Bent type piezoelectric ultrasonic motor

An ultrasonic motor, piezoelectric technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of difficulty in ensuring the working stability of piezoelectric ultrasonic motors, etc. To achieve the effect of good excitation effect, improve stability and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

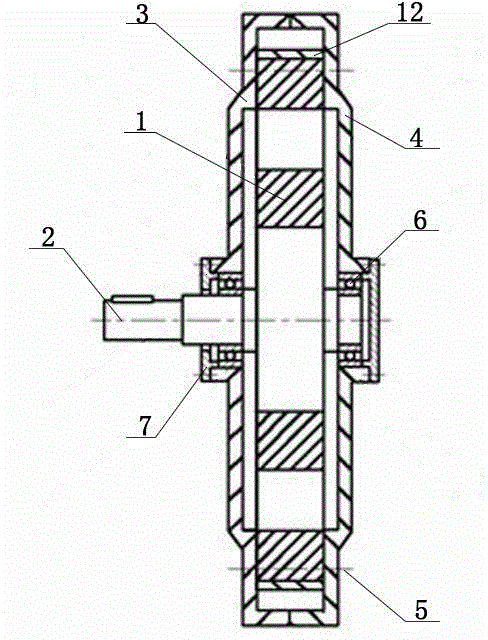

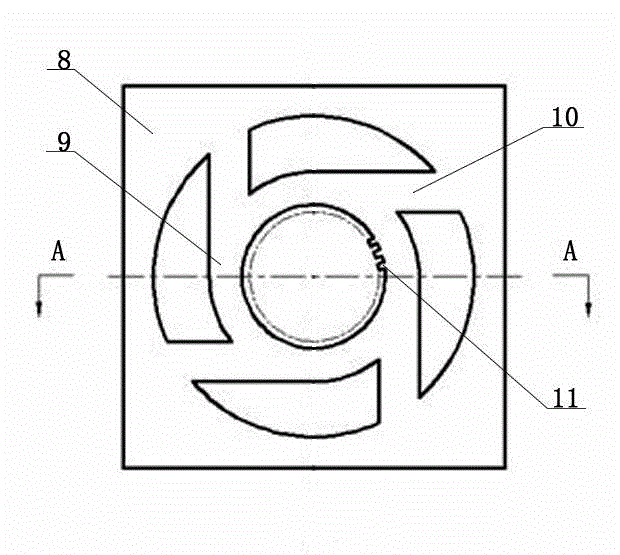

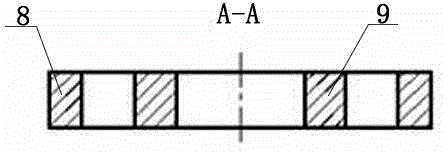

[0016] The present invention includes a stator 1 and a rotor 2 . The piezoelectric ceramic sheets 12 are pasted on the four end sides of the stator outer frame, and the shapes and sizes of the piezoelectric ceramic sheets 12 and the end sides of the stator outer frame are the same.

[0017] Such as figure 1 As shown, the present invention consists of a stator 1, a rotor 2, a front support 3, a rear support 4, a piezoelectric ceramic sheet 12, an end cover 7 and a bearing 6. The front support 3 and the rear support 4 are relatively fastened to form a motor housing; core holes with opposite openings are opened on the front support 3 and the rear support 4 respectively, and bearings are respectively installed in the two core holes 6. The two ends of the rotor 2 are supported and connected to the bearings 6 in the two core holes, and the end caps 7 are covered outside the two core holes of the front and rear supports. The stator 1 is also housed in the fastening cavity between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com