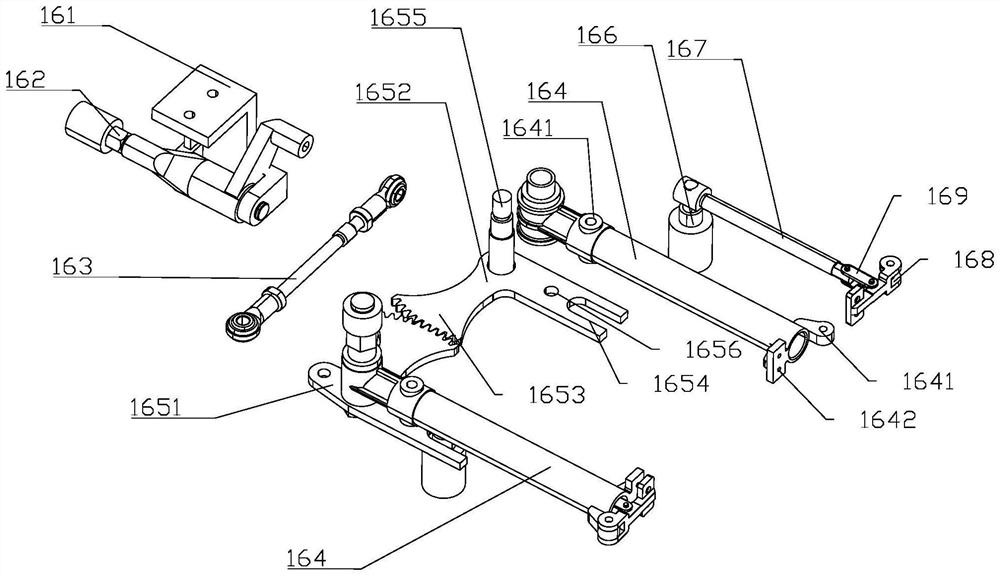

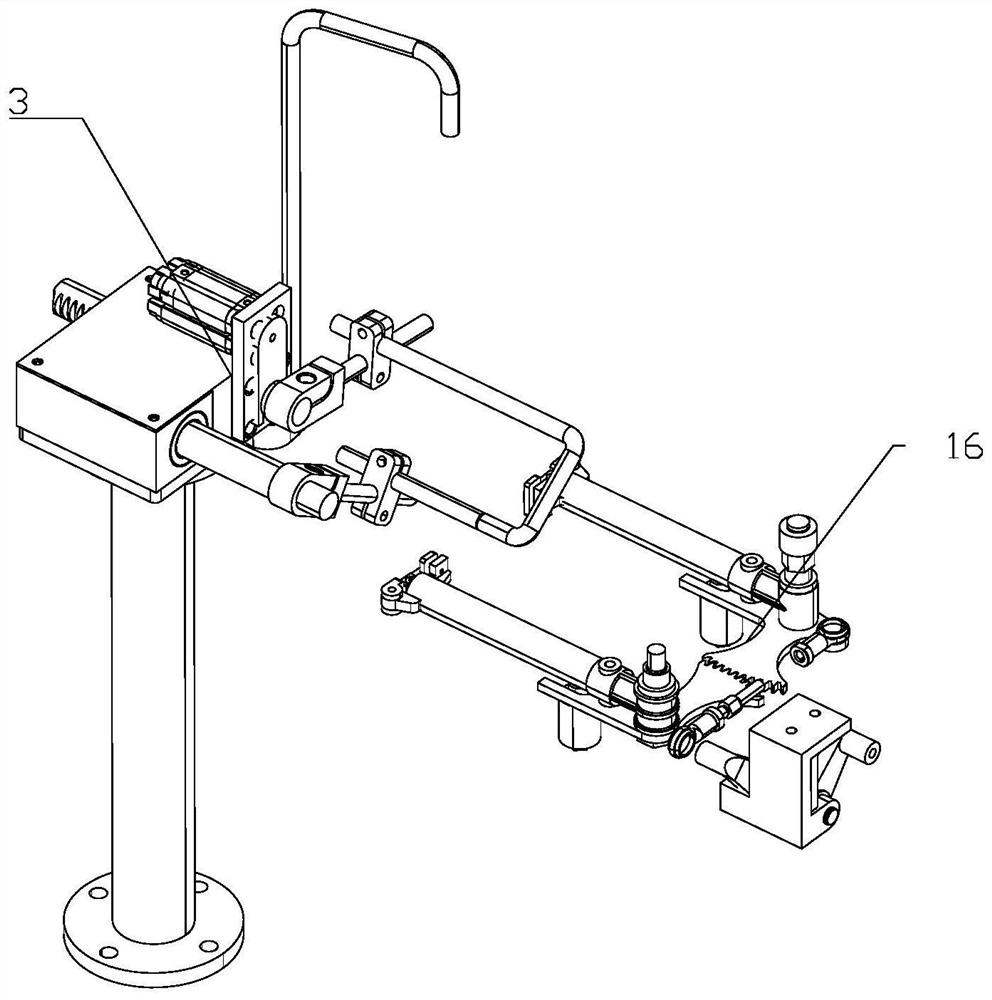

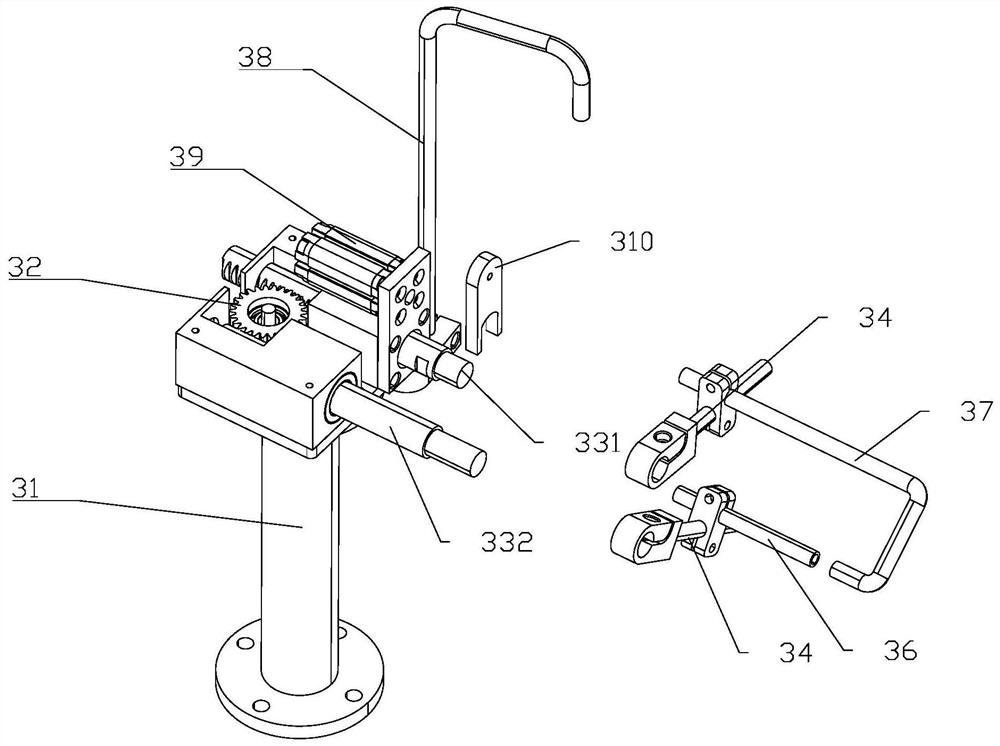

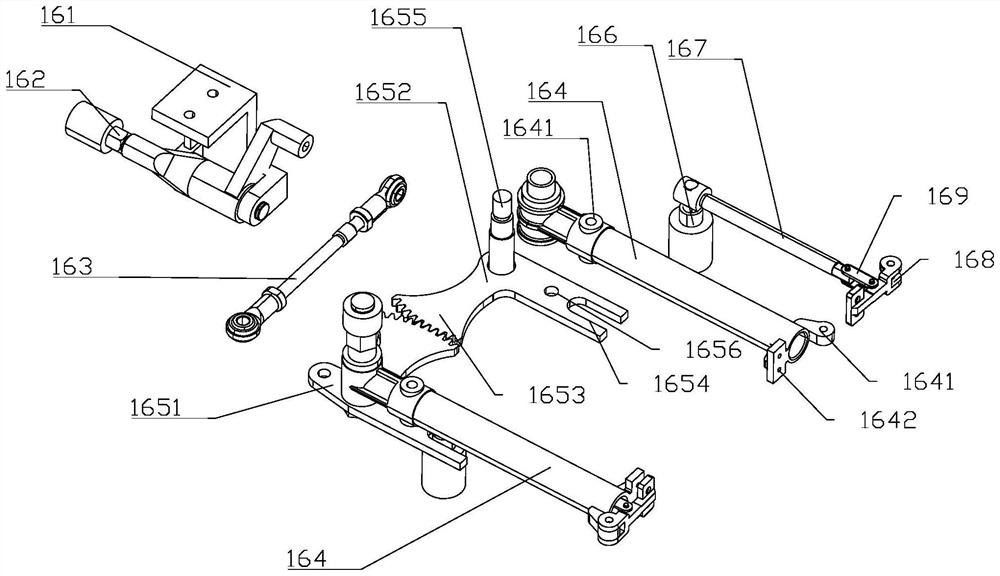

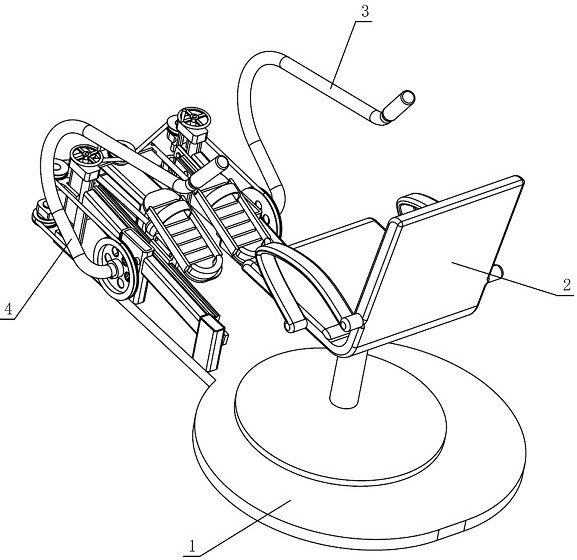

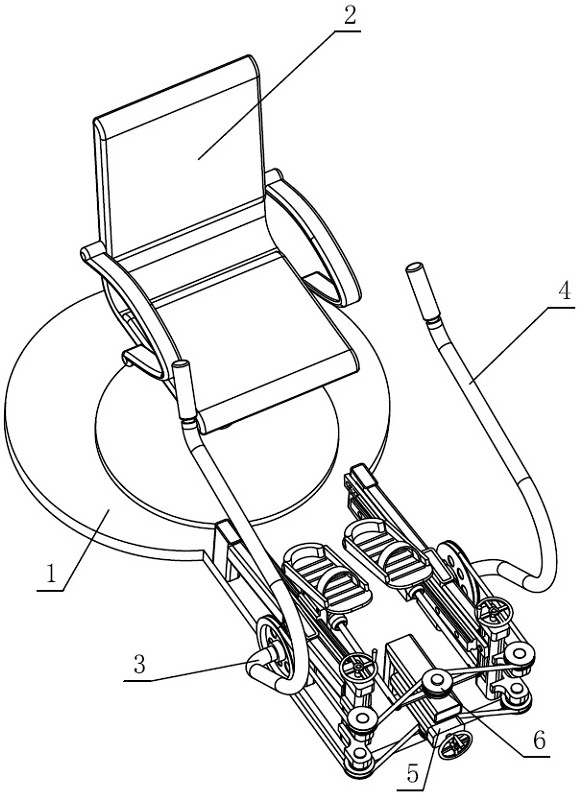

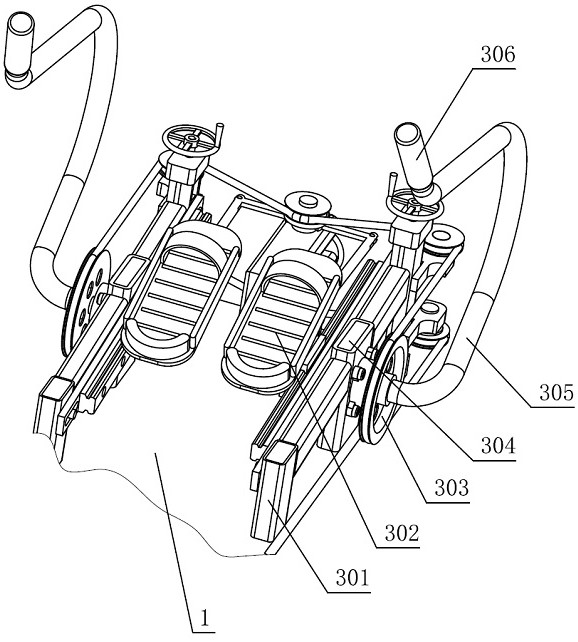

A four-limb synchronous gait exercise rehabilitation trainer

ActiveCN113680014BRealize tilt angle adjustmentHeight adjustableGymnastic exercisingPhysical medicine and rehabilitationFoot supports

The application discloses a limb synchronous gait movement rehabilitation training device, which includes a left mechanism and a right mechanism, and the right mechanism and the left mechanism are arranged symmetrically. The right side of the right side is fixed in turn from the middle to the front of the right rear, right middle and right front columns, the right middle column is rotated to install the right swing shaft, the right swing shaft is fixed to the right pulley and the right handle connecting rod, the right guide rail is fixed to the right guide rail plate, and the right guide rail plate The height of the front end can be adjusted. The right slider is installed on the right guide rail. The right slider fixes the right connecting plate. It is hinged with the right end of the right swing rod, and the left end of the right swing rod is fixed on the swing pulley. The base is provided with a rotating support structure for the swing pulley. The round belt forms a belt drive from the right pulley, the swing pulley and the left pulley. The utility model realizes the gait rehabilitation training of synchronous limbs with adjustable inclination angle of the lower limb foot support.

Owner:ANYANG INST OF TECH

Permanent magnet drive support equipment for gear machining

ActiveCN106787602BReduce radial forceExtended service lifeDynamo-electric brakes/clutchesElectrical conductorGear wheel

The invention relates to the technical field of gear machining, and particularly relates to permanent magnet transmission support equipment for gear machining. The permanent magnet transmission support equipment comprises a support seat and an installation seat which can be mutually driven to reversely move at the same time, wherein the support seat comprises a base and a support rod; the support rod is fixed on the base; a connection hole is formed in the upper part of the support rod; a support bearing is arranged in the connection hole; a motor is arranged on the installation seat; a motor shaft of the motor is connected with a conductor plate; the conductor plate is sleeved with an outer sleeve capable of shrinking under the action force of the support bearing; the outer sleeve can slide into the support bearing and is provided with an inner cavity containing lubricating oil; and the outer sleeve is provided with a seal cover capable of being opened outwards. The invention aims at providing equipment capable of supporting a permanent magnet in a transmission mechanism.

Owner:CHONGQING SUTENG MACHINERY MFG

An Improved Clamping Device for Butt Welding Machine

ActiveCN106312278BReduce temperature differenceReduce deformationResistance electrode holdersWelding/cutting auxillary devicesButt weldingMechanical engineering

The invention discloses an improved clamping device of a butt welding machine. The improved clamping device of the butt welding machine comprises a machine frame. A platform is fixed to the machine frame. A bottom plate is fixedly arranged on the platform and connected with a third electrode. A welding head is connected to the machine frame through a first air cylinder. A workpiece is clamped between the bottom plate and the welding head to be welded. The welding head comprises a clamping plate connected with the first air cylinder. The first air cylinder is connected to the rear side of the clamping plate. A rectangular through groove is formed in the rear side of the clamping plate, and a plurality of first electrodes are arranged on the front side of the rectangular through groove. Each first electrode comprises an insulating jacket fixed to the clamping plate, wherein a conductive head is slidably arranged in the insulating jacket and connected with the clamping plate through a first spring body, a first rubber layer is arranged between the conductive head and the first spring body, and a plurality of toothed parts are annularly distributed at the top of the conductive head. A strip-shaped second electrode is further arranged on the front side of the rectangular through groove. By adoption of the improved clamping device of the butt welding machine, the defects of the prior art can be overcome, and the welding quality in the welding process is improved.

Owner:京山新瑞达通用机器有限公司

Friction asymmetric inertial piezoelectric linear drive device and method

ActiveCN112803829BMotion speed regulationAchieve reverse motionPiezoelectric/electrostriction/magnetostriction machinesDrive by wireEngineering

The invention relates to a friction asymmetric inertial piezoelectric linear drive device and method, belonging to the field of precision machinery. The drive device includes a base unit, a drive unit and a slider. The drive unit is an asymmetric flexible hinge mechanism with a bridge-type displacement amplifying hinge and two pairs of left and right drive feet with different rigidities, which are connected to the slider via screws; the slider slides on the guide rail of the basic unit; the drive unit passes interference fit Installed in the U-shaped groove of the base unit. The driving method of the device is: the rigidity of the left and right pairs of driving feet is different, resulting in the difference in the maximum static friction between them and the U-shaped groove. When the continuous zigzag driving voltage is applied to the piezoelectric stack, based on the principle of inertial impact, The slider will produce linear stepping motion. The advantages are: simple structure, easy processing, assembly and control, high-speed, large-stroke and high-load output can be realized, and there is no retraction displacement. It has good application prospects in the fields of micro-nano manipulation, precision instruments, and precision machining.

Owner:JILIN UNIV

Speed changer, especially shifting device for bicycle driving device

InactiveCN1321600BChange gear ratioAchieve reverse motionMechanical apparatusCycle control systemsDisplay deviceEngineering

This invention relates to a gear-selection-device (1) for a shift-changing gear, especially for a bicycle-mover, with a control-device (5), which acts through a force-transmission-element on the shift-changing gear, an operation-device with a rotatably movable operation-element to manually operate the control-device (5), and a display-device (3) with an indicator-element (4), which can move alonga circular arc, to show the gear-changed state selected by the operation-device. The angle-movements are transferred from the operation-device or the control-device (5) through the gear-transmission-device to the display-device (3), so that the circular arc passed through by the indicator-element (4) of the display-device (3) is smaller than the circular arc passed through at the same time by theoperation-element of the operation-device. This results in an improved readability of the display-device (3) and also an improved ergonomics of the gear-selection-device (1).

Owner:SRAM

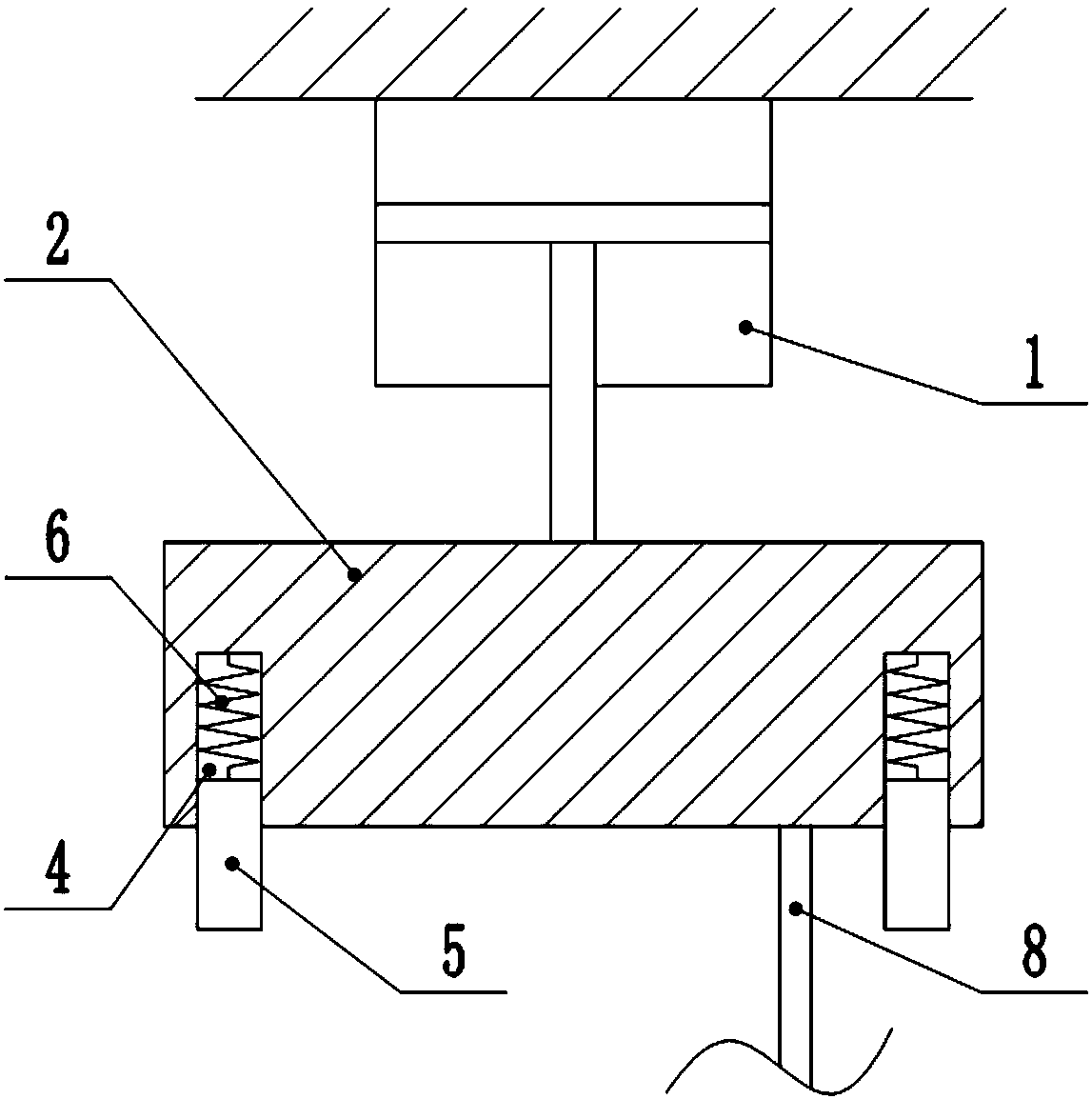

Combined multi-blade saw device and sawing method

ActiveCN104708673BExtended service lifeDo not change frequentlyGuide fencesFeeding devicesEngineeringHeat energy

The invention discloses a combined multi-blade saw device and a sawing method. A large amount of heat energy is produced in a sawing process of saw blades during the operation of equipment used for sawing so that quick damage of the saw blades is caused in the prior art. The method comprises the steps that a workbench (2) is mounted above a base (1); a group of auxiliary wheels (3) and a group of feeding parts (4) are mounted on the upper part of the workbench; the feeding parts are connected with one end of a spring (6) through a connecting bolt (5); the other end of the spring is connected with the lower part of the base; a group of supports (7) are mounted on the lower part of the workbench; the feeding parts are mounted on the supports; a feeding platform (8) is arranged on the workbench; a group of guiding plates are mounted on the feeding platform; a group of bearing seats (10) are mounted on the workbench; saw shafts (11) are mounted in the bearing seats; a group of saw blades (12) are mounted at one ends of the saw shafts; shaft belt pulleys (13) are mounted at the other ends of the saw shafts and are connected with power output wheels (16) of motors (15) mounted on the base. The combined multi-blade saw device is used for sawing.

Owner:HEILONGJIANG LINKE WOODEN PROD

Space-expanding mechanism driven by multi-piezoelectric vibrators in step-peristaltic mode

ActiveCN104967357BAchieve lockingAchieve reverse motionPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsDrive shaft

The invention discloses a space deployment mechanism driven based on a multi-piezoelectric vibrator step crawling mode, which relates to the field of space deployment mechanisms and aims at solving the problems of complicated structure, serious electromagnetic interference and complicated self locking existing in the current electromagnetic motor driving-type space deployment mechanism. The space deployment mechanism driven based on the multi-piezoelectric vibrator step crawling mode comprises a base, two shaft extension sleeves, two deployment mechanisms, four piezoelectric vibrators, two driving shafts and a mounting seat, wherein two opposite side walls of the base are provided with through holes, and the through holes in the two side walls are coaxial; the two shaft extension sleeves are fixed in the two through holes; the two deployment mechanisms are fixed on the two opposite side walls of the base respectively; the four piezoelectric vibrators are fixed inside the base via the mounting seat; and one ends of the two driving shafts are tightly connected with two piezoelectric vibrators via a pretightening force, and the other ends pass through the shaft extension sleeves to be connected with the two deployment mechanisms respectively. Thus, relaxation and contraction of the space deployment mechanism can be realized.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com