Double-layer gear oppositely-pushing rotary type nanometer piezoelectric motor

A double-layer gear and piezoelectric motor technology, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of reducing energy efficiency, nonlinearity, and difficulty in precise control and other problems to achieve the effect of overcoming the limitations of the stroke, high-precision step displacement, and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

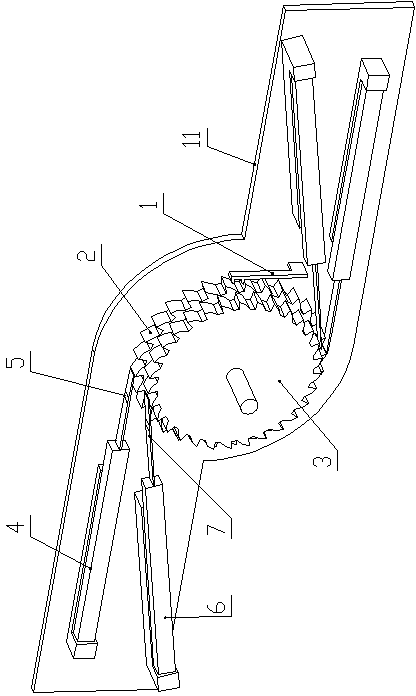

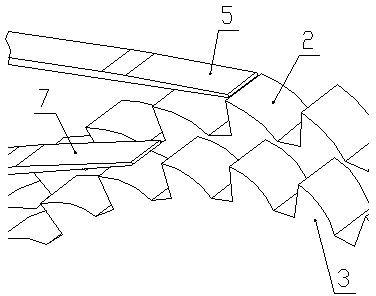

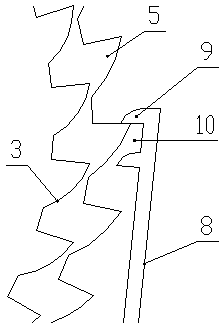

[0023] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a double-layer gear mutual pushing rotary nano piezoelectric motor of the present invention includes a housing (only a part of the housing is shown in the figure? the bottom plate 11), and the housing is provided with a central double-layer gear rotor, an outer piezoelectric The ceramic stack, the inner piezoelectric ceramic stack, the power drive part (not shown in the figure) and the one-way limiter 1 used to limit the unidirectional rotation of the central double-layer gear rotor and realize the self-locking function step by step, the power drive part It is respectively connected with the outer layer piezoelectric ceramic stack and the inner layer piezoelectric ceramic stack. The central double-layer gear rotor is composed of the outer layer gear 2 and the inner layer gear 3 with the same axis and the same module. The power output of the outer layer piezoelectric ceramic stack The end drives the outer ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com