Patents

Literature

105results about How to "Achieve continuous rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

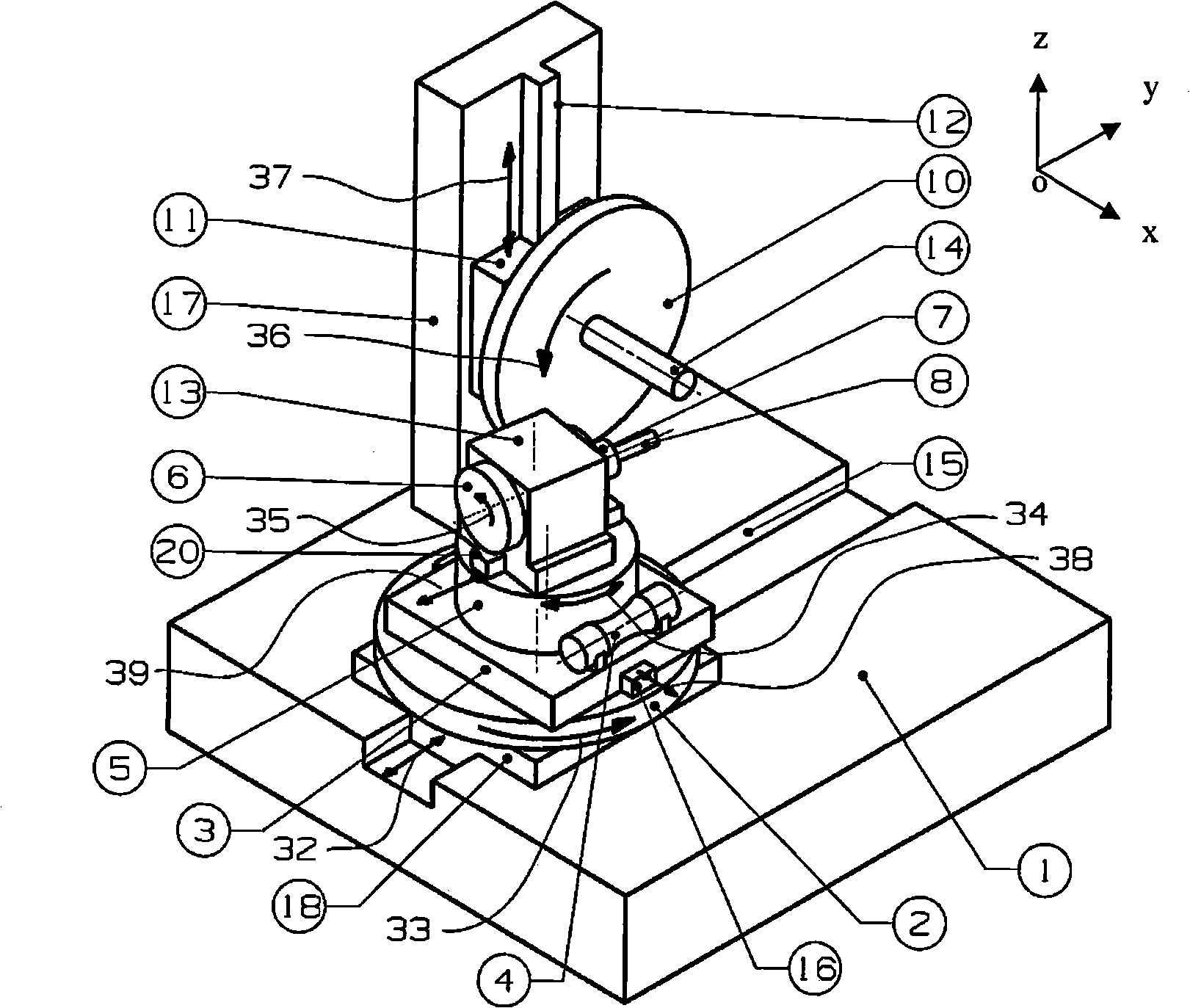

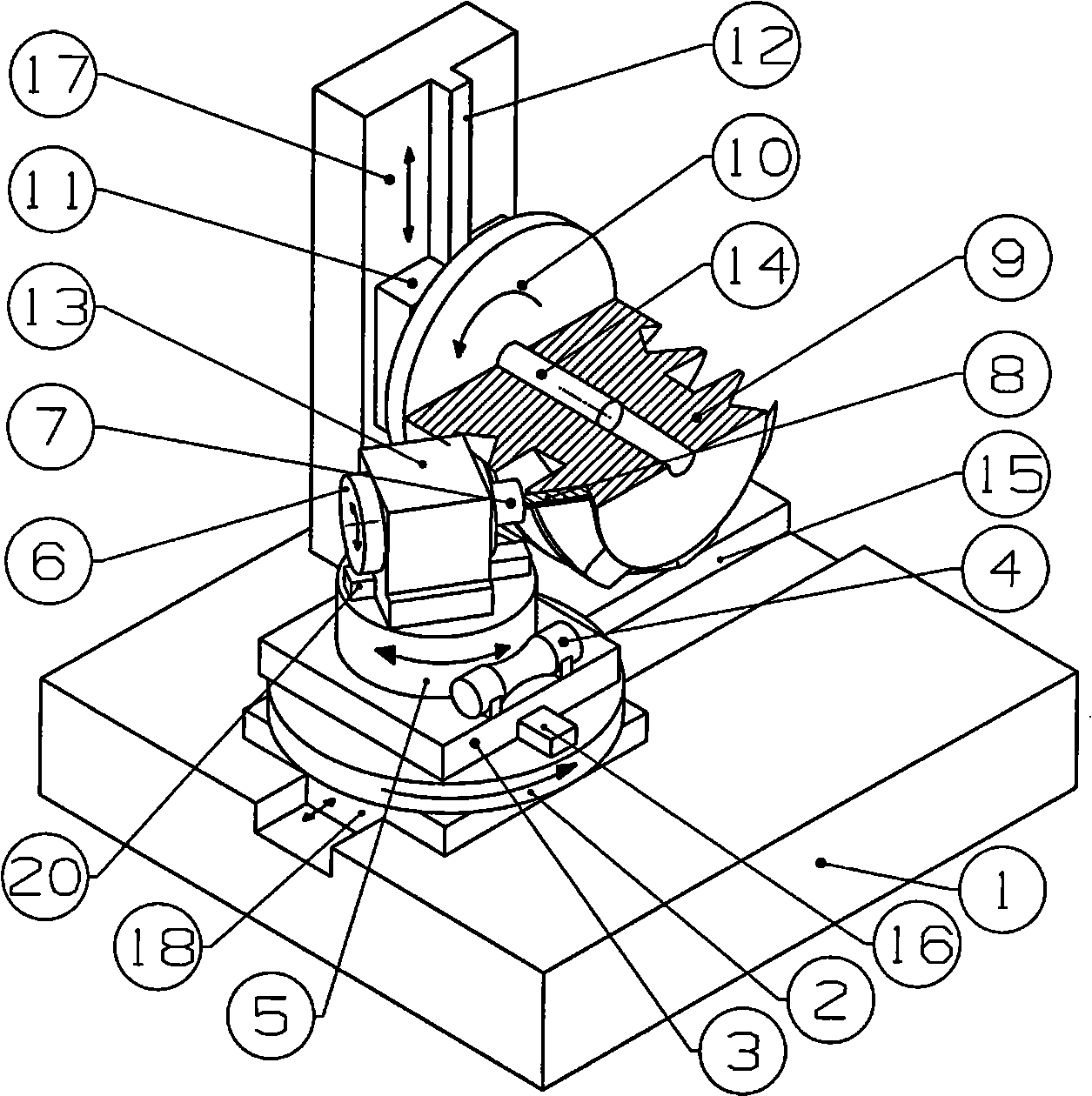

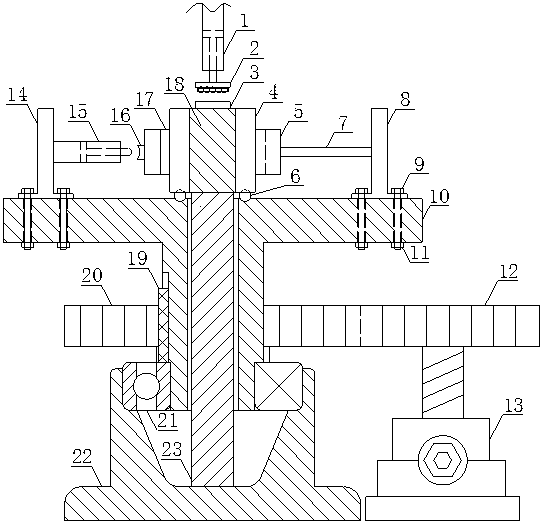

Milling machine for processing single screw compressor rotor

InactiveCN101301690AFast processingImprove machining accuracyLarge fixed membersMilling equipment detailsProcessing accuracyEngineering

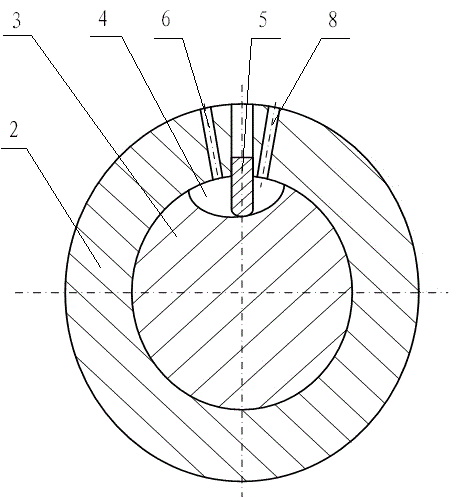

The invention discloses a milling machine used for processing single-screw compressor rotors, comprising a machine body, a vertical column and a mill support device which are arranged on the machine body, wherein, the vertical column is connected with a workpiece rotary chuck and a device which leads the workpiece rotary chuck to vertically move along the z-direction; the workpiece rotary chuck is connected with a transmission mechanism which leads the workpiece rotary chuck to rotate around the x-axis; the milling machine is characterized in that the mill support device comprises a mill seat and a mill axes arranged on the mill seat and used for mounting the mill, and a base arranged in a horizontal guideway along the y-direction of the machine body; the base is provided with a chassis rotated by the linking to the workpiece chuck; two translation mechanisms which lead the mill seat to horizontally move in the x-direction and the y-direction respectively are arranged between the mill seat and the chassis, and a rotation mechanism which leads the mill support to rotate along the x-y plane; the mill support is provided with a mill driver which leads the mill axes to rotate. The special mill machine of the invention has the advantages of high processing speed and processing precision, and can produce high-precision single-screw compressor engaged channel pairs.

Owner:XI AN JIAOTONG UNIV

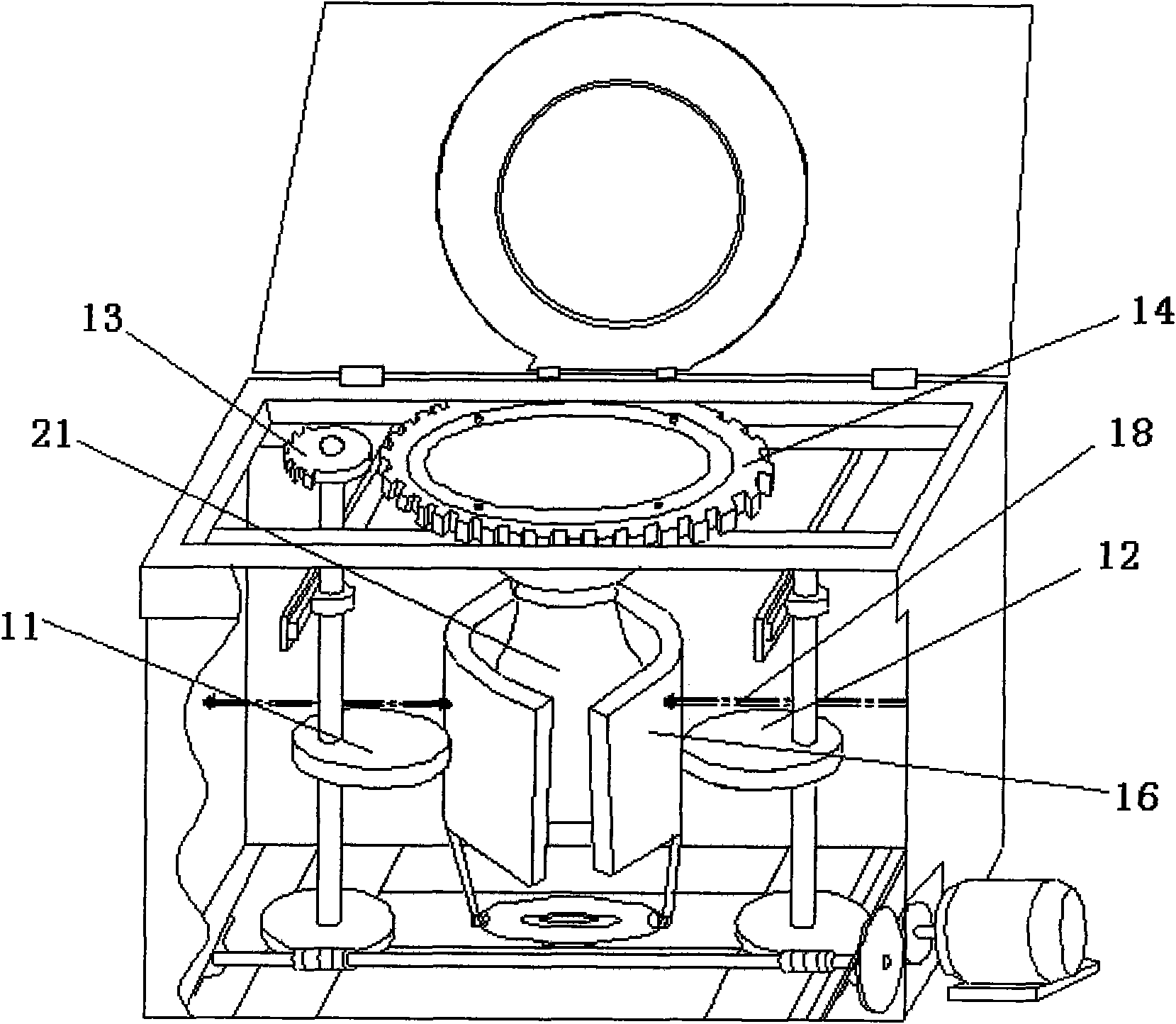

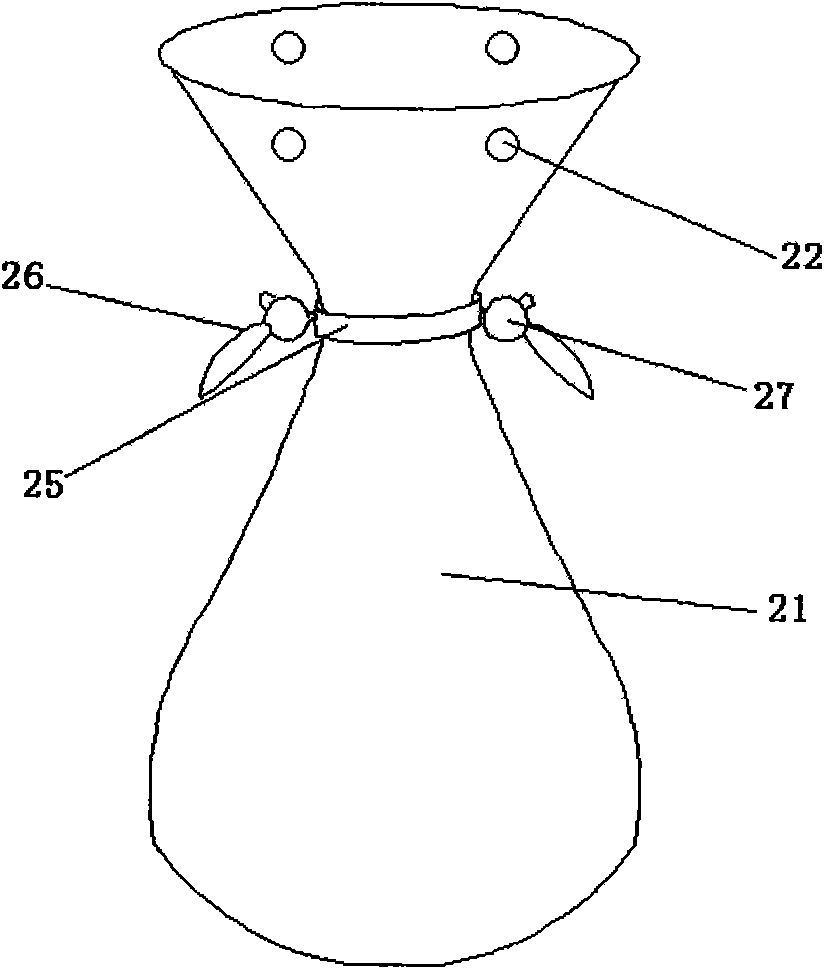

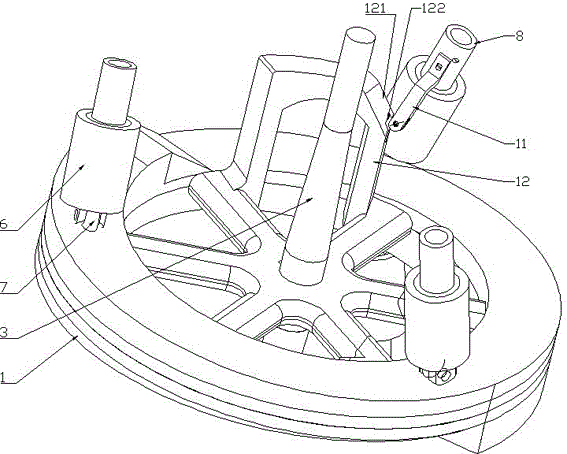

Precisely imitated manually extruding type dough making device

InactiveCN101623014ARotation does not affectAchieve continuous rotationMixing/kneading with vertically-mounted toolsGear wheelEngineering

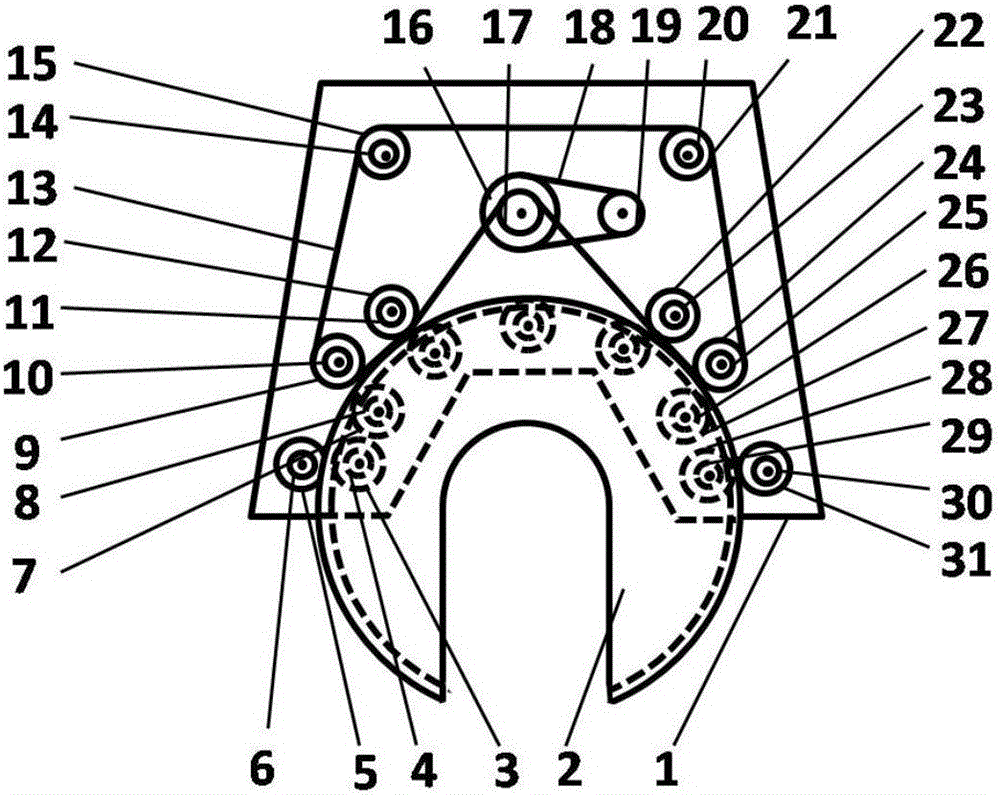

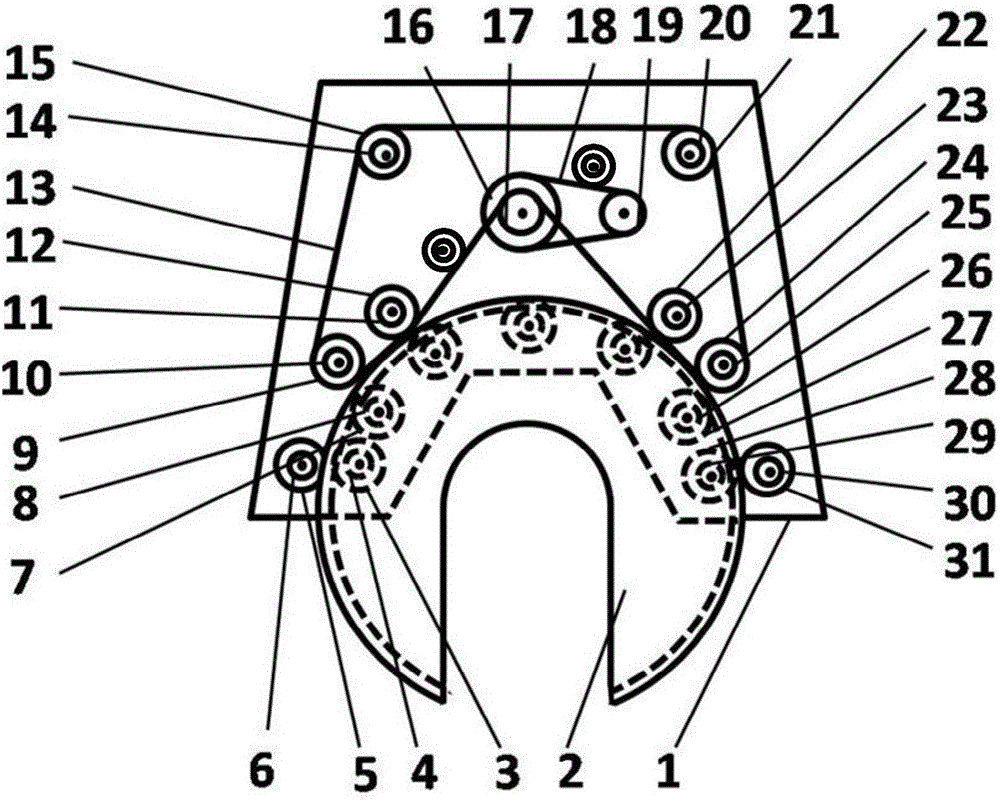

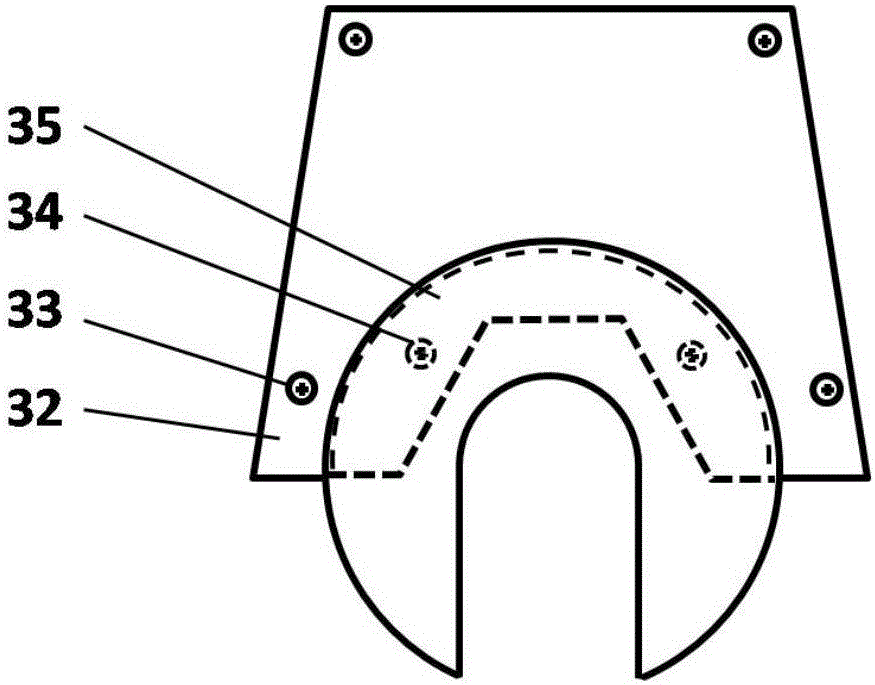

The invention relates to a precisely imitated manually extruding type dough making device which is characterized by comprising a casing, a motor, a worm shaft, two worms, two worm wheels, two vertical shafts, a semi-gear, an external gear ring and two elastic support frames, wherein the outside of the casing is provided with the motor; the output end of the motor is connected with the worm shaft which is transversely supported in the casing through a driving device; the two worms are arranged on the worm shaft at intervals and respectively drive one worm wheel; the two worm wheels are supported in the casing respectively through one vertical shaft; the middle parts of the two vertical shafts are provided with a pair of symmetrical cams; the top of the vertical shaft at one side is provided with the semi-gear; the external gear ring which is supported on the top of the casing is meshed with the semi-gear; one centremost tooth on the semi-gear forms 180 degrees with the long ends of the cams; the two elastic support frames are arranged at the center of the bottom of the casing; the tops of the two elastic support frames are connected with a pair of symmetrical arched extruded sheets; and the back parts of the two arched extruded sheets are respectively connected with the side wall of the casing through a tension spring. The invention can effectively reduce labour cost and improve work efficiency, thereby being suitable for middle and small wheaten food processing places such as families, upscale hotels, small canteens, and the like.

Owner:CHINA AGRI UNIV

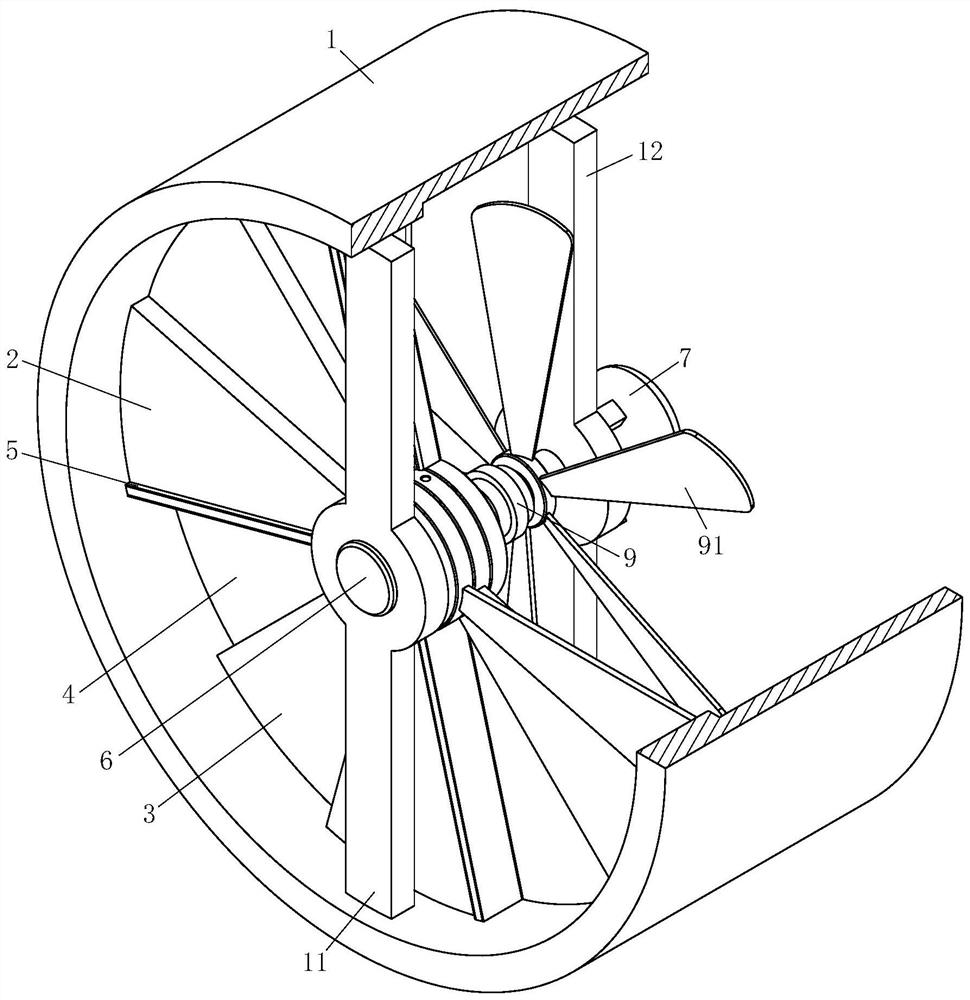

Rotating collision-type lunar piezoelectric energy collection device and working method thereof

ActiveCN105897049ASimple structureImprove work efficiencyPiezoelectric/electrostriction/magnetostriction machinesPV power plantsElectricityLunar soil

The invention discloses a rotating collision-type lunar piezoelectric energy collection device and a working method thereof. The piezoelectric energy collection device comprises a stirling engine, a rotating wheel, a fixed wheel and an energy storage module, wherein the fixed wheel and the rotating wheel are provided with piezoelectric power generation units respectively; a cold end of the stirling engine is arranged in lunar soil; and a hot end is arranged on the lunar surface. When the rotating collision-type lunar piezoelectric energy collection device works, an inert gas arranged in the cold end and the hot end is compressed and expanded by a temperature difference between upper part and the lower part of the lunar surface, so that the stirling engine is driven and the rotating wheel is driven to continuously rotate along the counter-clockwise direction (clockwise direction); the piezoelectric power generation units collide with one another along with rotation of the rotating wheel, so that piezoelectric ceramic is bent and deformed to generate charges on the surface; and the charges are collected into the energy storage module for achieving power generation. The piezoelectric power generation is achieved by the temperature difference on the moon; the structure is simple; the work efficiency is high; and the energy can be collected in an all-weather manner.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

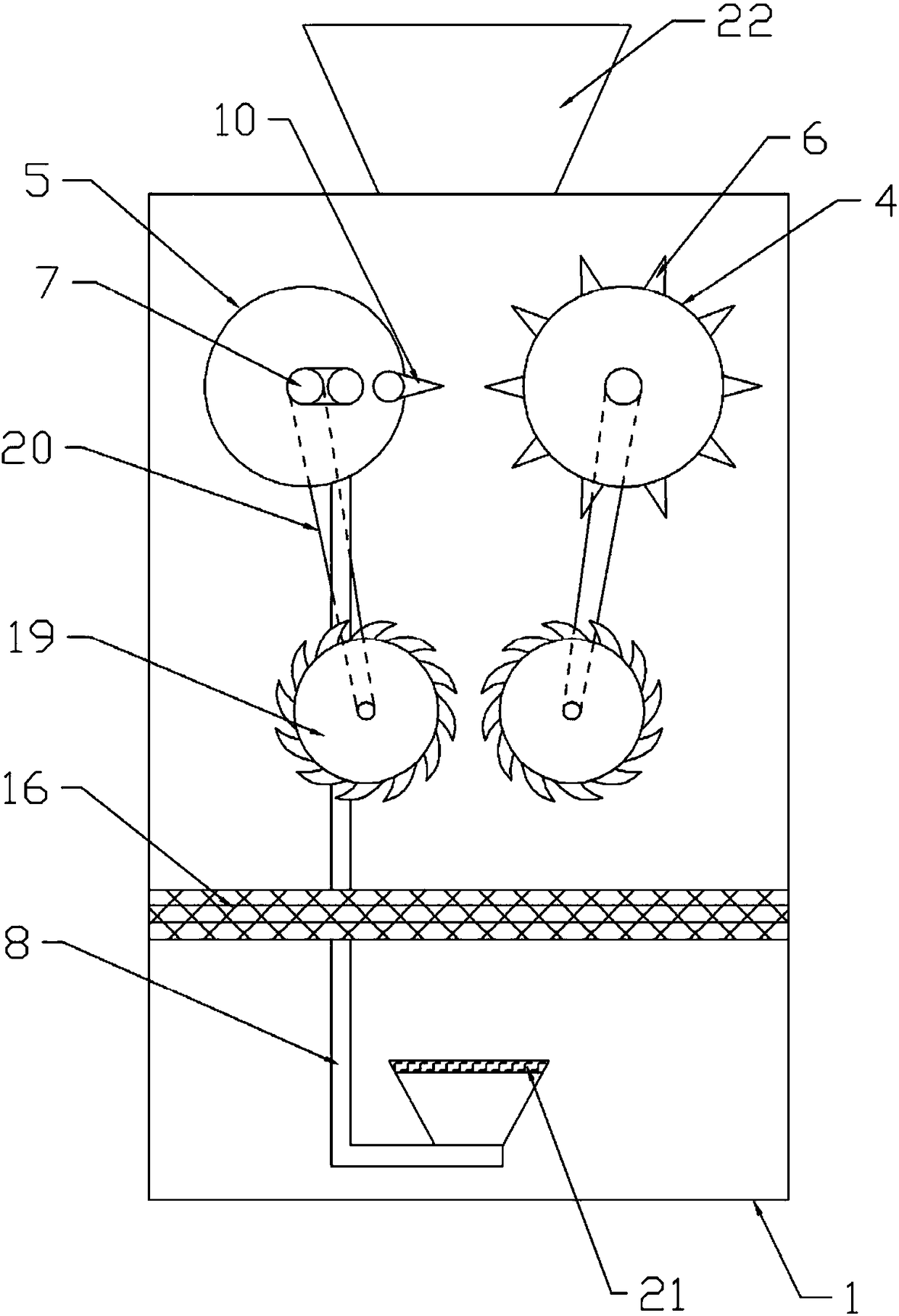

Magnetic separation equipment for waste tire crushing and processing

The invention relates to magnetic separation equipment for waste tire crushing and processing and belongs to the technical field of recycled plastics or other components of plastic-containing wastes.The magnetic sorting equipment comprises a crushing box, a motor and an air blower; a feeding hole is formed in the top of the crushing box, a first pressure roller and a second pressure roller are connected with the inside of the crushing box, the output end of the motor is connected with the first pressure roller and the second pressure roller, a stationary knife is mounted on the peripheral wall of the first pressure roller, a rotating shaft is coaxially connected with the second pressure roller, an air pipe is communicated with the free end of the rotating shaft, and an outlet of the air pipe is formed in the bottom of the crushing box; a cam and a moving knife are rotationally connected with the second pressure roller, a turbine is coaxially connected with the cam and is arranged at the free end of the rotating shaft, a first gear is coaxially connected with the moving knife, a rack is meshed with the first gear, a push block is connected with the rack, and a spring is connected with the push block; a magnetic separation screen is mounted in the crushing box, and a vibrator is connected with the magnetic separation screen. The magnetic separation equipment provided by the invention has the beneficial effects that a waste tire can be effectively crushed by utilizing the shearing forces produced by the stationary knife and the moving knife under high-speed rotation, and further, rubber is separated through the magnetic separation screen.

Owner:重庆九橡化大橡胶科技有限责任公司

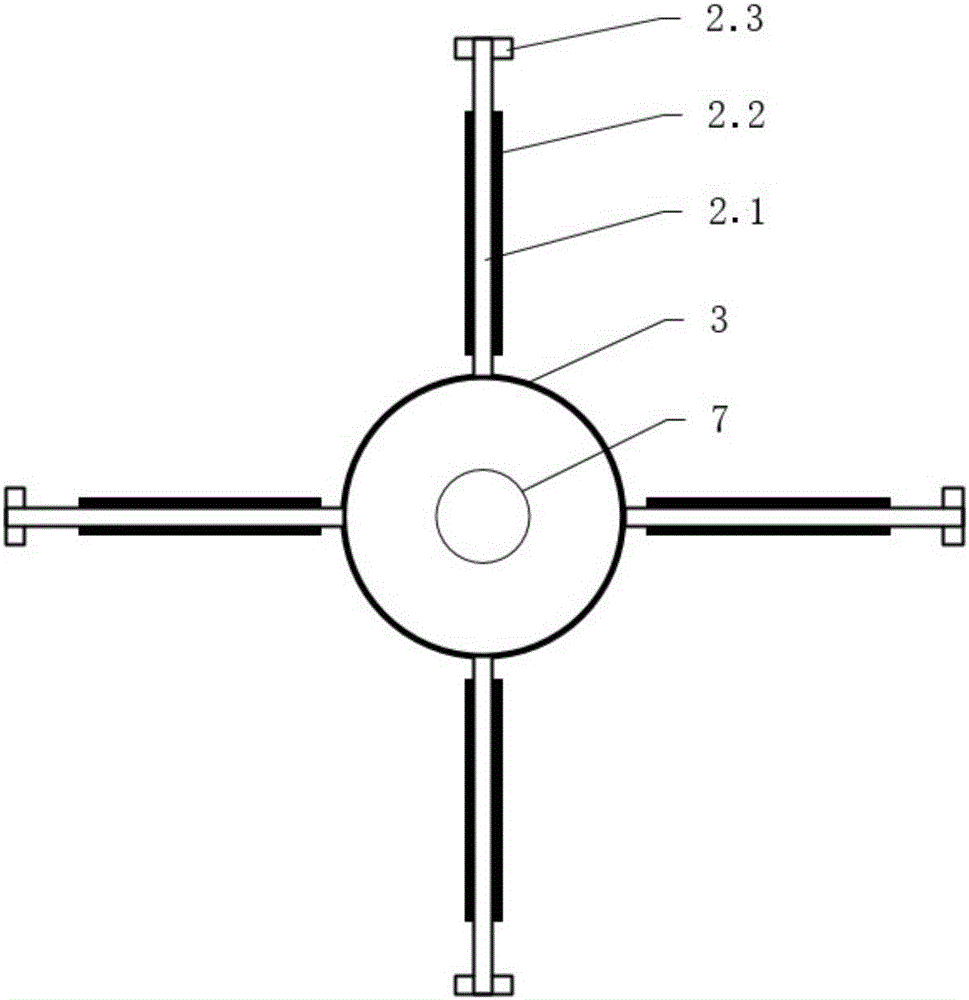

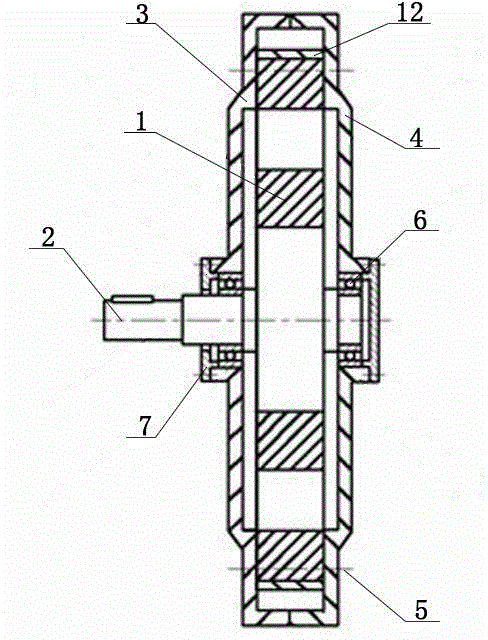

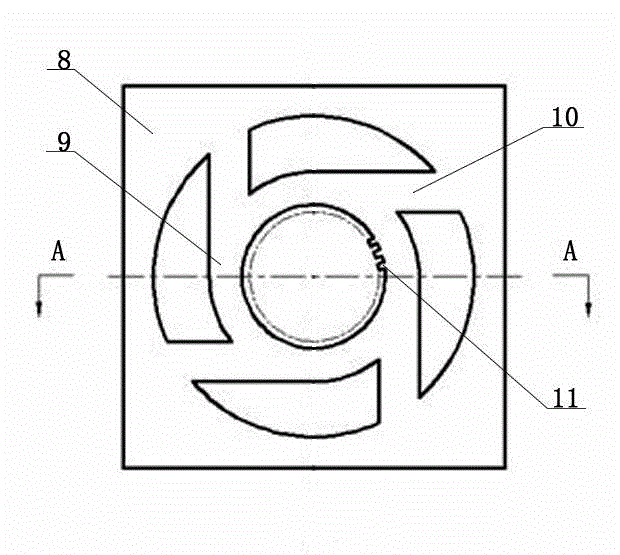

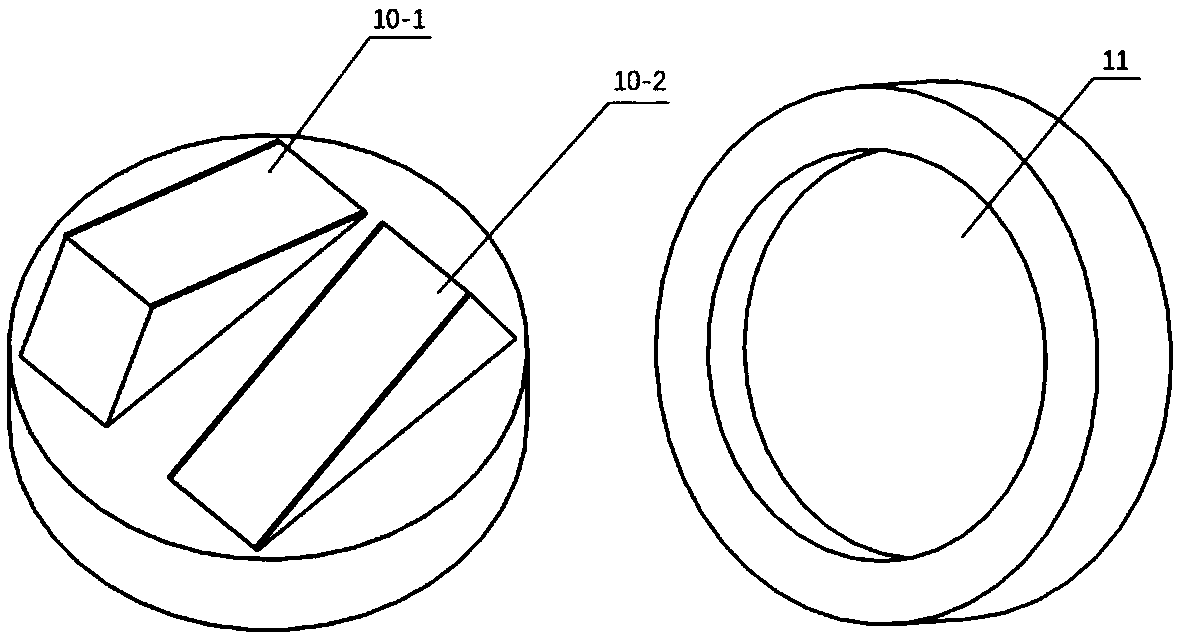

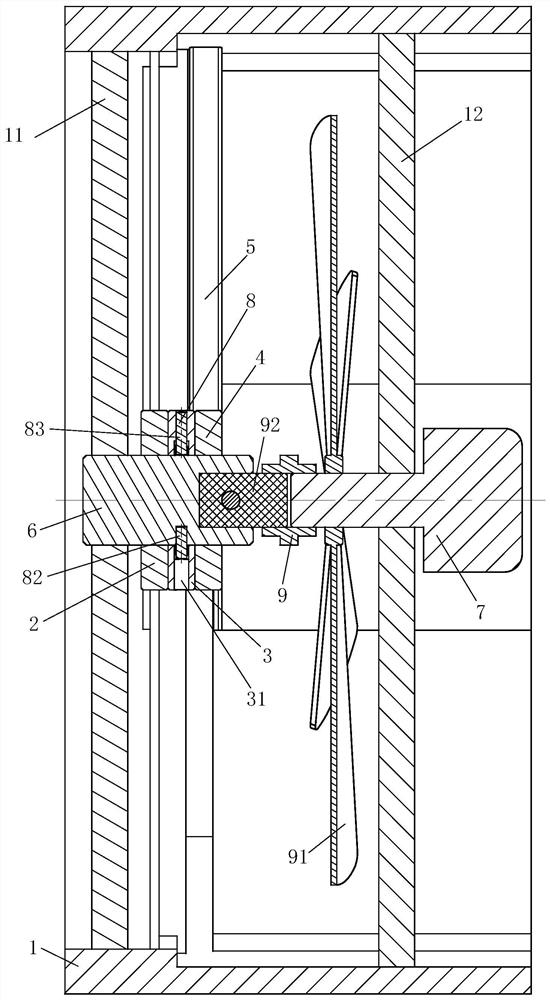

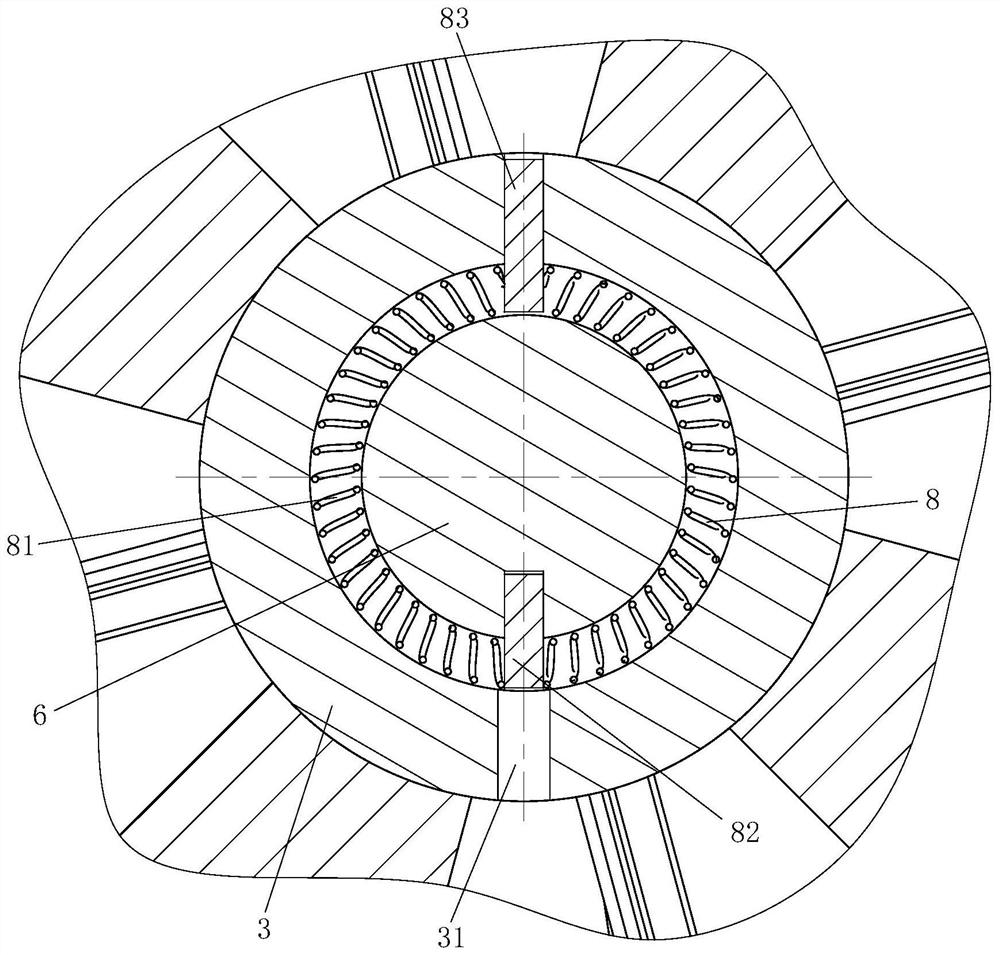

Bent type piezoelectric ultrasonic motor

InactiveCN103607136AAchieve continuous rotationImprove stabilityPiezoelectric/electrostriction/magnetostriction machinesEngineeringCircular face

The invention relates to a bent type piezoelectric ultrasonic motor. A front support and a back support are mutually buckled to form a motor casing, the front support and the back support are respectively provided with core holes of which hole ports are opposite, the two core holes are respectively equipped with a bearing, two ends of a rotor are in supporting connection on the bearings in the two core holes, a buckle chamber between the front support and the back support is further equipped with a stator, a shape of the stator is four radiation boards which are connected between an outer-square inner-circular outer border and a ring-shaped inner border along a circumference of the inner border uniformly, the four radiation boards have same directions along the circumference and are in tangential relation with the inner border, an inner circular face of the inner border of the stator is sleeved on an outer circular face of the rotor, and piezoelectric ceramic sheets are four and are respectively pasted on four end side faces of the outer border of the stator. According to the bent type piezoelectric ultrasonic motor, frequencies of bending deformation and torsion deformation of the stator are completely consistent, operation stability of the motor is facilitated to improved, and manufacturing cost can further be reduced.

Owner:HEBEI UNIVERSITY

Double-layer gear oppositely-pushing rotary type nanometer piezoelectric motor

InactiveCN103916044AAvoid adverse selectionInstant startPiezoelectric/electrostriction/magnetostriction machinesEngineeringControl theory

The invention provides a double-layer gear oppositely-pushing rotary type nanometer piezoelectric motor which comprises a shell. A rotor with two gears in the center, outer-layer piezoelectric ceramic heaps, inner-layer piezoelectric ceramic heaps, a power driving part and a one-way limiting piece are arranged in the shell. The power driving part is in transmission connection with the outer-layer piezoelectric ceramic heaps and the inner-layer piezoelectric ceramic heaps; the rotor with the double-layer gears in the center is composed of an outer-layer gear and an inner-layer gear, wherein the outer-layer gear is coaxial with the inner-layer gear, the module number of the outer-layer gear is the same as that of the inner-layer gear, the outer-layer gear of the rotor with the double-layer gears in the center is driven by the power output end of the outer-layer piezoelectric ceramic heaps, and the inner-layer gear of the rotor with the double-layer gears in the center is driven by the power output end of the inner-layer piezoelectric ceramic heaps. According to the double-layer gear oppositely-pushing rotary type nanometer piezoelectric motor, the piezoelectric ceramic heaps directly push the gears to rotate by extending in the radial direction, so that output efficiency is maximized, and the problems that torque of advance through frictional force is small and the energy loss is big are solved; the design of rotation and opposite pushing is adopted, operation of the motor is not limited by the stroke of the piezoelectric ceramic heaps, and the motor can rotate continuously at a high speed in a stepping mode.

Owner:ZHENGZHOU UNIV

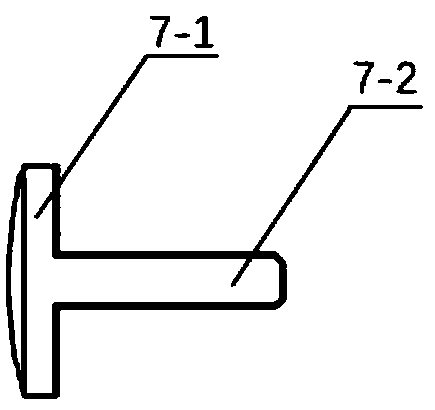

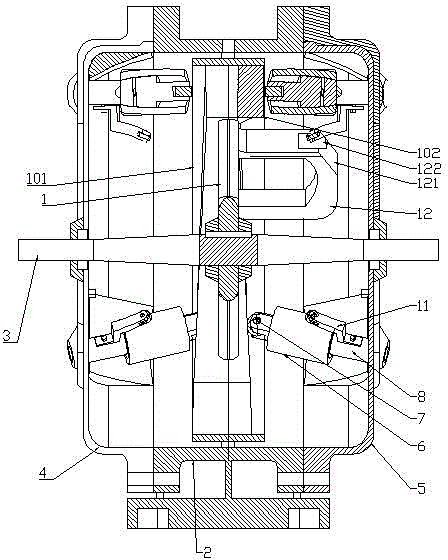

Impact piezoelectric rotary motor

ActiveCN108712103AIncrease frictionAchieve continuous rotationPiezoelectric/electrostriction/magnetostriction machinesMiniaturizationMechanical engineering

The invention discloses an impact piezoelectric rotary motor, which comprises piezoelectric stacks put into a hollow cavity of a cylinder sleeve, a vibration coupler and a rotor, wherein two symmetrically distributed bosses with inclined surfaces are arranged on a bottom fixed plate of the cylinder sleeve; the bosses with the inclined surfaces are arranged on the bottom surface of the vibration coupler in a mirror symmetry manner; two piezoelectric stacks which are symmetric around a center line are obliquely arranged between the bottom fixed plate of the cylinder sleeve and the vibration coupler; two end surfaces of the piezoelectric stacks are arranged at the top ends of the inclined surfaces of the bosses separately; a contact surface in contact with the top end of the vibration coupleris arranged at one end of the rotor and an output shaft is arranged at the other end; a preloaded spring also sleeves the output shaft; and the output shaft extends out of a bearing fixed on an end cover. According to the impact piezoelectric rotary motor, miniaturization of the rotary motor is facilitated, the problems that an existing rotary motor is complicated in structure and difficult to process, manufacture and produce in batches are well solved and the impact piezoelectric rotary motor is suitable for the field of precise control, such as high-precision nano drive.

Owner:HEFEI UNIV OF TECH

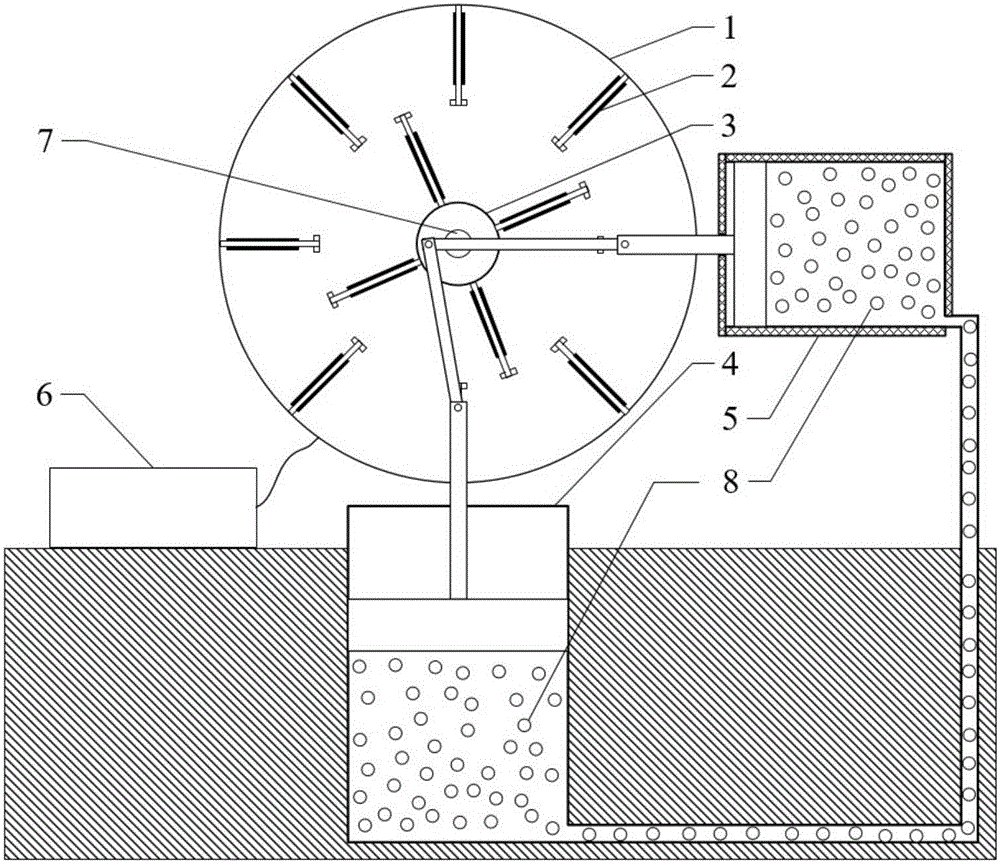

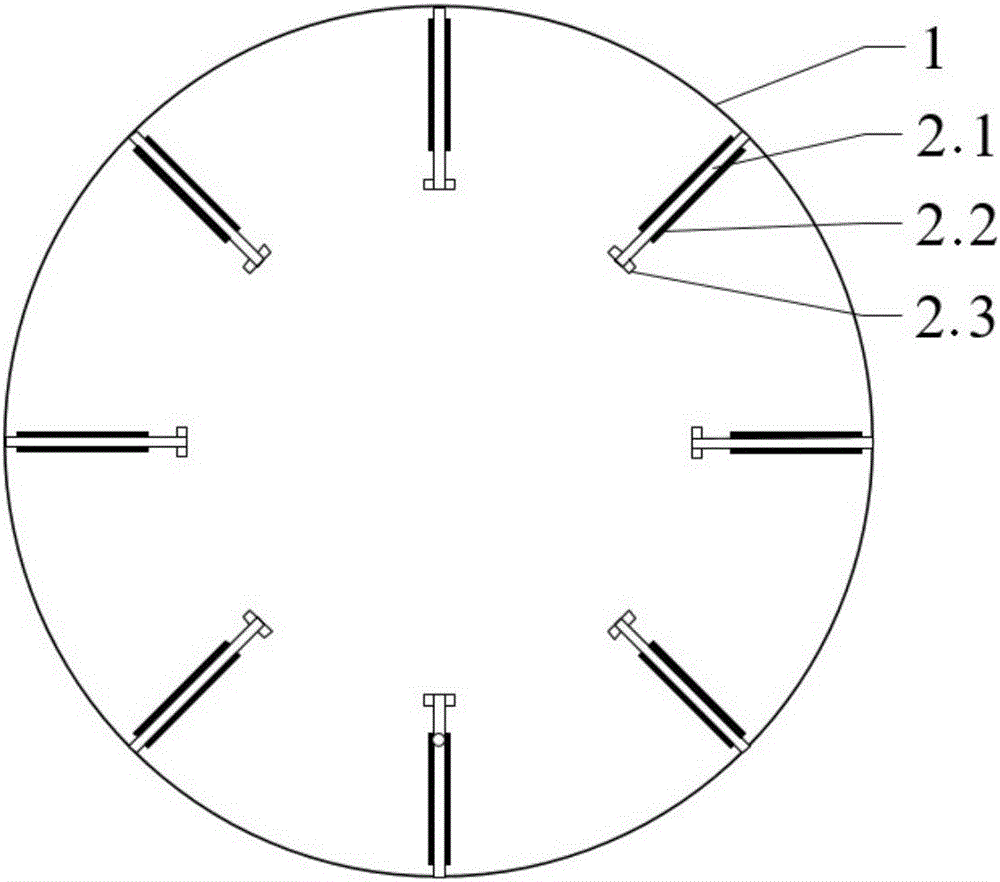

Rotary hammering-type moon-surface piezoelectric power generation device and work mode thereof

ActiveCN105915115ASimple structureImprove work efficiencyPiezoelectric/electrostriction/magnetostriction machinesHot gas positive displacement engine plantsElectricityTemperature difference

The invention discloses a rotary hammering-type moon-surface piezoelectric power generation device and a work mode thereof. The piezoelectric power generation device comprises a Stirling engine, a rotating wheel, a fixing wheel, a solar heat collection module and an energy storage module. The fixing wheel is provided with a piezoelectric power generation unit. The rotating wheel is provided with a driving hammer. A cold end of the Stirling engine is arranged in moon-surface soil and a hot end is arranged on a moon surface. During working, a temperature difference of an upper portion and a lower portion of the moon surface is used to compress and expand an inert gas arranged in the cold and hot ends so as to drive the Stirling engine to drive the rotating wheel to rotate. The driving hammer on the rotating wheel knocks the piezoelectric ceramic power generation unit on the fixing wheel so that a piezoelectric ceramic sheet generates deformation and charges are generated and stored through the energy storage module. In the invention, a temperature difference on a moon is used to realize piezoelectric power generation, the structure is simple, work efficiency is high and the device can collect energy in an all-weather mode.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

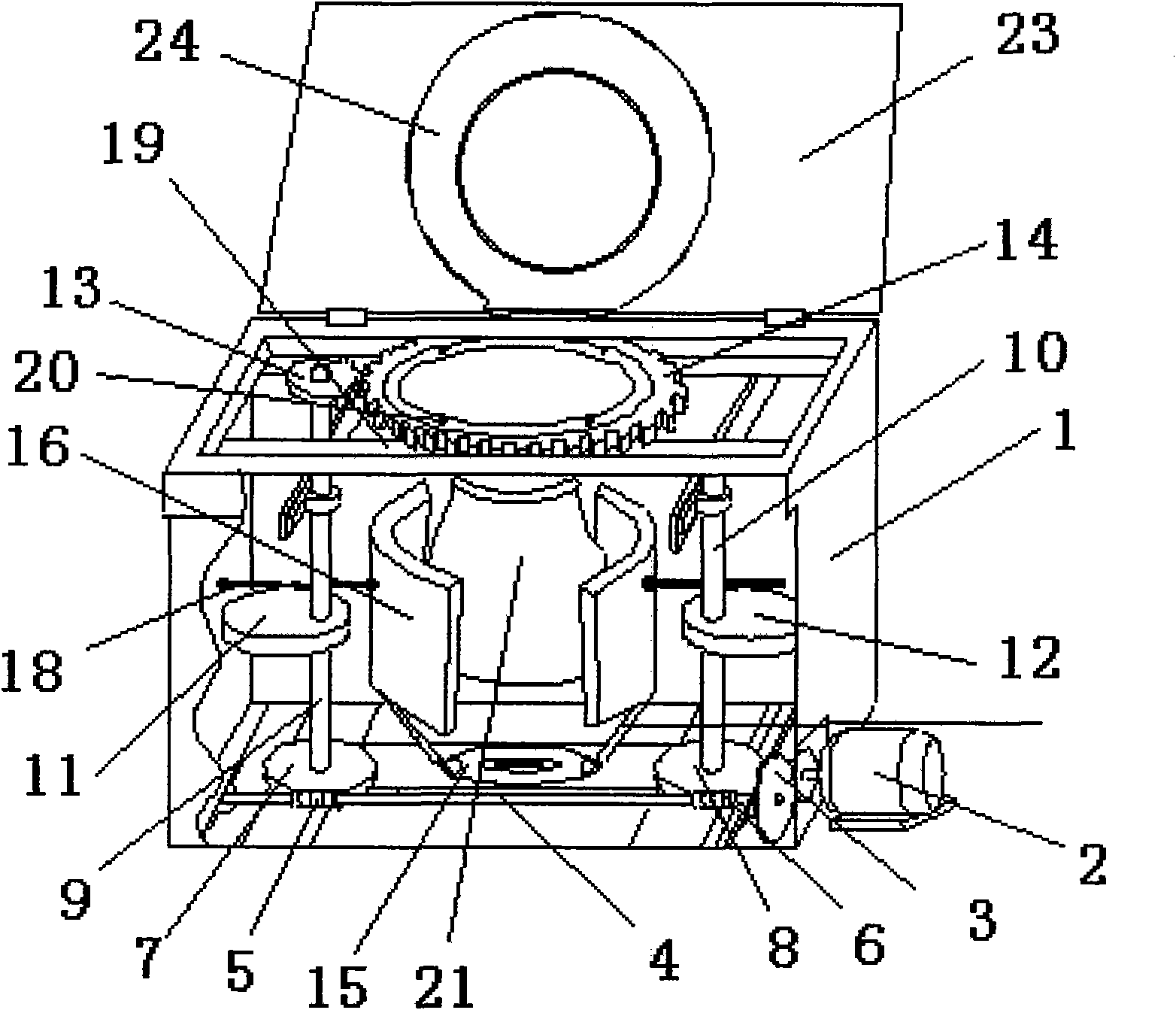

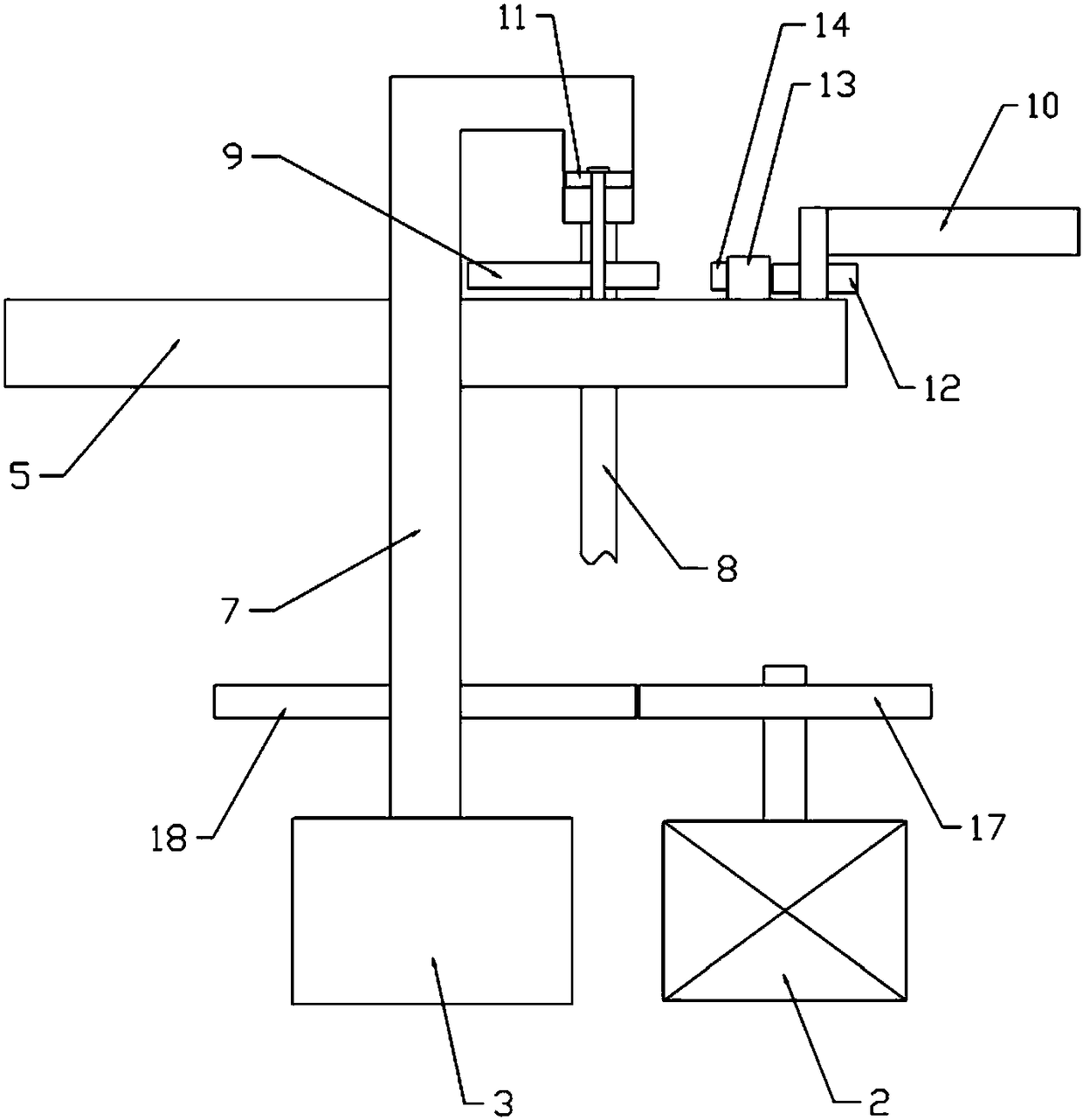

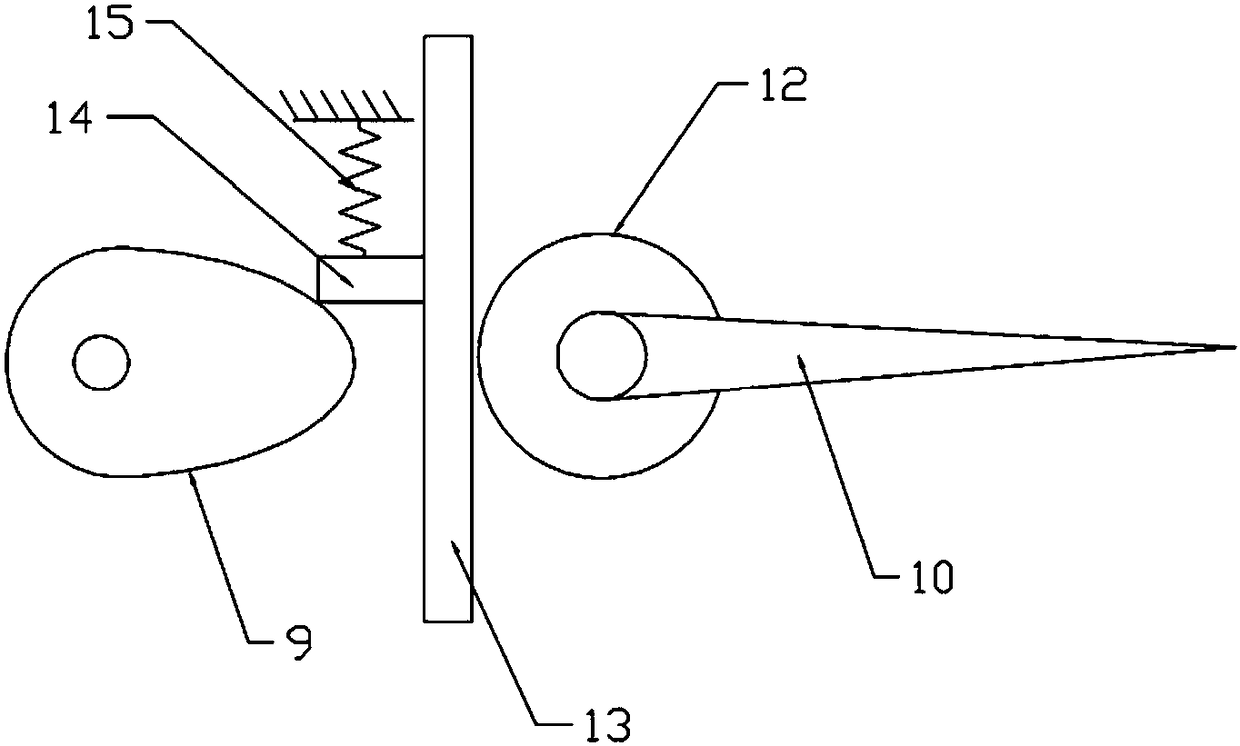

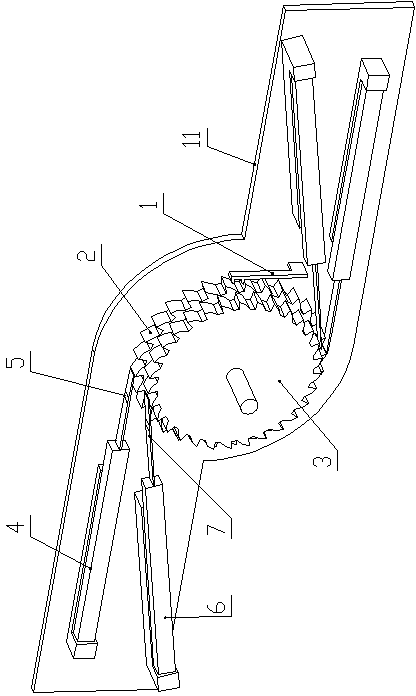

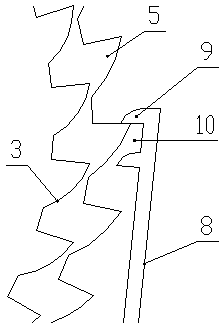

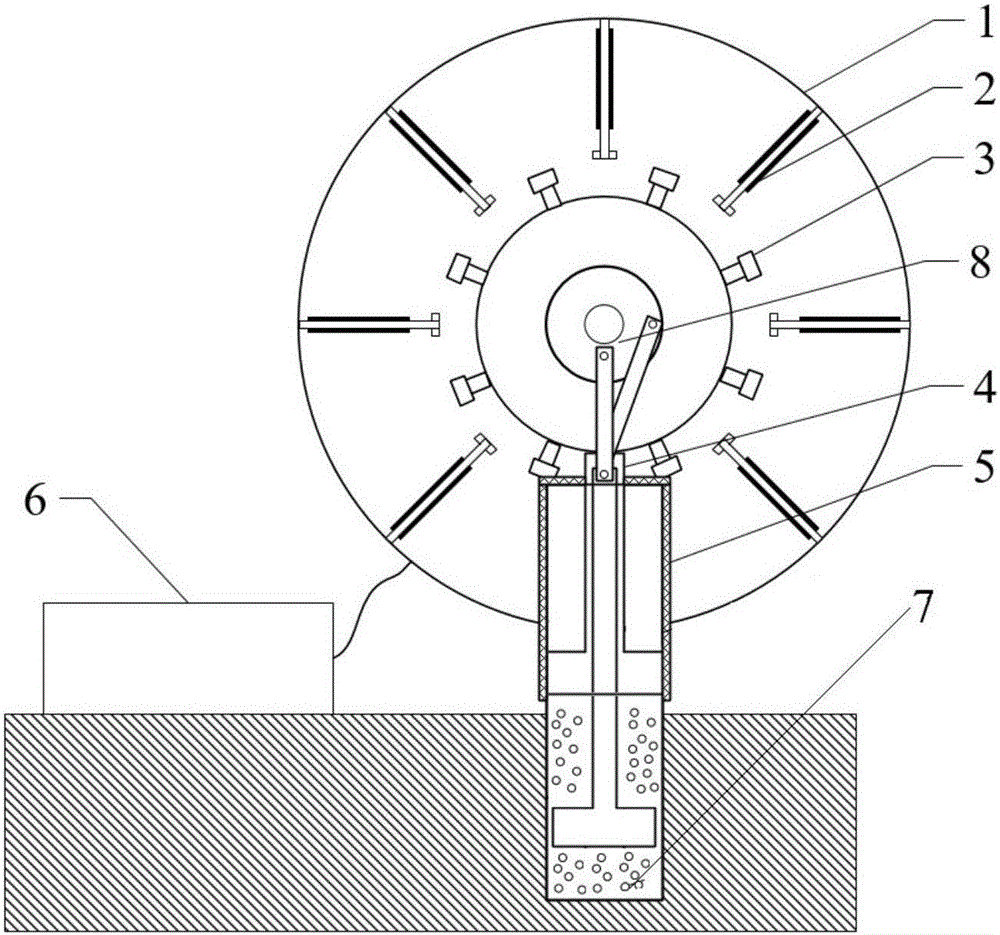

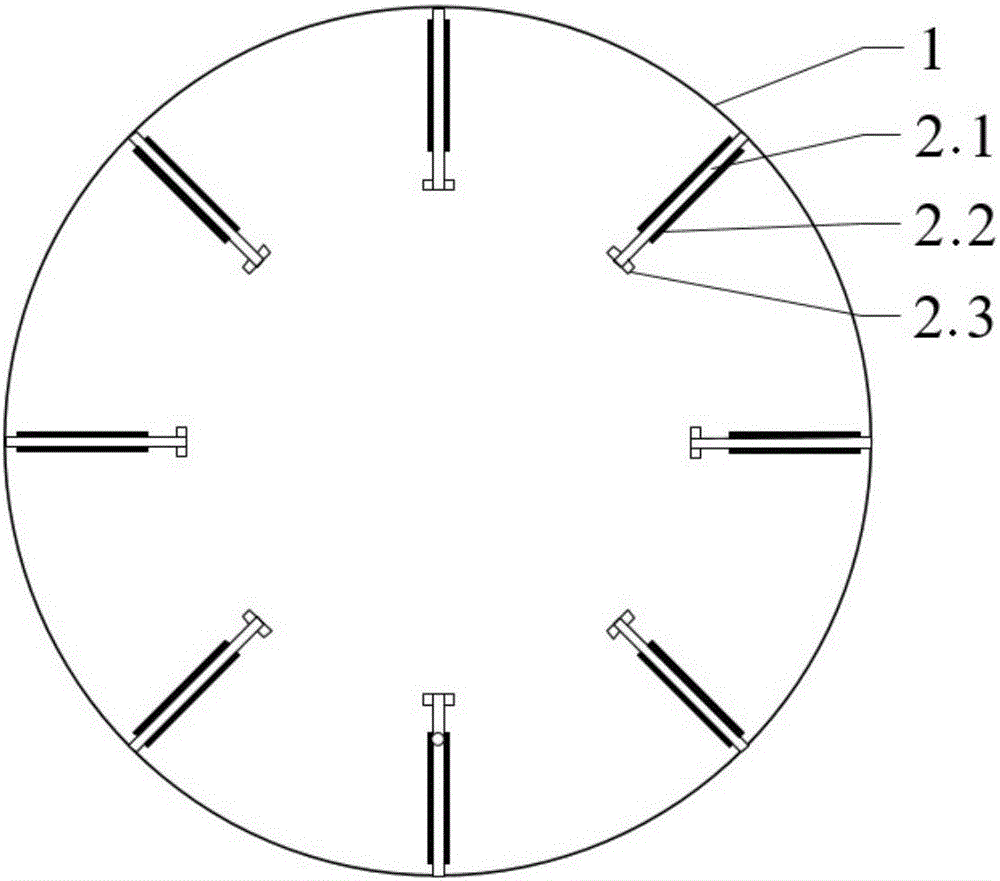

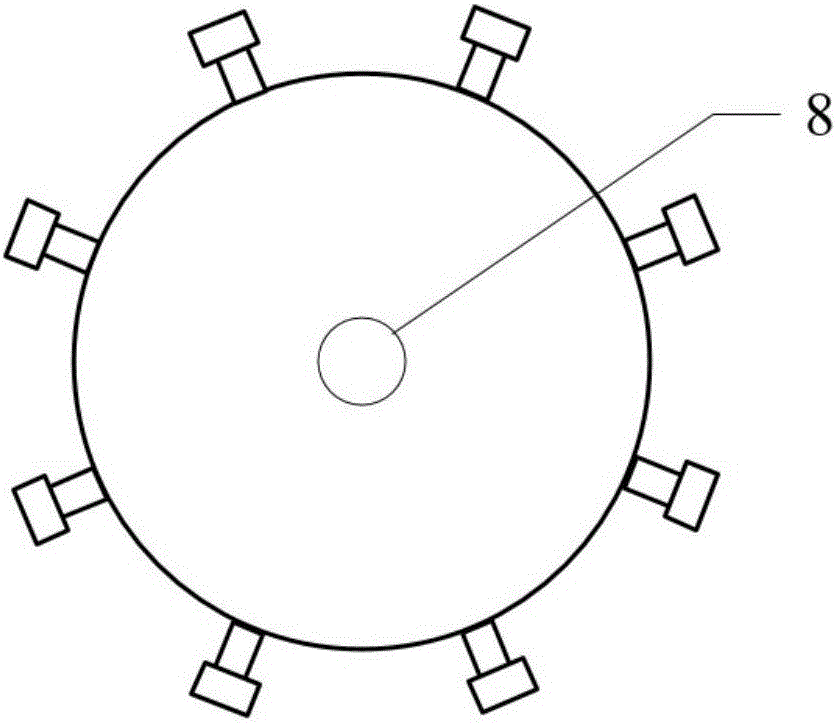

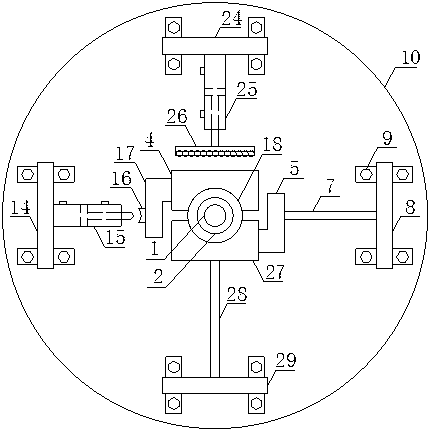

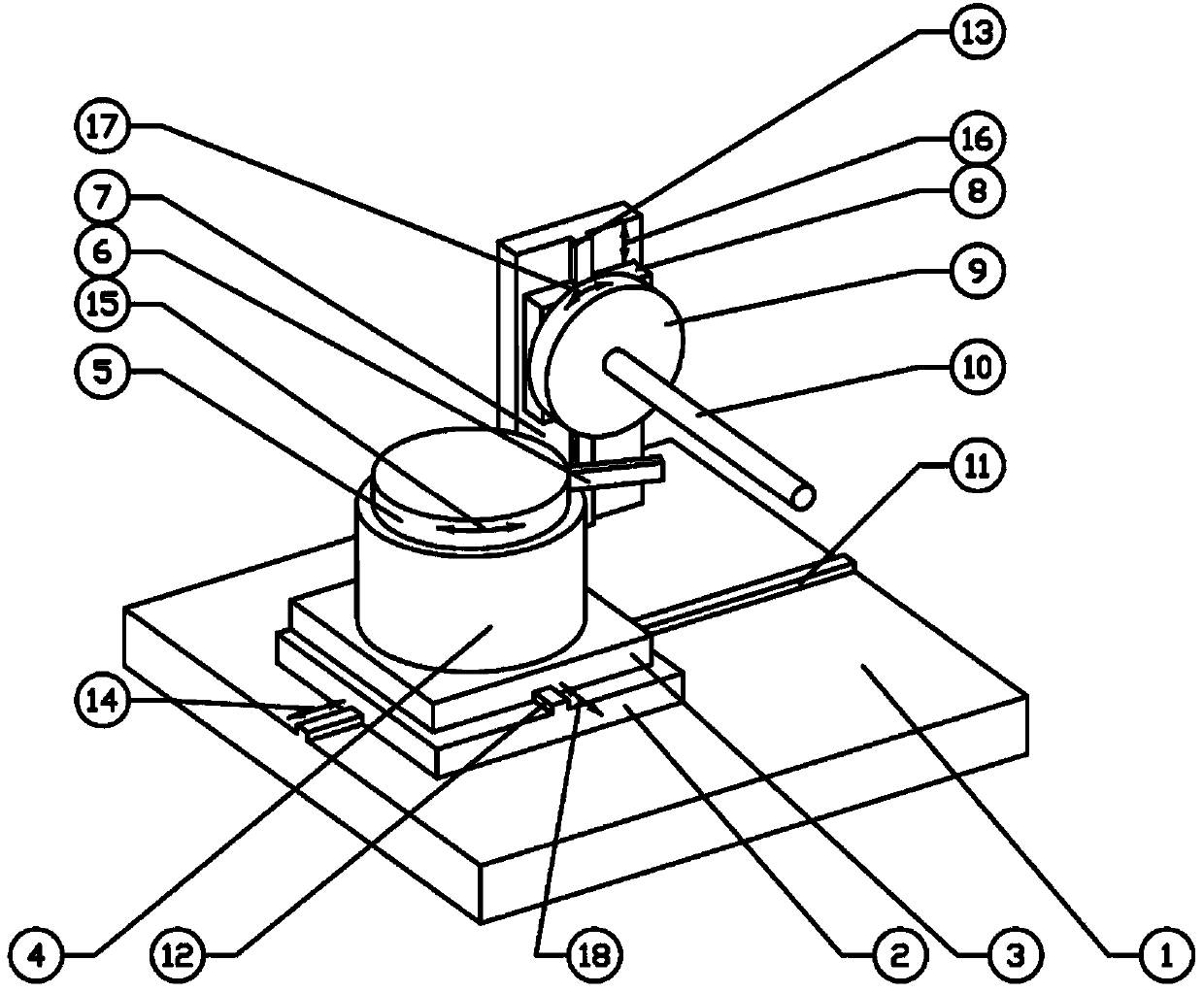

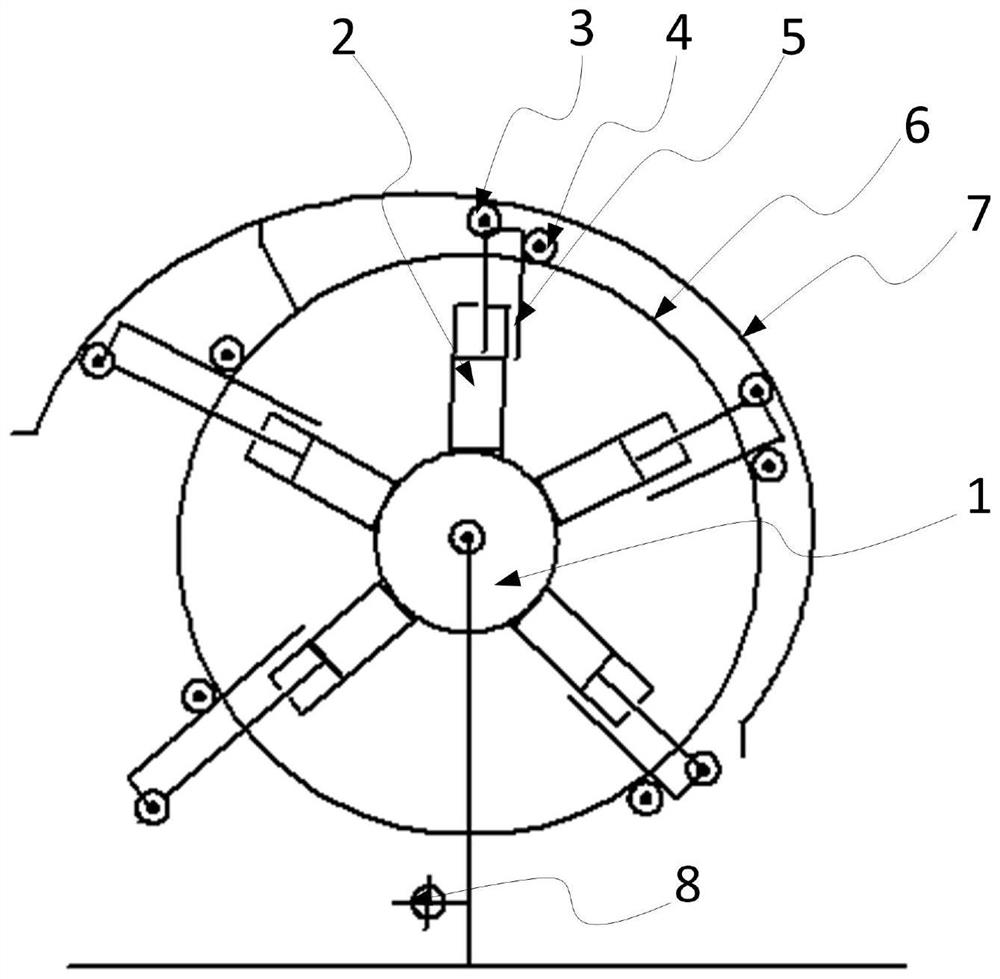

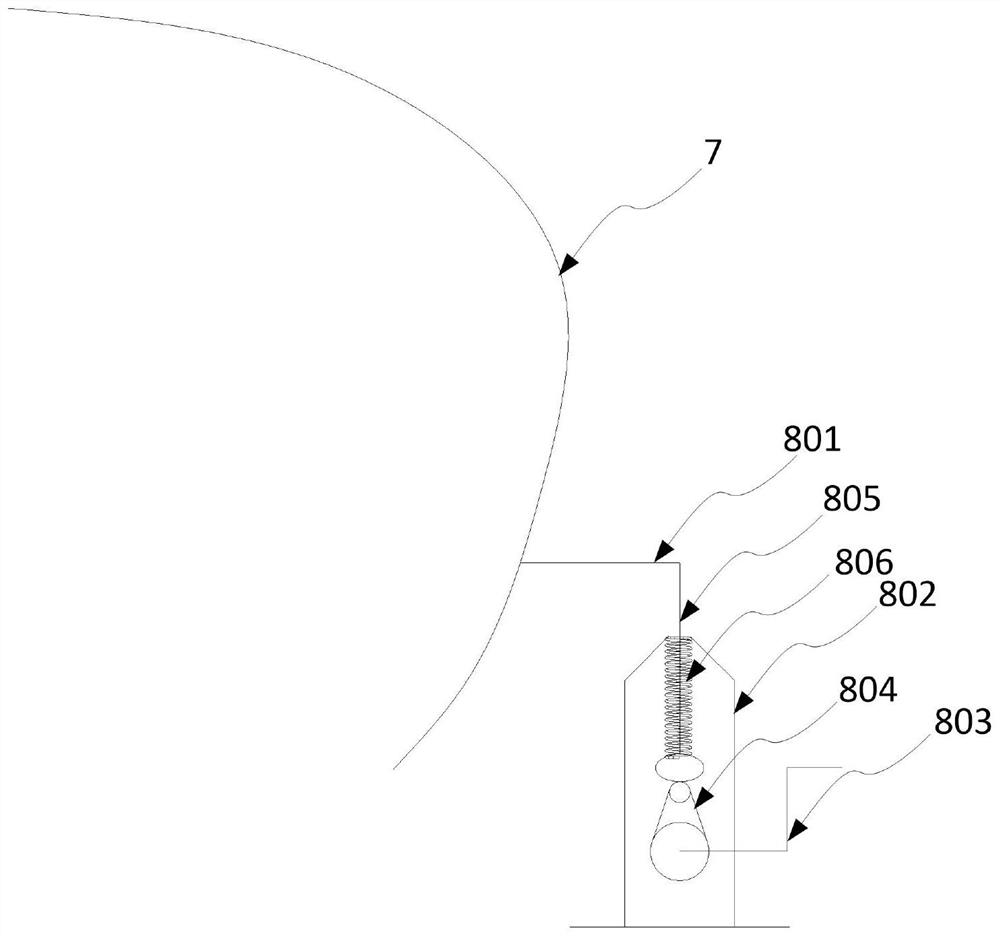

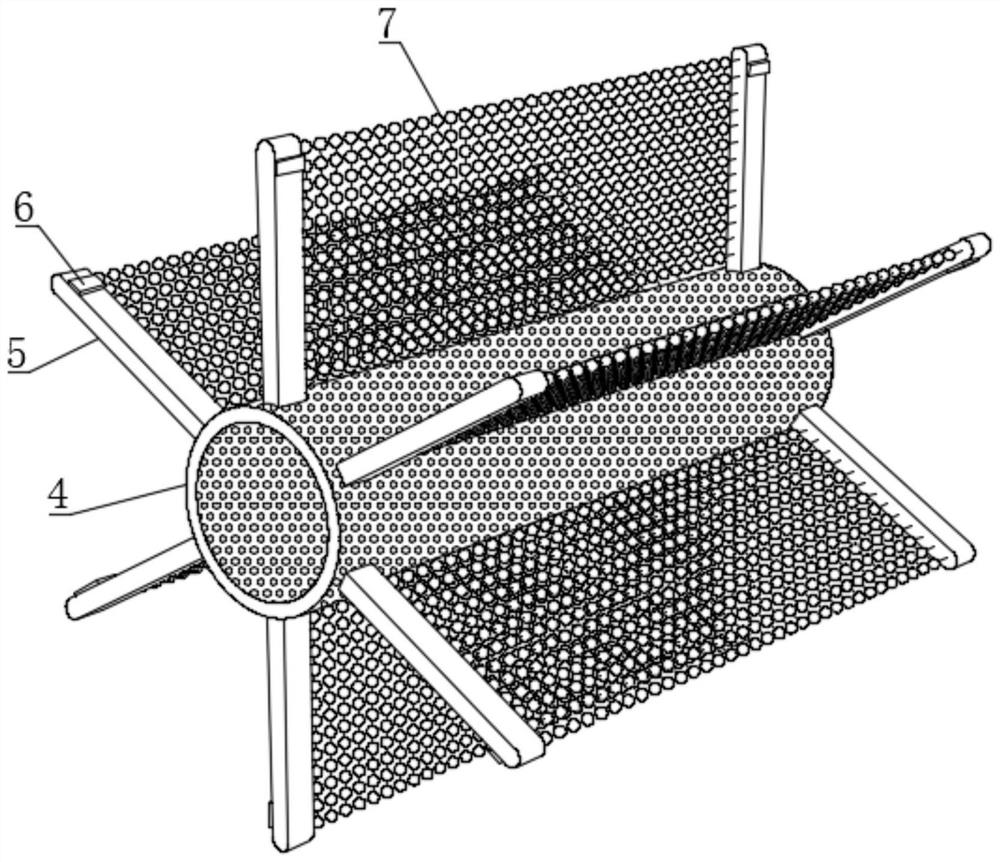

Rock mechanic testing machine capable of realizing continuous change of shear direction

PendingCN109269918ASimple output structureFast and easy processingMaterial strength using steady shearing forcesEngineeringFracture process

The invention relates to an indoor rock mechanical testing apparatus, in particular to a rock mechanic testing machine capable of realizing continuous change of shear direction and belongs to the technical field of geotechnical engineering. The testing machine comprises a bearing platform, a first gear, a motor, a second gear, a bearing, a bearing end cover, a supporting post, a shear box and a forcing device, solves the difficulty in changing the shear direction in the conventional shear test, can control applying of normal stress and shear stress and rotation of the shear surface individually or hybridly, is simple in structure and high in practicability, is applied to theory and test of rock mechanics, and can be used for precise description to a rock fracture process and a fracture system in engineering.

Owner:HENAN POLYTECHNIC UNIV

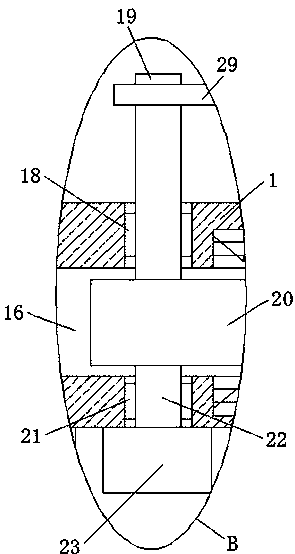

Runner rotating in radial direction due to end face stress and pressure power machine of runner

InactiveCN105626154AAchieve continuous rotationSimple structureReciprocating piston enginesPressure controlled ventilationPiston rod

A runner rotating in the radial direction due to end face stress comprises a runner body. At least one first spiral face is arranged on one end face of the runner body, and at least one second spiral face is arranged on the other end face of the runner body. Two sections of transition inclined faces are arranged at the head-tail combining positions of the first spiral face and the second spiral face. A pressure power machine comprises a box, an output shaft and the runner. The runner is arranged on the output shaft. A front end cover and a rear end cover are arranged at the two ends of the box. A plurality of pressure cylinders are arranged on the inner side of the front end cover, and a plurality of pressure cylinders are arranged on the inner side of the rear end cover. The pressure cylinders are obliquely arranged relative to the axis of the output shaft. Bearings are arranged at the heads of piston rods of the pressure cylinders on the two sides, and the bearings on the two sides make contact with the first spiral face and the second spiral face. The input end of each pressure cylinder sequentially passes through a pressure control device and an input pipeline to be connected with a pressure supply device, wherein the pressure control device can control closing / opening of the input pipeline. Pressure is exerted on the spiral faces, the spiral faces convert pressure into rotating force, and then the runner can rotate.

Owner:江国兵

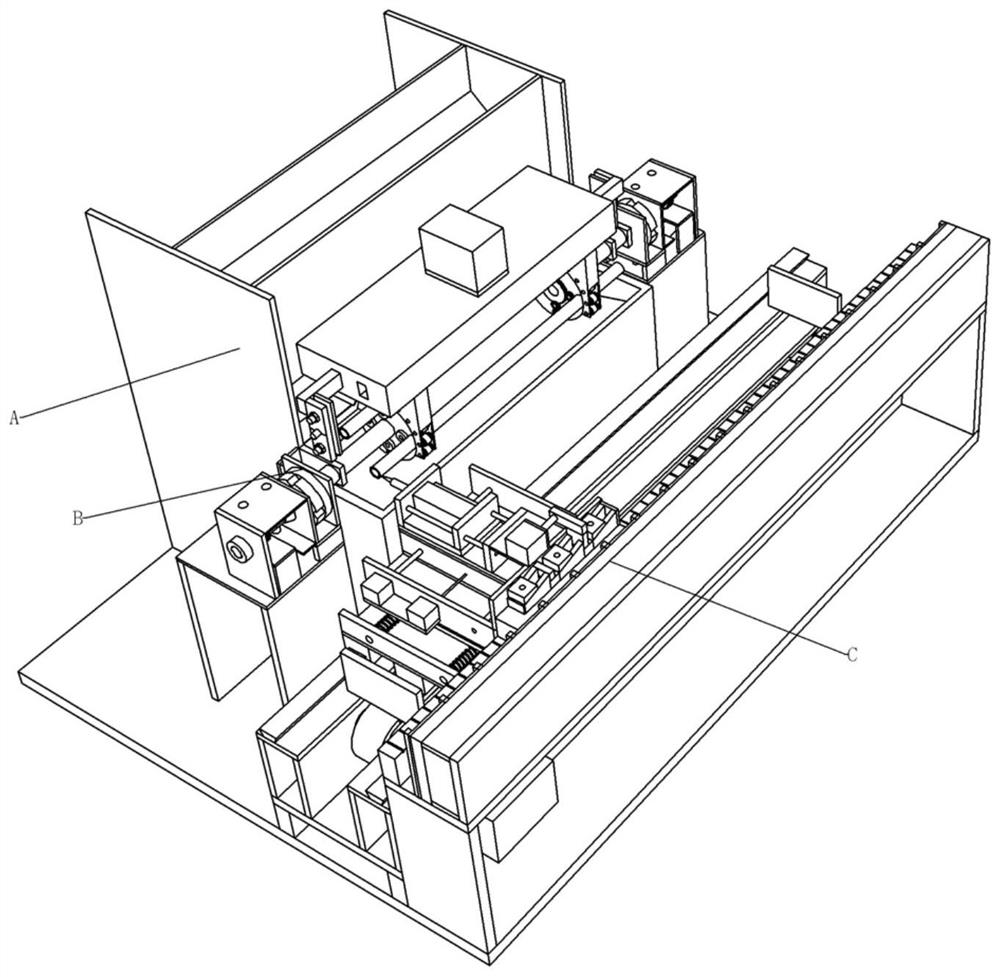

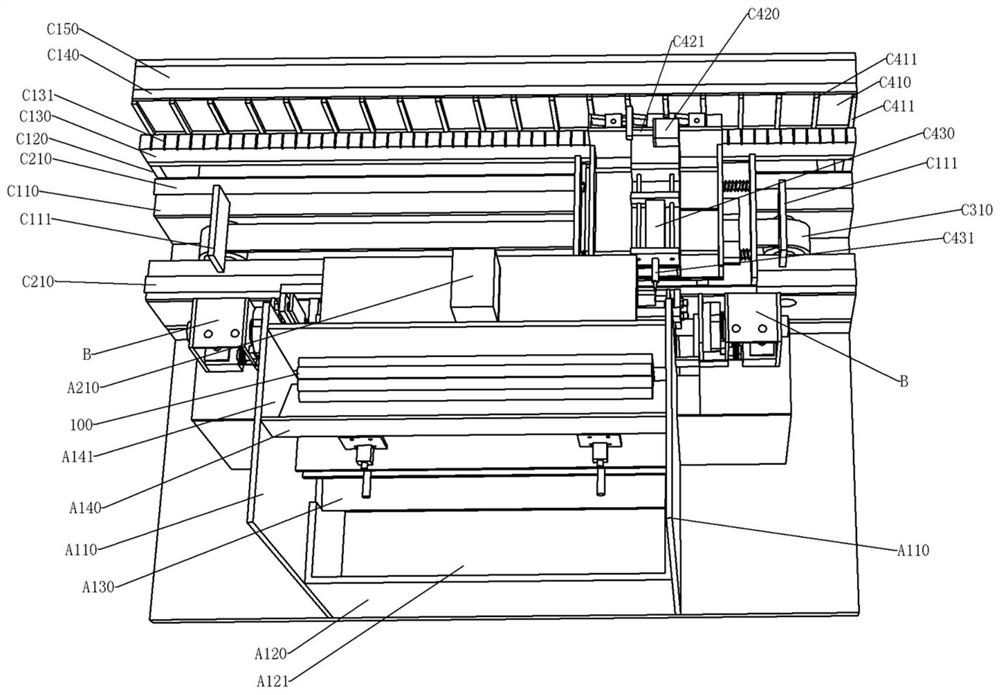

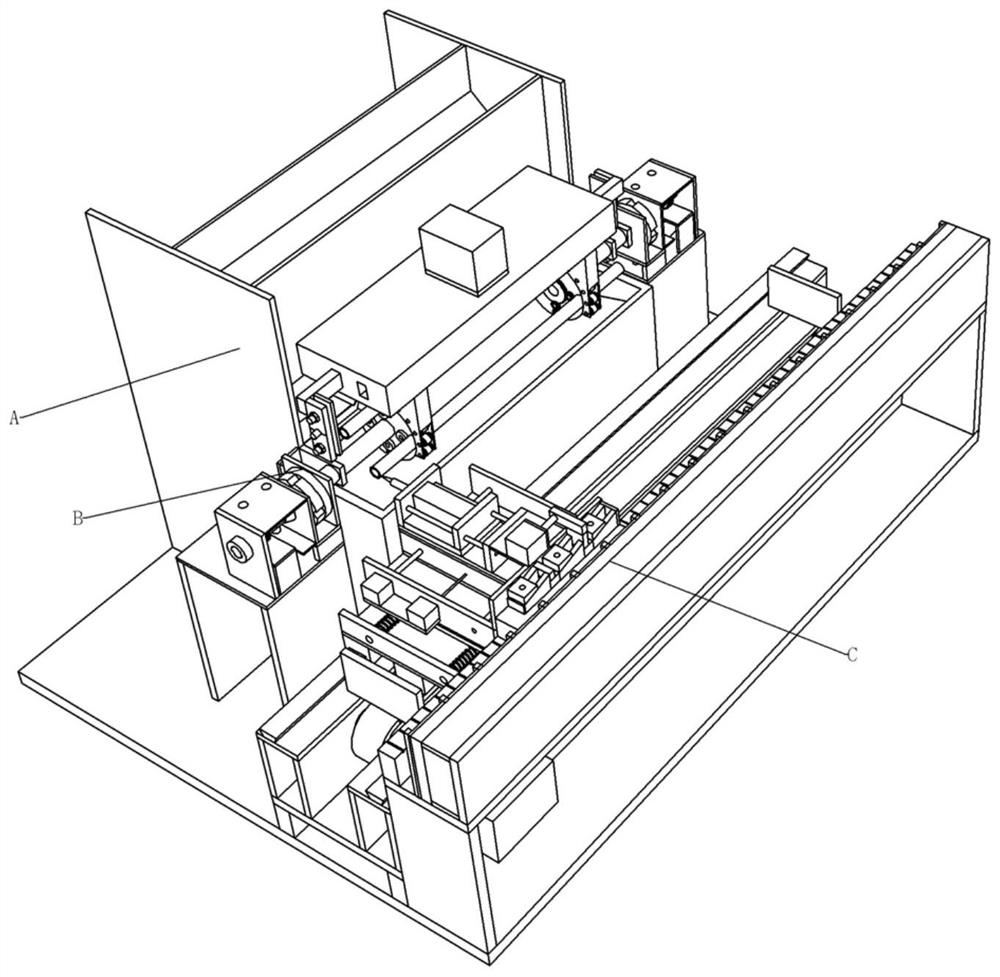

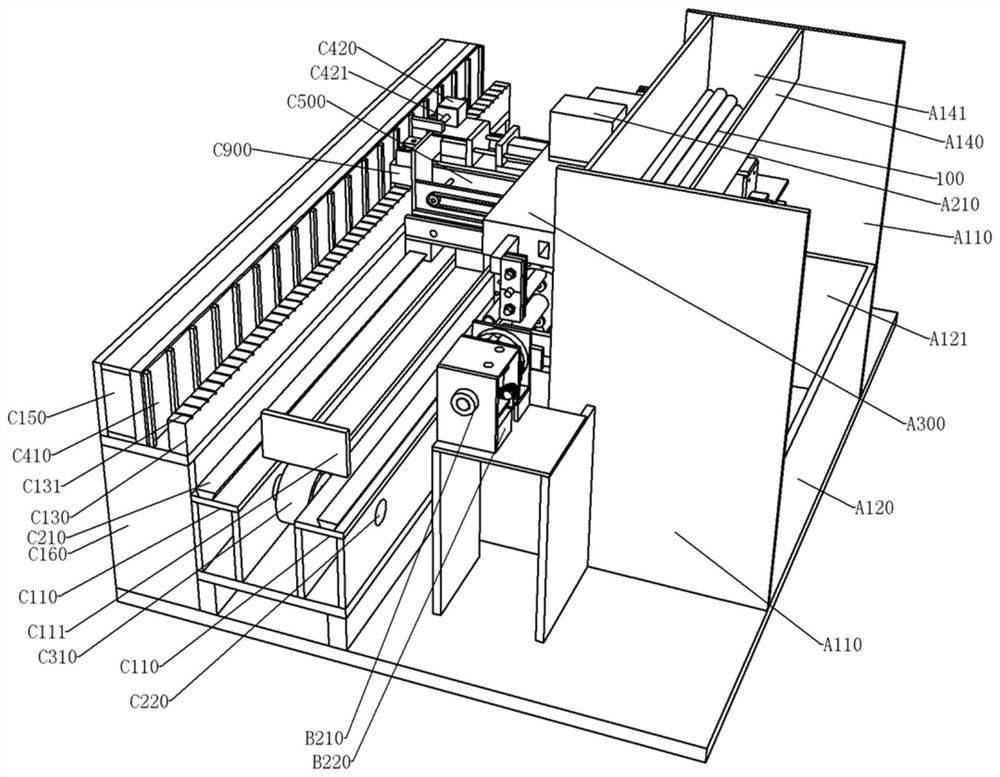

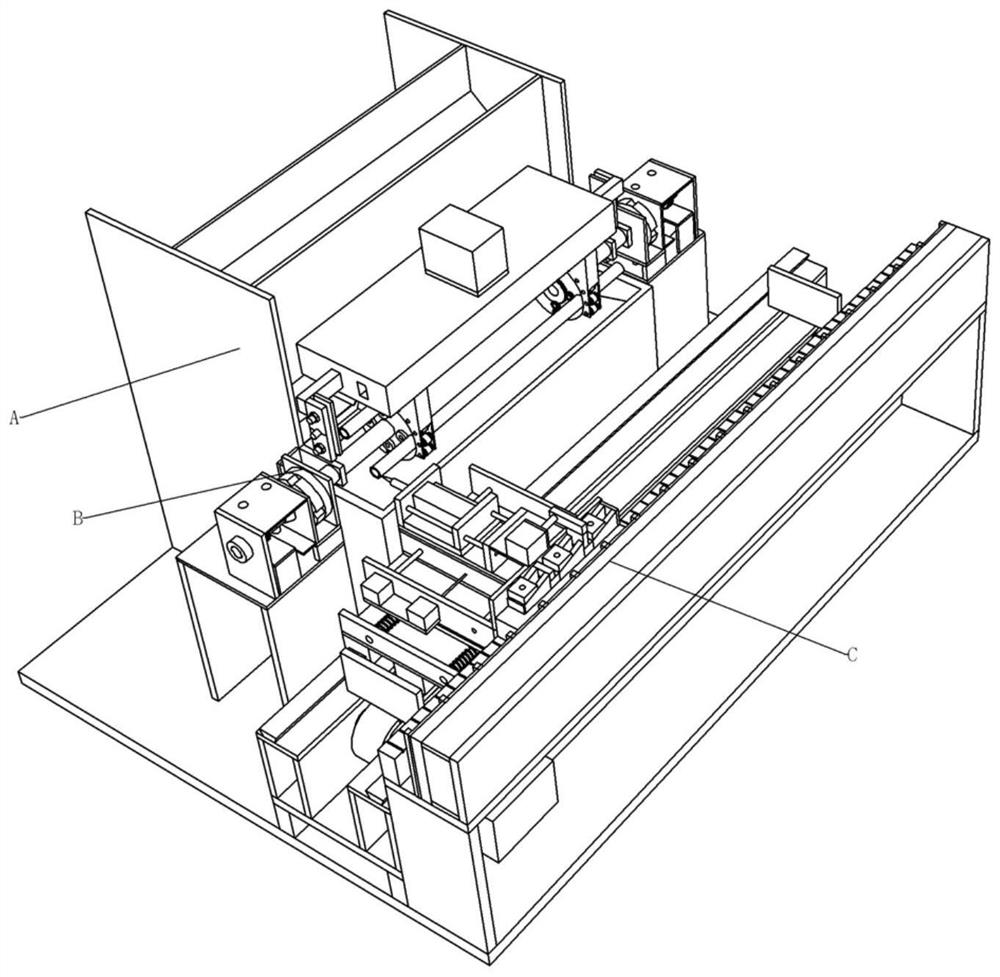

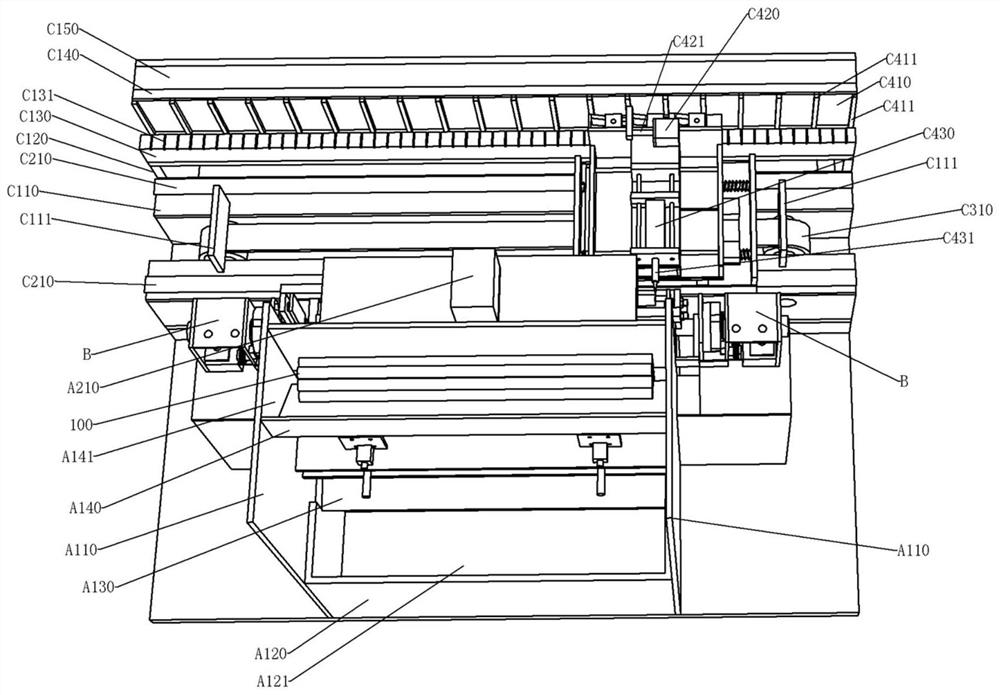

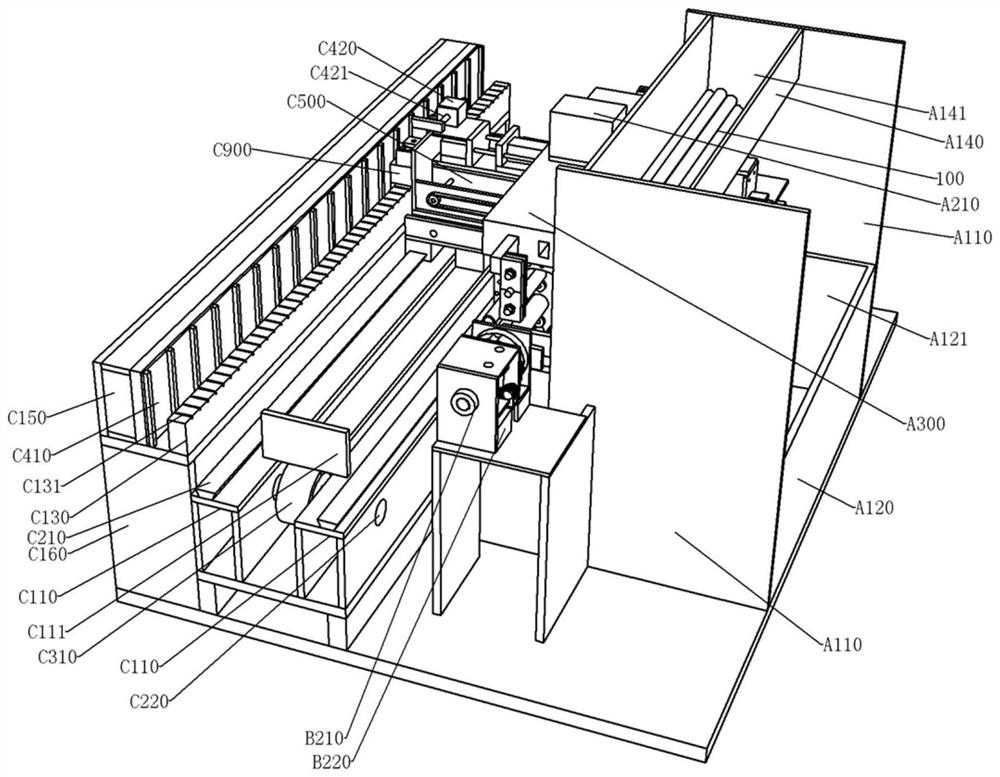

Material pushing mechanism and full-automatic laser pipe cutting machine

ActiveCN112207459ARealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a material pushing module and a full-automatic laser pipe cutting machine. The full-automatic laser pipe cutting machine comprises a feeding module, a power module and a cutting module, wherein the feeding module is used for loading pipes to be cut into pipe grooves of a feeding wheel one by one, and then the feeding wheel rotates to enable the pipes to be cut to be sequentially subjected to the procedures of feeding, centering, clamping, section cutting and discharging; the power module is used for driving the pipes at the section cutting procedure to rotate so as to ensure that the whole circles of the pipes are cut off, and intermittently driving the feeding wheel to rotate so as to complete procedure switching; and the cutting module is used for cutting the pipes through laser emitted by a laser device, the pipes are relatively fixed in the axial direction, and laser cutting heads move in the axial direction of the pipes and positioning is carried out, so that accurate cutting of the pipes is completed. Automatic feeding can be achieved, and the five procedures of feeding, clamping, axial alignment, section cutting and discharging can be synchronously achieved, so that the production efficiency is improved by at least two times or above. In addition, the mode that the laser device moves while the pipes are fixed is adopted, and the full-automatic laser pipe cutting machine can adapt to pipes with more lengths.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

Pneumatic helical tooth surface rotating table

InactiveCN112081894AImplementation angleAchieve continuous rotationProgramme-controlled manipulatorFluid gearingsRotary stageGear wheel

The invention relates to the technical field of pneumatic rotation, in particular to a pneumatic helical tooth surface rotating table. The rotating table comprises a shell, an inner gear and an air cylinder body which are sequentially arranged from outside to inside, and the centers of the shell, the inner gear and the air cylinder body are located on the same axis. The air cylinder body is provided with a plurality of air chambers which are arranged in a layered mode and are independent of one another, each air chamber extends outwards to form an air cavity channel, the air cavity channels are connected with an air source, and the air source controls the air chambers to be inflated or deflated. Each layer of air chamber is provided with a plurality of pneumatic piston units, and the pneumatic piston units are horizontally and uniformly arranged, penetrate through the air cylinder body and can movably abut against the inner gear; and each pneumatic piston unit is provided with a resetpiece. The internal structure of the rotating table is compact in installation, multi-angle rotation or continuous rotation can be achieved, and high environmental adaptability is achieved.

Owner:宁波魔象智能科技有限公司

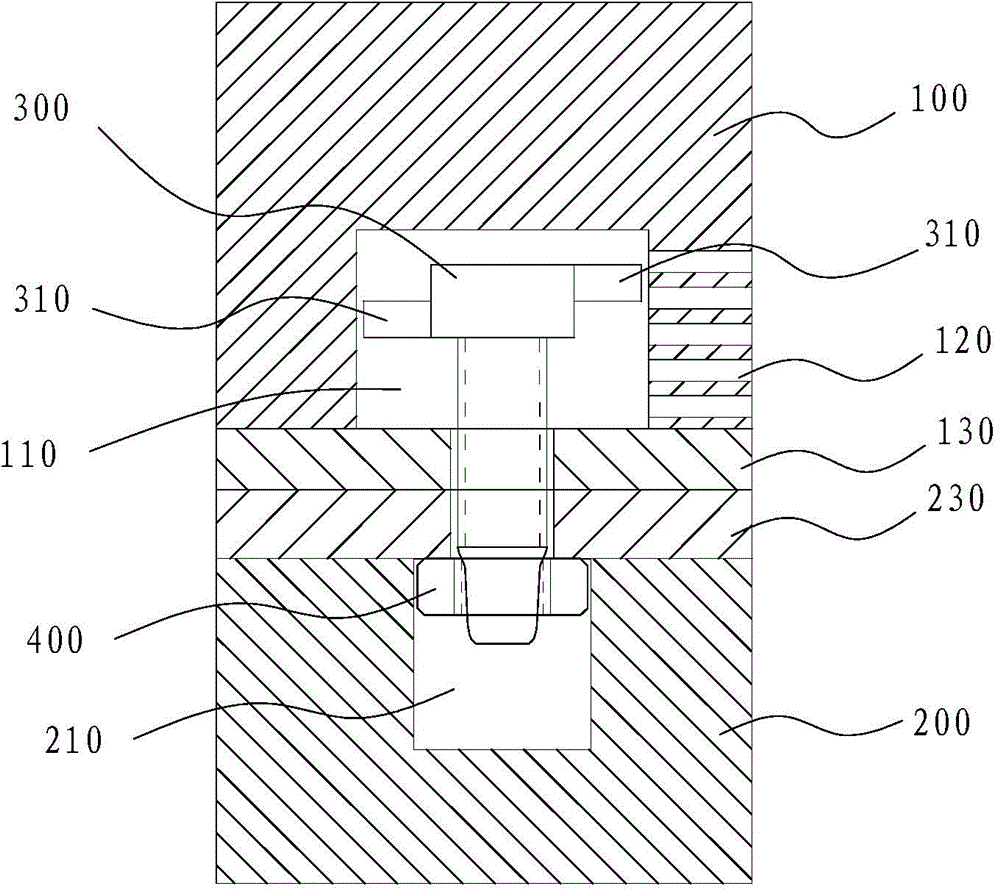

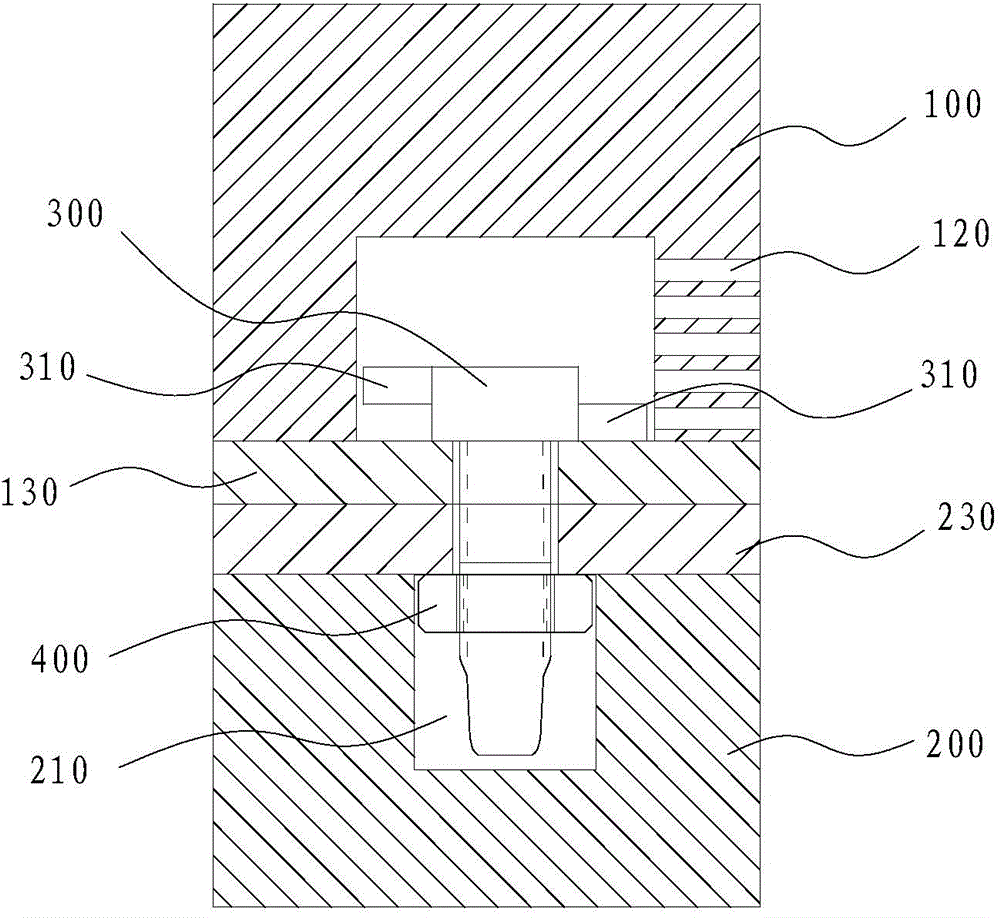

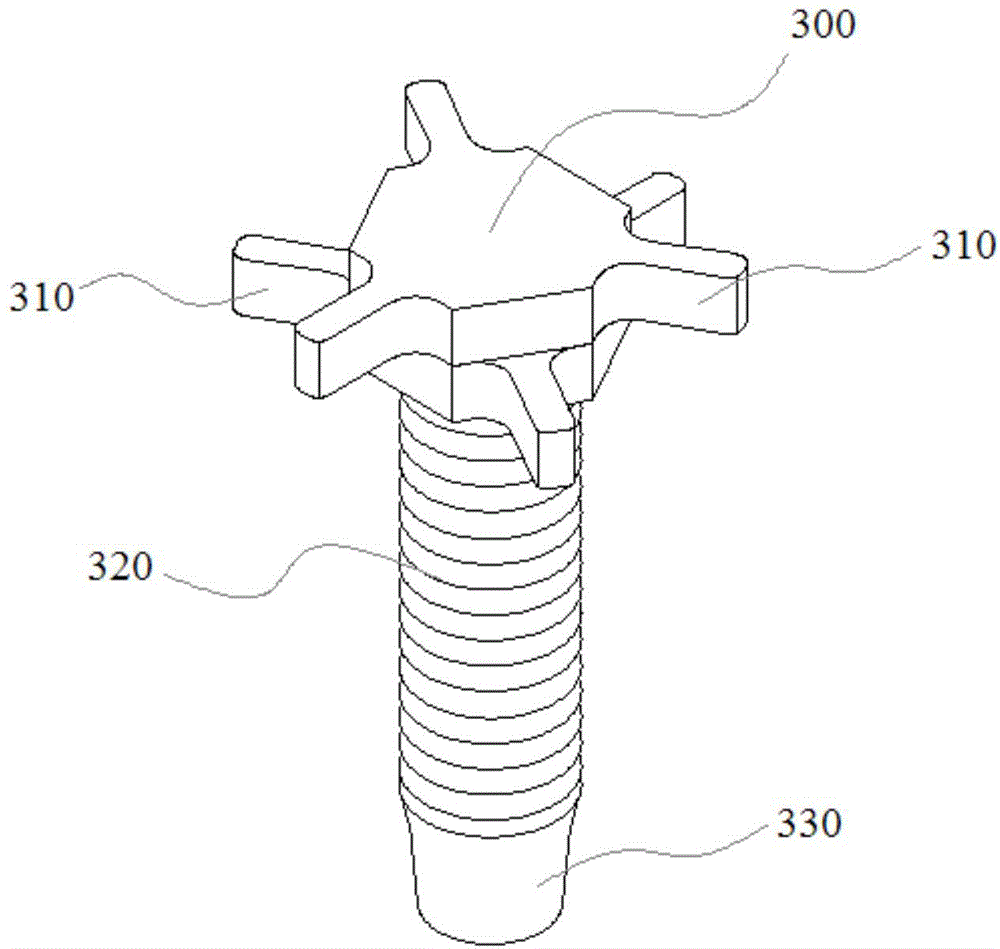

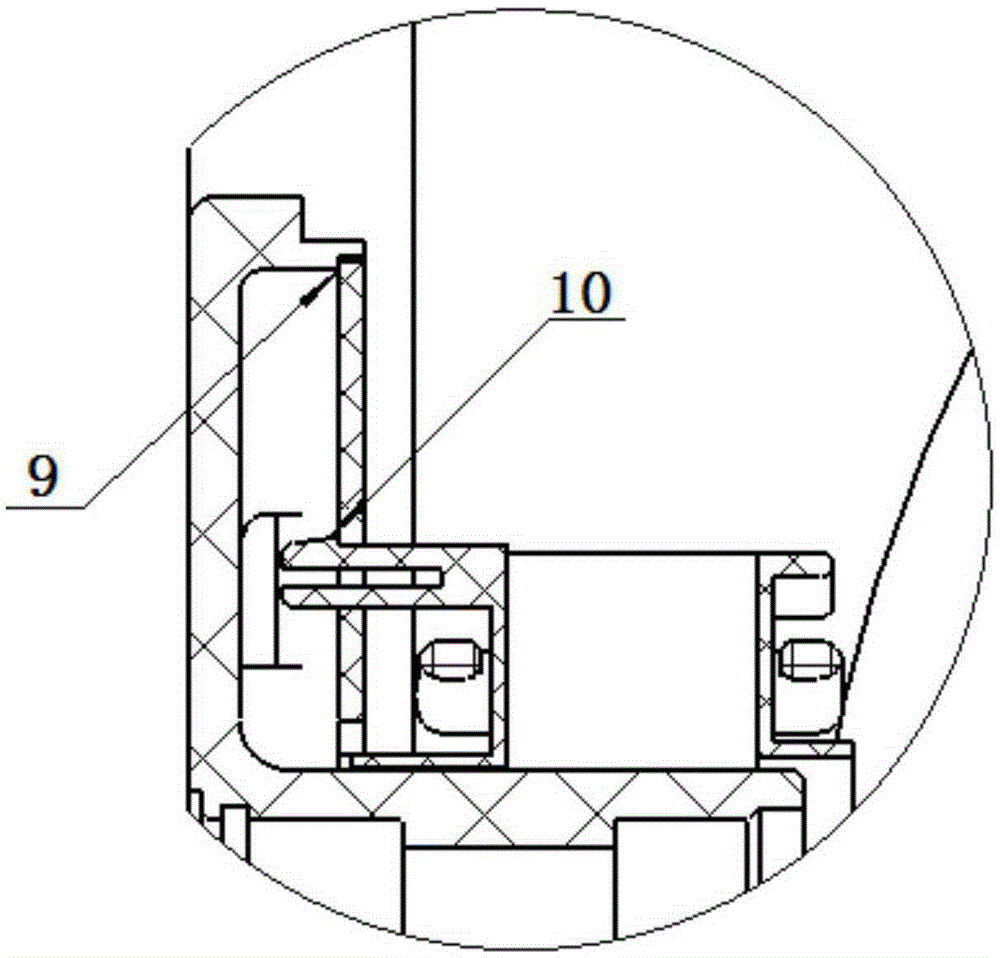

Connecting structure and connecting method

ActiveCN104912204AAchieve continuous rotationReduce in quantityBuilding constructionsHOLDING CHAMBEREngineering

The invention relates to a connecting structure and a connecting method. The connecting structure comprises a first body, a second body and a connecting piece, wherein the first body is internally provided with an embedded chamber, the connecting piece comprises a first threaded part and a turning part, the turning part is arranged at a certain side of the first threaded part, and the first threaded part is arranged in a holding chamber; the turning rod penetrates through a turning hole and is functioned on the turning part to drive the first threaded part to rotate, so that the first threaded part in the first body is in threaded connection with either a nut or a threaded hole in the second body. The connecting structure is simple in connecting operation and high in efficiency.

Owner:广州天行机械接头有限公司

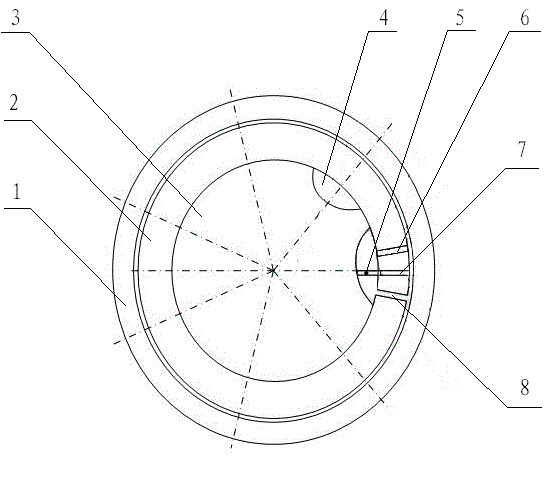

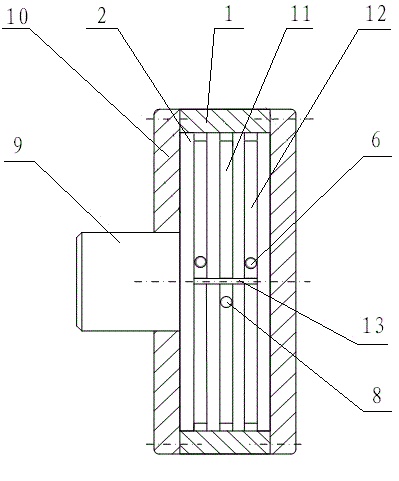

Hydraulic motor

InactiveCN103147908AImplementing a boot spinAchieve continuous rotationRotary piston enginesStatorHigh pressure

The invention discloses a hydraulic motor which comprises a stator and a rotor, wherein a gap is arranged in the outer peripheral surface of the rotor, an oil injection hole and an oil discharge hole are arranged in the inner peripheral surface of the stator, a blade slot is further arranged in the inner peripheral surface of the stator, a blade is in radial sliding fit in the blade slot, one end of the blade is in elastically abutting fit with the outer peripheral surface of the rotor, an oil storage chamber is divided into a high-pressure oil chamber and a return oil chamber by the blade, the high-pressure oil chamber and the return oil chamber are respectively communicated with the oil injection hole and the oil discharge hole which are respectively arranged at two sides of the blade correspondingly and adjacently, the oil discharge hole, the blade and the oil injection hole which are adjacent are arranged in sequence in the set rotating direction, and the peripheral span of the gap is greater than the span between the adjacent oil injection hole and the oil discharge hole. High-pressure oil in the oil storage chamber of the hydraulic oil is subjected to the circulation process from being filled to being entirely discharged out, compared with that in the starting state, the effective compression area of the high-pressure oil newly injected to the oil storage cavity is unchanged, thereby being capable of meeting the low-speed and high-load mechanical transmission requirement.

Owner:HENAN UNIV OF SCI & TECH

Multistage speed change mechanism of wire harness binding device and speed change method and application of multistage speed change mechanism of wire harness binding device

InactiveCN105836238AGuaranteed intermeshingAdjust the tensionPackaging machinesGear wheelElectric machinery

The invention discloses a multistage speed change mechanism of a wire harness binding device and a speed change method and application of the multistage speed change mechanism of the wire harness binding device. Motor torque transmission, the first-stage speed change and the second-stage speed change are achieved through gear synchronous belt transmission. The outward-expansion angle of a tensioning wheel is achieved through an eccentric bearing, and therefore the tensioning degree of a second-stage synchronous belt is regulated. A rotating body with an equivalent gear structure and an enveloping engagement structure between a gear part of the rotating body and a synchronous belt are adopted, and therefore continuous rotation of the rotating body with a notch and the third-stage speed change of a transmission are achieved. A structure for axially pressing and fixing the rotating body through an inner side guide wheel is achieved through a groove structure in the inner side of the rotating body. Due to the adoption of the structure of the rotating body with the notch, wire harnesses and other packaged objects can be allowed to relatively and continuously rotate relative to the rotating body in the notch. The multistage speed change mechanism can be used for various automatic binding tools or devices used for binding adhesive tape, cotton, cloth, plastic and other materials.

Owner:杭州鼎巅科技有限公司

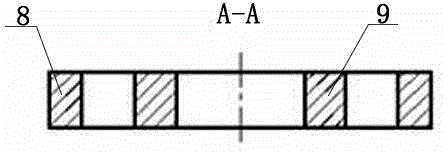

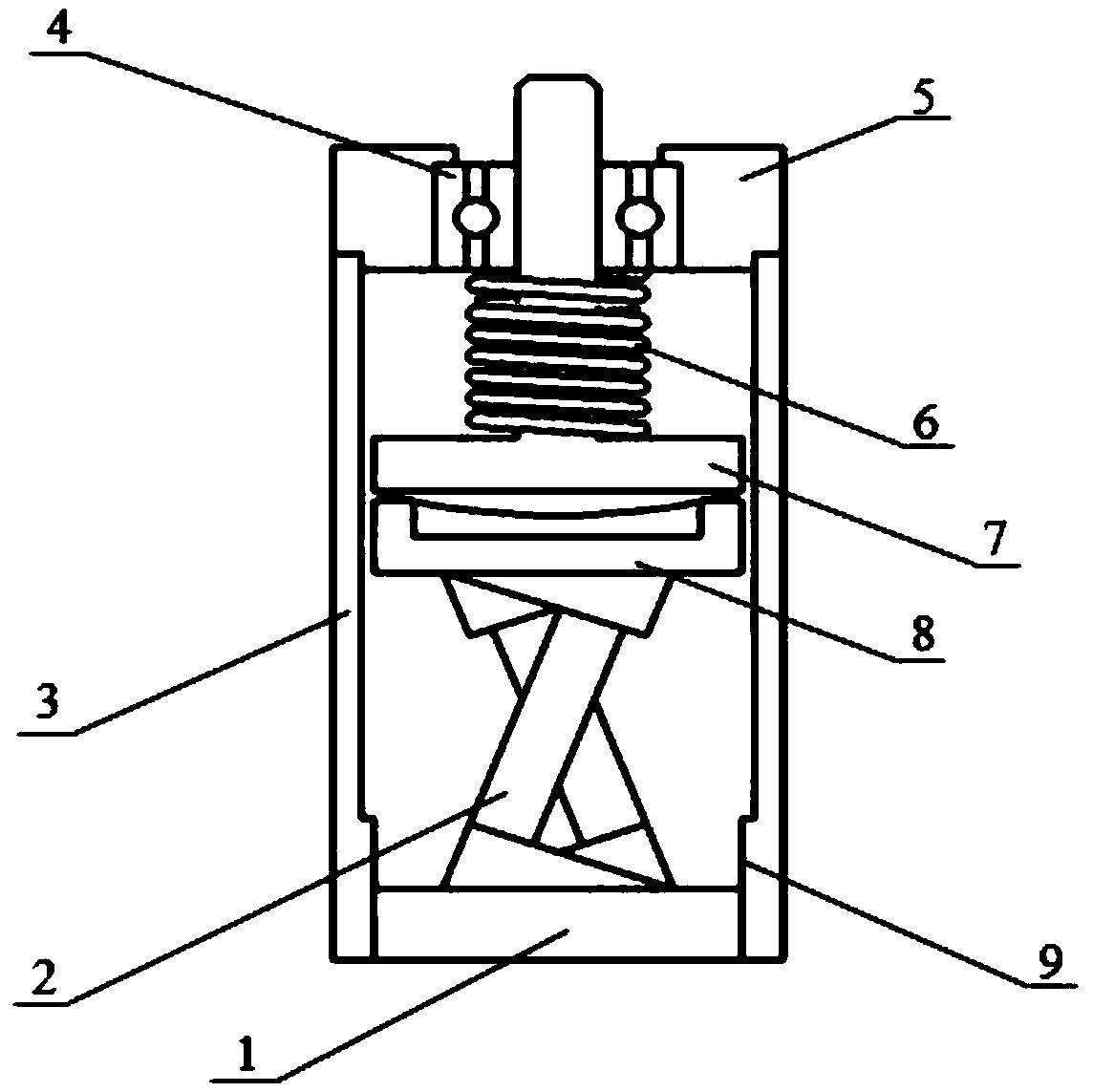

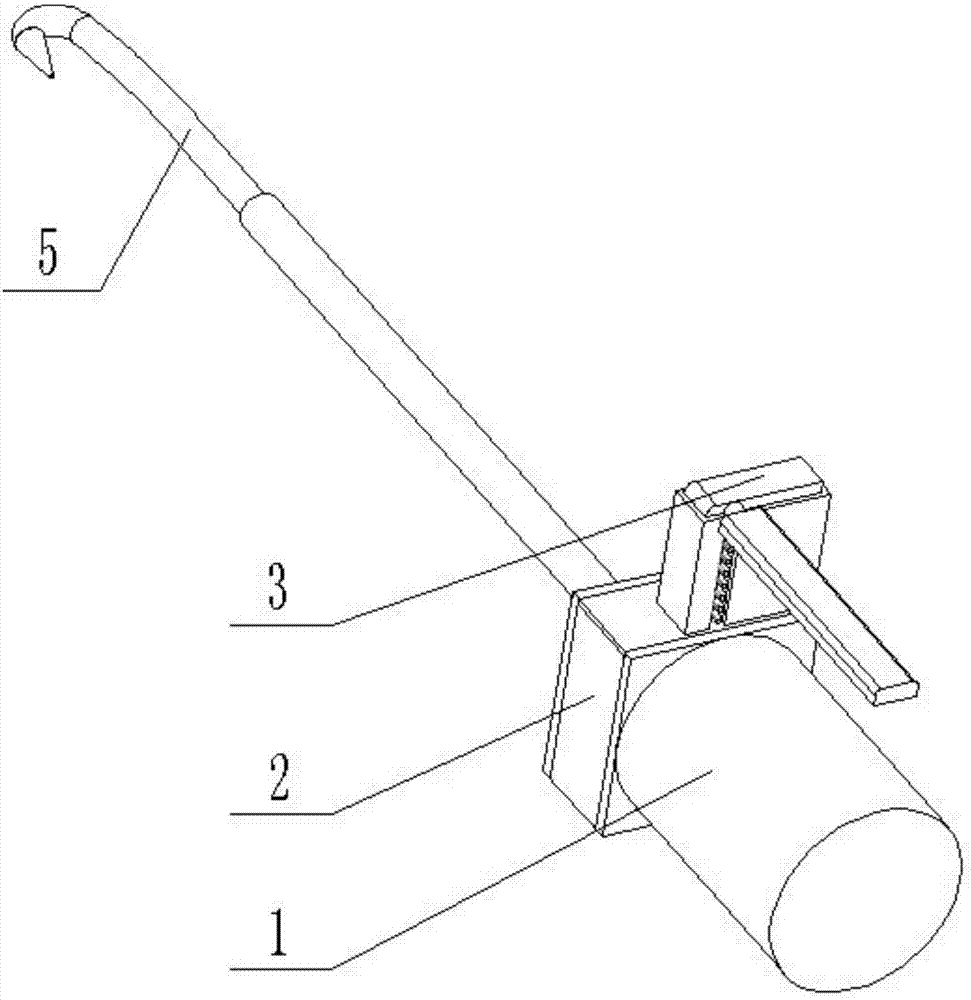

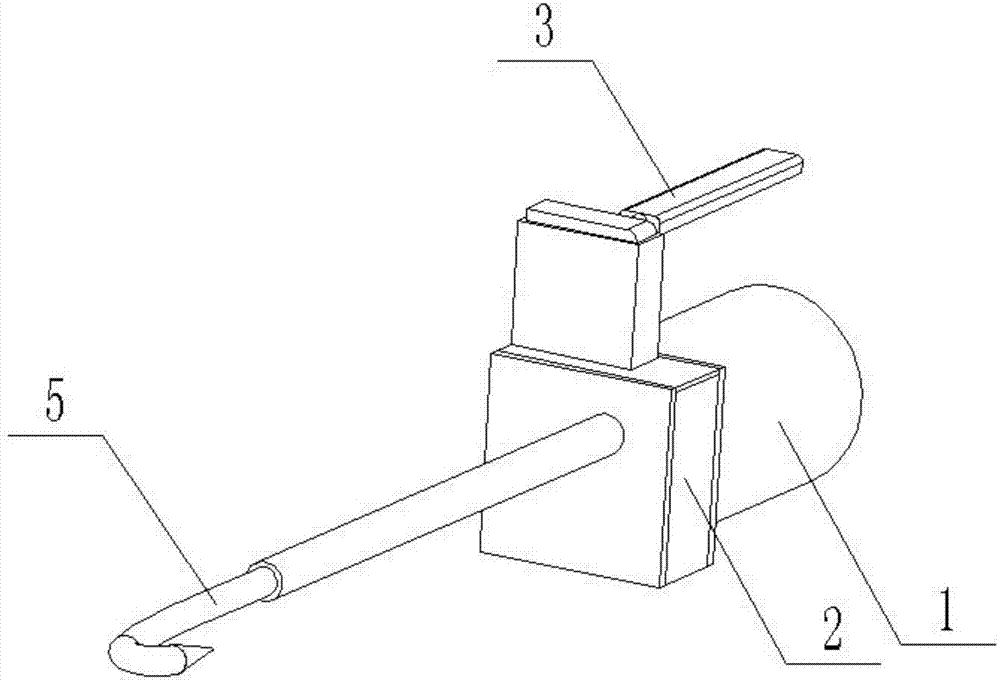

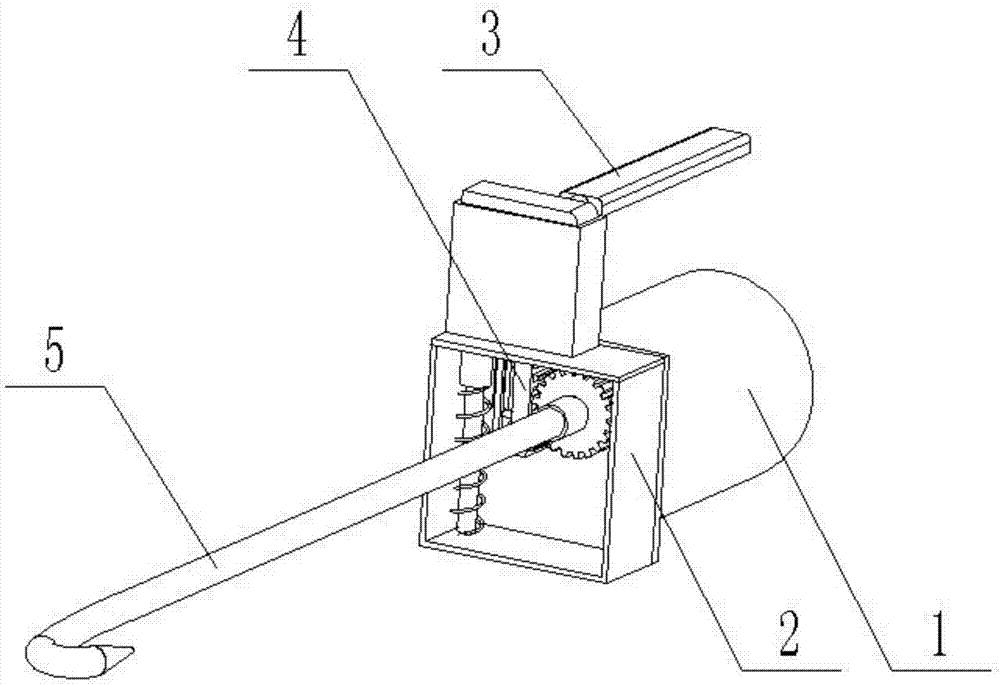

Hand-held self-rotated reinforcing steel bar hook

ActiveCN107130802AAchieve continuous rotationAchieve separationBuilding material handlingHand heldSteel bar

The invention relates to a building tool, and concretely relates to a hand-held self-rotated reinforcing steel bar hook, which solves the problems that a former reinforcing steel bar hook needs to be used by shaking a wrist, and is big in operation difficulty and low in work efficiency, and realizes hand-held rotation. The hand-held self-rotated reinforcing steel bar hook provided by the invention is simple to operate and high in work efficiency, and comprises a handle, a device box, a pushing and pressing device, a rack device and a rotary device. The hand-held self-rotated reinforcing steel bar hook is characterized in that the device box is arranged at the front end of the handle; the pushing and pressing device is arranged at the upper end of the device box; the rack device and the rotary device are arranged in the device box. The rack device comprises a rack, an upper positioning block and a lower positioning block; the upper positioning block is connected to the upper end of the right end face of the rack in a welding way; the lower positioning block is connected to the lower end of the right end face of the rack in a welding way; a first oblique sliding chute is arranged at the side end face of the upper positioning block, penetrates through the front end face and the rear end face of the upper positioning block, and is arranged along a direction from the left upper corner to the right upper corner of the upper positioning block.

Owner:池仁淼

Power module and full-automatic laser pipe cutting machine

ActiveCN112207457ARealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusLaser cuttingErbium lasers

The invention discloses a power module and a full-automatic laser pipe cutting machine. The full-automatic laser pipe cutting machine comprises a feeding module, the power module and a cutting module,wherein the feeding module is used for loading pipes to be cut into pipe grooves of a feeding wheel one by one, and then the feeding wheel rotates to enable the pipes to be cut to be sequentially subjected to the procedures of feeding, centering, clamping, section cutting and discharging; the power module is used for driving the pipes at the section cutting procedure to rotate so as to ensure that the whole circles of the pipes are cut off, and intermittently driving the feeding wheel to rotate so as to complete procedure switching; and the cutting module is used for cutting the pipes throughlaser emitted by a laser device, the pipes are relatively fixed in the axial direction, and laser cutting heads move in the axial direction of the pipes and positioning is carried out, so that accurate cutting of the pipes is completed. Automatic feeding can be achieved, and the five procedures of feeding, clamping, axial alignment, section cutting and discharging can be synchronously achieved, so that the production efficiency is improved by at least two times or above. In addition, the mode that the laser device moves while the pipes are fixed is adopted, and the full-automatic laser pipe cutting machine can adapt to pipes with more lengths.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

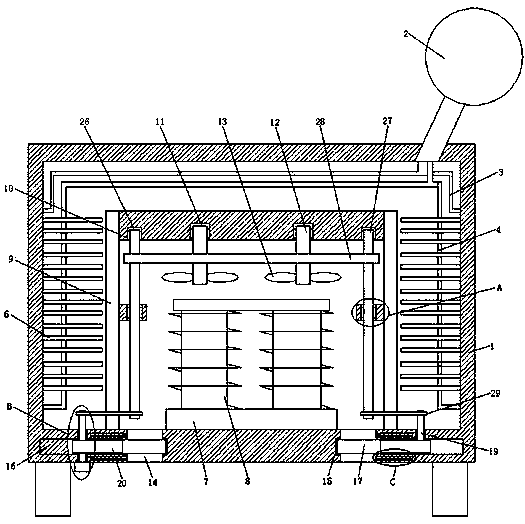

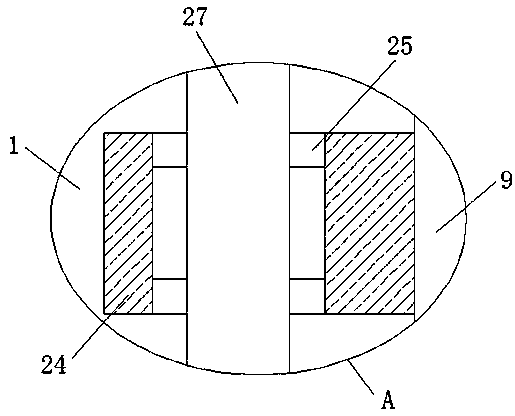

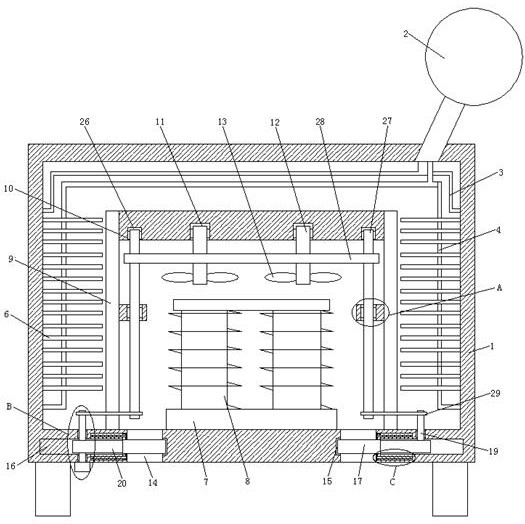

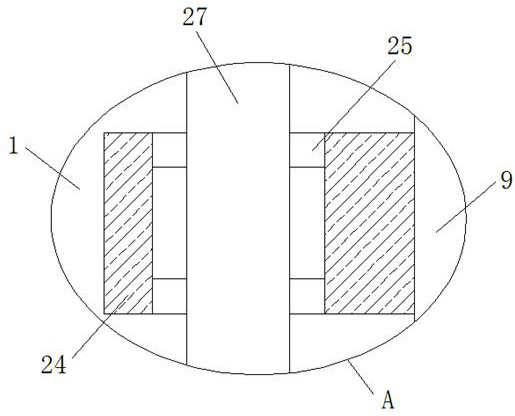

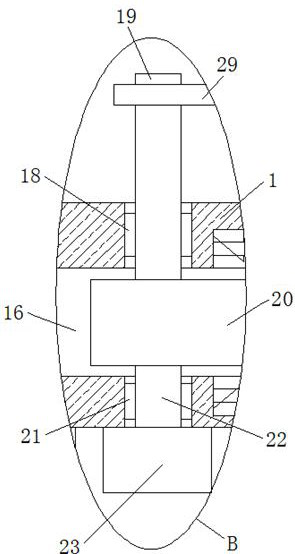

Oil-immersed three-phase transformer

ActiveCN110797168AEffective distributionGuaranteed to workTransformers/inductances coolingTransformers/inductances casingsTransformerEngineering

The invention belongs to the field of transformers, and particularly relates to an oil-immersed three-phase transformer. In the prior art, cooling fins are used for heat dissipation, but the cooling fins are generally arranged inside; or heat is dissipated through vent holes, but the heat dissipation efficiency is not high, and the open vent holes enable dust to easily enter a transformer to damage the transformer. In order to solve the problems, a scheme as follows is put forward: the oil-immersed three-phase transformer comprises a transformer shell of a hollow structure, an oil tank is fixedly installed at the top of the transformer shell, and an oil inlet pipe and an oil outlet pipe are fixedly installed in the transformer shell. The transformer is simple in structure and convenient tooperate. Heat generated in the working process of the transformer body can be dissipated, heat can be dissipated even when the external temperature is high, and normal work of the transformer body isguaranteed. Meanwhile, after heat dissipation is completed, heat dissipation openings can be sealed, so that dust is prevented from entering the transformer, and the requirements of people are met.

Owner:YANTAI MUPING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

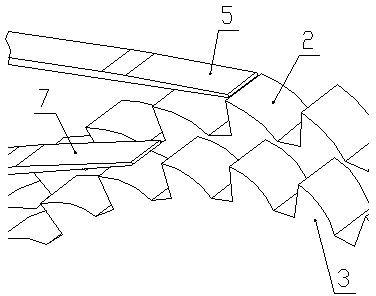

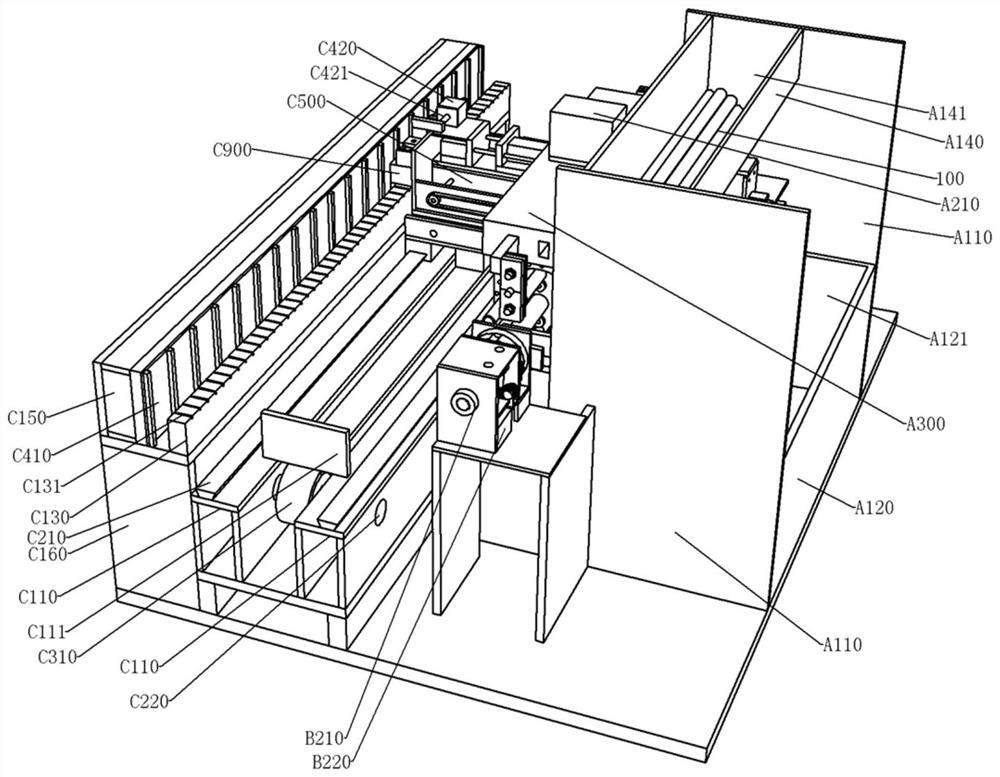

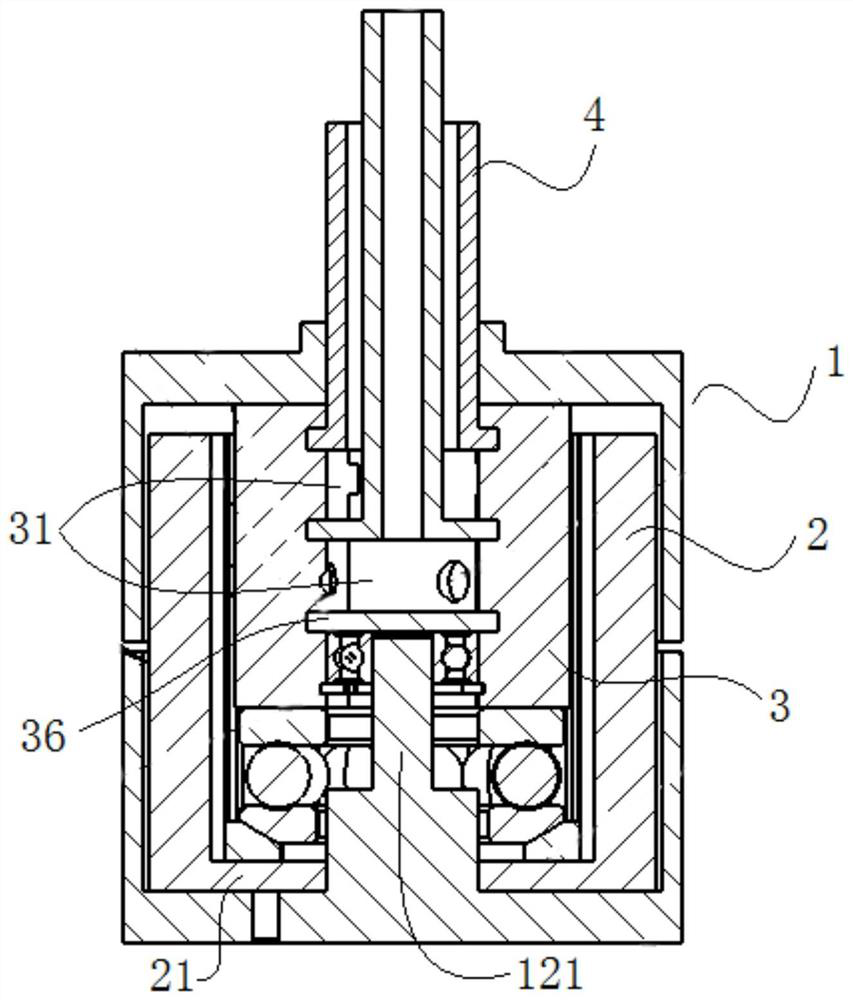

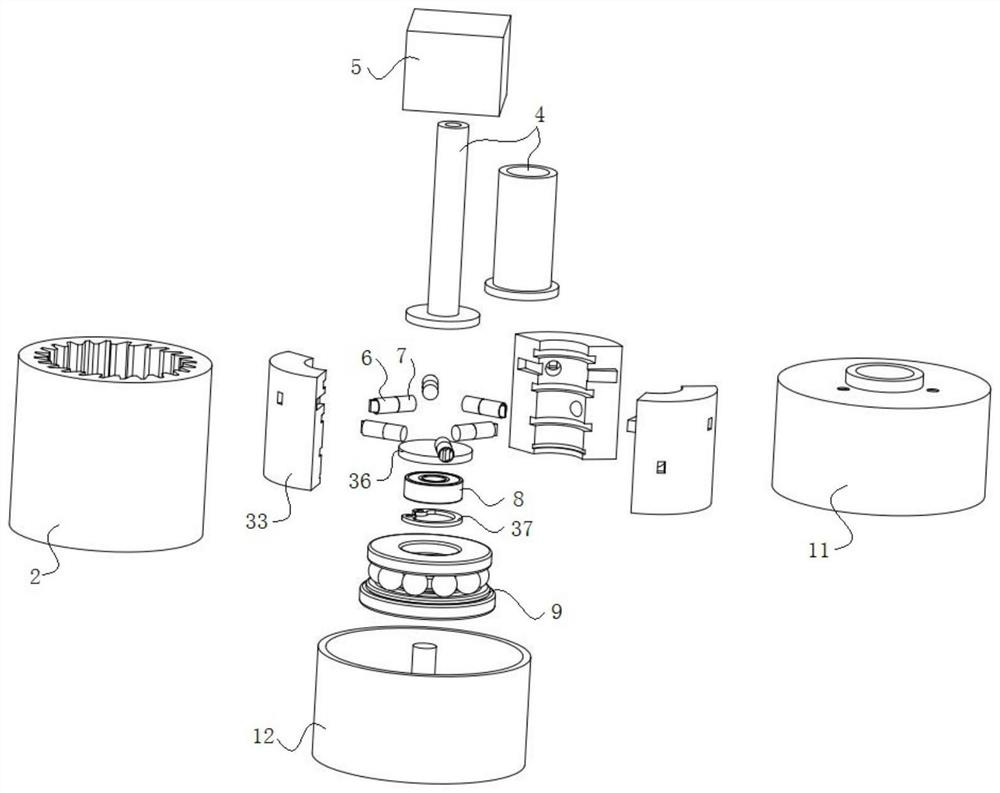

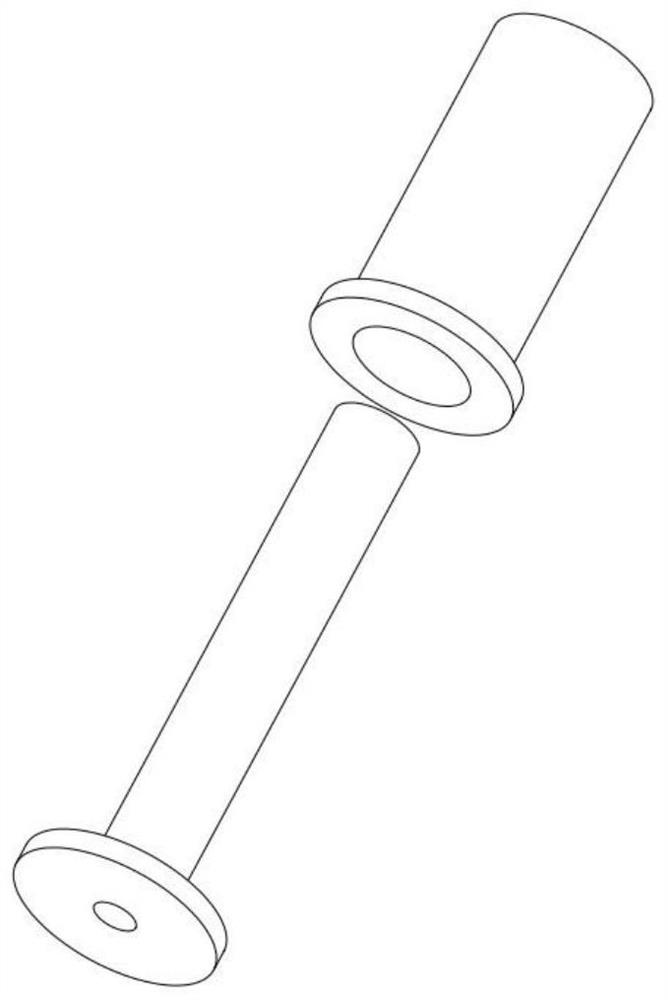

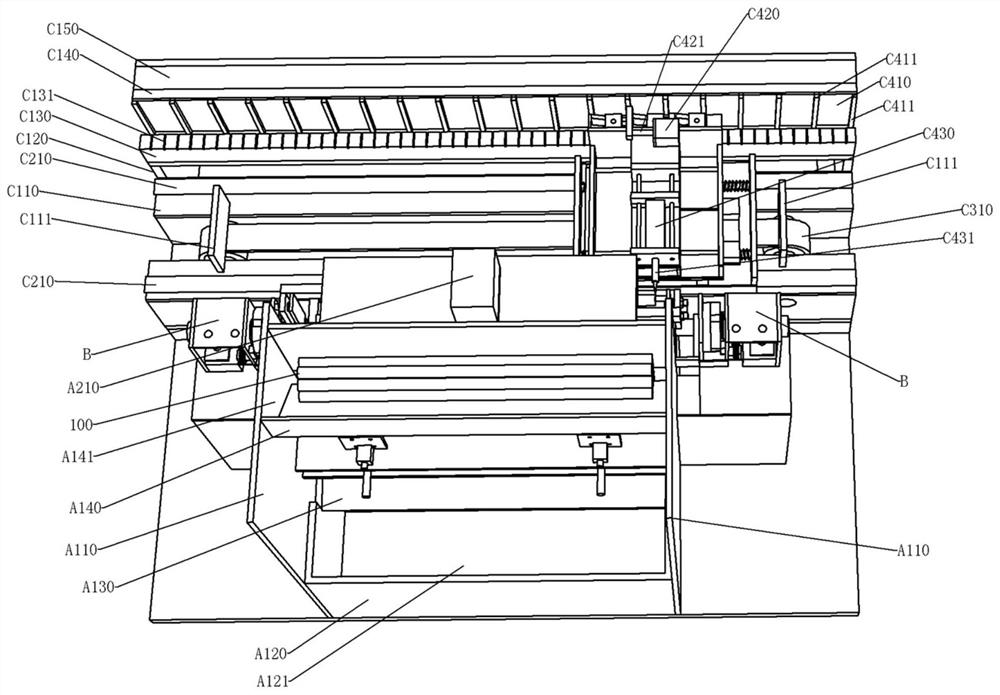

Rotor machining machine tool for single screw compressor

ActiveCN109604734AFast processingImprove machining accuracyFeeding apparatusGear teethEngineeringFast speed

The invention discloses a rotor machining machine tool for a single screw compressor. The machine tool comprises a machine tool body provided with a stand column and horizontal guide rails. Vertical guide rails are arranged on the stand column. A tool rest table is mounted on the horizontal guide rails. A screw workpiece clamping mechanism is mounted on the vertical guide rails. A tool is mountedon the tool rest table and can be driven to make front-back movement, left-right movement and rotary movement in the horizontal direction. A to-be-machined screw workpiece is mounted on the screw workpiece clamping mechanism, the axis of the screw workpiece is arranged horizontally and the screw workpiece is clamped tightly through the screw workpiece clamping mechanism, and the screw workpiece clamping mechanism can drive the screw workpiece to move up and down in the vertical direction and also can drive the screw workpiece to rotate continuously around the axis. A turning tool or a millingtool is adopted as the tool. By means of the machine tool provided by the invention, envelope strength line, envelope cylinder and other complex molded line single screw compressor screw toothed grooves can be machined, operation is easy, and the precision and the speed are high.

Owner:XI AN JIAOTONG UNIV

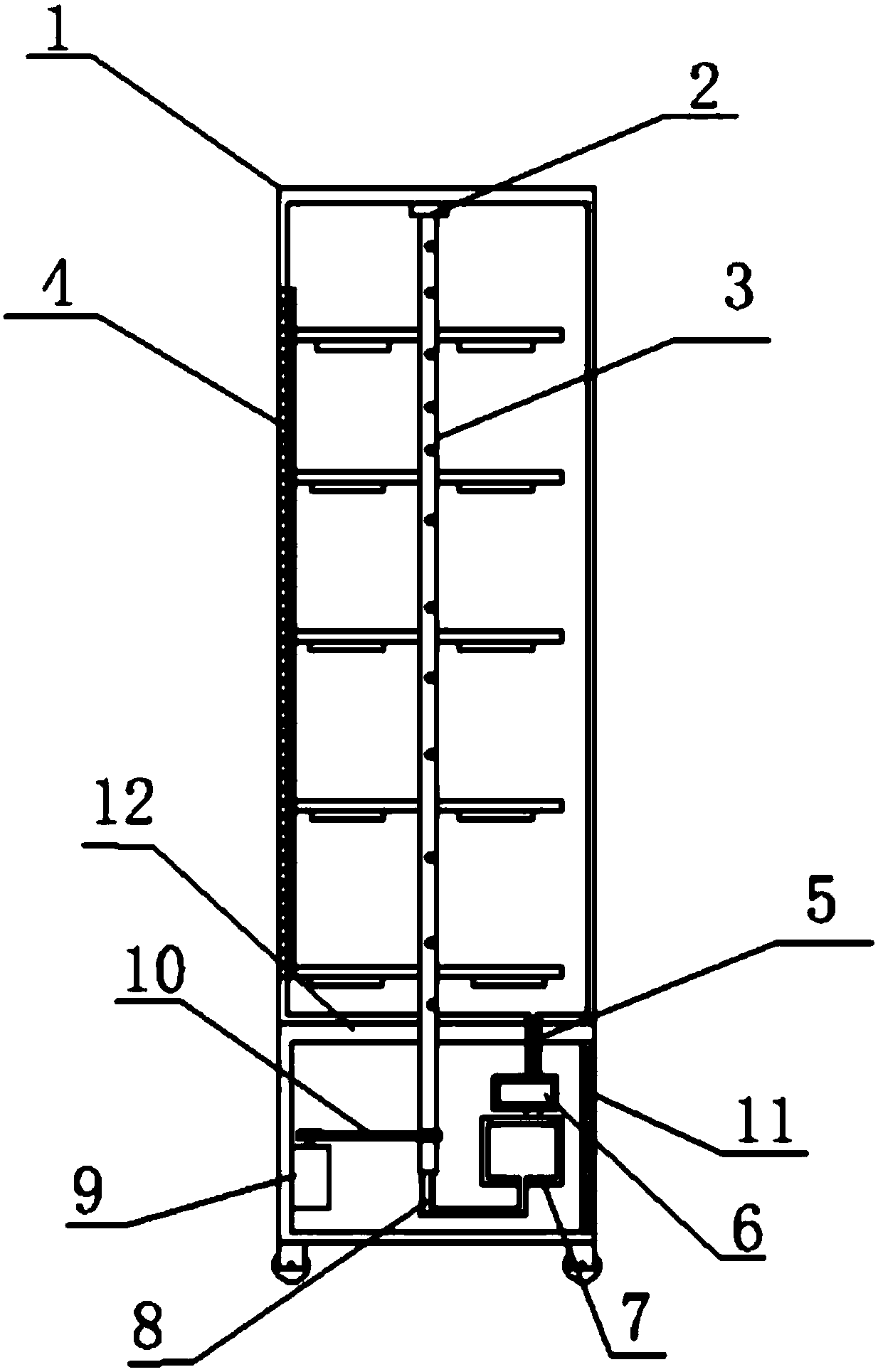

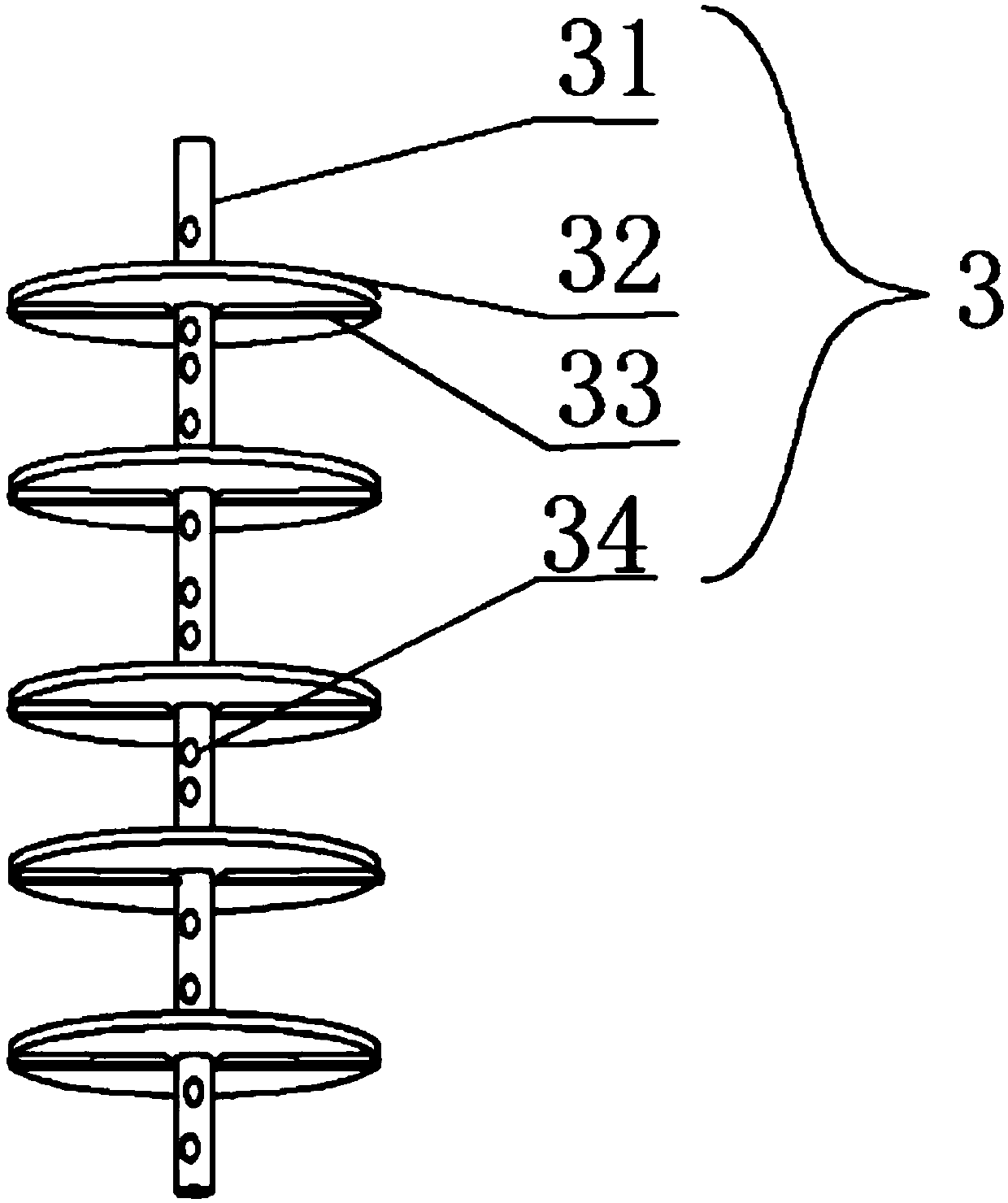

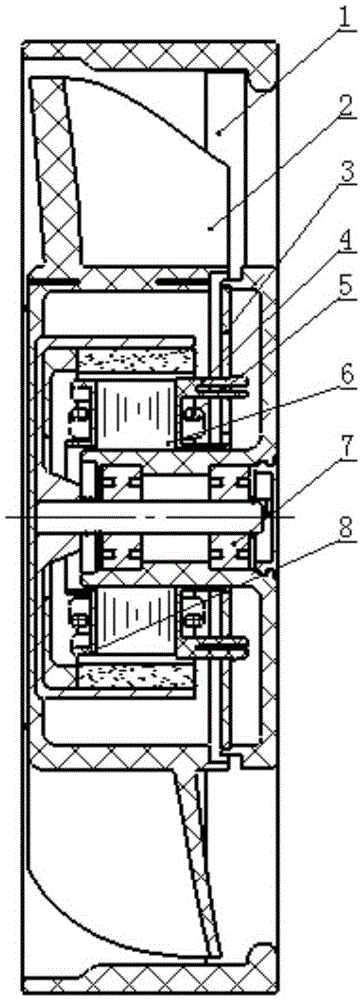

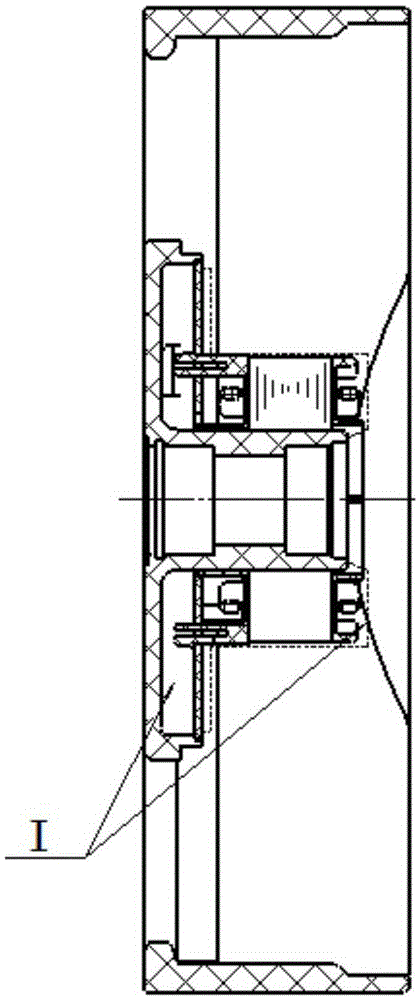

Refrigeration displaying cabinet with rotatable displaying effect

The invention discloses a rotatable refrigerated and frozen display cabinet in the technical field of freezer cabinets. A cabinet door is installed on the left side, an air intake pipe is arranged on the right side of the top of the box body, and the air intake pipe runs through the top of the box body and the bottom of the cabinet body, the bottom of the air intake pipe is connected with a fan, and the bottom of the fan is connected with a refrigeration device, so The bottom of the refrigeration device is connected with a delivery pipe, the other end of the delivery pipe is plugged into the bottom of the rotating device, a motor is installed on the left wall of the box, a transmission belt is installed at the bottom of the motor, and the other end of the transmission belt is installed on the surface of the rotating device , the right side of the box is equipped with a cooling plate, and the present invention can realize the continuous rotation of the display tray in the circumferential direction, making it convenient for consumers to select refrigerated and frozen products, and greatly increasing the display efficiency of the display cabinet.

Owner:江苏康宝电器有限公司

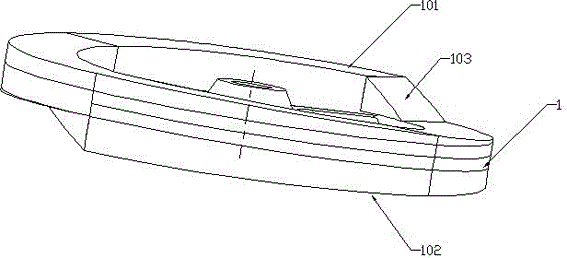

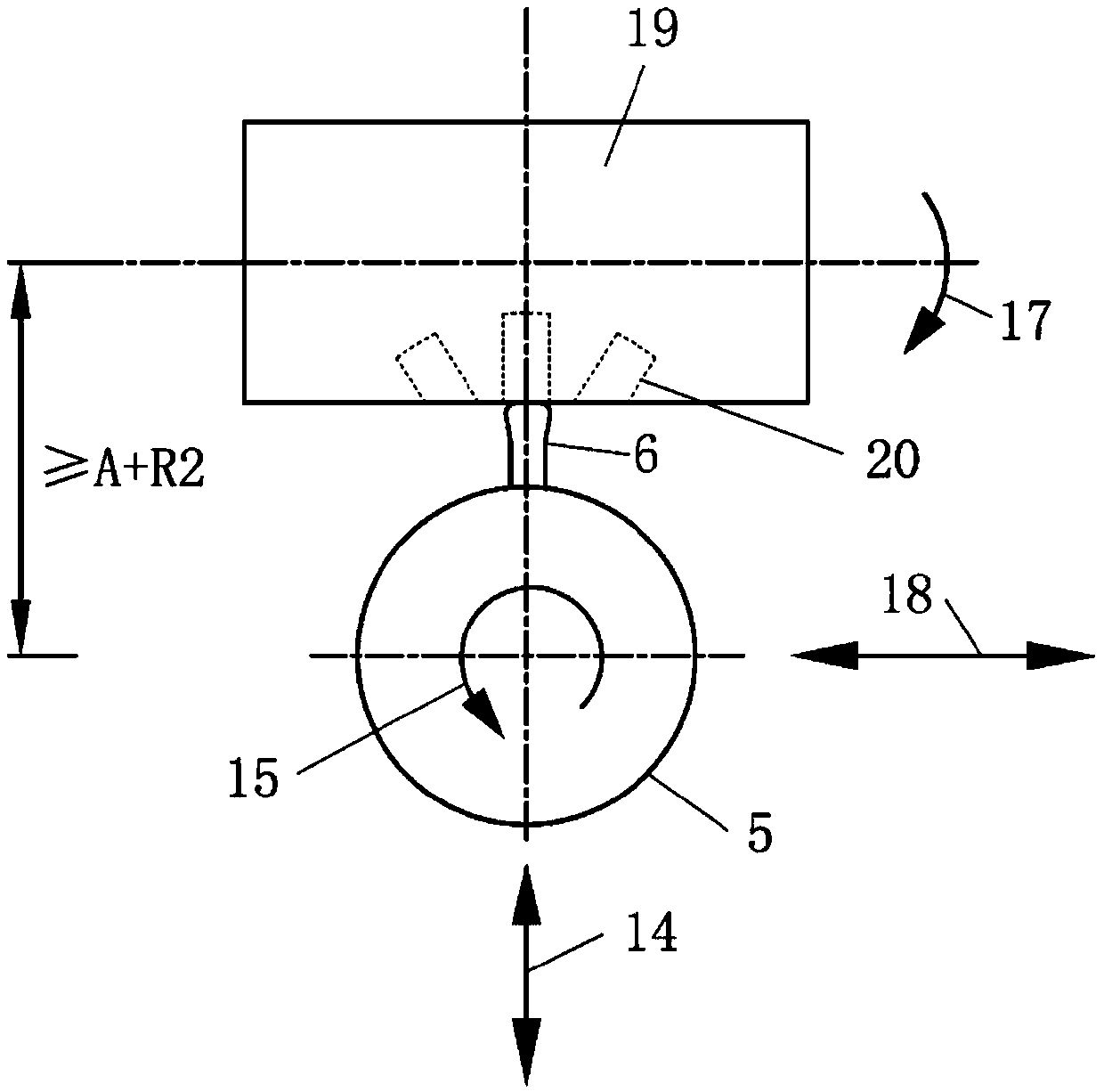

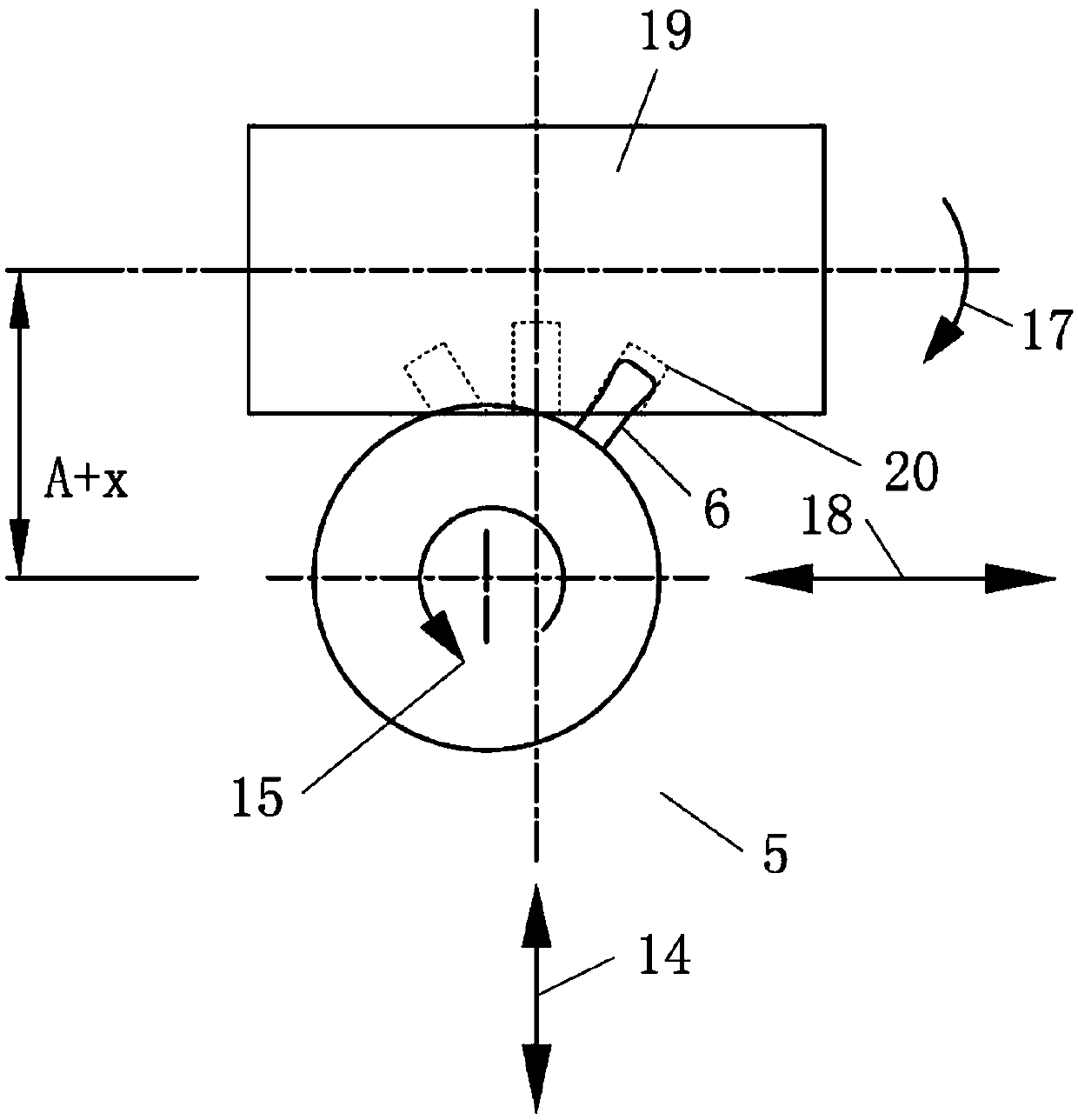

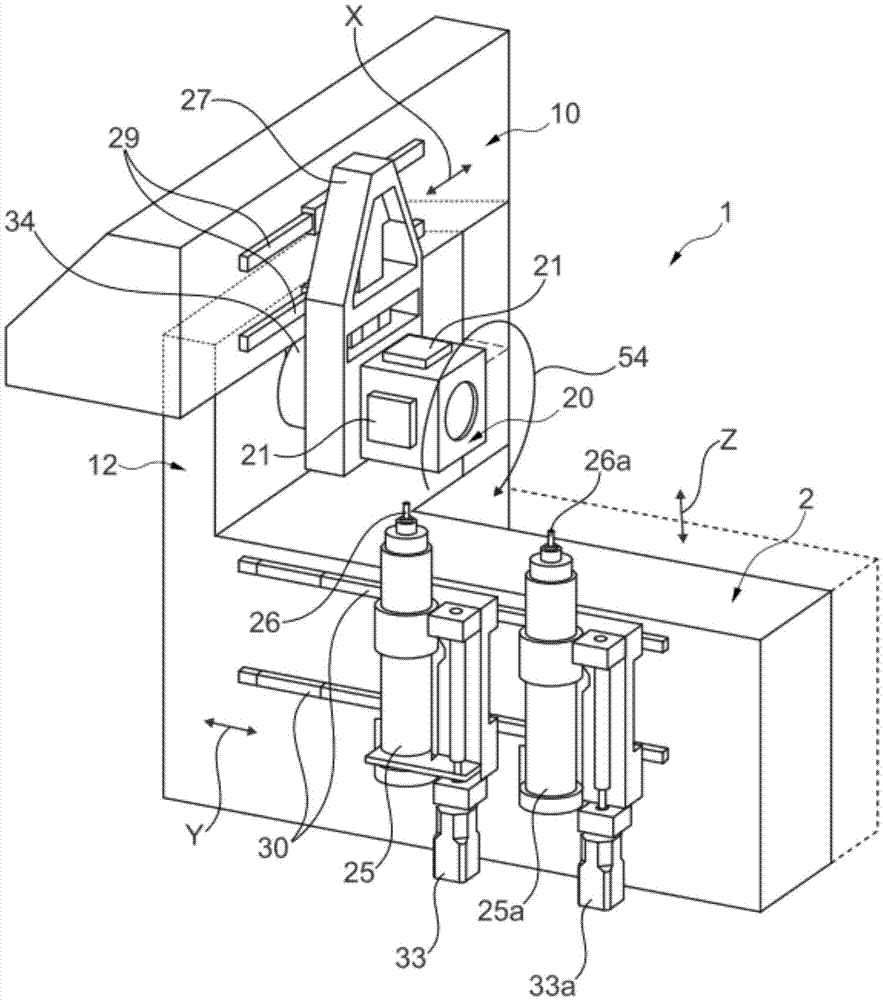

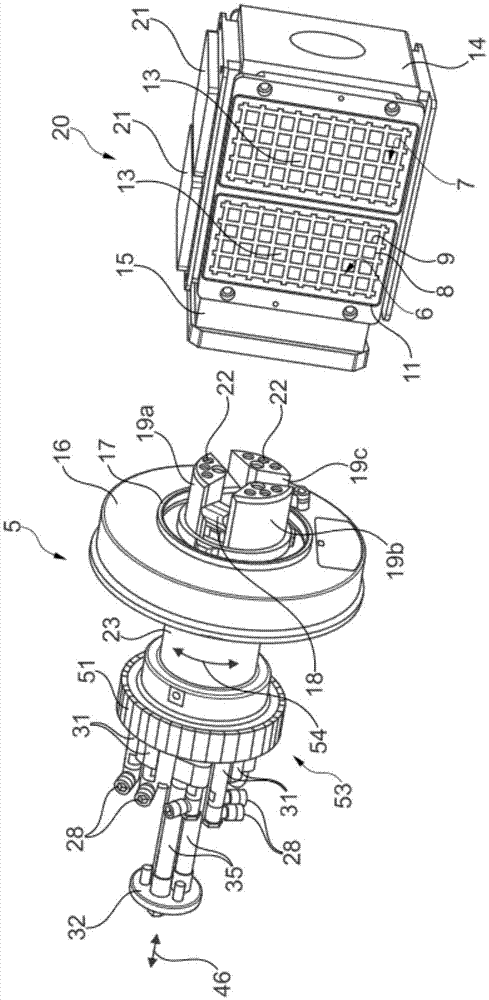

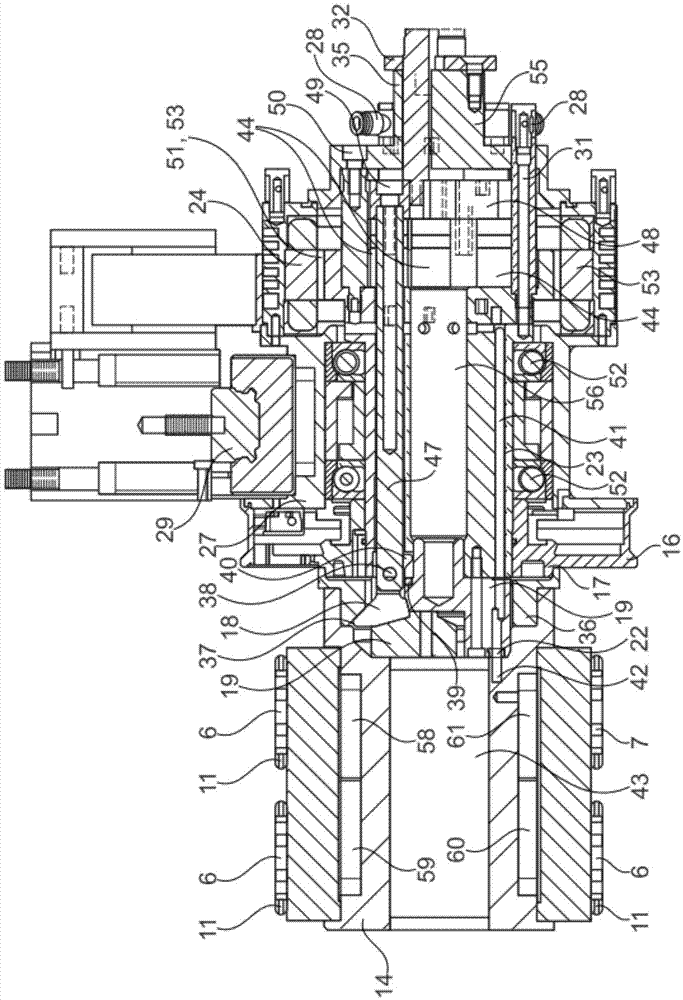

Workpiece clamping device with oscillating drive and vacuum supporting functions and relevant vacuum clamp

InactiveCN107081440AFast processingSimple and precise machiningChucksPositioning apparatusEngineeringMechanical engineering

The invention provides a workpiece clamping device (20) with an oscillating drive function, and the workpiece clamping device (20) is used for machining a workpiece (21) in a workpiece machining device (1). The workpiece clamping device (20) is provided with a plurality of vacuum clamping plates (6 and 7) distributed on different planes on the circumference, and the vacuum clamping plates (6 and 7) are connected with a vacuum clamp (5) in an airtight mode.

Owner:英格博格马夸特

Anti-salt-fog DC fan with potting structures at two sides

InactiveCN105262308AAchieve continuous rotationLarge air volumeAssociation with control/drive circuitsPump installationsPunchingEngineering

The present invention discloses an anti-salt-fog DC fan with potting structures at two sides. The DC fan is formed by a shell, a rotor assembly, a circuit board, a lower end piece, a winding, a stator punching sheet group, a bearing and an upper end piece. The stator punching sheet group is pressed in the shell. The lower end piece, the upper end piece, the winding and the circuit board are fixed in the shell through the stator punching sheet group. Both the lower end piece and the upper end piece are respectively fixed to the upper end and lower end of the stator punching sheet group through the winding of the winding. The circuit board is fixed through a jaw on the lower end piece and the groove of the shell. The anti-salt-fog DC fan with potting structures at two sides belongs to a single-phase permanent magnet brushless DC fan, the structure is simple, with the use of electronic circuit commutation, the anti-salt-fog ability of the fan is improved, the stator assembly of the fan is subjected to double-sided potting, and thus the circuit board assembly and the winding are completely isolated from the air.

Owner:沈阳兴华航空电器有限责任公司

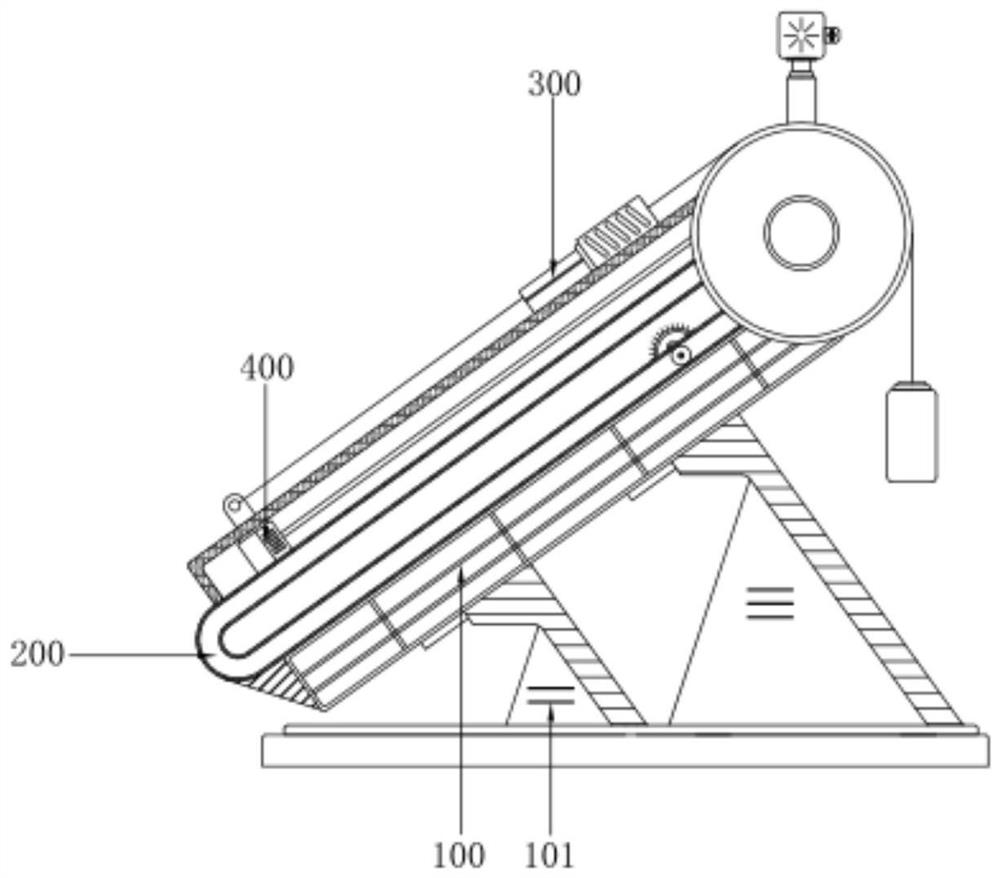

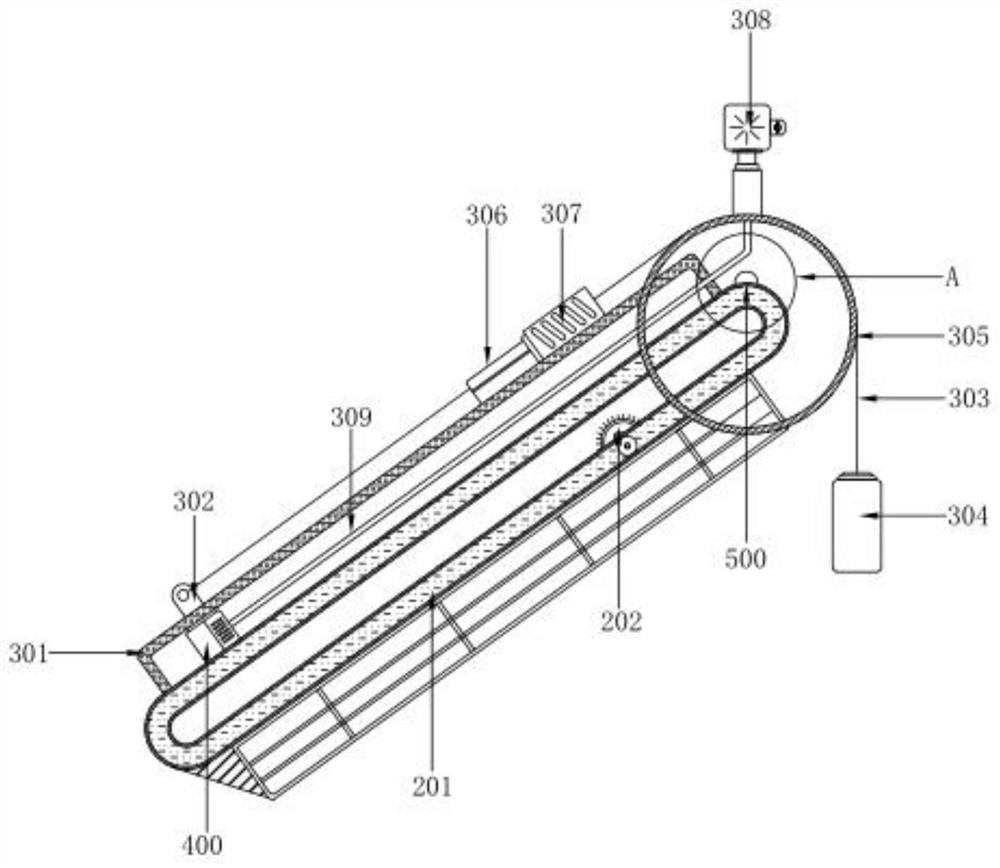

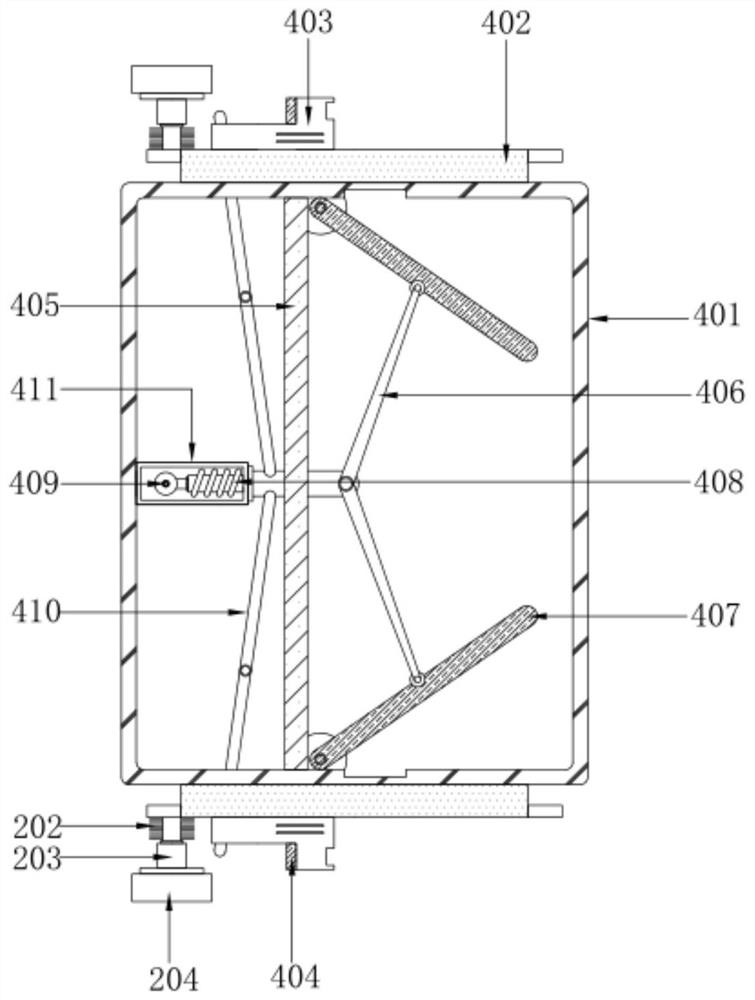

Cleanable photovoltaic power generation device capable of continuously circulating in windy and dusty area

ActiveCN112653386AAchieve continuous rotationHigh power generation efficiencyPhotovoltaicsPhotovoltaic energy generationEngineeringStructural engineering

The invention discloses a cleanable photovoltaic power generation device capable of continuously circulating in a windy and dusty area in the technical field of photovoltaics. The device comprises a photovoltaic panel which is fixed on amounting bracket, a cleaning assembly comprising a sliding rail fixed on the mounting bracket, a traction assembly comprising a concave bracket fixed on the sliding rail, and a moving assembly fixedly mounted on the movable block. In windy weather, the cleaning brush roller rolls from top to bottom along the surface of the photovoltaic panel to sweep away dust on the surface of the photovoltaic panel, and when the cleaning brush roller rolls to the bottommost end, the cleaning brush roller moves towards the upper-layer slideway of the sliding rail under the action of inertia and enables the supporting shaft to impact the positioning disc, the air flow introduced by the induced draft hose is thus discharged from both sides of the rectangular box body, the wind resistance of the rectangular box body is reduced to drive the rectangular box body to reset, so that continuous circulating rotation of the cleaning brush roller is realized by utilizing the wind resistance, the photovoltaic panel can still keep high power generation efficiency in a strong wind environment, and the risk of damage is reduced.

Owner:黄山富乐新能源科技有限公司

Pneumatic power device

InactiveCN114791003AAchieve continuous rotationRely on avoidFluid-pressure actuatorsFluid gearingsEngineeringPressure difference

The invention relates to an air pressure power device which comprises an air storage tank, a driving system and a pressure return system, the driving system comprises at least three driving air cylinders evenly distributed in the circumferential direction of the air storage tank, inner cavities of cylinder bodies of the driving air cylinders are communicated with an inner cavity of the air storage tank, and rotatable top wheels are arranged at the ends, away from the cylinder bodies, of piston rods of the driving air cylinders; a rack is arranged on a piston rod of the driving cylinder; the back pressure system comprises a gear ring, a half-moon ring and a one-way transmission structure, the gear ring and the centers of the driving air cylinders are arranged concentrically in a rotatable mode, the half-moon ring is arranged on the periphery of the gear ring and fixedly connected with the gear ring, a gap between the half-moon ring and the gear ring is gradually increased from the first end to the second end of the half-moon ring, and the rack is in transmission connection with the gear ring through the one-way transmission structure; therefore, the air pressure power device does not depend on existing fuel, but is driven through pressure difference, dependence on heat energy resources can be effectively avoided, emission is reduced, and energy conservation and environmental protection are achieved.

Owner:冯袖幅

Cutting module and full-automatic laser pipe cutting machine

ActiveCN112207456ARealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a cutting module and a full-automatic laser pipe cutting machine. The full-automatic laser pipe cutting machine comprises a feeding module, a power module and the cutting module, wherein the feeding module is used for loading pipes to be cut into pipe grooves of a feeding wheel one by one, and then the feeding wheel rotates to enable the pipes to be cut to be sequentially subjected to the procedures of feeding, centering, clamping, section cutting and discharging; the power module is used for driving the pipes at the section cutting procedure to rotate so as to ensure that the whole circles of the pipes are cut off, and intermittently driving the feeding wheel to rotate so as to complete procedure switching; and the cutting module is used for cutting the pipes through laser emitted by a laser device, the pipes are relatively fixed in the axial direction, and laser cutting heads move in the axial direction of the pipes and positioning is carried out, so that accurate cutting of the pipes is completed. Automatic feeding can be achieved, and the five procedures of feeding, clamping, axial alignment, section cutting and discharging can be synchronously achieved,so that the production efficiency is improved by at least two times or above. In addition, the mode that the laser device moves while the pipes are fixed is adopted, and the full-automatic laser pipecutting machine can adapt to pipes with more lengths.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

Cylindrical rotary opening fire-fighting fireproof valve

ActiveCN111911644AAvoid damageExtended service lifeOperating means/releasing devices for valvesSlide valveFlue gasElectric machine

The invention belongs to the technical field of fire-fighting fireproof equipment, and particularly relates to a cylindrical rotary opening fire-fighting fireproof valve. The valve comprises a valve body, a first supporting rod, a second supporting rod, a first rotary baffle, a second rotary baffle, a third rotary baffle, a sealing limiting plate, a rotary shaft, a motor and a transmission component. The motor drives the rotary shaft to rotate, then the second rotary baffle and the third rotary baffle are driven to rotate, in the process, the rotary shaft drives a first limiting pin to rotate,the first limiting pin drives a second limiting pin to rotate through springs, and the second limiting pin drives the second rotary baffle to rotate. When one side of the third rotary baffle is inserted into a first groove in the sealing limiting plate, the fireproof valve is closed, high-temperature flue gas is prevented from entering a pipeline, the high-temperature flue gas is prevented from entering other rooms through the pipeline, fire disasters in the other rooms are avoided, a fire disaster area is isolated, and fire spreading is avoided; and the losses caused by fire disasters to personal and property safety are further reduced.

Owner:山东兴恒环境科技集团有限公司

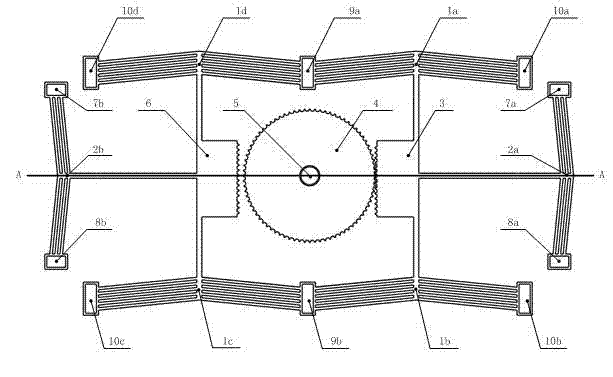

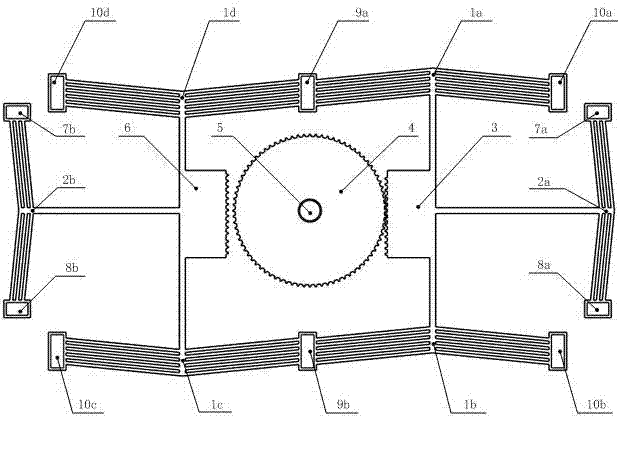

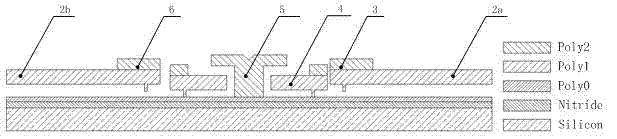

Electrothermal drive-based stepping micro-rotation device

InactiveCN102769371ASimple structureEasy to controlDynamo-electric machinesElectric heatingMicro motor

The invention relates to an electrothermal drive-based stepping micro-rotation device, which is used for converting reciprocating linear motion of an electrothermal actuator into rotary gear motion. The device consists of a driving actuator, a meshing control actuator, a rack and a gear. The whole device is made of a polycrystalline silicon material, is manufactured by a micro-electromechanical system (MEMS) surface silicon process and is not required to be assembled. The device converts the reciprocating linear motion of the actuator into rotary gear motion, is simple in structure and high in output efficiency and can be applied to MEMS devices such as micro grippers, micro operating tables and micro motors with the rack.

Owner:SHANGHAI UNIV

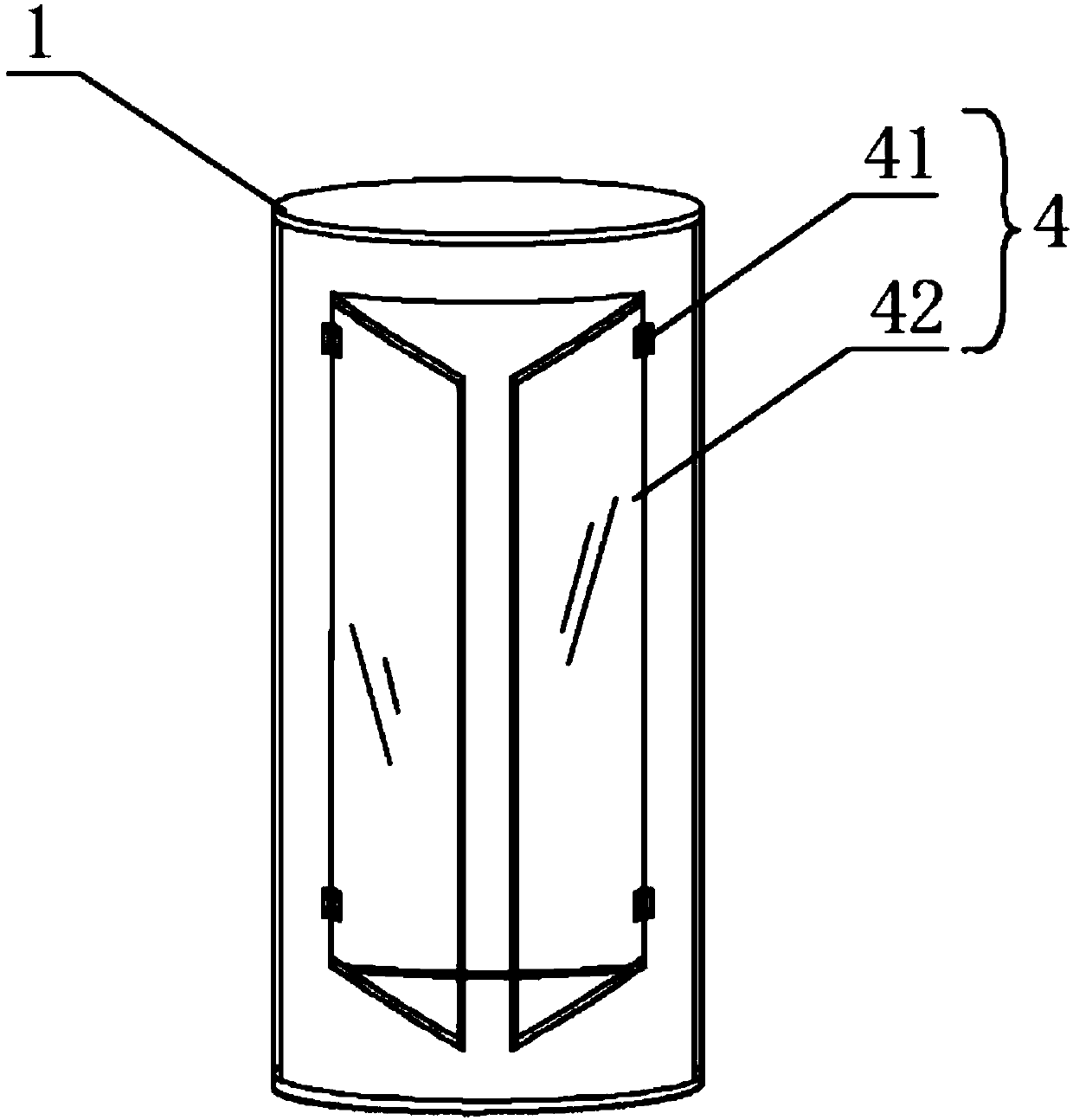

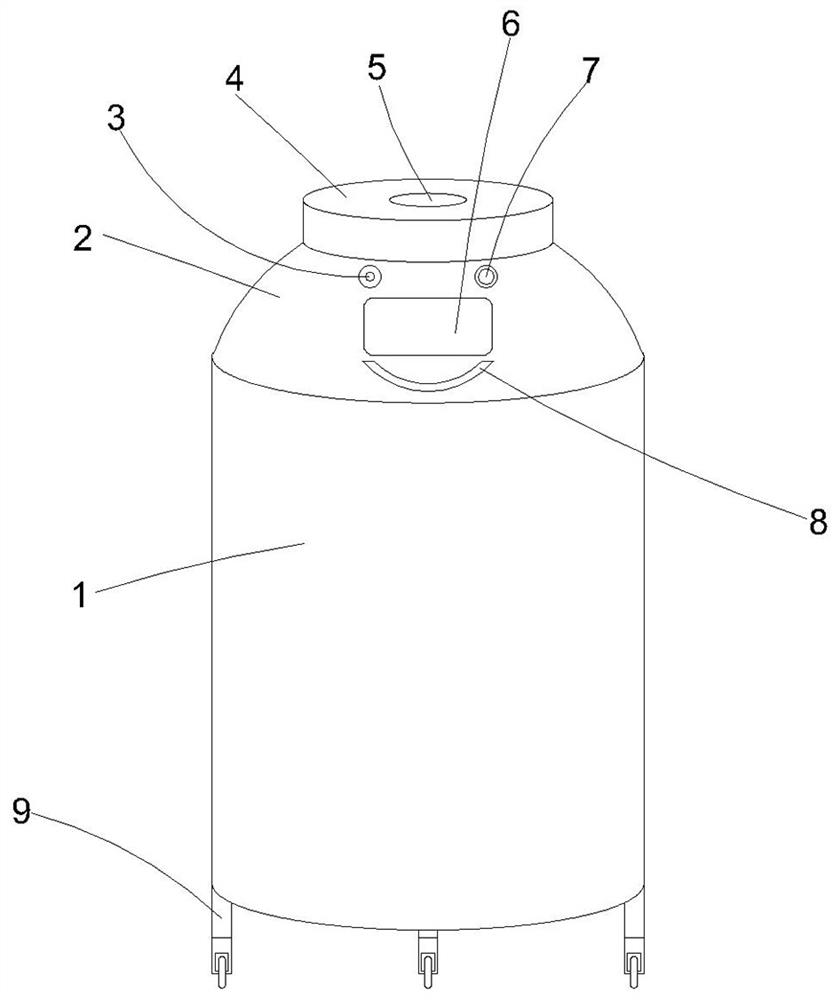

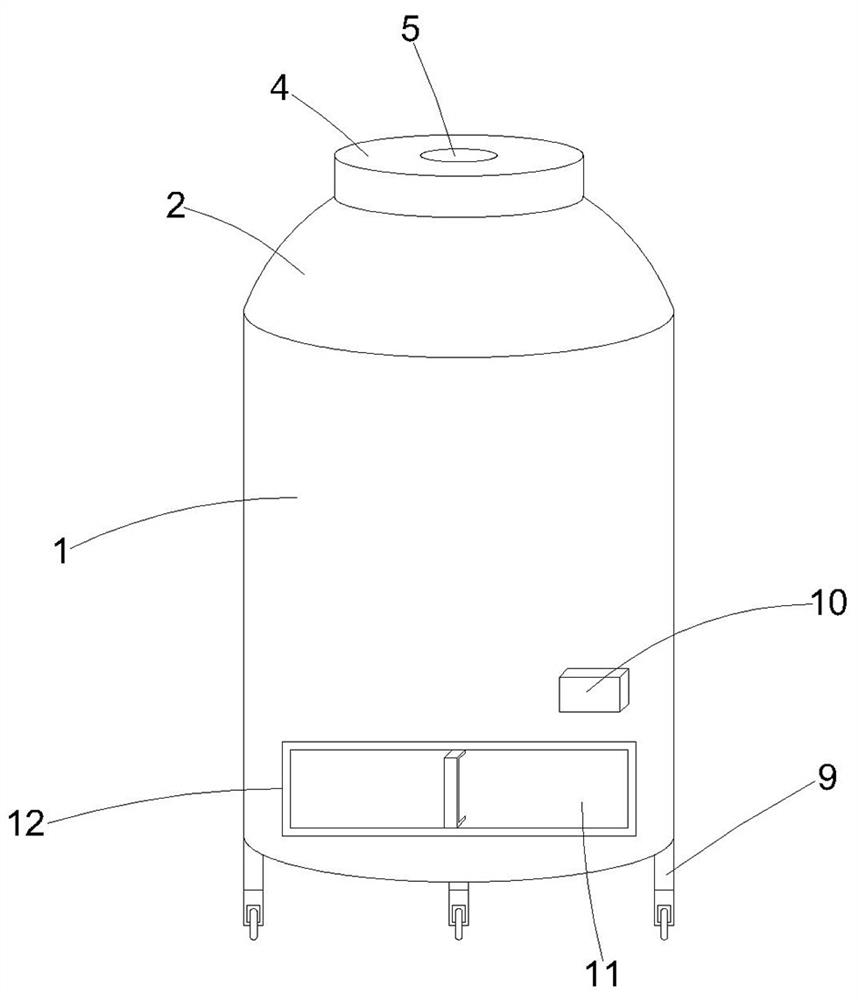

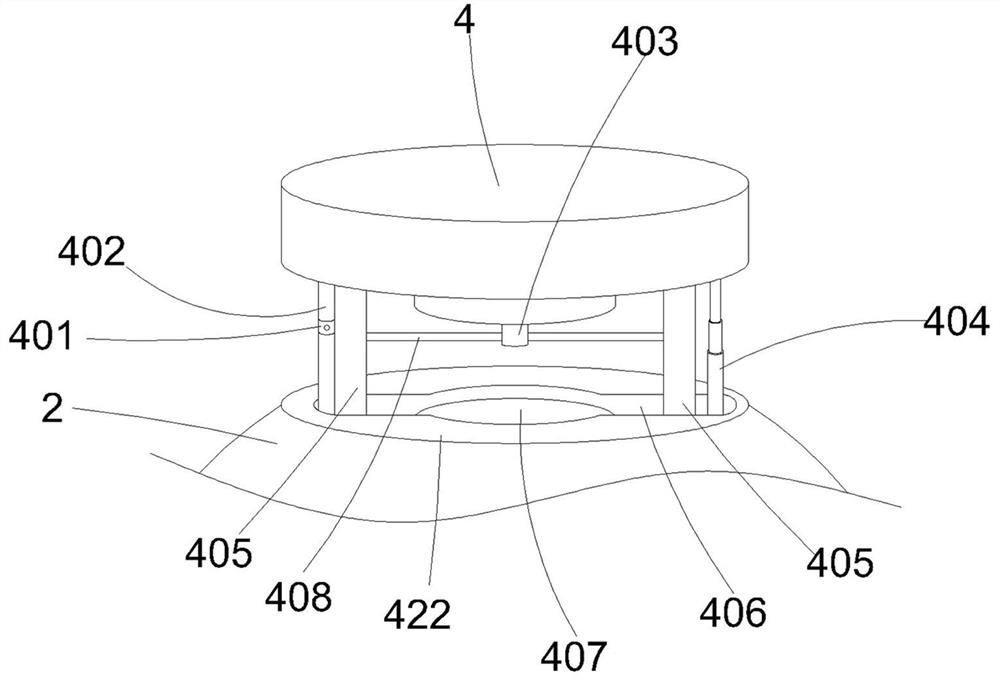

Blood sample temporary storage device and method for inpatient area

InactiveCN113830366AEasy to closeEasy to openWrapping material feeding apparatusPackage sterilisationBlood Collection TubeMedical waste

The invention belongs to the technical field of medical waste treatment, and particularly discloses a blood sample temporary storage device for an inpatient area. The blood sample temporary storage device comprises a temporary storage cylinder, wherein a sample temporary storage mechanism and a temporary storage control mechanism matched with the sample temporary storage mechanism are arranged in the temporary storage cylinder; a movement supporting mechanism is arranged on the bottom surface of the temporary storage cylinder; a temporary storage cover is arranged at the top end of the temporary storage cylinder, a temporary storage top surface is arranged at the top end of the temporary storage cover, a sample temporary storage opening is formed in the temporary storage top surface, and an automatic switch structure is arranged on the sample temporary storage opening; and a sample outlet matched with the temporary storage mechanism is formed in the temporary storage cylinder. According to the blood sample temporary storage device, by arranging the sample temporary storage mechanism and the temporary storage control mechanism in the temporary storage cylinder, collection and intelligent pretreatment actions of blood samples are achieved, centralized treatment and temporary storage of vacuum blood collection tubes are facilitated, the collection time of the vacuum blood collection tubes is effectively shortened, the time of contact with the vacuum blood collection tubes during manual operation is shortened, the collected vacuum blood collection tubes can be accurately recorded and counted, and the probability of losing the vacuum blood collection tubes is reduced.

Owner:HENAN CANCER HOSPITAL

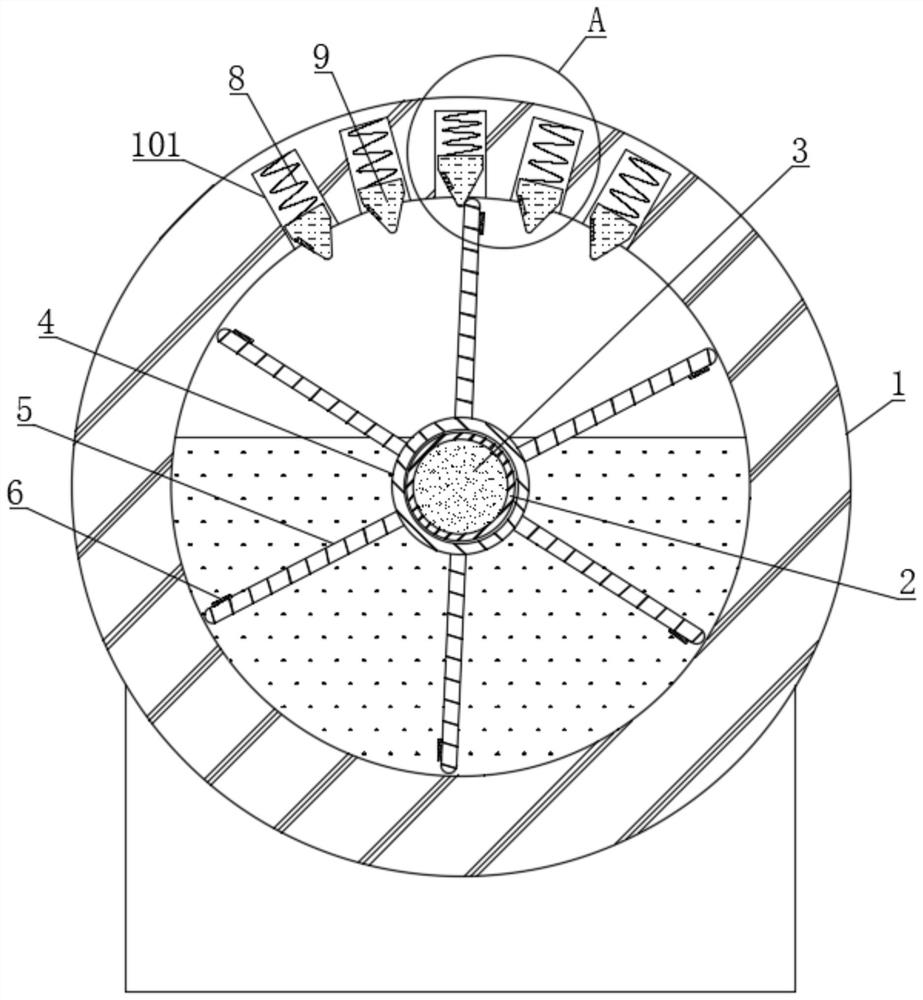

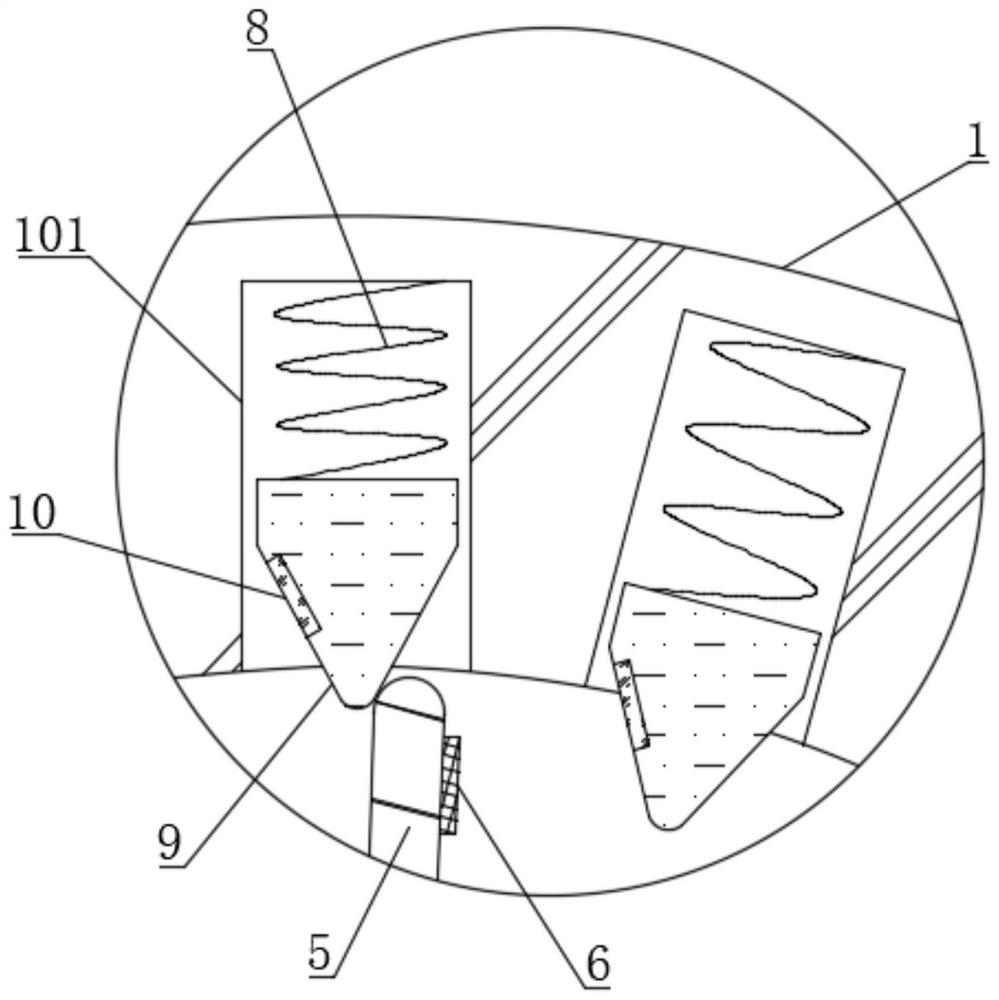

Agricultural seed flowing moisture-dissipating type continuous dynamic storage device

InactiveCN111891576AReduce moistureExtended shelf lifeDispersed particle separationLarge containersAgricultural engineeringAgricultural science

The invention discloses an agricultural seed flowing moisture-dissipating type continuous dynamic storage device, and belongs to the field of seed storage. The agricultural seed flowing moisture-dissipating type continuous dynamic storage device comprises a horizontal storage bin; the horizontal storage bin comprises a storage drum; and the bottom of the storage drum is fixedly connected with a supporting seat. According to the device, a mode of spontaneous and continuous dynamic storage is innovatively used for storing seeds; through mutual acting force between a rotating seed filter shelf and a non-balanced double force device, the rotating seed filter shelf is in a status of continuous slow rotation; the force acts on the inside of a seed stack so the seeds maintain a status of dynamicstorage and air flow inside the seeds is continuously increased; and at the same time, moisture inside the seeds is absorbed, and the internal moisture of the seeds is continuously dissipated and absorbed by dried materials, so the inside of the seed stack can maintain a dry status to the greatest extent. Compared with existing static storage methods, the device greatly lowers the moisture insidethe seed stack, and prolongs the storage duration of the seeds.

Owner:黄雄景

An oil-immersed three-phase transformer

ActiveCN110797168BAchieve continuous rotationRealize constant back and forth movementTransformers/inductances coolingTransformers/inductances casingsEngineeringThree phase transformer

The present invention belongs to the field of transformers, especially an oil-immersed three-phase transformer. For the existing cooling fins, the cooling fins are usually installed inside to dissipate heat through ventilation holes, but such The heat dissipation efficiency is not high, and the ventilation holes are all open, which will easily lead to dust entering the transformer and causing damage to the transformer. The following solution is proposed, which includes a transformer casing with a hollow structure, and an oil tank is fixedly installed on the top of the transformer casing , The oil inlet pipe and the oil outlet pipe are fixedly installed in the transformer shell. The present invention is simple in structure, easy to operate, can effectively dissipate the heat generated by the main body of the transformer during the working process, and can effectively dissipate heat when the external temperature is relatively high, so as to ensure the normal operation of the main body of the transformer. At the same time, when the heat dissipation is completed, it can The heat dissipation port is sealed to prevent dust from entering, so people's needs are met.

Owner:YANTAI MUPING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com