Oil-immersed three-phase transformer

A transformer and oil-immersed technology, applied in the field of transformers, can solve the problems of dust entering the transformer, low heat dissipation efficiency, transformer damage, etc., and achieve the effect of ensuring normal operation, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

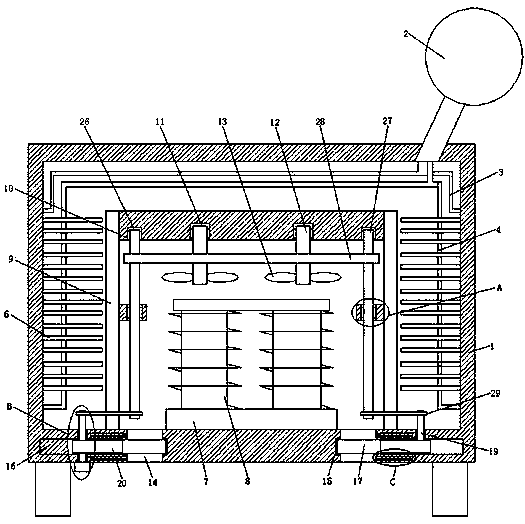

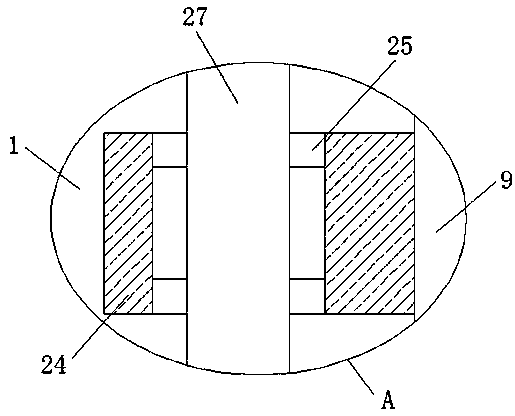

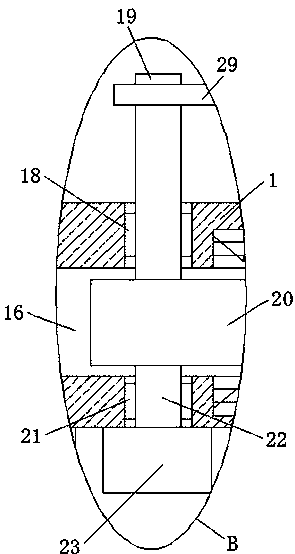

[0027] refer to Figure 1-5 , an oil-immersed three-phase transformer, comprising a transformer housing 1 set in a hollow structure, an oil tank 2 is fixedly installed on the top of the transformer housing 1, an oil inlet pipe 3 and an oil outlet pipe 4 are fixedly installed inside the transformer housing 1, and the oil inlet pipe 3 and the oil outlet pipe 4 are fixedly installed inside the transformer housing 1. The oil outlet pipes 4 are all connected with the oil tank 2, and a plurality of heat conduction pipes 6 are arranged on the outside of the oil outlet pipes 4. An embedded plate 7 is fixedly installed on the inner wall of the bottom of the transformer shell 1, and a transformer main body 8 is fixedly installed on the top of the embedded plate 7. A support column 9 is fixedly installed on the inner wall of the bottom of the housing 1, and the side where the two support columns 9 are close to each other is fixedly installed with the same support plate 10 above the transf...

Embodiment 2

[0038] refer to Figure 1-5 , an oil-immersed three-item transformer, comprising a transformer housing 1 with a hollow structure, the top of the transformer housing 1 is fixedly connected with an oil tank 2 through bolts, and the inside of the transformer housing 1 is fixedly connected with an oil inlet pipe 3 and an oil outlet pipe 4, and Both the oil inlet pipe 3 and the oil outlet pipe 4 are connected with the oil tank 2, and a plurality of heat conduction pipes 6 are arranged on the outside of the oil outlet pipe 4. The bottom inner wall of the transformer shell 1 is fixedly connected with an embedded plate 7 by bolts, and the top of the embedded plate 7 is connected by bolts. The transformer main body 8 is fixedly connected, and the bottom inner wall of the transformer housing 1 is fixedly connected with a support column 9 by bolts, and the side of the two support columns 9 close to each other is fixedly connected with the same support plate 10 above the transformer main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com