One-part propelling and back-off mechanism and endoscope lower cutting anastomat formed by same

A technology of stapler and cutting teeth, applied in the field of medical devices, can solve the problems of complex cutting process, many device mechanisms, complex structure, etc., and achieve the effects of simplified and unique structure, reduced torque, compact size and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

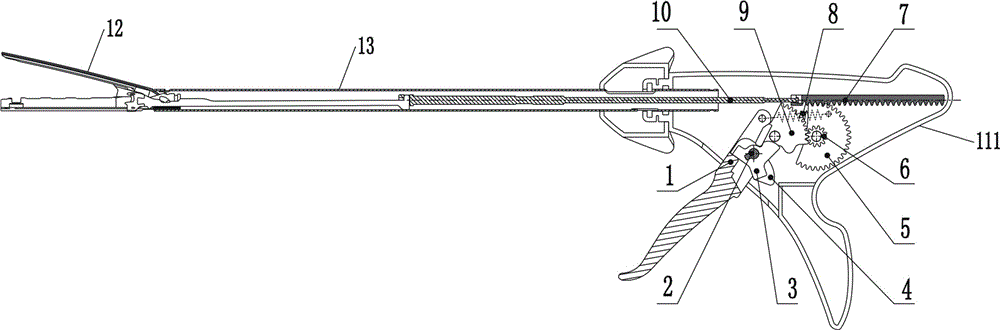

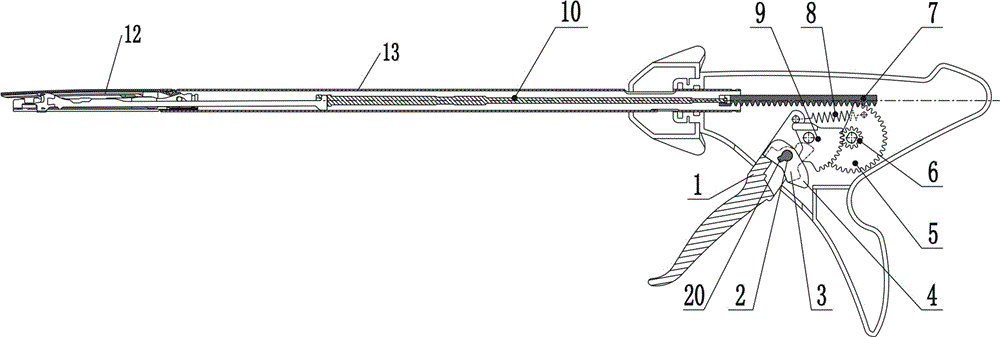

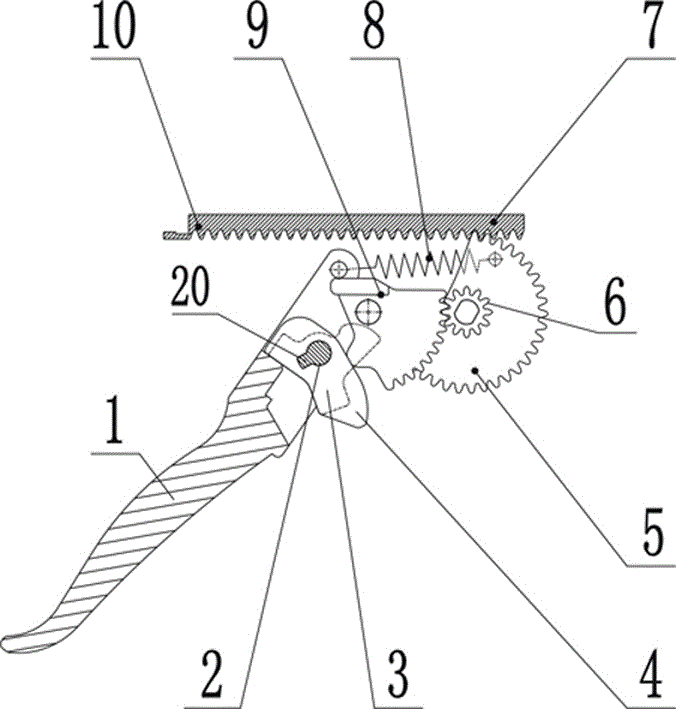

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings (1 to 3).

[0022] The one-stage advancing and retreating mechanism involved in the present invention includes a rotating rod 1, a driving dial 3, a return dial 4, a driving tooth plate 9, a transmission gear 6, a cutting tooth plate 5, and a cutting rack 7. Rod 1 is rotated by overcoming the pulling force of spring 8, and described driving block 3 and return shifting block 4 all rotate through drive shaft 2 described rotating rod 1 together, and described driving shifting block 3 and return shifting block 4 are driven The shaft 2 is coaxially and fixedly installed on the rotating rod 1 . The driving tooth plate 9 is located between the return shift block 4 and the transmission gear 6, the cutting tooth plate 5 is installed coaxially with the transmission gear 6, and the cutting tooth rack 7 is located on the transmission gear 6 and above the cutting toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com