Automatic mechanical part machining clamp

A technology of mechanical parts and fixtures, which is applied in the field of automatic mechanical parts processing fixtures, and can solve the problems of low clamping and clamping of processed parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

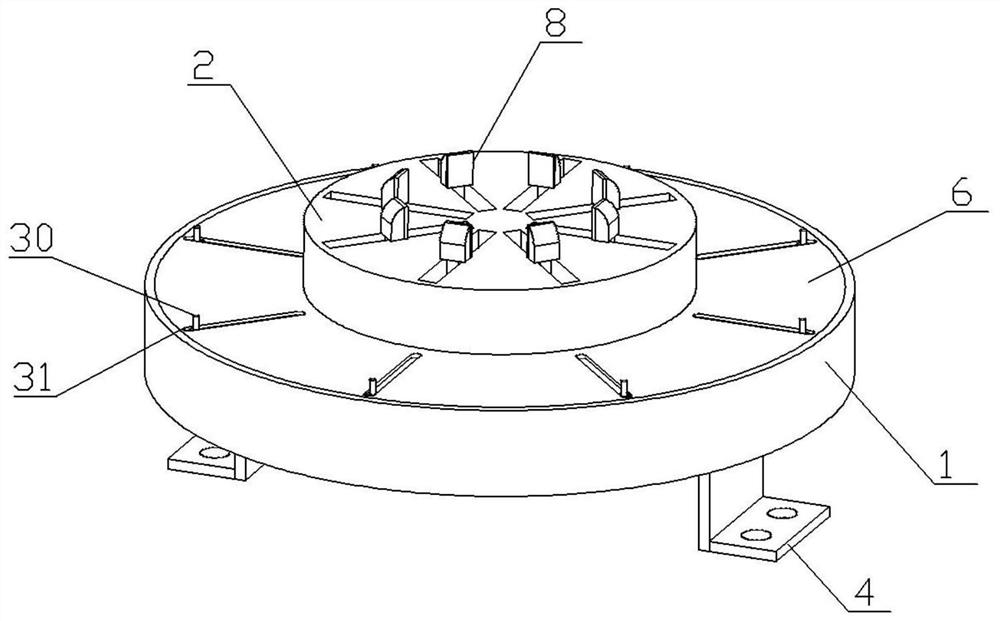

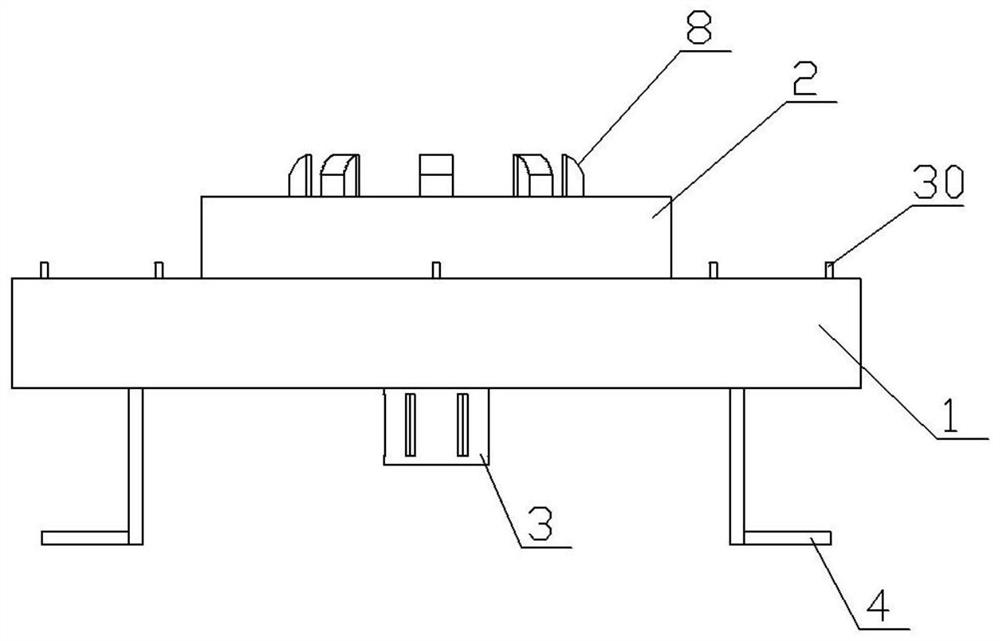

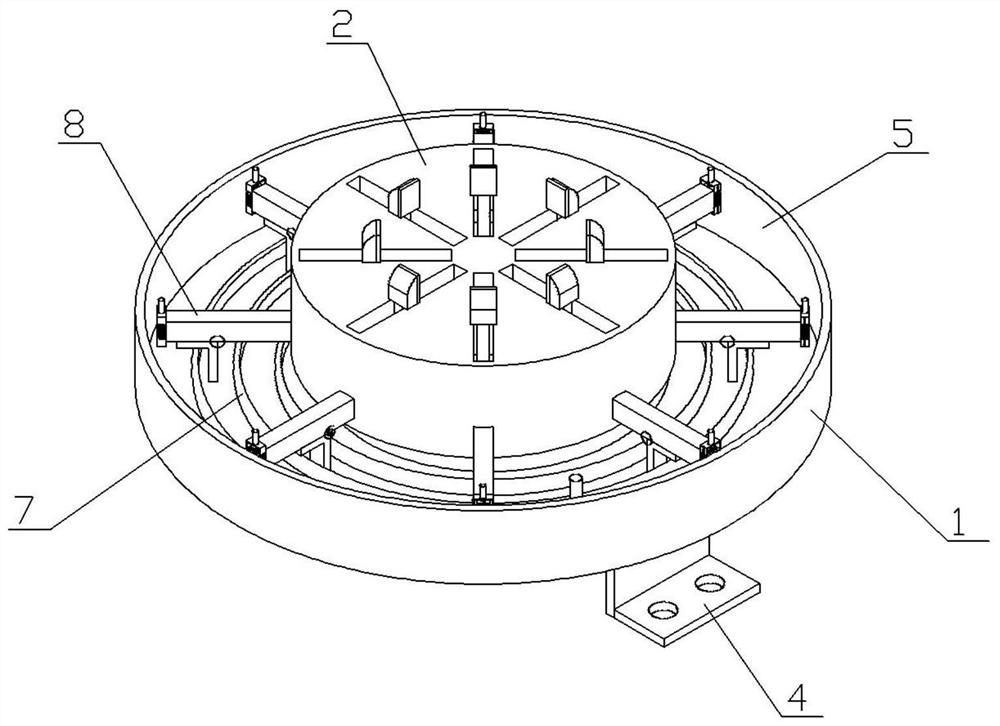

[0028] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

[0029] A jig for processing automatic mechanical parts, including a jig body 1, a guide plate 2 for guiding the clamping direction, and a motor 3. A motor 3 is arranged on the lower side of the jig body 1, and the driving end of the motor 3 extends through the jig body 1 to the void. The cavity 5 is connected to one end of the spiral center of the mainspring 7. The driving end of the motor 3 drives the mainspring 7 to shrink inwardly and extend outwardly for reset. There is a cavity 5, the upper side of the cavity 5 is provided with a pinch plate 6, and several rod grooves 31 are set on the pinch plate 6, and a spring 7 and multiple sets of clamping bodies for clamping the processing parts are provided in the cavity 5 8. Each clamping main body 8 independently clamps the processing parts, and the spiral outer end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com